If you are a beginner master and do not have sufficient experience in construction ...

|

|

Horizontal blinds are made of wood, plastic or aluminum. They have ... |

Today, painting the ceiling is still popular. It is simple and ... |

How to choose cassette ceilings

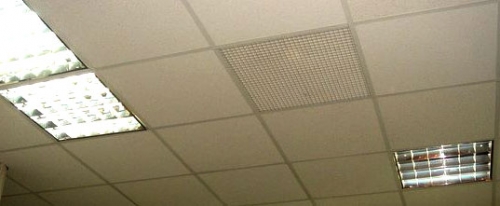

Cassette -type suspended ceilings can be safely attributed to the better option of ceiling design. Impeccable functionality and aesthetic appearance, ease of installation and safety of use in combination with the variety of design and color solutions allow you to harmoniously enter cassette ceilings into the modern architectural style of residential and office premises, trading halls and sports complexes.

Content:

- Cassette ceiling device

- Advantages of cassette ceilings

- The scope of application

- Types of cassette ceilings

- Choose the manufacturer

- Cassette ceilings Sky

- French cassette ceiling

- The ceiling of the cassette Armstrong

- Casset Cassal Casset

- GEIPEL Cassette ceiling

Cassette ceiling device

Recently, cassette frame constructions collected from small same -type elements that are laid in special mounting frames have become greatly widespread. These elements are the slabs made of mineral wool or glass wools pressed with fillers made of cellulose, starch and clay. The absence of asbestos and phenol -formaldehyde resins makes raster (cassette) ceilings environmentally friendly, safe and non -flammable.

So, the name of cassette ceilings speaks for itself the basic element of the ceiling structure is a cassette. In its manufacture, aluminum, covered with a bimetallic layer or galvanized metal rental, can be used. Aluminum cassettes are additionally subjected to chemical polishing, which gives products in mirror properties. Cassettes made of metal galvanized materials are usually covered with powder paints, thanks to which the cassette ceiling remains initial attractiveness for a long time.

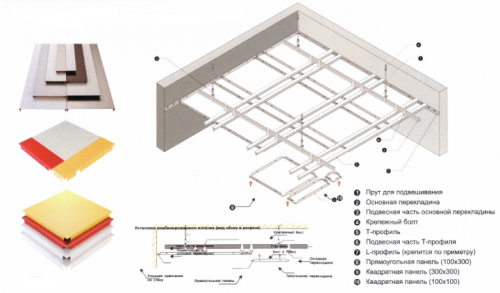

A special system of fasteners of cassette suspended ceilings, based on the use of load -bearing and intermediate profiles, dumbbells and suspensions, allows you to easily install the ceiling in a short period of time, it is also easy to dismantle it completely or partially.

The supporting elements of raster (cassette) ceilings are able to withstand a high load, calculated on the basis of the load from the ceiling elements. It is 8-10 kg/m. The suspensions with profiles to the base of the ceiling are carried out using dowels. As a result, Euromoduli with parameters of 1200x600, 600x600 mm are formed, in which cassettes are subsequently laid through longitudinal grooves located in ceiling panels or on T-shaped profiles.

Advantages of cassette ceilings

Among the key properties of cassette ceilings can be distinguished, first of all, from the point of view of execution, installation, long service life, excellent hygiene and operational indicators, resistance to increased humidity and fire resistance, the ability to combine with modern lighting systems and equipment to control microclimate.

1. Simple installation.Installation and dismantling work takes a little time, which means that if necessary, you can quickly replace any structure of the structure.

2. Long -term operation.Thanks to the use of steel and aluminum in structures, manufacturers have achieved a long service life. Such ceiling systems do not rust, for many years retain their original qualities and color.

3. Hygiene.Having set the ceilings of the cassette type, you do not have to carefully monitor cleanliness in the room, it is enough to periodically carry out wet cleaning with a cloth. The structures do not appear mold, they are reliably protected from the consequences of high humidity, so cassette ceilings are successful in healthcare organizations.

4. Moisture protection and fire safety.The multilayer coating of the metal surface reliably protects the structure from oxidation, the negative effects of substances dissolved in the liquid and high temperatures. Due to this, excellent indicators of moisture and fire resistance are achieved

5. Compatibility with modern lighting devices. In addition to all the advantages, cassette -type ceilings are excellently combined with lighting systems of various types and climatic installations. So, the device of the cassette ceiling allows you to install any design lighting, and the presence of free space between the surface of the ceiling and the overlap allows you to install a climate control system.

The only disadvantage of the cassette structure is the concealment of a significant number of room space, so it is preferable to install them in rooms with high ceilings.

The scope of application

The scope of the use of cassette -type ceilings is quite wide: office and store rooms with high ceilings, entertainment centers and medical facilities, restaurants and sports complexes, private buildings and other public premises. And all this thanks to the aesthetics, strength and durability of the ceiling structure.

