Despite the fact that manufacturers provided the floor of flooring with a variety of ...

|

|

Laying laminate on an old wooden base constantly raises many questions ... |

When building a new house or the device of an old, an important part of the repair work ... |

Terrace deck. Features and installation

There are many options for covering floors in the interior, which allows you to achieve the desired result. But over the arrangement of the terrace, the open area or the basin zone you have to work, here the choice is not so wide. So, the concrete screed does not have decorative qualities, moreover, under the influence of atmospheric phenomena, it begins to crumble over time. Ceramic tiles in this regard are both durable and attractive from an aesthetic point of view. However, this material itself is cold and it is not recommended to put it on it easily on it, and the edges are quite sharp on it. Decing gained great popularity in this regard. In fact, it is a deck board, which is distinguished by high performance characteristics, a presentable look and naturalness. The article will talk about terrace decking.

Content:

- Classification of terrace decking

- The dimensions of the terrace decking

- Manufacturers of terrace decking

- Additional costs for arranging terrace decking

- Do -it -yourself deing

Classification of terrace decking

Today, the terrace board makes it possible to stylishly equip the adjacent plot to the house, it is profitable to beat the territories near the reservoirs, and stylishly arrange recreation areas. Decing is divided into 3 groups.

Decing from the array of wood

- A real exclusive is a coating made of little -known wood, but widespread in the forests of Africa, Asia and South America. Exceptional texture and service life up to 80 years make such a board truly unique.

Decing photo

- For example, terrace decing of the red tree of the massararanum is moisture resistance, can be used in conditions of intense loads. The high content of rubber resins does not make it possible to multiply with molds.

- The flooring from the Australian walnut (Kekatong) is durable and stable, such qualities are important in the decoration of zones in the open air. Wood is used in ship construction, as it is perfectly in contact even with salt water.

- The advantage of the boards lies in their strength and, of course, naturalness. But since it is still wood, it requires professional care, and the price of the deck terrace board is quite high from 5 to 13 thousand rubles per square meter. The flooring of such familiar trees as oak, pine, cedar, larch 500-1000 rubles/sq.m. will cost a little cheaper.

Terrace delaging wood

- At this time, two methods are used to protect the material from premature destruction of imperative and heat treatment. The first technology implies the impregnation of wood with special substances in compliance with technical conditions.

- The finished board at the same time slightly changes its natural shade, but at the same time acquires such properties as resistance to rotting and resistance to the reproduction of fungi. The life of the processed material will be 15-20 years. It should be noted that it is impossible to cut down wooden decking boards; when removing the protective layer, unique qualities are also lost.

- The impact on the forest with high temperature (about 200C) forever changes its properties. The weight is noticeably reduced, the absorbing characteristics decrease.

- Thanks to the fermentation, the board acquires a noble honey shade. However, it is not recommended to install it in places with intense loads, due to low density, the surface can roth.

It is quite easy to distinguish an impregnated product from a boards treated with steam, for this it is necessary to scrape the upper layer. If the shade of the inner and outer layers does not differ, then the wood has passed deep, vacuum impregnation.

- The cost of processed products is in the range of 700-1700 rubles per square meter.

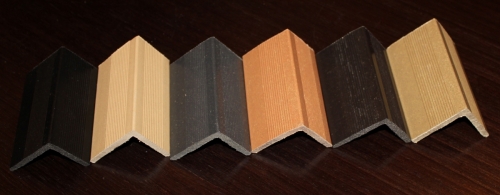

DPK board (wood-polymer composite)

- The name clarifies the composition of the mass used for the manufacture of flooring elements. Such a product will withstand almost any climatic conditions. It is also called a plastic deck.

- Composite deck is not susceptible to combustion, resistant to high mechanical stress, unattractive for the class of invertebrates and mushrooms. Significant disadvantages of panels are unnatural appearance and exposure to fatigue deformations.

