Each of us sooner or later faces the installation of new beautiful windows. How...

|

|

Automatic doors have recently gained more and more popularity. They are... |

Granite a symbol of hardness and unshakability. Natural stone unites in ... |

How to choose a piece parquet

Since ancient times, and still piece parquet due to the aesthetic qualities for decoration of residential premises has been used everywhere. In our country, and in principle, throughout Europe, for the production of piece parquet, a traditional wood breed is oak, which is characterized by high strength characteristics and durability. However, today, in addition to oak, other wood is used for the manufacture of piece parquet. Let's figure out how to choose a piece parquet for home.

Content:

- Advantages of piece parquet

- Parquet or massive board

- The design of the piece parquet

- Parquet production process

- Woodcock

- Types of piece parquet

- The geometric dimensions of the dies

- Figus parquet selection criteria

Advantages of piece parquet

Fitty parquet is the most ancient variety of parquet coating. The traditions of the manufacture of piece parquet go far into the past. The laying of the parquet floors of its perfection reached under Peter the Great. They were a sign of a rich dwelling, an indicator of well -being and prosperity in the family. The highest classes in their house always had a parquet hall.

But parquet flooring are used by people not only for the sake of a presentable appearance and demonstration of the financial situation. The piece parquet has many advantages. First of all, the piece parquet acts as one of the most environmentally friendly materials, which only exist. Unlike such artificial flooring, like laminate, a tree for the production of parquet in its composition does not have extraneous chemical compounds.

The durability and strength of the natural parquet coating entered the legends: such a floor will last from several decades to a hundred years, or even more! Thus, the purchase of a piece coating is a long -term investment of money, and with damage and loss of the original gloss, it is enough to simply restore its original appearance. Parquet cycles can be performed up to 8-10 times.

In addition, a piece of oak or beech parquet is distinguished by good thermal insulation and sound insulation. The wood for the production of parquences is characterized by low thermal conductivity, and this allows you to equip not only a beautiful floor, but also significantly save on the purchase of floors with heating.

One cannot but pay attention to a wide selection of colors, shades and drawings of this flooring, which provides designers with great opportunities for creating the interior. The piece parquet looks much more effective than a massive board, due to the fact that it has much smaller sizes, the dicks are combined in various drawings during styling: decking methods, a basket, a Christmas tree and a square.

Caring for such flooring as piece parquet does not create difficulties, because it does not collect dust. Since such a floor is characterized by a high level of wear resistance, it is easily repaired and restored by varnishing.

Parquet or massive board

When choosing a parquet, it is recommended to take into account many factors: the budget, design of the room and much more. Quite often, the buyer faces a choice between two options such as piece parquet and a massive board. To understand this, you need to compare these solutions by considering the photo of the piece parquet and analyzing the advantages and disadvantages of each of them, only then you can determine which coating your requirements meets more.

The main difference between a massive board and a piece parquet coating is their structure. As you know, piece parquet is small plates, which are combined in different ways in any patterns. A massive board is called a large layer of wood, which does not leave a special choice for design. However, a massive board on the other hand allows you to achieve a retro effect and create a unique atmosphere in housing. Even decorative parquet will not allow this effect to recreate.

Now it is worth analyzing these two types of coatings from the position of practicality. If we talk about the installation of parquet, then thanks to simplicity, a massive board definitely wins. As for the piece parquet coating, the time costs are compensated with the more sufficiently to create any patterns.

Regarding the monetary equivalent, I must say that a piece parquet will cost you more than a massive board. However, these costs eventually pay off. And I take into account the simplicity of the procedure for repairing piece parquet, such a difference in price becomes invisible. After all, you can simply replace the plate that has become unusable. In the case of a massive board, you have to change a large section of the floor. In addition, a piece parquet will last longer than the highest quality massive board.