Types of cassette ceilings

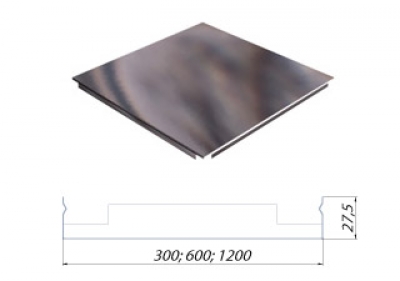

The standard sizes of the stove for cassette ceilings are 1200x1200, 1200x600 and 600x100 mm with a thickness of 15 to 40 mm. Traditionally, the slabs are white, and their texture is very extensive: smooth, with dots and zazubins, embossed and geometric patterns and a rough surface.

The range of decorative raster panels is complemented by special moisture -resistant panels, anti -guided and antimicrobial panels. Today, special acoustic ceilings are increasingly found that reduce noise. Such panels refer to specialists to special materials, which means that their cost is slightly higher than the cost of traditional decorative materials.

So, depending on the material of manufacture, cassette ceilings are divided into:

1. Metal.Cassettes are made of aluminum or steel, have a different texture. The surface can be painted with paint or covered with anodized spraying, which allows the use of structures in rooms with high humidity: pools, spacious lobby.

2. Made from chipboard and fiberboard.Excellent option for strict office design. Despite the complexity of installation and the apparent weighting of the interior are characterized by a respectable appearance, giving a chamber atmosphere. Thanks to the rich selection of textures and color solutions, as well as the possibility of imitation of any surface, cassette ceilings from chipboard and fiberboard are actively used to create exclusive ceiling decoration.

3. Glass.The manufacturing material is transparent or colored glass or plexiglass.

4. Mineral.Made from the Ministry of Walls, cassette ceilings are resistant to fire and high humidity. Ecologically safe.

5. Mirror.Excellently cope with the task of visual expansion of space, create the illusion of infinity, fill them with light and air. Presentable appearance and variety of design solutions, a high level of functionality and excellent performance, excellent lighting level and convenient installation in combination with the possibility of applying decorative patterns to the surface of decorative patterns in a separate group of ceiling coatings. To create an exclusive design of the ceiling space, designers use both a light and tinted mirror.

There are cassette ceilings depending on the texture:

1.Perforated.Perforated panels can significantly improve ventilation and acoustic properties, are perfectly compatible with various engineering equipment, are easily mounted and disassemble both completely and partially. The diameter of the holes varies within 2 millimeters.

2. Stamped. Cassette ceilings of a stamped type are interesting for their decorative pattern applied to the surface of the cassette.

3. Smooth.The outer surface of the smooth cassette ceilings is covered with paint and a layer of anti -corrosion coating.

Choose the manufacturer

Cassette ceilings Sky

Sky cassette ceilings are a new high -tech solution in the field of suspended ceilings. Sky panels attract with their ergonomics and excellent performance, a wide palette of noble shades (white, superchrom, gold, aluminum, aluminum, aluminum silver), moisture and fire resistance, durability and simplicity of installation. Aluminum 0.43 mm thick or painted steel 0.5 mm thick is used as a manufacturing material. Aluminum panels can be perforated, while the diameter of the hole does not exceed 3 mm, the distance between the openings of 10 mm.

Due to the variety of configurations of the panels of the cassette ceiling of Lumsvet, designers manage to get exclusive ceilings of the following type:

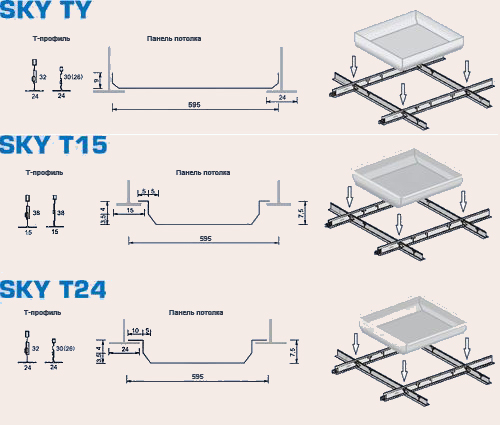

1. Sky T24 of the edge of the ceiling plate is presented in the form of steps.Sky T24 (Tegular) panels are used for installation on the suspension system, the visible width of the planks of which is 24 mm (the suspension system T24). Thanks to this edge, the suspended structure looks in the plane of the ceiling seemed to be drowned.

2. Sky T15 - the edge of the ceiling plate is presented in the form of steps.Sky T15 (Tegular) panels are used for installation on the suspension system, the visible width of the planks of which is 15 mm (suspension system T15). Thanks to this edge, the suspended structure looks in the plane of the ceiling seemed to be drowned.

