When performing repairs in the apartment, quite often the question arises of how ...

|

|

One of the most difficult stages of repair is rightfully considered to be filled with screed. Really... |

The device of the suspended rack ceiling is quite simple, like its technology ... |

Laying a downstone

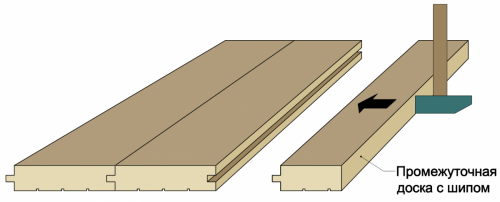

A modern dodgy board is a product made of wood, which passes the drying stage in the autoclave. It is equipped with a spike-paz system that allows you to reliably fasten two elements among themselves, carry out quick installation, and enhance the strength of the structure. Fastards can be located on the sides of the boards or on all four. The back side of the material has bevels that allow air to circulate, preventing wood rot from the inside. The article will talk about the choice and method of laying a dodgy board.

Content:

- The manufacturing process of a dodgy board

- A variety of species of rogue boards

- Calculation of the required amount

- Laying flooring from a dodgy board

By connecting the dinked boards, they receive a flat surface with a representative appearance, with excellent operational characteristics. Elements are so tightly fastened with each other that there are not the slightest gaps. Even in the production process, the material acquires excellent sound and thermal insulation properties. The floor is attractive, reliable, resistant to wear. It was for these characteristics that the rogue board gained widespread. It is used when creating both black and finishing coating.

Sex lapped boards are reliable, durable, aesthetic. They will become even more attractive if they cover them with special means. Environmental friendliness The main advantage of natural materials. It is impossible to remain indifferent from the spectacle of the wooden floor, the quality of which is amazing. After all, ordinary boards after laying quickly refer, forming the cracks.

The manufacturing process of a dodgy board

Drill boards on special high -precision equipment. The machine itself is represented by a mechanism that serves the board and a special cutter, which cuts the material on the sides. The whole process is mechanized, and the engineer only controls his work. At home, it is impossible to achieve such a high level of navigation.

But home craftsmen can try to create downstot boards on their own. To do this, you will need a hand cutter or landscape.

Stages of work

- The material is carefully selected. It is easier to work with coniferous breeds of trees, but their operational characteristics are lower, therefore it is recommended to give preference to larch. The scope of its use is incredibly wide. The larch is used both when creating a floor of indoors, and to cover open terraces.

- The material should be well dried. If there is a need to dry the boards, then they are laid in a room that is well ventilated. The humidity should be low. Between the canvases leave gaps for ventilation. It is impossible to dry the wood in the sun, since it will heat up from one side, and from the other it will remain moist. In the future, this will lead to various defects.

- The board is laid on the working surface and fixed with clamps.

- On the lateral surfaces, the axis on which work will be carried out is determined. They are marked with a pencil.

- Then, with the help of a milling machine, a quarter groove is taken on the side strictly in the middle of the quarter groove.

- A spike is made out of the other side, selecting a quarter on both sides of the axis.

Such manual curtaining is inferior in quality to industrial and it cannot be used for solid trees.

Spooned board photo

A variety of species of rogue boards

Depending on the wood used to create a board, the following types of floorboard are distinguished, each of which has its own characteristics:

- Pine or spruce. Soft wood, insufficiently moisture resistant. It has a low cost, but requires mandatory varnish. They are used to create a black coating.

- Larch. Boards from this material have a solid structure, excellent moisture resistance. They are not afraid of insect attacks. They differ in a pleasant structure, rich in color. It is not necessary to varnish, but with the coating of the board they will last much longer. The cost of gender downstone boards made of larch is several times higher than from pine. Used to create a finished coating.

- Ash, oak. The floorboard is solid. It is characterized by the average indicator of moisture resistance, susceptibility to insect attacks. The cost of the material is quite high.