- The price per square meter is 1-1.5 thousand rubles.

- Two types of composite products are offered on the market, polished and unnecessary boards. Visually, they are no different and have the same technical characteristics. So what is their difference?

- Some manufacturers assure that grinding allows you to get a surface that prevents slipping. Here the manufacturer is misleading the consumer. After a month of operation, the terraces made of both types of boards will have absolutely identical sliding characteristics.

- The main reason for such processing is the correction of defects obtained due to non-compliance with the technological process, but sometimes the use of poor-quality raw materials becomes wine. These factors affect the geometric shape of the finished product and to hide some imperfections, the boards undergo grinding.

- Everything would not be so scary, but the polymer layer obtained by extrusion is broken, thereby exposing the particles of the wood component. Direct contact of unprotected wood with the environment leads to their destruction. In addition, the rough surface promotes the accumulation of dirt.

The dimensions of the terrace decking

Terrace decking boards are distinguished in thickness:

- thin 18-22 mm;

- average 25-30 mm;

- fat 42-48 mm.

The width of the product is in the range of 90-250 mm, the length is usually standard 3, 4 or 6 meters. To arrange small zones, tile decing from the DPPs are available. The dimensions of the sections are from 25x25 cm, up to 50x50 cm.

Manufacturers of terrace decking

- The main manufacturer of elements for flooring from outlandish wood, growing in the tropical forests of Brazil and Panama, is the corporation Junglwood. Today, plants producing a massive board are located in Portugal and Indonesia. The company works according to the new technology of processing valuable wood, which retains the natural characteristics of the finished product.

- High quality is the products of another equally well -known manufacturer Ital Parchetti. The raw materials in the form of a circle entered a woodworking factory from Africa and South America. Speaking and further processing of wood are already going on directly here. Hard control at all stages of production allows us to attribute the manufactured products to class A.

Both domestic and foreign manufacturers of a terrace board from a composite are more widely represented on the market. The products of each brand have distinctive features that allow you to perform a comfortable arrangement of the house territory.

- The leading position is occupied by a trademark Trex (USA), producing a full -bodied board for terrace decking. Using their own developments, the manufacturer managed to achieve very significant results regarding the wear resistance of the finished product. High quality is confirmed by a 25-year guarantee for the absence of defects (chips, cracks), loss of color.

- Korean company LG better known as the manufacturer of household appliances and digital electronics, but, nevertheless, boards for flooring under the brand are also successfully produced at one of the factories Woozen. A hollow board imitates the surface of unstable wood. The manufacturer gives a 10-year guarantee for his products.

- The largest domestic manufacturer is DPK engineering. Products under the brand EcoDekthey have a lower cost, due to the lack of customs duties, margins of intermediaries and local wood. The composition of the raw materials is specially designed under adverse climatic conditions. Effective operation is confirmed by a 7-year guarantee.

- German-Ukrainian enterprise Holzdorf works on modern German and Italian equipment. For production, European raw materials are used. Hollow boards are equipped with a castle connection according to the principle of a spike-paz, which allows you to mount the flooring without cracks and gaps. The warranty from this manufacturer is given for 7 years.

Additional costs for arranging terrace decking

- If only screws act as additional costs for the installation of natural boards, then end elements are required to lay decing from the DPP. The edging performs both functional and aesthetic functions. Here, G and F-shaped profiles, the edging bar, the adjustment plan between the flooring and the wall of the structure are used.

- At first glance, the flooring of processed wood of non -valuable species will cost cheaper than the DPC products, but natural material requires regular care using impregnation.

- So, for example, lazor oil protects wooden surfaces from the formation of rot and the influence of ultraviolet radiation. Sliding oil is mainly used to cover the terrace boards located in the open air near the reservoirs. It is worth noting that such drugs do not belong to the category of cheap pleasures. Banks of protective oil, worth 5,000 rubles per 2.5 liters are enough to cover 40 sq.m. In one layer.

