The finish of the facade is a very important process that determines the appearance of the building and its ...

|

|

Today, the share of quick -collection houses in the country's country has reached about 35 ... |

Until recently, we could not imagine what could be done with the ceiling ... |

Soft roof laying technology: tips

Work on laying soft roofs is increasingly widespread due to the availability of high -tech roller and piece materials. A soft roof is a universal solution that combines the waterproofing of the roof and its finish layer. Flap membranes and bitumen-polymer coatings differ in the technology of laying a soft roof. They are successfully used where other methods of completing the installation of the roof are unacceptable.

Table of contents:

- What is important to know about the soft roof?

- How to choose materials for a soft roof?

- Properties of soft roofing materials

- Advantages and disadvantages of materials with the base and without the basis

- Soft roof laying technology

- Technology for installation of membrane materials

- Bitumen tile laying technology

- Final advice

What is important to know about the soft roof?

The soft roof is a convenient and affordable method of waterproofing with membrane and roll materials. The construction market offers several varieties of plastic materials for arranging reliable waterproofing flat and complex roof configuration. The cost of work directly depends on materials for laying a soft roof and installation features.

In this segment of roofing materials there are proposals in various price categories, so it does not make sense to spend a lot of effort and money on a small country house. The cost of technological laying of a soft roof is not only a total meter multiplied by a square meter of roller materials. This includes related and consumables, as well as the purchase or rental of equipment for salary and other devices.

As practice shows, this is one of their most affordable methods of waterproofing roofs. Materials for processing surfaces in layers are lined or melted on a prepared base, screed or other basis. But some varieties are designed for facing roof slopes, others for intermediate insulation with stitched membranes. For each variety of soft swimming, the roof is its own styling technology, which allows you to optimize expenses and achieve long -term results.

How to choose materials for a soft roof?

It is difficult for people to give preference to some specific type of roller material, far from understanding the device of a soft roof and styling technology. It probably seems to the home master without experience in this matter that there is no particular difference in which option to choose, the main thing is to make quickly and inexpensively. But it is here that the whole snag lies, since it makes no sense to overpay for beauty if the roof is flat, and focusing on tightness, if it is a gentle gable.

1. Is there a large area of \u200b\u200bsuburban construction, or is it a small country house? Is it somewhat often planned to make a roof repair? The old roof or the final stage of the new building? How to evaluate the repairs of morally obsolete coating? Is independent laying of a soft roof of the selected type available? All these questions have to answer before buying materials. And for the installation of some varieties, the experience of professionals or the rental of special equipment is required.

2. The total weight of the floors and soft roof material during the repair of the roof is no less important aspect when we are talking about choosing. The heavy structure creates additional pressure on the foundation. And there is a structure is located on unstable or problematic soils, it is important to facilitate the construction as much as possible and correctly strengthen the building on the site.

3. The house is completed completely or it is supposed to make extensions, respectively, build the area of \u200b\u200bthe roof. In this case, it is important to achieve the monolist of the cover, while it is extremely inappropriate to completely change the roof.

4. The total costs include the rental of equipment, roller materials for laying soft roofs, additional fasteners, sealants and other components of competent installation.

Attention: Rolled materials used in the old fashioned way are not suitable for high -quality sealing the roof using modern technology. For example, only and roofing material, which were lying in the country in sufficient quantities, probably became unusable, and there is no need to count on high -quality styling here. They can only be used for fragmentary repair of the leaked roof as a temporary solution.

Properties of soft roofing materials

Rolled and membrane materials for laying a soft roof are produced by different manufacturers and differ in some characteristics, but have much in common. They will be successfully used in the near future, since they do not have another alternative in the modern construction market.

Basic properties:

1. Convenient packaging and small width allow rolling rolls in any direction and used for waterproofing roofs as a self -sufficient or auxiliary component.

2. Do not lose their basic properties from temperature changes and adverse external factors.

3. High strength strength.

4. A simple technology for laying a roll soft roof with minimal equipment with a tool and installation devices.

5. The possibility of a 100%coating of roofs of any configuration with complex geometry is available.

6. All work can be carried out without the temporary resettlement of the residents of the house, thanks to the small noise and the almost harmless process of the spike of the seams.

7. After laying the soft roof of the shinglass and other roll materials, the level of sensitivity to the noise (rain, hail, birds, etc.) decreases.

8. Increased service life relative to old roofing materials from 10-15 years.

In recent years, the main types of rolled roofing materials have undergone serious modernization. Rolled materials based on polymers and fiberglass can be with a substrate and rootless. The most popular materials:

- UNIFLLERS CHPP 3.5 with a fuel base based on fiberglass, the average price category;

- Uniflex HKP 4.5 with similar properties and improved characteristics;

- Linker HPP 3.6 Economical material with a fiberglass -based substitute;

- Linker HKP 4.6 Flapping the upper layer based on fiberglass, budget segment;

- Icoplast of CPP 3.0 fiberglass with a substitute and improved characteristics, more expensive than analogues;

- Isoplast ECP 5.0 excellent characteristics, it costs more than all of the listed materials;

- flexible tile of Katepal with a large assortment of shades and textures;

- flexible tiles of shinglass for the pitched roof in the middle price segment;

- high-quality bitumen-polymer membrane of a technonic for laying a soft roof, etc.

Advantages and disadvantages of materials with the base and without the basis

Regarding work on laying the soft roof has long been disputes, since their durability is disputed. But this opinion is based on old roller materials, such as roofing material consisting of cardboard saturated with resin. He warmed up from the sun, contracted and crackled in the cold, and then it all filled with rain.