3. Sky ty edges of the edge has rectangular shapes.The panels are used for installation on the suspension system, the visible width of the planks of which is 24 mm (the suspension system T24). The surface of the installed ceiling is flat.

French cassette ceiling

Cassette -type suspended ceilings, made using French design technique, are incredibly in demand on the market. The variety of designer and color solutions, an extraordinary flight of imagination and a magnificent optical effect distinguish French cassette ceilings in a separate group of finishing materials.

Equipped with a mirror coating, French cassette ceilings, photos of which can be seen on the Internet, visually expand the room and fill it with light. The use of colored cassettes as a guide line in the corridors creates an amazing optical deception visually lengthens the room. The correctly selected color sets accents and divides the room into zones. It is for these reasons that the cassette ceilings are the most popular and demanded tool in the design of any architectural space.

Installation of the French ceiling is carried out almost instantly, while a special stinger and a hidden suspension system provide reliability of the structure. Aluminum cassettes 300*300 mm and 600*600 mm are presented on the market. Designed for installation in residential and office premises.

The ceiling of the cassette Armstrong

Armstrong cassette ceiling is very popular and installed in the suspended ceilings of modern office, administrative and retail premises.

Armstrong ceiling frame, made of load-bearing and additional T-shaped profiles, is mounted to the basic ceiling using suspensions. The ceiling structure is directly assembled from panels mounted in the frame from below or from above, or sheathed with drywall below on screws. Along the perimeter of the room, corner and P-shaped profiles are fixed.

As a manufacturing material, a solid or soft mineral fiber with the addition of cellulose is used to increase strength. The variety of textured and color solutions, the convenience of installation and the durability of use, in combination with excellent operational characteristics, determine the undoubted success of Armstrong ceilings.

The following models of cassette panels are most common: panels with a smooth surface (oasis ceiling), perforated with a surface or various decorative pattern (Baikal ceiling).

Casset Cassal Casset

Casal cassette ceilings (Cesal) is a high -tech solution in the field of ceiling finishes. The highest quality and magnificent appearance, wide color scheme and the possibility of choosing a suitable suspension system (closed, open, combined), long -term operation and the possibility of multiple installation and dismantling, high resistance to chemical reagents and water resistance allow the use of Cesal cassette ceilings in the laboratories and shopping centers, stations and sports halls, residential and office premises.

The panels are made of high -quality aluminum with a bimetallic coating consisting of two layers: the first protects the surface from wear, and the second layer allows it to smooth it.

Thanks to the huge selection of decorative coatings (powder spraying, galvanic coating, lamination, coloring with polymer dyes), you can choose a finishing material that is ideally corresponding to the existing operating conditions.

By installing Cesal cassette ceilings (Cesal), you can successfully combine all kinds of models, harmoniously combine with other varieties of ceiling and modern lighting sources to create a unique interior. Design features allow the dismantling of the plates locally. This will greatly facilitate the maintenance of climatic systems.

A clearly installation process of Cesal's cassette ceiling is shown in YouTube.

GEIPEL Cassette ceiling

The GEIPEL cassette ceiling rightfully occupies a leading place in the market of ceiling structures. GEIPEL Cassette ceiling is a reasonable combination of modularity and functionality with excellent characteristics in fire and moisture resistance. Equipped with mirror panels, Geipel cassette ceilings visually expand the space. All these positive points make them possible to install them in office and residential premises, conference rooms, educational and medical institutions, as well as in rooms with a high level of humidity.

Square panels are made of durable aluminum or galvanized steel. Being painted synthetic paints, cassettes are durable and stable in a humid and aggressive environment. Durable material and sufficiently persistent coating provide the possibility of multiple assembly and disassembly of the ceiling.

The modern market offers customers the cassette ceilings of the Geipel of two main types:

- with a hidden suspension system;

- with an open suspension system.

Stages of installation

And in conclusion, I would like to pay attention to the installation of cassette -type ceiling structures. It should be noted that the technology for installing cassette ceilings is comparable to the installation of other suspended structures. Installation of a cassette -type suspended ceiling includes several stages:

1. Fastening of corner molding using construction glue.At this stage, it is extremely important to accurately calculate the height, taking into account lighting devices and wiring, which will be hidden by ceiling slabs.

2. Installation of suspensions using metal anchors.Suspens are mounted in sections of intersections with intermediate guides. Additionally, suspensions are installed in the places of attachment of equipment.

3. Fastening the main guides.The edge of the main guide during installation should be located on wall molding. In places of connection of the main guides, another suspension is attached.

4. Statement of intermediate guides.The angle between the intermediate and the main guide should be 90. The intermediate guides should be fixed between the main carriers that are bearing at a distance equal to the width of the cassette.

5. Installation of cassette panels.Experts recommend starting installation from the middle of the ceiling space, performing the necessary trimming of the panels along the walls.