Monolithic construction is a complex technology, but its principle ...

|

|

The bulk roof is usually used in the construction of household and industrial ... |

The maximum sophistication, chic and originality is able to add both to the interior and in ... |

We lay a laminate on a wooden floor

Laying laminate on an old wooden base constantly raises many questions. Some claim that to do this is undesirable, others do not see any problems. How to understand this issue?

If the choice in favor of panel parquet has already been made, it will be useful to find out some nuances and rules for placing a laminate on a wooden floor.

- Laminate on a wooden floor: Features of laying

- Lying laminate on a wooden floor: choice of material

- Preparation of a wooden floor for laminate

- The selection of a substrate for a laminate on an old wooden floor

- We lay a laminate on a wooden floor: installation technologies

- How to lay a laminate on a wooden floor: step -by -step instructions

- Service and care

Laminate on a wooden floor: Features of laying

Laminate is an affordable alternative to expensive parquet. This coating is used in residential and commercial premises. The laminate is quite simple in installation, but at the same time it is demanding on the quality of the base of the floor.

The owners of old houses and apartments in which the floor is made of wood often face the question: is it possible to lay a laminate on a wooden floor?. Experts assure that this technology is quite acceptable if the main requirement is observed high -quality preparation of a wooden foundation.

To understand the features of laying panels, it is necessary to understand the specifics of the wooden base and determine the possible causes of violation of the integrity of the laminate.

- The tree is not enough stable material. He is characterized by reference, damage, etc. These processes lead to the formation of cracks between the boards. If the laminate panels are laid on top of a shaken wooden floor, the load on the parquet locks will increase significantly. The castle connection is a weak flooring site.

- The wooden floor eventually loses its characteristics. Therefore, it is very important, before laying the laminate, to carry out the audit of the floor and identify the weaknesses of the floor itself and underground structures (supporting bars, lag). When determining any problems, repair work is necessary.

The laying of the laminate will have to abandon non -heated rooms and in rooms with high humidity, kitchens. Under the influence of moisture, the bar can deform and lose their original appearance.

Lying laminate on a wooden floor: choice of material

The durability of the operation of the flooring largely depends on the correct choice of laminate. There is a certain classification of panels, the main parameter of the choice of the premises.

- Class 31 for styling in houses, apartments and commercial premises with small cross -country ability;

- Class 32 is suitable for decorating rooms with patency of the average intensity of the kitchen, corridors;

- Class 33 laminate is designed for public buildings with high cross -country ability;

- Class 34 Scope of use large shopping centers, airports, clinics, schools and other premises where many people are constantly accumulating.

Its cost depends on the type of laminate. Class 31 coating is most affordable in price. Class 34 laminate is very durable, wear -resistant and is able to withstand significant mechanical loads. The only drawback is high cost.

The price policy of the flooring is influenced by additional characteristics:

- the thickness of the HDF plate (the base of the laminate) the larger this size, the more expensive the coating;

- the thickness of the protective layer;

- the presence of embossing, chamfers, additional processing, etc.;

- the manufacturer of European manufacturers evaluate their goods more expensive, Chinese and domestic;

- the brand laminate of popular brands that have proven themselves in the construction market will cost more than the panels of unknown companies.

Preparation of a wooden floor for laminate

Diagnosis of old flooring

The base of the floor before laying the laminate must be carefully examined. It is recommended to check the serviceability of both the external coating and the internal frame. Usually, the dismantling of the floor does not need a visual inspection.

The satisfactory condition of the floor and the possibility of laying the laminate are evidenced by a number of factors:

- While walking, the floorboards do not bend. Minor changes in the floor level under heavy furniture, for example, under a dams are permissible.

- The wooden coating does not have hollows, protrusions and knots.

- The horizontalness of the floor is the maximum allowable difference in the plane of the base in height is 2 mm for every 2 meters.

- Lack of cracks between floor boards. The presence of places affected by rot is unacceptable.

- When walking, the wooden floor does not creak.

If the listed requirements are met, then you can proceed to the next stage of the substrate. Otherwise, you will have to repair the base.

Important! To identify rotten floorboards or make sure of the normal condition of the tree, you need to get rid of the old layer of paint. The appearance of the coating should be almost the same color along the entire plane of the floor.

Repair of a wooden base

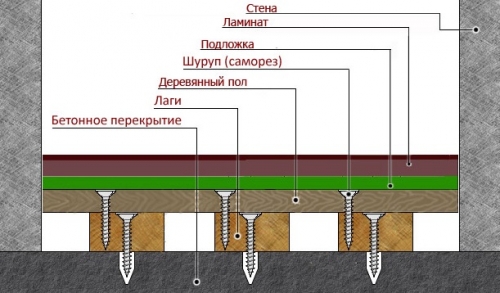

Elimination of creaks. It is necessary to walk on the floor and identify places where the base creaks greatly underfoot. If some of the halts bend, then the boards are additionally fixed with nails or self -tapping screws to the lags. In the case when the measures carried out did not give the proper result, the overhaul of the lag themselves may be required. Bricks or bars are installed under the inner body of the floor, they reliably fix the wooden base, preventing its loosening.

