When you want to make repairs in the bathroom in the shortest possible time, spending at ...

|

|

A drainage system is a design for collecting excess water across the territory of the site .... |

Modern production technologies provide the opportunity to make ... |

DIY

Thinking about the construction of their own home, developers are increasingly preferring two -story cottages, as this is the most optimal way to expand the living space in a relatively small area. The construction of multi -storey private buildings is associated with the need to arrange a reliable staircase that ensures safe movement along the floors. According to experts and experienced developers, inter -story stairs are not only a functional, but also a decorative interior detail that allows you to transform the room beyond recognition. In this regard, if you are owners of a suburban cottage with an attic in which there is still no staircase, it is time to think about its correct layout and construction, the procedure in which will be considered in the real material prepared by our experienced specialists.

Content

- Inter -story staircase: minuses of the factory structure

- Varieties of inter -story stairs: main characteristics

- Randy staircase: a tribute to fashion or a functional structure?

- Fundamental information on the safety of staircases

- Selection of material for the manufacture of an inter -story staircase

- When to start the layout and the construction of a staircase? The advice of the master

- Making a high -quality staircase with your own hands

- And, finally: criteria for choosing wood for the manufacture of stairs

Inter -story staircase: minuses of the factory structure

Unhindered rise to the floor can be provided by acquiring and installing the finished design, which is characterized by a number of shortcomings:

- High price characteristics;

- The need to spend additional time to fit the design parameters, since it often does not correspond to the parameters of the house;

- And, of course, there is always a risk that you will purchase a low -quality product.

In order not to face serious production shortcomings once again, we advise you to use our tips and engage in the manufacture of an interfloor staircase with your own hands.

Varieties of inter -story stairs: main characteristics

Rifle stairs They are ornate compositions, the design of which resembles a spiral twisted along the axis. The main purpose of the screw stairs is the installation in small -sized rooms where there is an acute need to save each square meter. It is important to familiarize yourself with the main constructive parameters of the screw stairs: in accordance with the building standards, the diameter of the spiral staircase is 1.3 m, while the central width of the step is from 20 to 25 cm;

Marching staircase - One of the most common designs built during the construction of multi -storey cottages. It is a supporting step structure located at an angle of 45 degrees. The marks of marching stairs are also stepped, while the number of steps in one span is up to 15 pieces;

Turning stairs They are characterized by a similar design, marching stairs, which differs from the previous rotation by 180 degrees. Despite the fact that the design of such stairs is quite traditional, its manufacture is associated with certain difficulties, and therefore, it is better to entrust this to specialists;

Bolzer stairs - Another version of marching stairs, the design of which involves their fastening not on support, but directly on the wall, in connection with which it acquires some originality and, at the same time, airiness.

Randy staircase: a tribute to fashion or a functional structure?

The new time of recent times was screw stairs, which deserved their popularity thanks to elegant design and certain functional virtues. What do we mean when speaking of virtues? In this case, we are talking about the possibility of stretching the spiral staircase to any height you need, spending the installed, minimum area under the stairs. An important advantage of the assembly of the screw ladder is the possibility of its assembly by a person without professional skills.

Despite this, it is characterized by a number of serious disadvantages:

- The size of the drama, that is, the main one, is the following of the steps is optimal and safe only in the middle, where they almost never step;

- The angle of inclination of the stairs changes two or more times;

- Differences in structures intended for left -handed and right: they must be made in mirror reflection - for left -handed people twisted counterclockwise, for right -handed - vice versa;

- It is forbidden to raise furniture and other heavy objects on a screw staircase.

Fundamental information on the safety of staircases

Before answering the question: how to make an integrated staircase?, Consider the basic requirements for the safety of staircases.