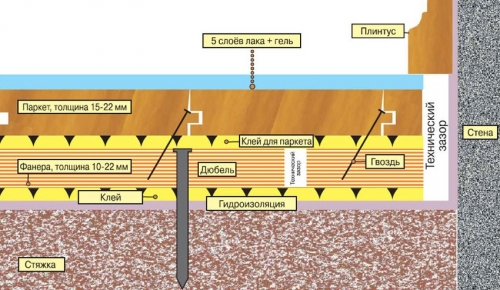

The design of the piece parquet

The piece parquet is a homogeneous layer of whole array of wood, small rectangular planks that have a smooth top. For the production of such a product, a whole array of wood from valuable species is used, for example, oak, ash, maple, so that the output is an amazingly beautiful flooring.

All parquets are applied like spikes, which greatly simplify and facilitate the procedure for laying piece parquet made of walnut, ash and other breeds. On opposite rib sides, the bar is present:

- The crests are the protruding parts of the parquet parquet, which are necessary when laying the floor to connect with adjacent strips. As a rule, the sizes of the ridge are 4 by 4 millimeters.

- Swalls of recesses on the end and lateral edges of Parkertin. It is in these grooves that when connecting neighboring planks enters the crests. The sizes of the groove have dimensions of 4 by 5 millimeters.

The parquet bar is left or right, depending on which side of the end comb is located from the observer. The wear of the parquetin is determined by the thickness of the so -called layer of wear of the parquet - from the front part of the board to the upper surface of the ridge. For example, a layer of wear for conifers has a thickness of 10 millimeters, for deciduous 7 millimeters.

Parquet production process

To get a parquet from the tree trunk, it needs to be cut, dry, processed and sorted. Three sort of simple stages, but simplicity is often deceiving.

Drying of the material

Today, there are many methods of drying the parquet up to ultramodern methods using ultrasound and microwave waves. For the final consumer, the drying method itself does not matter, the main thing is to withstand the manufacturer of the technology and the necessary humidity of the product at the output. Violation of the technology of drying the material can lead to the formation of internal stresses in the wood, and as a result you will receive a parquet deformation in the near future.

Processing processing

Wood is a heterogeneous material in its structure. In the future, a poor -quality procedure for its processing can lead to the fact that certain stresses will appear inside the planks. When processing strips, whether it is a piece of ash or an oak product, they give it the desired shape, and the type of parquet coating in the end depends on the accuracy of geometry.

Violation of tolerances in the manufacture of products is manifested in the impossibility of conducting high -quality laying of the parquet and the appearance of deformations. Today, two basic processing of the artistic parquet is used laser and mechanical. Mechanical processing is a classic process of wood, tested for centuries. Now it is carried out on machines with software control to get high quality parquet.

Laser processing only for the manufacturer has its advantages and disadvantages. This is the absence of wearing elements, high processing speed. In addition, the laser is not stupid, unlike the cutter, and does not need frequent replacement. The disadvantages of such processing lie in the following: in the parquet, which is processed in a similar way, you can notice at the edges the darkening of wood, which is caused by high temperature. And this is not always on the appearance of the coating positively.

Sorting the planks

The probability and percentage of the defective parquet coating, as well as the criterion for compliance with the parquet declared sorting, will depend on how responsibly, will depend on the responsibilities of the responsibly. In addition, the parquet needs special storage conditions with the maintenance of fixed humidity and a given temperature range. Failure to comply with these conditions will also affect the useful life of the coating.

Remember that only specialized stores can comply with these conditions, which cannot be said about many small retail outlets. Therefore, it is better not to take risks when choosing a parquet and buy it exclusively in specialized stores. A slight difference in price will be a guarantee of the long operation of your parquet. Therefore, do not take into account cheap parquet.

Woodcock

The quality of the final flooring will largely depend on the material. Each variety has its own disadvantages and advantages, its own operational characteristics and requirements for use, wear resistance, moisture resistance, and a variety of color shades. Parquet is not made of coniferous species of wood, because they differ in excessively high softness. Let's look at the main wood species for the production of parquet:

- Oak. From this tree, the most piece parquet coating is released, it is the oak in itself that combines decent operational characteristics, low cost and pleasant shades of brown. Parquet from oak has high hardness and sufficient moisture resistance. In order for the oak to retain all these qualities, the right drying is required, and the acceleration of drying processes is unacceptable. Oak parquet has one specific feature it darkens over time, and it is worth remembering when designing the interior of your home.

