The basement is an additional room, the construction of which is always justified ...

|

|

The stretch ceiling is the ideal option for finishing the ceiling for lazy and practical ... |

Work on laying a soft roof is becoming increasingly widespread, thanks to ... |

Types of linoleum: photo, characteristic, choice

Despite the fact that the manufacturers provided the floor of flooring with a variety of assortment that meets all the requirements and construction standards, in the process of choosing a coating for his home, the consumer still opens his choice on traditional linoleum. This is due to the fact that, using the example of this floor covering, the manufacturer has the opportunity to demonstrate the optimal combination of price and quality, which is not always possible regarding similar materials. In addition, linoleum is one of the most unpretentious and, unlike parquet, lungs in the installation of materials. It would seem that the choice is obvious, but here there are pitfalls. The flooring market is developing, and linoleum also continues to improve. All this leads to the fact that the consumer has to face a large number of varieties of linoleum, each of which is characterized by its purpose, advantages and disadvantages. Finding a choice, an inexperienced master, who does not have theoretical knowledge about various types of linoleum, is often not able to quickly orientate, which leads to the emergence of various kinds of difficulties and errors when choosing a suitable material. To prevent them, and help inexperienced masters in the process of choosing a popular flooring, our experts have prepared a real article telling about the purpose, advantages and disadvantages of each of the varieties of linoleum.

Content

- Linoleum: the main advantages and disadvantages

- Linoleum use scope: main varieties

- Layer composition and technical characteristics of a semi -commercial linoleum

- Varieties of linoleum in accordance with the material used

- Varieties of linoleum in accordance with the type of basis

- Special types of linoleum: Brief description

Linoleum: the main advantages and disadvantages

For linoleum, rightfully called one of the most economical and demanded materials among those that offers the construction market, certain advantages and disadvantages that we will consider later are characteristic.

The fundamental advantages of linoleum:

- The ease of installation of the flooring is one of the main advantages of linoleum, thanks to which you can decide the flooring yourself;

- The simplicity of operation and unpretentiousness in leaving, since, unlike laminate or parquet, traces of street dirt are less visible on linoleum, which is especially true for rooms with great cross -country ability;

- Lack of need for a protective coating that is mandatory for parquet;

- Moisture resistance and resistance to acids, which makes the flooring of linoleum in rooms with frequent wet cleaning;

- Elasticity and low sliding level, ensuring the safety of people's movement, which allows the use of linoleum as flooring in gyms and public places;

- High heat and sound insulation characteristics, which is also relevant not only for residential, but also public premises;

- Due to the variety of decor and colors, designers get an inexhaustible field for the implementation of their most daring undo.

Linoleum disadvantages:

Before making a linoleum flooring, you must make sure that the basis on which you will lay linoleum is perfectly even. But in general, this applies to any flooring;

- In the process of using synthetic linoleum, chemical components are used, however, PVC coverage corresponds to sanitary and hygienic requirements and norms;

- In the case of the movement of furniture, you can detect dents on the floor covering left by furniture.

Important! If we carefully analyze the disadvantages and advantages of linoleum, you can notice that the latter prevail and are more convincing, and therefore, not every floor covering is able to compete with linoleum.

Linoleum use scope: main varieties

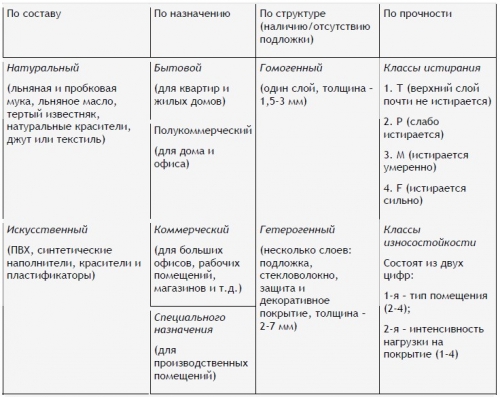

In the process of choosing linoleum for residential or public premises, it is important to consider not only the external characteristics of the material, but also its physical properties. Elastic PVC covers, in accordance with the degree of wear resistance, distinguish several classes of linoleum. In accordance with European standards, linoleum is classified by 21-23, 31-34, 41-43 grades of use. Russian standards involve the separation of linoleum in accordance with the sphere of its use, that is, there are three main types of flooring, each of which includes linoleum of a certain class.

In accordance with this feature, household linoleum, commercial and semi -commercial linoleum are distinguished, each of which is designed for laying in rooms with various cross -country ability. In addition, special -purpose linoleum is separately distinguished.

Under the concept household linoleum It implies the floor covering of 21-23 class, made on a foamed basis and characterized by a multilayer structure. Among the advantages of the material of this class, high -quality soundproofing indicators, environmental friendliness, high decorative characteristics and pleasant tactile sensations when contacting the coating surface are the main characteristics that the manufacturer provides during the manufacture of cheap linoleum can be distinguished. However, it is impossible to create a material that meets all the requirements, in connection with which, the budget option loses to its more expensive analogues. The thickness of the protective layer of domestic linoleum does not exceed 0.1-0.35 mm, as a result of which this material sins with low wear resistance and insufficiently spectacular appearance. Used only for residential premises.