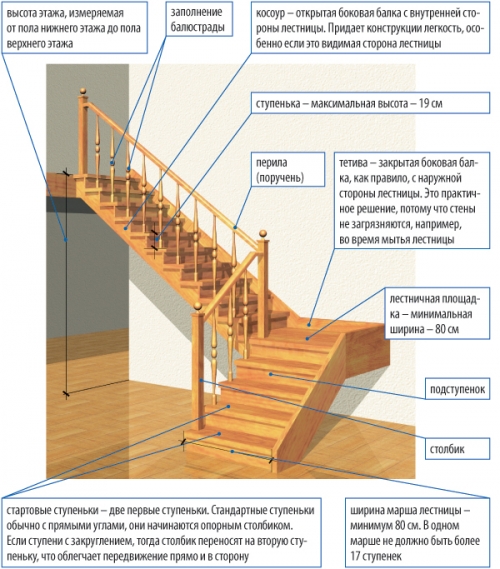

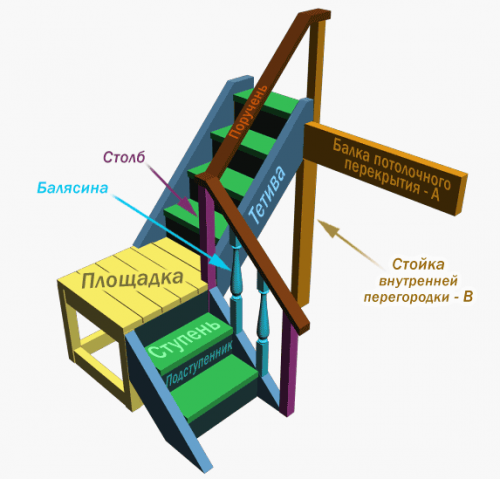

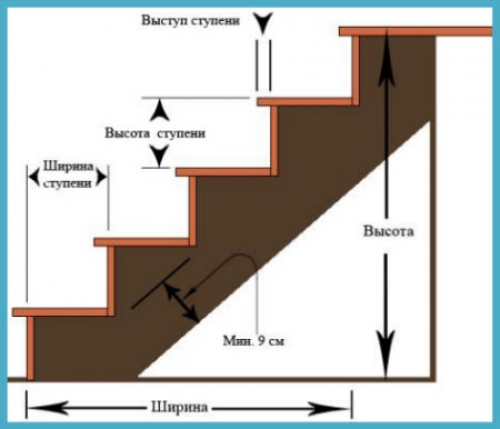

- The main concept that needs to be followed in the manufacture of inter -story stairs safety of movement, which depends on the degree of observance of the optimal size and technical characteristics of the entire staircase. Since the main element of the stairs that determines its safety is the steps, it is necessary to correctly observe its main parameters: a horizontally oriented surface, the approaches is vertically. These dimensions are determined based on the angle of lifting the stairs;

- To prevent falls and injuries, it is believed that the optimal angle of inclination of the stairs is 45 degrees, while the width of the step should be at least 45th leg size. The height of the vertical part of the step should not exceed 20 cm;

- The handrails, balusters and pillars are an integral element of the stairs, especially installed in those houses where there are children. If the thickness of the balusters does not exceed 5 cm, they must be installed with a step of 15 cm. But if you plan to install a wide staircase, equip it with an additional fence with a parietal handrail.

Thus, the basic requirements for the security of the inter -story ladder in a private house are the following provisions:

- Convenience and reliability of the design;

- The presence of a convenient approach to the stairs;

- Safe and convenient arrangement of the railing;

- Correspondence of the length and height of the steps of the step;

- The presence of sufficient lighting over the stairs.

Selection of material for the manufacture of an inter -story staircase

Wooden inter -story stairs: advantages and disadvantages

Intersective wooden stairs are the most accessible way to install the stairs for an inexperienced master. However, a significant disadvantage of staircase structures made of direct -layer wood of conifers is their relatively quick failure, due to the fact that the stairs begin to creak and dry out. But given the fact that a substantially lower loading load on the wooden staircase, it can easily be repaired, or in the case of major repairs, it is set to install a new one.

As for stairs made of high -density small density, their service life is significantly longer, however, their cost is many times higher than the cost of the previous ones.

Important!Despite the fact that deciduous wood is more durable, it is subject to malicious effects of insects and fungus. In this regard, an integral and one of the first operations in the manufacture of wooden stairs from deciduous wood is the impregnation of them with complex protective compounds from pests.

However, in certain cases, the installation of inter -story ladder from coniferous wood is quite acceptable. Consider these cases.

If you plan to install an attic, especially a folding or retractable staircase, which will last no less than a staircase from small -layer breeds, which is due to a special microclimate of the attic;

- If your house has a seasonally inhabited attic or an unheated one and a half floor, the transition to them can also be equipped with a staircase of coniferous breeds;

- In one and a half or two-story dacha, inhabited only in the warm season, you can also equip the same staircase;

- The sleeping attic can also be equipped with such a staircase, however, they must first be protected from drying, processing with special water-polymer emulsion, varnish and paint.

Metal inter -story stairs: advantages and disadvantages

In private housing construction, stairs made of metal are usually used in combination with other materials:

- The frame is often welded metal;

- Steps are made of wood or concrete;

- Whereas decorative decoration is carried out using any materials at your request.

Despite the fact that the manufacture of a stairs with a metal frame is much more laborious and costly, however, its operational period is practically not limited, due to the features of the material, it can be changed or repaired of the staircase, without radically changing the structure of the stairs.

Concrete stairs: advantages and disadvantages

The construction of reinforced concrete stairs is associated with mass typical construction. But private construction does not do without the construction of such structures. They come in two types: monolithic and combined with metal. In the first case, their installation technology involves the manufacture of steps by pouring concrete into a frame similar to a metal -powered staircase, reinforced with reinforcement. Horizontally oriented surfaces, in this case, are less susceptible to wear, are made in any other way.

Stairs Inter -story photos

When to start the layout and the construction of a staircase? The advice of the master

Often, the main mistake of the developers is that they think about the construction of an inter -story staircase upon completion of the construction of the house. Ideally, the design of the staircase must begin at the stage of erecting the foundation, so you can correctly calculate the load on the stairwell, as well as correctly calculate the inter -story staircase and its location.

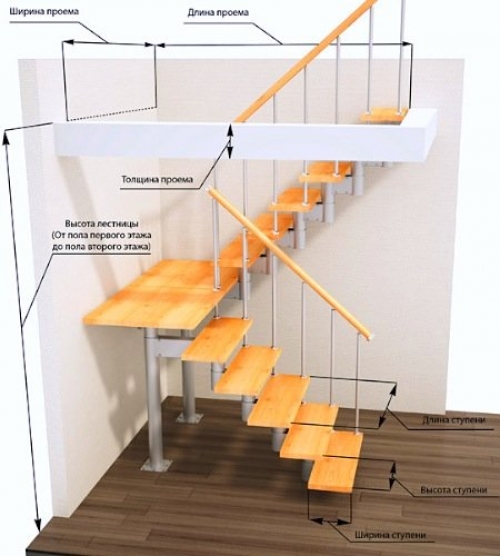

When calculating the parameters of the inter -story staircase, pay attention to the following characteristics, withstanding which, you mount a safe staircase:

- The angle of inclination of the stairs is at least 45 degrees;

- Stray width 30-35 cm;

- Rise height from 14 to 18 cm.

Making a high -quality staircase with your own hands

Before proceeding with the manufacture of a staircase, it is necessary to develop its project and make calculations of the parameters of the future design;

Decide on the location of your future structure and measure the parameters of the room;

Given the width of your future staircase, calculate the height of the steps according to the following scheme:

For example, if the height of the stairs is 250 cm, and the height of the steps is 18 cm, the first indicator must be divided into the second. As a result, having received the private and rounding it to the whole number, we come to the conclusion that the desired number of steps is 14. To determine the height of the steps, the height of the entire structure (250 cm) is divided by the number of steps (14 pieces) and we get the number 17.86 This is exactly what the height of the steps should be.

Next, it is necessary to determine the shape and height of the railing. It is important to remember that this is the main safety parameter of the entire staircase. The height of the railing should be at least 90 cm, while you can choose their design at your discretion.

Next, decide on the material from which you plan to make a staircase. To do this, you can choose metal, stoves or traditional wood. In addition, you can use additional materials such as glass or ceramics.