- Protection processing is necessary when installing the coating, and then every 2nd year of operation. If the owner will follow all the recommendations regarding the care of the deck board, then in ten years the expenses will amount to about 15 thousand rubles. For 1 (!) square meter.

As for the supporting elements for any coating, they can also be made of various materials:

- lags are wooden They are laid with a step of 0.6-1 meter depending on their cross section. The wood should be dry, no more than 25% of the humidity, so that under the influence of atmospheric phenomena it is not deformed. Mandatory processing by various protective equipment;

- composite lags Passed 30-40 cm from each other. Supports of such material are recommended for installation in difficult climatic conditions, but with low operational loads (home standard). Laying should not be carried out directly on the soil or concrete base, pillows made of dense rubber are installed between the surface and the lags;

- aluminum lags They differ in minimal temperature expansion. They can be mounted with a step up to 1 meter. Metal supports are quite expensive, so they are used in most cases in responsible, capital areas.

Do -it -yourself deing

- The deck is mounted on a flat surface (concrete base, wooden structures, adjustable supports and more). It is not recommended to equip a field on the ground, a pillow of sand and gravel, and so on.

- An excellent solution for concrete bases is adjustable supports. Such devices make it possible to adjust the height and slope during the installation of the terrace. Polypropylene products perfectly tolerate severe climatic conditions, can accept significant loads.

- If the surface is covered with waterproofing materials and provide good ventilation, then various communications can be placed in the educated space.

- Screw piles are used to arrange terraces on complex reliefs and where the composition of the soil does not allow the traditional type of foundation. High strength characteristics and a large supply of bearing capacity provide reliability of any structure.

- The laying of the boards should be carried out in accordance with the recommendations of the manufacturer. Depending on the type of product, their installation can be carried out in a seamless way, or with a compensation gap (4-6 mm) between the elements. The indentation from the wall, fence, etc. should be at least 15-20 mm. Linear expansion is also taken into account, so for each linear meter a gap of 4 mm is provided.

- A slope of the surface of 1.5-2% in the direction of laid boards is necessarily observed. The voids between the lags are not filled in order to ensure good circulation of air flows under the coating.

Mounting decking

- The optimal distance between the logs for any flooring is 40 cm. The fasteners of the boards can be either hidden or open. The last method gives the finished coating a not very attractive appearance. In addition, operational loads and ground movements lead to weakening of screw elements, thereby the screws of the screws may appear on the surface.

- But, if it was decided to apply this particular type of installation, then in products made of exotic wood, it is recommended to drill a hole in advance. Such manipulations will facilitate the work and prevent the cracking of wood during tightening the marks. As for boards from larch, pine, cedar, here you can perform fasteners without any preparations.

- Hats of screws are closed with caps or covered with special glue to the color of the flooring.

- Hidden installation involves the use of various mechanisms. The type, specificity of working with them may differ. As a rule, the manufacturer offers along with boards and fasteners with a unique development, which takes into account the presence or absence of a seam between decing.

But there are several main positions that are relevant for the installation of boards from any material:

- the end of the board should not play beyond the edge of the lag, the exception is a board from the array, a ledge of up to 30 cm is allowed here;

- during installation, the starting profile can be used, or the ends of the structure are closed after installing all the elements of the decorative (finish) bar;

- installation clips or other connecting parts are used at each intersection of the board with lags;

- some types of lag have a groove along the entire length, which makes it possible to insert rubber terminals. Such devices effectively act with temperature expansion of the material. Special antennae allow you to compensate for the gap between the boards. In addition, they will help to expose a uniform gap along the entire length of the board.

Each manufacturer is attached to terrace decking with step -by -step descriptions and photos on installation, so there will be no difficulties in work. If in the process of studying the instructions there are doubts, then you can contact a specialized company that will perform work without a bitch and a bitch. And you will only have to enjoy the beautiful view of the finished flooring.