Installing the fence on brick pillars is distinguished primarily by good ...

|

|

It would seem that the baseboard is a very insignificant detail in the interior. Does he need it ... |

Когда планируется капитальный ремонт жилого помещения, без выравнивания пола не... |

Monolithic construction of houses

Monolithic construction is a complex technology, but its principle is understandable to the simple developer. First, it is customary to erect a structure from the formwork, which is filled with a solution of concrete. As a result, concrete walls of the building are formed directly on the construction site. Therefore, if you plan to build a residential building of your dreams, it is recommended to use the technology for the construction of monolithic houses, which allows you to build reliable cottages of any configuration.

Table of contents:

- The advantages of monolithic buildings

- Monolithic-frame construction

- Materials for construction

- Creating a fixed formwork

The advantages of monolithic buildings

It is first necessary to make a reservation that the construction of monolithic houses does not need to use such heavy equipment as cranes. In this case, it is customary to use concrete pumps, using which concrete is poured into special forms and can be laid at an altitude of up to 4 meters. This will help save the landscape on your site.

Using such a technique, you can build a house of any number of storeys and configuration. A significant advantage of this technology is the possibility of using a curved form. It is also important that the walls and ceilings will be immediately ready for decoration. At the same time, the terms of work are reduced to a minimum. Such construction of houses using fixed type formwork, in comparison with other technologies, accelerates the construction process to 10 times, while saving money savings.

Carrying monolithic walls are 2.5 times thinner than walls built of brick. The walls about 0.3 meters thick in their thermal conductivity will replace the brick wall, the thickness of which reaches 2.3 meters. Monolithic construction of a house with your own hands allows you to reduce the costs of heating houses by four times, compared with brick buildings. Therefore, when erecting a house in size 10 by 10 meters, you will notice that its interior space increases by another 15 square meters. It turns out in the end a whole room!

You can find out the price of VVKZ brick in the price list on the plant’s website. The quality that you notice and evaluate. Brick at the prices of the manufacturer, without intermediaries, throughout Russia.

The special characteristics of monolithic buildings include its rigidity and strength. We can say that such residential buildings in this regard have no equal. Using this technology, you will get the opportunity to reduce the load on the foundation of the house, which allows you to use new finely-and-deep-lubricated foundations in suburban construction with a low consumption for their construction.

The video about the construction of monolithic houses shows that the combination of non -removable formwork and traditional materials is allowed, which makes it possible for the developer to implement any project for the construction of a cottage or cottage from an individual layout to an extravagant architectural style.

The shrinkage of the house is carried out evenly, so cracks are not excluded. In addition, atmospheric precipitation practically does not affect monolithic houses. There are no joints between the plates, which is the main weak point of panel buildings. Work can be carried out in any time of the year and at any climate - even at subsequent temperatures. Such an almost seamless structure is very durable. The term of his useful service often reaches 150 years.

Monolithic-frame construction

The ultramodern monolithic-frame construction is a unique method that combines the frame and monolithic principle of erecting houses, developed at the end of the last century and has earned huge popularity today. A simple technology of high -quality, cheap and fast capital construction can significantly save money on housing heating.

The technology of monolithic -ocature construction is based on the use of polystyrene stoves, on which concrete under pressure is applied. Such a cottage is characterized by increased reliability and strength compared to other structures. A residential building is guaranteed to avoid cracks, deformation of window openings and uneven sediments of the foundation.

Monolithic-frame construction of buildings allows you to build only stable houses that will steadfastly transfer strong hurricanes and earthquakes. That is why such a technique is recommended to be used on subsidence ground and in seismically dangerous areas.

The technology of monolithic construction construction has long been checked in Europe, the USA and Canada. The life of such houses is 200 years. In addition, they are sealed. The absence of cold bridges and seamless construction make cottages comfortable and soundproof. Inside the buildings, the effect of thermos is created, thus, it is cool in them in the heat, and warm in the winter. A high-tech erection of a monolithic-frame house will cost cheaper than the construction of a traditional cottage.

Materials for construction

Regarding the calculation of the needs in the material, the concrete consumption of an average of 1 meter square total area will be 0.4 - 0.7 meters of cubic, became reinforcing 25-70 kilograms. For the manufacture of formwork, it is customary to use a variety of materials.

Metal

Elements that perceive the main loads on themselves are mainly made of aluminum alloys and steel. Steel, which is used to manufacture the bearing elements of the formwork, galvanized or galvanized, with a powder coating that protects it from corrosion and provides rapidly cleaning during operation.

Aluminum formwork is 3 times easier than steel, which significantly reduces the price and complexity of the transportation and installation of formwork, and, accordingly, the price of the construction of a monolithic house, and also allows construction work without the use of a tap.

Wood

To make wooden formwork elements, they mainly use plywood and adhesive wood. Glued elements are characterized by high strength and low deformation. However, it is known that wood has one significant drawback of hygroscopicity.

Elements made of wood are subjected to swelling and crust. For this reason, it is customary to use a laminated plywood laminated with a special phenomaldehyd coating, which sharply reduces concrete adhesion and provides high turnover.

