Cassette -type suspended ceilings can be safely attributed to the better version of the ceiling ...

|

|

Since ancient times, and still piece parquet due to the aesthetic qualities for ... |

The roof is the most important structural element of the building. From how high quality ... |

PVC floor tiles

PVC Tiles is a rather popular item in the decoration of the premises. Due to the presence of a number of advantages, this type of decoration is easy and ease of installation, as well as an affordable cost. Next, we consider the varieties and recommendations for laying PVC tiles on the floor.

Table of contents:

- Features of the manufacture of PVC tiles for the floor

- Advantages of installing PVC floor tiles

- The scope of the use of PVC tiles for the floor

- Varieties of PVC tiles for the floor

- Calculation of the number of PVC tiles

- Preparation for the installation of PVC tiles for the floor

- PVC floor tiles - laying

- Recommendations for the selection and installation of PVC tiles

- PVC tiles self -adhesive: installation features

- Installation of a warm floor for PVC tiles

Features of the manufacture of PVC tiles for the floor

Polyvinyl chloride tiles used for floor decoration have the shape of a rectangle, square or mosaic.

As a material for the manufacture of PVC tiles, high -quality PVC plastric is used. Production technology consists in gradual mixing PVC granules with dyes. After that, the material goes through the drying process and is loaded into a special bunker. From the hopper, the material is poured into flat forms. In the final stage, PVC tiles cools and trimming in accordance with the intended shape, size, quality and shrinkage. After the expiration of a certain time, the tiles are checked for the docking and packaged for further sale.

The standard structural composition of PVC tiles:

- a special protective coating that prevents mechanical damage to the product;

- Decorative shell - is responsible for the appearance of PVC tiles;

- fiberglass inserts - stabilize the size of the product;

- To increase strength and stability, the main part made of plasticity serves.

Technical requirements for PVC tiles for the floor:

- the ability to withstand heavy loads;

- oil resistance;

- gas resistance;

- resistance to chemical influences;

- Lack of sliding;

- fire safety;

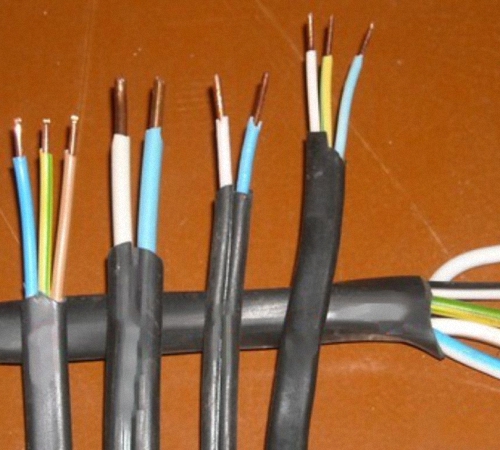

- lack of electrical conductivity;

- The attractiveness of appearance.

PVC tiles photo:

Advantages of installing PVC floor tiles

Studying about PVC tiles for the floor, we will highlight such advantages of this finishing material:

1. The ease of transportation is explained by the fact that the tile is produced in a square or rectangular shape, unlike linoleum, the rolls of which are characterized by large sizes and weight.

2. The ease of replacing PVC tiles is another advantage of this material. If linoleum is damaged, the entire coating should be replaced, and the tile allows you to save on repair.

3. The original design and attractive appearance - PVC tiles are distinguished by the possibility of imitating any textures: from ordinary tiles to wooden coatings.

4. Water resistance - the property of tiles that allows you to install PVC tiles in the bathroom or in rooms with high humidity.

5. Available cost - for PVC tiles for the floor, the price is affordable, and therefore this material is highly popular among buyers.

6. Elasticity and hardness - allow you to protect the tile from mechanical influences and large loads.

7. Creation of a variety of color compositions by combining various color colors and materials.

8. High level of sound insulation.

9. does not require the use of the substrate, before installation.

10. High wear resistance - PVC Tiles have a long service life of about 8 years.

The scope of the use of PVC tiles for the floor

- finishing of the kitchen or bathroom;

- the arrangement of the floor in the garage, basement;

- warehouses;

- floor decoration in industrial premises;

- Consciousness of temporary sexes, for example, at exhibitions, presentations;

- floor decoration in public buildings, such as shops, shopping centers;

- Use on the street to install temporary floors.

Varieties of PVC tiles for the floor

Depending on the number of layers, PVC tiles are distinguished:

- a single -layer or homogeneous type,

- multi -layer or heterogeneous type.

Single -layer PVC Tiles consists of one layer of PVC plastic. Drawing - passes through the entire thickness of the tiles, and therefore, even in the process of long -term operation, such a tile has a original appearance. There are many color solutions of such a coating, but the drawings - practically do not differ from each other. A single -layer PVC tile is mainly stylized under the marble coating or has abstract patterns.

PVC tiles of a multi -layer type has several layers, the main of which enters the laminated - protective layer. The thickness of this layer does not exceed 0.5 mm. The color and pattern of tiles depend on the second layer. Heterogenic PVC tile imitates such materials as:

- parquet coating,

- wood,

- Floors made of natural or piece stone,

- herbal lawn,

- marble,

- pebbles.

The basis of such a tile is a substance made of foamed polyvinyl chloride, which provides high sound insulation, thermal conductivity and high level of rigidity. The thickness of this layer is about 1.5 mm.

Some multilayer types of PVC tiles have an additional layer of glue, which helps tiles better attached to the main floor.