Next, evaluate the strength of the floor and other ceilings at the site of installation of the future structure. This is necessary so that in case of exceeding possible loads, the destruction of the ceilings does not occur.

Important! The destruction of the supporting structures can occur if the permissible weight of the stairs is exceeded, in the case of use of low -quality materials, insufficient number of support points, as well as with insufficient strength of mounts. In this regard, it is necessary to carry out preliminary mounts according to the approximate location of the support points, the strengthening of insufficiently reliable ceilings, as well as the choice of structures, the weight of which corresponds to the reliability of the supporting elements.

Strengthening the site is another integral stage of preparatory work, since it is the basis of the staircase.

After you have decided on the location of the future design and its configuration, carried out calculations and chose suitable material for the stairs in general, fully carried out preparatory measures, get the basis for future parts, and then independently adjust all the details. You can also seek help from specialists who will fully fit all elements, as well as assemble the structure.

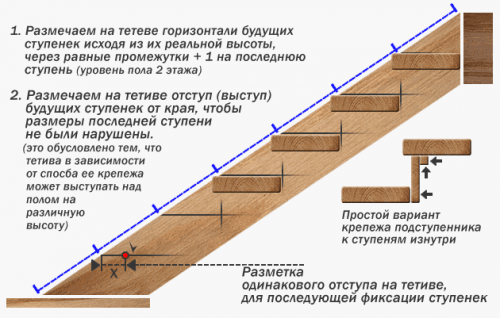

Preparation of beam structures, as well as mark the steps. This is necessary for subsequent preparation for the installation of steps.

Do not forget that the calculations of the parameters of the staircase are made taking into account the staircase configuration. In this regard, before making the calculations of the spiral staircase, it is necessary to perform a rounded opening, while when installing a marching staircase, an opening of a rectangular or square shape.

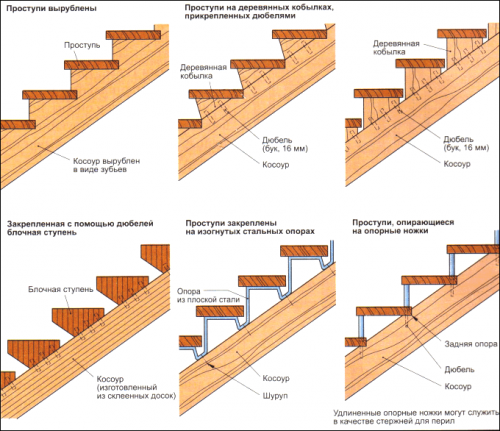

The steps of the stairs are mounted using special braids, or bowstring. There is another way of attaching steps, implying the insertion of steps in the form of the side parts of the bowstring.

If you prefer the first method of fastening, install the supporting pillar, and on the load -bearing beams, mark the location of the steps. Using a disc tire, carry out the application of recesses on the steps. Using self -tapping screws, attach the Kosuors to the wall in accordance with any method of you known. It is important to remember that the inter -story staircase is always located in the immediate vicinity of the wall.

If you have chosen a screw staircase, first of all, make the installation of a rack that will act as a supporting beam for the entire structure. In this case, it is better to give preference to a metal rather than a wooden rack. Next, put a wooden sleeve, a metal washer on the rack and proceed to install the steps.

At the final stage of the installation of the stairs, fasten the railing, balusters and racks, as well as other decorative elements available to you, which are secondary details of the stairs and are installed in order to give the design of a certain highlight. In conclusion, cover the staircase with varnish.

And finally: criteria for choosing wood for the manufacture of stairs

When choosing a material for the manufacture of a staircase and giving preference to string wood, follow these recommendations.

- The surface of the material should be characterized by the absolute absence of dark spots;

- Defects, cracks and chips on the surface of the material, as well as any roughness;

- If you plan to make only steps and approaches from the material you have chosen, the presence of small knots and defects is allowed. We must not forget about the humidity of the material, in connection with which, refuse to acquire the material, which is characterized by a large mass.

Regardless of the design of the stairs you have chosen, there are many options for installation and assembly of each of them. After watching the video presented in the article, you can acquire additional practical skills to make an inter -story staircase from various materials.