Linoleum commercial, also called technical, is a floor covering of increased wear resistance, belonging to 41-43 grades of application. The manufacturer guarantees at least 10 years of service in areas characterized by increased cross -country ability. These include school corridors and classes, foster, trading halls and even airports. The strength of such a coating is provided in various ways. If the strength of the homogeneous (single -layer) linoleum is ensured by the density and homogeneity of the material, then to ensure the reliability of heterogeneous material, the manufacturer uses additional strengthening and stabilizing layers. In environmental friendliness, the technical linoleum is in no way inferior to domestic varieties, in connection with which, it can be used for household purposes, which is significantly limited due to the high cost of the material.

In addition to technical and domestic linoleum, there is a golden mean - semi -commercial linoleumimplying material with 31-34 class of application. It is characterized by greater wear resistance in comparison with domestic linoleum, and less demand to styling than commercial flooring. A semi -commercial linoleum can be used both in household and public premises characterized by average cross -country ability.

Types of linoleum photo

Layer composition and technical characteristics of a semi -commercial linoleum

This type of flooring consists of three layers:

- PVC bent (for a semi -commercial variety only foamed). Some models are characterized by the addition of a foam fiber, which increases the strength of the material and avoids its sprains. In addition, fiberglass performs heat and soundproofing functions, which even allows it to be released in a separate, independent layer;

- Decorative layerresponsible for the appearance of the flooring. It can be either plain or include several colors, as well as imitate any natural materials, including stone, granite or wood;

- PVC or polyurethane protective layer, preventing premature wear of the coating. For semi-commercial varieties of linoleum, its thickness is 0.4-0.6 mm.

Technical characteristics of a semi -commercial linoleum:

- Weight 1 sq. meters 2-2.5 kg, unlike domestic linoleum, weight of 1 sq. meters of which does not exceed 1.2-1.8 kg;

- Choosing a semi -commercial linoleum, the width of which is from 2 to 4 meters, you should know that due to the optimal thickness of the protective layer, it is stable not only to temperature, but also to mechanical influences;

- Warranty for this linoleum from 7 to 20 years.

Varieties of linoleum in accordance with the material used

Given this feature, the following varieties of linoleum are distinguished:

- Natural linoleum;

- Polyvinylchrod (PVC-linoleum);

- Colloxilin (nitro -cellulose linoleum);

- Glyftal (alkyd linoleum);

- Rubber linoleum or, so -called reign.

Consider each of them in more detail.

Natural linoleum, a distinctive feature of which is the presence in the composition of only natural components, is considered absolutely harmless and environmentally friendly material. For its manufacture, use wood and limestone flour, flour obtained from cork wood, linseed oil, natural resin of coniferous trees and natural dyes. For the manufacture of the supporting base, natural materials are also used most often this jute fabric. Sometimes, to increase the wear resistance of natural linoleum, it is covered with a polymer, but you can purchase a flooring without a varnish layer. Natural linoleum can be either atlerable and on a fabric basis. The following advantages are characteristic of natural linoleum:

- High wear resistance, combined with a spectacular appearance;

- Optimal fire resistance and obstacle to the spread of flame in case of fire;

- Ease of care, limited to dry or humid cleaning, and prolonged preservation of the original characteristics;

- Bactericidal properties provided by the linseed oil that is part of it;

- Lack of tendency to accumulate static electricity;

- Resistance to ultraviolet radiation, non -centered acids and ethyl alcohol.

Important! Despite the indisputable advantages, this material has one significant drawback of insufficient plasticity, and therefore, difficulties in its transportation often arise, since careless handling of it can cause excesses.

PVC linoleum, as well as natural material, can be produced using the base, and without it. In the role of the basis, natural materials are rarely used, which replaced synthetic. Distinguish between an unconscious synthetic linoleum, linoleum on a foam, tissue or heat -insulating non -woven basis.

Important! A popular representative of linoleum using non-woven heat-insulating substrate is PVC-linoleum on a felt-tiped basis, during the manufacture of which a thick substrate of artificial felt is used. Due to its unique structure, with a linoleum flooring, there is no need to glue or use the screed on a felt basis. This type of linoleum, the dimensions of which vary from 1.5 to 3.5 m in width, has a transparent protective layer, as well as an needle-resistant heat and soundproofing subsonov from polypropylene and lavsane fibers, is used mainly for domestic purposes.

An important disadvantage of synthetic linoleum, with the exception of those models for which foamed or the base of fiberglass is used, is a large shrinkage when it is used in conditions of elevated temperatures and the presence of artificial components in its composition. Despite the fact that they comply with all quality standards and are absolutely harmless, the world has developed in the world, that the presence of artificial components in the composition of the material affects not only its quality, but also environmental safety. In addition, a characteristic feature of such a flooring is a specific smell that disappears during its operation.