- Beech. The next most popular wood breed for the manufacture of piece parquet coating is a beech. This tree has a level of strength similar to an oak, but the book is more capricious and whimsical. The piece of the beech parquet is more subject to deformation due to moisture and temperature drops, so it needs more attention and more careful care. Parquet floor from beech became widely widespread thanks to light shades of reddish and yellow.

- Maple. This wood breed is also characterized by high strength. Some of its varieties, for example, Canadian maple, have even large strength than oak indicators. Maple is also whimsical in drying, it does not tolerate the Express Sushka procedure. A piece of maple parquet coating, dried using impaired technology, will not last a long service, in the parquet floor, cracks may soon arise. The color of the floor of the maple will slightly change during operation, at first it is light, almost white, and then acquires a yellowish tint.

- Merbau. This is a representative of the exotic species of trees, which in our country is in greatest demand. Merbau lives in the thickets of Southeast Asia. The parquet coating of this exota due to a large percentage of resins present in wood is characterized by high strength and high resistance to water. But the presence of these substances makes the wood difficult to process. Merbau's piece parquet has brown shades and beautiful patterns.

- Cherry. This breed is less spicy than, say, oak, but it acts as a more obedient material that is easier to process. The color scheme of piece parquet begins with light shades and ends with a dark brown color with the presence of pink.

Types of piece parquet

Parnish professionals are conditionally divided into 6 groups in color: yellow (tick, olive, chestnut, flounder), light (ash, grab, bamboo, oak, maple), pink (tallow, beech, pear, cherry), red (African patrol, Mahagonikempas, Yarra, Dussia), brown (walnut, jacaranda, mirbau, kumaru), dark (ebone tree, wenge, moraine oak).

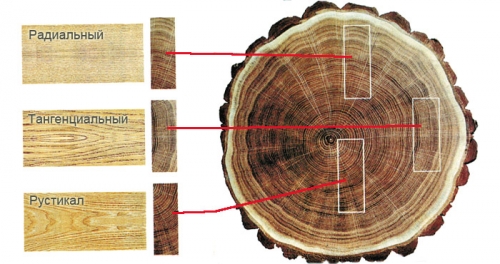

Type of cut

By the type of cut, the texture of the patterned parquet coating is divided into such types:

- Radial cut - Fibers of wood textures are located along the bar. This type of sawing is used mainly in the manufacture of a piece of plate of the highest grades. Thanks to this direction of the fibers, the radial piece parquet is more solid and stable.

- Tangential sawing - The fibers do not have a clear direction. On the front surface, the arched structure of the rings is clearly noticeable. Parquet with a similar sawing reveals the natural and natural texture of the tree and is suitable for any room.

- Mixed cut - It includes a radial and tangential sawing, which allows you to make a parquet with a rich texture, which conveys natural appearance and all the beauty of the tree.

Selection

According to selection, piece parquet is divided into such varieties:

- Radial - The most monophonic and homogeneous variety of parquet, which is made only by the methodology of radial sawing. Refers to the most expensive variety of parquet coating.

- Select The monophonic and homogeneous texture combines mainly tangential and radial cut. At the same time, knots, tone differences and sapwood are not allowed in the piece parquet.

- Natural- A variety of texture, which is characterized by a game of flowers and a different direction of the textural fibers of wood. In this case, the presence of small tone changes and knots is allowed, which have a diameter of up to 3 millimeters.

- Rustik- Different in orientation and color, tone fibers create a variegated image, sapelon, knots with a diameter of up to 10 millimeters and large tone changes are allowed.

- Gestra (Antik) - Different in the orientation and color of the fiber create a bright pattern with sinking, large tone differences and knots with a diameter of 10 millimeters or more.

Dog is a young outer layer that is present on the roots, wood trunk and branches. The difference between the sapwood and the inner layers of wood lies in the bright color and the smaller level of mechanical strength of the tree and resistance to the lesions of the fungus. Some breeds consist completely of sink, for example, aspen. This fact must also be taken into account when choosing a piece of birch parquet.