The advanced materials of the new generation are made on a non -native basis (fiberglass, film membranes). They are resistant to ruptures, fit not like their predecessors and have a lot of other advantages:

- small specific gravity;

- a more durable base;

- spaciousness of transportation and installation;

- elastic and strong cut with hydro- and noise insulation;

- a higher level of heat conservation;

- resistance to temperature changes.

Minuses:

- the styling technology involves welded seams along each panel;

- possible depressurization in poorly processed places and a decrease in vapor barrier properties;

- during depressurization, water accumulates in layers of insulation without the ability to evaporate, which leads to red stains on the ceiling;

- the bitumen base is gradually aging and destroyed, but polymers are added to it.

Rolled waterproofing happens with a substrate (basis) and without a base (a baseless film). They also have their advantages and disadvantages. These panels are produced with an astringent filler using rolling technology with the addition of plasticizers and antifungal additives. The basis or substrate is a special roofing cardboard, fiberglass or asbestos paper, which contain the impregnation with polymer mixtures or bitumen.

Rolls without a base, such as isol or brisol are perfectly adapted to deformations of the structure, counteracting ruptures. And this is the main advantage of these materials.

The second category of roll materials with the application on the basis of various additives to increase durability:

- fine -grained spraying index m;

- large fractions K;

- dusty baby n;

- scaly spraying of Ch.

Soft roof laying technology

Roofing installation with roll materials is done in 1-2 layers, depending on the state of the roof base and the choice of waterproofing film. On flat roofs, waterproofing rolls are melted on a prepared base (screed or roofing). The main stages of laying after preparing the surface for the installation of a new coating:

- insulation (not necessarily in some cases);

- the lower layer of the material for laying the soft roof;

- a surface layer of waterproofing (preferably);

- treatment with sealant or mastic in the places of adjacency to individual parts of the roof (border, drain, visors, etc.).

The preparation of the base includes:

- inspection of the integrity of the previous coating;

- dismantling the old Sentwitch (if necessary);

- cement screed;

- other work on leveling the coating and processing of adjacent planes (chimneys, water intake, ventilation wells).

Sometimes the roof is placed on fertile plates or prefabricated structures. The fusion of roller roof involves the use of fire received from a gas burner and passing cylinders. This obliges all fire safety requirements and the use of gas equipment. The waterproofing layer on the pitched roof is also applied to flexible tiles on the rafter system.

According to the technology, the roofing Sentwitch on the pitched roof, ideally, contains:

- Isospan (vapor barrier);

- Izover (thermal insulation);

- Utafol (waterproofing);

- finish roofing (soft tile).

The installation technology on the pitched roof also involves the arrangement of a subcutaneous space or attic. This is done to prevent the formation of mold and fungi due to dampness.

The most commonly used 2 types of installation technologies of the soft roof:

- hot fusion of rolls;

- mechanical fastening of rolls.

Frontation is carried out by warming up materials based on bitumen, after which they are glued on the roof base after processing by a primer. This technology cannot be produced without gas equipment.

Mechanical fastening of a flexible roof is carried out using washers and screws. Additionally, it is important to ensure waterproofing in the areas of the rolls of rolls and fastening.

Technology for installation of membrane materials

Polymer canvases are produced in a certain size so that it is convenient to roll them on the roof and solder. The less seams are obtained, the simpler and faster the installation. But the most difficult thing is precisely to competently produce hot welding of the joints for the absolute integrity of the waterproofing coating.

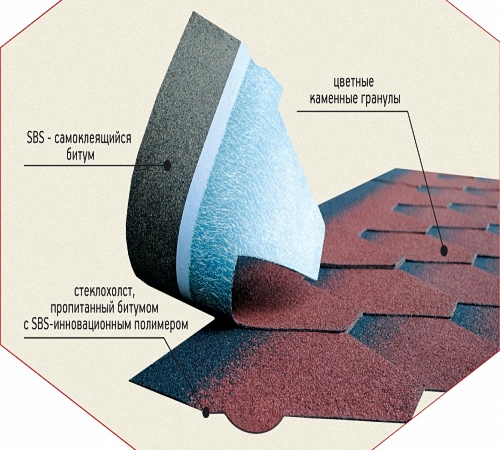

Bitumen tile laying technology

Roofing tiles or flexible tiles are most often used in private housing construction. A large selection of shades, textures and forms of piece materials. Elastic sheet in the form of a polyhedron based on a pressed fiberglass of a certain format. Fixation is carried out for prepared waterproofing with a special set of fasteners on special bridges (filtles) of a smooth base. All the difficulties of installation are agreed upon in the instructions for the release of soft tiles. But if there are questions, see the technology of laying a soft roof, a video that is at the end of the article.

Final advice

Each manufacturer of rolled and membrane materials involves its own technology for laying the soft roof of Katepal, Isospan, Izover, etc. They have different technical characteristics, so it is important for the buyer when choosing a material for the installation of a soft roof to take into account the climatic zone and roof features.

The rolls are overlapping, that is, with a slight overlap of the edges before soldering the seams, this affects the consumption add up to 10% width. Do not save on materials and installation if there is no desire to return to the issues of roof arrangement in the coming years.

Great article! Highly

Great article! Very interesting, thanks. By the way, in my VKontakte group you can find a lot of information on this topic and not only. https://new.vk.com/vse40_com