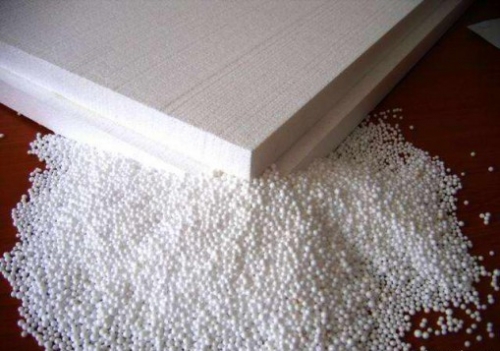

Foam polystyrene

In low -rise construction of monolithic houses, a polystyrene non -removable formwork foam is actively introduced, which is collected dry with the use of connections between the inner and outer layers of blocks. The material in its structure is very similar to natural material - a cork tree bark, which consists of micro granules.

Polistyle foam in a foamed form is a vapor -permeable building material. It is not radioactive, neutral from a chemical point of view, resistant to humidity, does not pollute ground water, and does not attract harmful insects and rodents.

I would like to add that this building material is considered so harmless that molding packages that are used for food products are even made from it. Outwardly, it resembles polystyrene, but in terms of characteristics it differs radically. However, during the production of raw materials, phenol impurities are derived from it and add additives that protect the material from combustion.

Built houses using such a technology for monolithic construction of private houses are inherent in the following wall characteristics:

- According to the thickness of the structure - 30 centimeters, 15 centimeters of them are monolithic concrete and the rest of the polystyrene;

- The walls of the house without finishing are 340 kilograms per square meter;

- Heat transfer per square meter reaches 3.2 K/W;

- Moisture absorption per day 0.1%;

- Acoustics 53 dB;

- The level of fire resistance is II degree of protection.

Creating a fixed formwork

The process of creating a residential building using this technology includes the following stages of building a monolithic house: preparation of concrete, preparation of monolithic formwork and installation of finished concrete. The construction formwork is treated with a special solution and is installed using components of connecting locks, racks and brackets.

Monolithic formwork is poured after that prepared concrete. After solidifying the solution, the formwork is removed, and the fixed formwork remains on concrete. She will continue to play the role of the thermal insulation layer.

The formwork in monolithic construction can be of different types. For example, the formwork of walls, floors and foundation. Therefore, it is customary to install it differently. If you make a formwork for the foundation, then you need to use special slopes and horizontal spacers.

For formwork of floors, telescopic or volumetric racks are needed. They make a monolithic formwork using all kinds of materials - plastic, aluminum, wood and steel. Its properties and qualities vary depending on this.

Non -removable formwork, as a rule, is made of dense polystyrene foam. It is blocks with two plates connected by stable jumpers. The cavities that are in the formwork design are reinforced during the construction of monolithic houses and poured with concrete.

The planes in the system are equipped with castles of complex shape, which resembles the assembly of Lego cubes. A similar design allows you to get away from the use of retaining elements and withstand the geometric wall parameters, thereby ensuring the tightness of the compounds.

Fencous polystyrene formwork is called a perfectly flat surface. Therefore, it immediately allows you to finish the walls with any building materials. The finish is mounted with adhesive connection with polystyrene or introduced into the body of concrete mechanical fastening.

When using a monolithic construction of non -removable formwork during one operation, a reinforced concrete wall of a monolith is erected, which has a thermal insulation and soundproof membrane on the outer and inside, which completely eliminates the formation of cold foci.

The layer of thermal insulation material protects from the outside and protects monolithic structures from factors that come from the environment and freezing. This layer from the inside serves as a thermal exchange barrier between the internal rooms that are in the house and the warmed air of the walls.

After reading the material we proposed, you can judge whether the technology of monolithic construction of residential buildings is suitable for you or not, and about the cost of building a monolithic house. Analyze all the advantages of this technique again, and their innumerable, the most important of which is the rapid construction of the house, thin walls, saving money in the process of erecting and heating the house.

Interesting, and the one who wrote

Interestingly, and the one who wrote the article heard about thermal conductivity?

"Walls about 0.3 meters thick (meaning concrete - judging by the text), the brick wall will be replaced by its thermal conductivity, the thickness of which reaches 2.3 meters." - Vranya.

I read the article to the end. 0.3

I read the article to the end. 0.3 meters mean 0.15 concrete + 0.15 foam. This clarifies the essence of the article a little. And anyway, well, why the house is a wall equal to 2.5 meters of brick, if the normal brick house of the middle strip of Russia has 0.6-0.7 meters?

It feels like some

It seems that some people write comments without fully reading the article. The author writes that he compares in heat supply with brick. And the heat of polystyrene is the heat and not concrete ... well, you and personnel)))

Good technology, but there are nuances ...

Polystyrol emits styrene,

Polystyrol distinguishes Stirol, which makes in lifeless and from which there will be no kids. They lived in wagons on BAM, where polystyrene was thermal insulation and most women could not have children. The author of the article does not own the question that he writes about. What can you do, we have such an education.