How to choose a dodgy board

- At the time of acquisition of rogue boards, it is worth checking them for an acceptable level of humidity. It should not exceed 12-16%. Measure it using a special device. If it is not, then you can check the boards yourself:

- the material is tapped. The sound should turn out sonorous;

- to the touch. Moisture should not be felt on the skin;

- in tint. The wood acquires a brilliant shade.

- In addition to humidity, it will be useful to check the geometry of the material. The boards are looked from the end along the canvas and the plane is evaluated. If it is not even enough or there are any doubts, then it is better not to acquire this sample.

- Extra varieties are used to create a finished coating. They do not contain knots, the surface is flat, polished. Lower boards are used for laying a black surface. Such material admits the presence of knots in large quantities and through openings in the place where knots were located.

- Black floor involves the location on top of the flooring. They spread the carpet with a soft pile or hide the floor under plastic tiles. The surface of conifers of trees will be an excellent basis for fiberboard, laminate, linoleum. As an independent flooring can only be used in rooms of rare use. Be sure to treat the coating with antiseptic compounds and apply varnish.

Scope of use.The use of a downted boards are not limited to creating the floor in houses and on the balcony. Since the material from the larch is not afraid of moisture, even in saunas, rogue boards are often used near the pools. They are laid on both lags and concrete, while using a special substrate, which will enhance the soundproofing characteristics of the material.

The cost of the material

If the question is worth it, choose the dinked boards or trimmed, then it is better to give preference to the first. The cost of pine boards starts from 5000 rubles. for m3. A high -quality wiped board will cost the same amount. The material of the Extra class material will cost the most expensive, class A. Until the purchase, it is worth considering and calculating all options to choose the one that arranges at cost and quality.

- The board of the AB variety from pine costs about 6000 rubles/m3.;

- the varor B can be purchased for 5000 rubles/m3.;

- the highest variety costs 8000 rubles/m3.;

- since the larch is valued more, its cost depending on the variety will fluctuate within 654-2000 rubles per 1 board.

The price of a downted board also affects the price. So, if the length and width remain standard 6000 mm/135mm, then the width can vary from 28 mm to 50 mm.

Calculation of the required amount

Before the installation of the floorboard, you need to purchase it in advance. But in order not to spend extra money, and also did not have to visit the store once again, it is worth right to correctly calculate the required amount of material. It is desirable that the boards are from one batch, from one manufacturer, therefore, they acquire the necessary material 1 time in the right amount.

- They calculate the area of \u200b\u200bthe room, changing the indicators of the length and width. If the room is represented by a complex shape, then it is conditionally divided into rectangles, calculating separately their area, and then summarizing.

- It must be remembered that the starting and finish board should be along the length of the entire room, and the rest can be purchased smaller.

- Next, calculate the indicator of the running meter of the material, multiplying the width and the length of the board. Based on this, the required amount of linear meters is calculated for laying the coating in the entire room.

Laying flooring from a dodgy board

Distinguish 2 methods of fastening the dowels of the boiled boards:

- on a concrete base or screed;

- on the lags.

Regardless of the styling method, the base should be quite even and durable. If the lag is laid, then the tree is mandatory treated with an antiseptic.

Instruments for mounting a dodgy board:

- nails, screws;

- hammer, kiyanka;

- yardstick;

- hacksaw, circular saw;

- brackets.

Installation of a dodgy board on concrete

- Between the base and the floorboard, waterproofing is necessarily carried out. As it is used as a moisture -resistant plywood, the thickness of which is over 10 mm. Plywood canvases are laid perpendicular to the future layer of the floorboard. A small gap of 2 mm should be left between the canvases. Between the walls and the plywood, they form an indent of 1.5 cm.

- The sheets are attached by means of dowel-grooves, the hats of which are shed in the surface of plywood. If necessary, grind the coating to obtain a smooth surface.

- Then, downstone boards are attached to the faner by means of self -tapping screws.