Calculation of the number of PVC tiles

To calculate the number of PVC tiles, determine the area of \u200b\u200bthe room. To do this, measure the length and width of the room, and then multiply these numbers with each other.

After choosing the material, find out the size of one tile. Divide the area of \u200b\u200bthe room into the area of \u200b\u200bone PVC tile.

In the case of installation of PVC tiles in a room with an irregular shape, the area should be divided into several areas, a rectangular or square shape, and then summarize the area of \u200b\u200bthese sites.

Preparation for the installation of PVC tiles for the floor

Installation of PVC tiles is carried out for compliance with special technologies. Before installing PVC tiles, be sure to study the instructions and technical features of the established material.

The room should be a temperature of 15-24 C.

Preparation of the floor for PVC Tiles includes the installation of a concrete screed. Before starting the installation of tiles, you should make sure that the screed is dry. For these purposes, use a hygrometer. The humidity of the screed should not exceed three percent. With non -compliance with this rule, PVC tiles will begin to collapse over time.

When installing PVC tiles on a concrete base, make sure that there are no cracks and protrusions on the main floor. In the presence of floor deformations, special leveling solutions should be used, which will help make the concrete floor perfectly even.

If PVC tiles are installed on a wooden floor, you should make sure that there are no protrusions and hats from nails. The cracks between the boards need to be sealed with putty.

When installing PVC tiles on a tile base, use special mixtures that will help to align the floor and remove inter -screen irregularities.

If the floor has kavrolin, linoleum or other soft coating, it should be removed and the floor is completely aligned or the installation of a new concrete screed.

In order for the result of the installation of PVC tiles to be most effective to perform a number of actions:

1. Divide the area of \u200b\u200bthe room into four parts, using roulette, level and pencil. To do this, draw two lines intersecting in the center of the room.

2. Put a number of tiles that passes from the central part of the room to the walls.

3. Measure the distance that remains between the last whole tile and the side wall. If the interval is less than half of the tile, then you should shift the central line in the other direction. Thus, you get a beautiful tile styling.

PVC floor tiles - laying

1. Using a roller, apply a primer to the surface, previously cleaned floor.

2. Install the first tiles, according to a pre -made marking in the central part of the room.

3. Glue the rest from the central beach tile.

4. To install PVC tiles, use PVA glue or special tile glue.

5. It is better to apply glue to both tiles and on the floor. Then, install the tile, pressing tightly to the floor surface.

6. Take the roller and press on the surface of the tile. Instead of a roller, it is possible to use a rubber hammer.

7. Excess glue should be removed and a new tile should be glued.

8. To install PVC tiles on a wooden floor, use a double -sided adhesive tape.

9. To cut the tiles, use the mounting knife.

Tip: To simplify the process of cutting PVC tiles, use an industrial hairdryer.

Recommendations for the selection and installation of PVC tiles

- It is better to purchase several square meters more than PVC tiles to compensate for sections near the walls;

- After buying tiles, you should leave it indoors and wait 24 hours so that PVC tiles take the necessary shape;

- Before installing PVC tiles, remove the skirting board, if any;

- PVC tile pruning is made on the front side;

- For small rooms, it is better to purchase PVC tiles that simulates a three -dimensional image.

PVC tiles self -adhesive: installation features

Preparing the surface for the installation of self -adhesive tiles should be more thorough than for ordinary tiles.

Remove the old coating, align the floor, get rid of small differences, potholes or cracks.

Before installing, remove dust and dirt from the floor. It is better to use a sandy-coudy solution or special self-leveling mixtures for finishing the floor.

In the absence of a hygrometer, to measure the moisture of the floor, use an ordinary glass jar. Install the jar on the floor, and after 24 hours check the presence of condensate on the walls of the jar.

Use a household vacuum cleaner to clean the floor.

To install a self -adhesive PVC tiles, the availability of:

- mounting knife,

- roller for wallpapers,

- corner,

- roulette,

- pencil.

Determine the middle line of the room, from which the installation of PVC tiles will be made. Use a pencil and roulette to measure the central part of the room. It is not recommended to use chalk to avoid tiles.

When installing PVC of a square -shaped tile, you should begin laying in the central place of intersection of two lines. The first tile is laid in any of the corners from the central point. Before laying, a protective film should be removed from the tile.

After laying the tiles, press the tile several times with a roller.

When sailing tiles near the walls, use a mounting knife. Leave the gap between the tile and a wall of 0.5 cm, which will hide the baseboard.

When installing the tiles of a rectangular shape, you should start from the window, smoothly passing to the doors. The first row is laid in whole tiles. The last tile is cut with a knife. A new row is installed from a cut surface. Thus, brickwork is obtained.

Installation of a warm floor for PVC tiles

For a warm floor installed under the PVC, the best option would be to install an electric film heating material.

To install a warm floor under PVC, the tile is necessary:

- PVC tiles,

- plywood,

- thermostat,

- waterproofing,

- warm floor systems,

- thermal insulation,

- Glue for the installation of PVC tiles.

Instructions for installing a warm floor for PVC Tiles:

- Prepare the main floor, having previously leveled and cleanse the surface;

- Install thermal insulation;

- Place the thermal gun on the entire surface of the main floor;

- Install the wires and carry out electrical insulation work;

- Use tape to seal a warm floor;

- Install the tile with glue and rubber hammer.

PVC tiles video: