Floors made of marble crumbs are most often found in the halls of public buildings. But in ...

|

|

More recently, the doors for the balcony were almost invisible in the interior of the room ... |

Each of us is trying to diversify the interior of our home, choosing the original ... |

Membrane roof. Installation of a roof from PVC membrane

The roof is the most important structural element of the building. It depends on how well it is made, whether the conditions inside will be quite comfortable. Therefore, during construction or repair, it is necessary to especially carefully approach the choice of material for the roof. In the article, we consider the modern and high-tech method of arranging a roof from PVC membrane.

Content:

- Roofing membrane PVC

- Characteristics of the PVC membrane

- In what cases is a membrane roof used

- Advantages and disadvantages of the material

- Roof device from PVC membrane

- Roofing cake over the old roof

- Roof installation technology from PVC membrane heat-welded method

- The ballast method of installing a roof from PVC membrane

- Roof mount from sheet PVC with glue

- Manufacturers and prices

- The choice of the contractor

- PVC possibilities of the roof

The membrane roof has recently become extremely popular, which is not surprising, since it has excellent technical indicators, and most importantly, it is easy to use and operation. For the first time, the membrane was presented more than 40 years ago and has since maintained a leading position in the market. In Europe, she had long and unconditionally prefer, covering almost 80% of the roofs with her help, and now she is gaining trust in Russia.

Roofing membrane PVC

This is an innovative waterproofing roofing material made on the basis of polyvinyl chloride (PVC).

The membrane itself consists of three components, which are the basis of its unique qualities:

- the upper layer of PVC is resistant to temperature changes and ultraviolet radiation. It is offered in a wide color spectrum, so it is easy to choose any depending on needs or wishes;

- reinforcement by a polyester grid (for reinforced types of membranes);

- the lower layer of a darker shade. It would seem why they paid attention to this, but in fact this moment is important. The fact is that if a dent deformation appears on the roof, a cut, a break, then, due to the difference in color between the upper and lower layer, this place will be clearly seen that it will facilitate the search for leaks and guarantees fast repairs.

Characteristics of the PVC membrane

The main secret of the longevity of the membrane roof is the presence of special stabilizers in the upper layer, which protect against aggressive environmental exposure. Ultraviolet is especially dangerous for her, so membranes supply them with a layer of special absorbers, which create a barrier that prevents the penetration of ultraviolet rays and the destruction of the material.

Manufacturers are not afraid to give 10 years guarantees for their material, and the service life of a membrane roof is about 50 years.

Absolute tightness, provided by this material, is achieved due to the fact that the sheets are cooked, using hot air, forming a reliable seam and integrity of the coating. This styling method allows the use of the membrane at any time of the year and significantly accelerates the process of installing the roof.

In what cases is a membrane roof used

The membrane roof is ideally suited for both the operated and unexploited flat roof, for example, in modern multi -storey residential buildings, at industrial enterprises, warehouses, shopping centers.

Less commonly, it is found in low -rise cottage construction. This is partly due to a fairly high price, partly due to the traditional inclined architecture of roofs of private households, for which sheet roofing materials are more suitable.

A properly designed and unmistakably operated flat roof from a membrane, practically does not require care and repair, only regular monitoring for clogging of the drainage system.

Why is the membrane recommended specifically for flat roofs?

- She has a low weight, she does not have a large load on the supporting supports of the building and the foundation. The thickness of the membrane varies from 0.8 to 2 mm, on average weight 1 m2 of this material does not exceed 1.5 kg;

- a wide selection of the length and width of the roll allows you to choose the optimal amount of material to minimize joints and the number of seams.

Advantages and disadvantages of the material

The advantages that allocate a membrane in the market are:

- ease of installation and speed of installation;

- durability;

- resistance to an aggressive external environment, withstands the temperature up to -60 degrees;

- high coating strength, and elasticity preserved at the same time;

- vapor permeability, eliminating the appearance of moisture and accumulation of condensate;

- the possibility of laying on uneven surfaces, including the old roof;

- fire resistance, membranes are non -combustible material and meet all fire safety standards.

The main disadvantage of the membrane roof is its price, which significantly exceeds, for example, the cost of bitumen-polymer.

However, durability with more than pay off the expensive value of the material. So, the bitumen coating becomes unusable after 2-3 years and requires repair. With the membrane, you can be sure that it will not require repairs and even more replacement for 40-50 years.

Roof device from PVC membrane

Modern roofing material, which is undoubtedly a membrane, is obliged not only to protect the room from rain and wind, but also to maintain heat in it, to remove excess moisture, which will prevent the development of mold and fungus. The roof along with the foundation is the most important element in the structure, it is responsible for its functionality and durability.

Experts introduced the concept of a roofing pie, which assumes the presence of three main components: vapor barrier, insulation and waterproofing. There can be more layers, depending on the type of roof and its purpose.

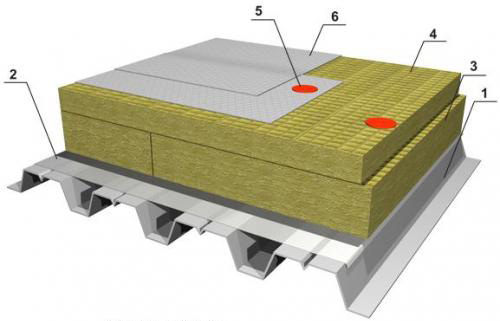

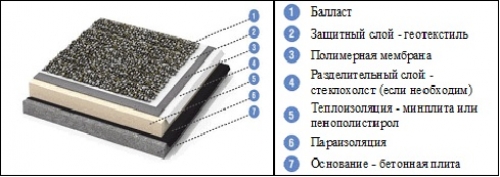

Scheme for a membrane roof

1- Foundation in this case is a professionalist.

2-vapor barrier. It is a vapor barrier film that performs the function of preventing moisture or condensate from the room into a layer of insulation.

3- thermal insulation of the lower layer. The most common material for insulation or thermal insulation is mineral wool. Extruded polystyrene foam and glass wool are also used.

4- Thermal insulation top layer. The separation of the insulation into two layers is no coincidence, the upper acts in the role of the load distributor, is usually made of mineral wool of greater density.

5- telescopic fasteners.

6-roof membrane.

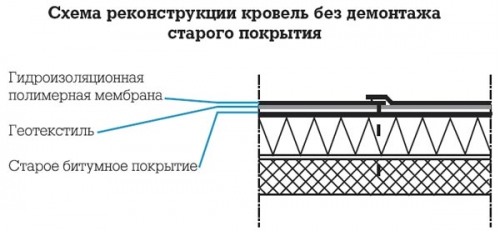

Roofing cake over the old roof

Another undoubted advantage of the membrane is the possibility of its use on almost any surface, in other words, it does not require mandatory leveling. Therefore, it is very convenient to use it to repair or update the roof.

Below are two examples of a roof pie without it dismantled the old coating using PVC membrane.

With alignment and insulation

- The base of the old roof;

- vapor barrier;

- thermal insulation material;

- dividing layer (geotextile);

- pVC membrane.

Without alignment and insulation

This is possible only if the old roof is flat and there is a heater.

- The base of the existing roofing;

- separation layer (high density geotextiles);

- pVC membrane.

A pie for a flat roof depends directly on its purpose (operated or not), however, in any case, the main layers will remain unchanged: vapor barrier, thermal insulation and waterproofing.

Roof installation technology from PVC membrane heat-welded method

Laying a roof from a PVC membrane should be carried out in dry weather, while the base on which it is mounted should also be absolutely dry.

Often it is used on flat roofs, and the sequence of work is as follows:

- everything that can interfere with work (advertising signs, antennas, garbage) is removed from the roof;

- if necessary, the old roofing is repaired or its complete dismantling is carried out;

- a vapor barrier material with overlaps and gluing all seams is laid;

- next, a layer of insulation is placed (mineral wool, foam, etc.)

- on the prepared base, the PVC-membrane canvases with an overlap 15 cm are fixed. If it is required to be attached to a wooden crate, then telescopic fasteners with a self-tapping screw will be suitable, the same fasteners will require the same fasteners, but only with a dowel-clamps;

- the required number of fasteners is calculated individually for each roof, and depends on the climatic conditions of the region and the design of the roof itself;

- when the entire roof is closed and fixed, the joints of the material are welded by a stream of hot air using special equipment. The nozzle of the welding machine should be at an angle of 45 degrees;

Tip: before starting work, equipment should be warmed up to 550 degrees. And before starting to work directly with the roof, it is recommended to practice small pieces of PVC membrane. But there are membrane roofs that can only be connected by glue or adhesive ribbons intended for this.

- after the roofing material is grabbed with hot air, it needs to be immediately roll off with a silicone roller;

- do not rush, and after the first section made, you need to check its quality. When trying to tear the seam with your hands:

- the material broke along the seam, it means that too high temperature was used;

- the absence of the seam is too low temperature;

- the gap occurred next to the seam, the work was done efficiently.

For clarity below, a video about laying a roof from a PVC membrane is presented below.

The ballast method of installing a roof from PVC membrane

This method is applicable only on flat roofs with a maximum inclination of up to 10 %. It consists in the fact that the membrane fixed to the fasteners is closed with geotextiles and is evenly covered with ballast. As which gravel or green spaces are used.

Roof mount from sheet PVC with glue

This method resembles a mechanical one with the only difference that for sealing the joints of the material, not welding equipment is used, but special construction glue.

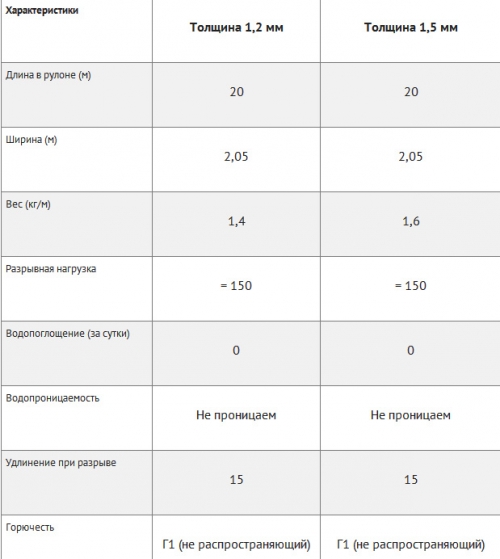

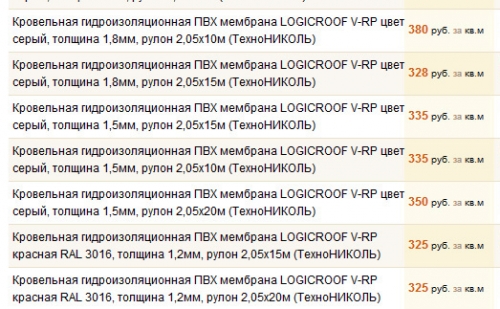

Manufacturers and prices

Russian manufacturers

Manufacturer Technonikol

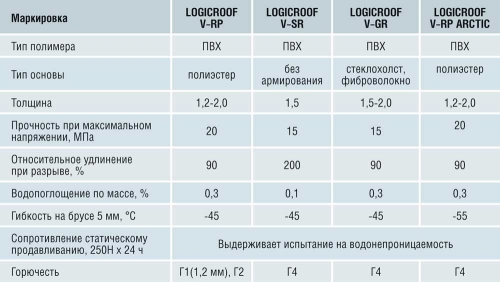

Logicroof. Produced a three -layer PVC membrane. A special layer containing a high concentration of ultraviolet rays is created on its surface.

Manufacturer BuildPopolimer

Croilon. Waterproofing material, two types are produced:

And a two -layer is a very strong film with reinforcement, used as roofing material;

G- has 2 layers, suitable for waterproofing work.

Plastfoil. This is a membrane consisting of three main components:

- stabilizers, plasticizers and antipyrene;

- a fabric with a complex weave of a polyester thread;

- PVC dark color.