In accordance with the number of layers, PVC linoleum can be divided into two groups: homogeneous, consisting of one layer, and heterogeneous, which includes several layers.

- Homogeneous linoleum It is a panel with a thickness of 1.5 to 3 mm, characterized by a plain pattern. For its production, limestone, talc and kaolin are used. So that the fillers that are part of the linoleum do not reach its surface, polyurethane protection is applied to it. A significant drawback of such linoleum is the need to grind the protective coating at least once every 3-6 months;

- Heterogenic PVC linoleums are a more universal and practical flooring with a multilayer structure. As the basis for the specified flooring, fiberglass is used, impregnated with polyvinyl chloride paste, covered on the front side of the PVC layer with another composition. It is on it that the manufacturer applies a drawing that is protected by a transparent polyvinyl chloride layer of high strength, the thickness of which does not exceed 0.15 mm.

Important! Linoleum, the drawing on which is not applied with a chemical, but mechanically way, to a greater extent corresponds to quality standards and is a more reliable flooring.

In addition to fiberglass, a substrate is used in the production of linoleum, which can be foamed, polyester, tissue or jute. It is applied to the fiberglass base from the wrong side and prevents the appearance of linoleum deformations when exposed to high temperatures.

The following types of flooring are less common, but still used in construction practice, the varieties of linoleum:

- Colloxilin Or the so -called nitro -cellulose linoleum, which is a subtle rootless flooring, characterized by elasticity and high moisture resistance. But, despite these advantages, he is unstable to the fire;

- Glyftal linoleum, superior to polyvinyl chloride varieties in heat and sound insulation indicators, are made using a fabric base. A characteristic feature of this variety is its increase in width and a decrease in the length of the bands;

- Relin rubber linoleum It is a material consisting of two layers, the lower of which is represented by chopped rubber associated with bitumen-containing materials, and the upper mixture of synthetic rubber, fillers and pigments. A distinctive feature of Relina is elasticity and high moisture resistance.

Varieties of linoleum in accordance with the type of basis

In order to fully answer the question: how to choose linoleum?, You need to familiarize yourself with its varieties depending on the type of foundation used, systematizing the previously received information. In accordance with this sign, they distinguish:

- Unconferential linoleum, which is a thin single -layer coating, devoid of the basis. It is characterized by a low cost and is used for household rooms with high humidity, such as kitchens and bathrooms. Due to the small thickness, it should only be laid on an absolutely even base;

- Linoleum on a foamed basis It is a multilayer structure with a thickness of 2 to 3.5 mm and does not need to glue over the entire area of \u200b\u200bthe canvas, but only in diagonals and angles. Like the previous variety, it is used in household rooms with a high level of moisture, where joints are brewed with hot welding or cold, using specialized liquid compounds;

- Warm -based linoleum It is a floor covering consisting of a base represented by a natural or artificial jute or felt, and the upper protective polymer layer. The thickness of linoleum on a felt basis is at least 5 mm. Due to its elasticity and ability to maintain heat, a warm -based linoleum is used in household rooms with a normal level of humidity. Experts recommend laying it with a single canvas, without joints, as this will avoid moisture entering the joint to the base. Since it expands slightly during operation, this must be taken into account in the laying process, leaving a small gap between the coating and the wall not exceeding 5 mm.

Special types of linoleum: Brief description

Antistatic linoleum It is characterized by a structure that prevents the accumulation of static electricity associated with a large number of working electrical appliances. Due to the fact that dust negatively affects highly sensitive devices, the antistatic coating of linoleum prevents its accumulation. Unlike other types of linoleum, antistatic linoleum can be used in rooms where high -precision equipment is located;

Sports linoleumMaterial designed to install flooring in sports rooms. Due to the fact that high -strength polyvinyl chloride is used as the upper layer of sports linoleum, it is able to withstand increased loads and while maintaining its original operational characteristics. It is characterized by strength, elasticity and traumatic safety;

Liquid linoleum, also called a polymer bulk floor, is an innovative development and does not externally differ from the usual linoleum, but it resembles ceramic tiles to the touch.

What are its main advantages?

- Due to the fact that the floor filling is carried out at a time, there are no gaps and docking seams;

- You can use it in rooms with various configuration complexity without wasting time to dock the pattern;

- Due to the inclusion of various dyes of decorative pigments in its composition, it is characterized by the widest color palette;

- High strength, reliability and impact resistance of the coating, due to its significantly larger, compared to other varieties, thickness (more than 1.5 mm);

- Absolute water resistance, which ensures the effectiveness of its use in rooms with high humidity;

- Environmental safety that makes it possible to use it in children's rooms.

3D-linoleum Another innovative development of flooring manufacturers, which allows emphasizing the unique style of any room. The ability to visually increase the space of the room several times, thanks to 3D effects, is not the only advantage of this material. Thanks to the use of modern technologies, the manufacturer, taking into account the wishes of the customer, inflicts drawings with 3D effects on linoleum, when viewed, which will create the impression of volume. Like other innovative developments, 3D-linoleum is characterized by high wear resistance, impact resistance and resistance to temperature fluctuations.