Important! If after strengthening the draft floor it is planned to align it with an electric rhuban or cycling, then nails must be used to fix the lag. The hats of nails before cyclation should be deepened into wood.

Harpses can creak due to friction against each other. To exclude this phenomenon, it is sometimes enough to fall asleep with a talcum or graphite, and the visible gaps are thrown.

Damaged/rotten boards are subject to replacement. To identify them, the floor surface is tapped with a hammer. Sounds from tapping on healthy wood have a more loud sound, and dull dull.

Even if the boards are only partially rotten and at first glance look reliable and durable, they still need to be replaced, otherwise the rot will switch to healthy floor elements.

It will be possible to prevent the appearance and spread of mold/fungus by treating the wood with an antiseptic composition and providing the base of the floor with good waterproofing.

Important! If deepening (small grooves) are revealed on the floorboards, then the surface must be treated with a bio -protective composition. The presence of grooves indicates that the flooring is affected by the tree.

Paul subsidence. The damaged area is disassembled by several floorboards. Several support wedges are placed under the lags. If the vast majority of wooden lag is in unsatisfactory condition, you will have to dismantle the floor and install new parts of the frame.

Setting the floor for laying the laminate

Consider three methods of aligning the wooden floor:

- the surface cycle is optimal if irregularities are not significant;

- laying of sheet materials;

- the arrangement of wet screed.

The following tools will be needed to cycle the floor:

- sandpaper;

- rubber spatula;

- cyclisting machine;

- manual rubbish;

- building level.

Before processing the floor, it is necessary to deepen the nails. After passing the cycling machine, check the evenness of the coating with a level. If chips are detected on the floor and cracks must be eliminated using wood putty. When the solution is completely dry, it is necessary to grind the floor again.

The cycling of the floor is a very dusty and noisy process. Upon its completion, the chips and dust must be removed with a vacuum cleaner even before laying the laminate.

You can prepare the base under the laminate using chipboard, OSB, GVVV, plywood and other sheet materials. For these purposes, sheets of plywood with a thickness of 12-15 mm, dimensions 50*50 cm or 75-75 cm are well suited. It is advisable to use moisture-resistant material.

Some nuances associated with the use of plywood:

- The coating is laid out in a run, a step of displacement of the floor of the sheet. Thanks to this technology, the load on the flooring is distributed evenly.

- Plywood is planted on glue and attached to a wooden base with self -tapping screws. The glue is applied with a gear spatula for the entire area of \u200b\u200bthe sheet, the screws are distributed along the edges of the plywood.

- Between the plywood plates, as well as between the wall and the plywood coating, technological gaps (10 mm) should remain. This distance is necessary for the temperature expansion of plywood.

The stacked sheets of plywood should be treated with a grinding machine, and at the end, covered with olifa.

Another way to align the wooden floor is a wet screed. A flat concrete coating is an ideal option for installing a laminate. For its implementation, you will need to strengthen the design of beams and lag. This is necessary so that the base calmly withstand the severity of the concrete solution.

The process is quite laborious, but the result will allow the operation of the laminate coating for a long time without repair work. This is due to the practicality and immobility of the concrete layer.

The selection of a substrate for a laminate on an old wooden floor

Before putting a laminate on a wooden floor, it is necessary to cover the base with a substrate. This layer performs a number of important tasks:

- eliminates minor irregularities of the floor;

- increases heat and sound insulation;

- serves as additional protection against moisture;

- prevents the contact of the black floor with laminate slabs, preventing friction and rapid wear of the flooring.

The construction market offers three main types of substrates under the shield parquet.

Polyethylene substrate foam The most popular option, as it has the optimal price-quality ratio. The material contains a layer of aluminum foil or metallized film. The main characteristics: thermal insulation, moisture resistance and bio resistance. Disadvantages of subsidence and exposure to UV rays.

When choosing a polyethylene background, you need to pay attention to the density of the material, the higher it is, the better and more durable. Under the apartment laminate, a 2 mm thick substrate is suitable. For laminated panels with a thickness of 9 mm, it is necessary to select polyethylene with a thickness of at least 3 mm.

Good operational characteristics shows a two -layer polystyrol substrate. Protective material consists of aluminum foil and a layer of polystyrene. The substrate is not affected by fungi, mold, is not afraid of moisture and relatively inexpensive. Cons of material: polystyrene is pressed under a large load and is poorly rolled out when laying.

Advice. Extruded polystyrene has minimal indicators of moisture absorption. Laying such a substrate under the laminate allows you to do without a moisture -proof layer. When placing polystyrene along the walls, a ventilation gap is left about 10 mm.

Camping substrate It is made of pressed crumb of oak bark. Such material can be completely natural or combined with bitumen or rubber.

Among the main advantages of the substrates are:

- the rigidity of the material is not extended at loads;

- safety of application;

- good heat and sound insulation qualities;

- better the rest of the coating masks the unevenness of the black floor;

- bio -resistant;

- unlimited service life.

The main minus of cork material is a fear of moisture. Therefore, such a substrate is not suitable for installing a warm floor and for the arrangement of kitchens, bathrooms and rooms with a high level of humidity.

Advice. High quality cork substrate is not visible. To lay a laminate on a wooden floor, a cork 2 mm thick is suitable.

We lay a laminate on a wooden floor: installation technologies

Installation of a laminate on a wooden floor is carried out in several ways:

- click system;

- lock system;

- glued laminate.

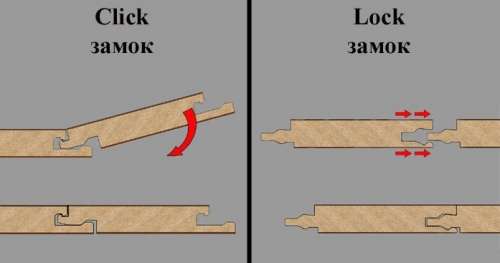

Click Castle Connection The most common way to install laminate. The panels are easy to fasten the spike in the groove at an angle of 30-40. The laminate panel is lowered to the neighboring lamel and is fixed in the lock. The seam is almost invisible. Installation work should begin from the corner opposite the door.

Lock mount is rarely used, since such a laminate needs even. Lock is laid by clogging the groove of one lamella in another hammer. Due to this fixation, it will be difficult to disassemble the coating for repair.

The most expensive method is adhesive. This method resembles a parquet masonry for the use of grooves and screed. Glue is applied to the ends of the panels, after which the strips are securely fixed with each other. The adhesive mount is used where the floor is subjected to high loads public premises with high cross -country ability. For domestic use, this method is rarely used due to the high complexity of the process.

Laminate laying differs not only in the mounting method, but also with options for the location of panel parquet:

- Classical masonry is the most common and economical. Waste with this installation is about 5%. The laminate is creeping from the window in the direction of light. Cutting panels with a length of 30-40 cm are used at the end of the row.

- Diagonal masonry is identical to the classic location, but the panels are laying at an angle of 45. Such masonry looks very beautiful and visually expands the room. The minus of the diagonal method is increased waste of finishing material to 15%.

- Brick masonry each subsequent row of panels shifts in relation to the previous one by half. The brick method provides maximum coating strength. Lack of layout is a high overrun of the laminate (15-20%).

- Christmas tree laying Lamelian location at an angle of 90 on the principle of parquet. For this method, it is necessary to use stripes with special shifts.

How to lay a laminate on a wooden floor: step -by -step instructions

First of all, it is necessary to decide on the method of laying the laminate and perform the calculation of the necessary material. Procedure calculation of the number of laminate when the lamella is located with the traditional method:

- Calculate the total area of \u200b\u200bthe room to multiply the width of the room by its length.

- The resulting value is increased by 10%. This gap will compensate for the consumption of panels during cutting.

Laminate laying sequence:

- The flooring of the substrates. Roll protective material along the main coating. Propher the joints between the canvases with construction tape.

- The assembly of the laminate begins from the left corner of the room opposite to the door. From the panels laid in the front row, cut the locks. When performing the installation, it should be remembered that there should be a gap between the coating and the wall to compensate for linear extensions. To keep this distance, plastic pegs or wooden spacers are exhibited.

- The first panel is located in a corner, and spacers are inserted along the walls. The second board is installed in the mounting groove at an angle of 30 and with a light press, it is closed.

- To cut the laminate, it is better to use carbide cutting discs. If the pruning of the last lamella is required, but its length after that will be less than 30 cm, then it is necessary to shorten the first panel. As a result of cutting, the length of the first and last lamella should be more than 35-40 cm.

- The laying of the second row begins with a trimmed panel from the previous row, if it is no shorter than 30 cm. After a full assembly of the row, it is trained under the side fasteners of the first row, installed in the groove at an angle and soaked.

- All subsequent ranks are collected by the described method.

- To lay the final series, it may require trimming the panels along the length. It is performed taking into account the compensation clearance.

If there are heating/water supply pipes in the room, they will have to go around them:

- To measure the distance of the wall to the pipe and apply the mark on the lamella, where there will be a section.

- Measure the diameter of the pipe.

- Cut in the laminate a circle with a diameter of 15 mm larger than the pipe.

- Cut the panel across, passing through the center of the cut circle.

- Put parts of the laminate on the floor and connect them with each other. It is advisable to put fragments of the laminate on glue.

- Around the pipe, fix special plugs.

Service and care

In order for the laminate for a long time to please a beautiful appearance, you will need to follow some rules of maintenance and flooring:

- avoid a large amount of water at the joints of the panels;

- put under the legs of sofas, armchairs, massive tables and cabinets soft fabric or use felt overlays;

- clean the laminate immediately after pollution, using special products;

- it is not advisable to sweep a panel parquet with a broom with a broom to use a vacuum cleaner or a mop for dry cleaning.

Laying laminate on a wooden floor: video

After laying down the estate ...

After “Lying Lamy ....” trust in the article drops sharply.

Also, after lies laminate

Also, after "Lying Laminate" stopped reading.