Plastfoil is difficult to sprinkle and prevents the spread of flame over the roof surface, is used on roofs with increased fire safety requirements.

Foreign manufacturers

Manufacturer Renolit SE (Belgium)

Alkorplan. Polymer roofing waterproofing material based on PVC. It is characterized by high strength. Not a grief, does not rot, is not exposed to ultraviolet radiation. The service life is more than 50 years.

Manufacturer Sika (Switzerland)

Sikaplan. Reinforced PVC membrane of several layers, resistant to UV radiation, is great for waterproofing roofs.

Manufacturer icopal (Netherlands)

Monarplan.Modern material consisting of one layer of PVC membrane, designed to waterproof the flat roof in any climatic zone.

Manufacturer Ruvitex (Bulgaria)

Ruvimat. Polymer waterproofing material based on PVC. High -strength, stable to UV rays, fireproof. The service life is more than 50 years.

The approximate price per square meter of PVC-membranes of a foreign manufacturer ranges from 15 to $ 25 per square meter. Russian manufacturers offer the price below, about $ 8-10. This cost does not include work on styling, as well as the cost of other materials for the roof pie.

The choice of the contractor

The membrane roof is innovative and requiring certain knowledge and skills when laying. Therefore, it is not recommended to engage in its device on its own. This work is best entrusted to specialists with experience and the necessary tools.

Given the fact that the membrane of the material that recently appeared on the Russian market is not so much common as, for example, in Europe, firms that can truly professionally perform a roof from the PVC membrane a little.

When choosing them, you should pay attention to:

- work experience;

- if it is possible to see the previous executed orders;

- read customer reviews.

The price of the installation of PVC membrane roofs cannot be low, it is also an indicator of the professionalism of the contractor. It varies within 3-15 $ per square meter, and depends on the complexity of the roof design, time of year, surface condition, selected material, etc. Experienced manufacturers of work in one working day can cover up to 1000 sq.m. roofs.

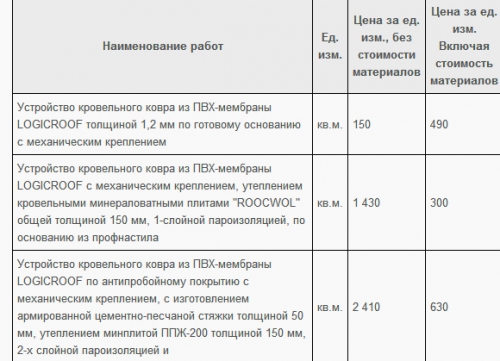

The table, for clarity, presents the cost of the work of one of the construction companies.

One of the advantages of working with the contractor is complete support: the executor conducts all measurements, advises on materials, gives advice on its device. And most importantly, the contractor provides a guarantee for his work, and, if necessary, performs warranty and post -warranty services.

PVC possibilities of the roof

In addition to high techniques, membrane roofing makes it possible for creativity and the implementation of interesting ideas on the roof.

For example, you can apply an advertising slogan or company name on the membrane if the roof is made for an industrial enterprise or warehouse. Thus, the roof will become not just a reliable protector from bad weather, but also a place for expressing individuality.

Or, instead of ballast, use the turf, thanks to which you can make a beautiful green roof.

Certified specialists

Certified specialists in the installation of a membrane and roofs of floating materials.

Guarantee. Quality. Dates.

We work in Russia.

LLC SK Everest

tel. 8- (351) -776-20-36, hundred. 8-919-357-08-08

E-mail: EVEREST-CK@ya.ru

you can weld membranes

you can weld membranes by Laron and Roofon devices, these are German devices, no worse than varimets !!! Testified! If anything call, I tell you 8-495-640-66-82 Dmitry

Installation of the roof of the PVC membrane.

Installation of the roof of the PVC membrane. We work on the Central Federal District and beyond, the presence of several mobile brigades allow you to withstand the deadlines. LLC "Unitersvis" (920) 221-03-32 unitserv@bk.ru

Fast installation of the membrane

Fast installation of the membrane https://hidropro.ru