Installation of rogue boards on lags

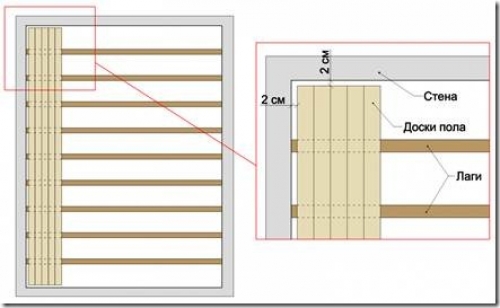

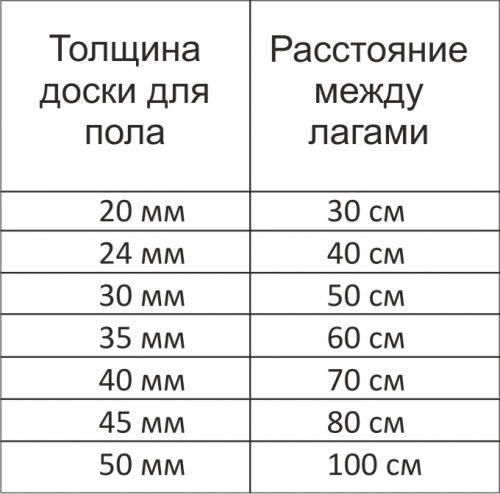

- Lags are a design of boards with a thickness of at least 50 mm, located at a distance of 50-60 cm. Between them you can place a layer of insulation. Lags lags in a certain way, keeping a gap of 2 cm at the junctions. This is done so that the board does not deform due to the natural expansion of the material in the off -season.

- Further fastening of the rogue boards to the lags will be implemented by means of self -tapping screws.

- Under the wooden floor, it is necessary to leave voids, since the tree needs ventilation. Under it you can not mount the system of warm floor, since natural material is subject to fire and the effects of high temperatures.

- An exception may be infrared film floor, which is laid on a foil isolon over the boards.

- They begin to lay the first row, placing the board in a comb against the wall, observing the necessary gap. The starting board should be a length of the entire wall. The same requirements are imposed on the finish board. Fix the starting board with self -tapping screws screwed at right angles. The length of the fasteners is 40 mm, and they are screwed every 30 cm.

- The following few rows of material are not fixed with self -tapping screws. The spikes are tightly inserted into the groove, providing tight fit of the paintings. The rows in the center can be laid from short boards, the joints of which will be without fail are located on the lags. The joints alternate in a checkerboard pattern. The finish board is laid with an indentation from the wall, its length should be throughout the wall.

- During styling, neighboring boards are tightly connected to each other. If there is a need, then they are attracted to each other with wedges. A gap of 2 cm is left around the perimeter of the room, which is then hidden with a floor skirting board.

- The finish board is adjusted to the required size, taking into account the clearance. Then it is laid in place, inserted into the groove of the previous row and fixed with wedges. After the last row is screwed with self -tapping screws, the wedges can be removed.

- So that the boards do not change the forms after laying, it is recommended to leave them in the room where they will be laid 12 weeks before installation. The moisture content of the wood will be optimal and the material is not deformed.

Drowned board video

Useful tips:

- for a tight connection of the boards, each is tapped with a kiyanka along the entire length. To save the crests, a piece of material with a groove is used between the hammer and the board;

- for high -quality docks of boards, a bracket, squeezing boards, are driven in front of them for a while. This design holds the boards and allows them to be correctly fixed.

The rogue board is probably the best option for creating a wooden floor. It is reliable, durable and does not dry out, like an ordinary board. According to the styling technology, it is similar to the designer, which will not cause the master of the slightest difficulties. If you cover the floor boards varnish, you can leave it as a finished floor. It will look beautiful, elegant and original. If necessary, the update, the sexual dodgy board is cycle and covered with a new layer of varnish.