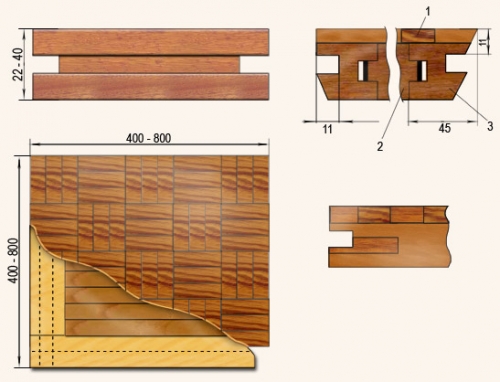

The geometric dimensions of the dies

Manufacturers of floor parquet coating produce piece parquet, the strips of which have different thicknesses, as a rule, 14 - 22 millimeters. The thickness of the upper layer affects the durability of the parquet, since the more thicker this layer, the more cycles and updates it can withstand. But the thickness of the upper layer of the total thickness of the parquet bar is not always proportional. Say, in a parquet with a thickness of 15 millimeters, the upper layer will be 7 millimeters thick, and in thick strips of 22 millimeters equal to only 9 millimeters.

Remember when choosing a piece parquet that an overly thick coating has its drawbacks. The thicker than the bar, the less elastic, and accordingly, more requirements for the base will be presented. If the draft floor is not perfectly even, then most likely a thick piece parquet that is laid on it, will soon begin to deform and puff.

Many manufacturers of flooring go to the trick. They make the lower part of the planks not smooth, as is customary in the traditional version, but make notches in the form of perpendicular longitudinal recesses on the back of the bar. They are multifunctional: increase the elasticity of the parquet, relieve voltage, increase the strength of gluing parquet coating with plywood, stabilize the form of the bar at temperature and humidity drops.

The durability of the piece parquet, namely, the level of elasticity and its deformation indicators, is affected not only by the thickness of the planks, but also by their length. Those strips that are longer than 350 millimeters after installation provoke the same problems as when using 22 mm. This is due to the fact that, the most moisture absorbs parquet through unprotected ends, since the coating is protected from below and from above. Although manufacturers produce parquet up to 50 centimeters long.

But if the strips have a large width, this will not entail deplorable consequences, since there will be fewer joints on the floor. But this applies only to situations when the wood was well dried in compliance with the necessary technology, otherwise the probability of deformation will increase in the presence of residual tension in a tree.

Therefore, it will be better if the width of the parquets does not exceed the thickness, which is multiplied by five. For example, if the bar has a thickness of 14 millimeters, then the width should be no more than 70 millimeters. In addition, manufacturers according to standards can allow a slight roughness of the upper layer, as a rule, this indicator does not exceed 125 microns.

However, the floor with large parquetans is much more beautiful. This problem has found its solution thanks to modern methods of drying wood, sorting and processing of wood, and improving the technologies of laying parquet coating. The use of stable wood, which is particularly hard to increase. Today there are planks in size 120 by 9.5 by 2.2 centimeters and even 240 by 13.2 by 2.2 centimeters.

Figus parquet selection criteria

Before choosing a piece parquet, you need to pay attention to the criteria for its choice. Let's look at the main of them:

- Package. Remember that the piece parquet is a 100 % natural material for flooring, sensitive to temperature and moist rests and mechanical load. A clear sign of such protection against these factors is primarily a high -quality sealed packaging, which protects parquet from the effects of moisture and overdrying, as well as during transportation. To maintain these indicators normally benign manufacturers, they put their parquet in packaging made of polyethylene.

- The quality of drying. It is important to pay attention not only to the moisture indicator of the parquet coating, but also to the method of drying. Each wood breed shows its own drying mode, which allows you to minimize internal stresses. At the bottom of the parquet, there should be unloading grooves that relieve voltage in the dies and collect when laying excess glue. Cracks in the depths and on the surface of the planks indicate the preserved internal tension in the tree, which is caused by an accelerated procedure of high -temperature drying. According to the standards, the residual humidity of the parquet should be no more than 9% 3%.

- Geometry Parquet. It is mandatory to check the geometric indicators of parquetin. The evenness and parallelism of the parquet coating is determined by applying the planks one to the other. For a control check, parquet from different packs is arbitrarily selected: 3% of the total number of dies. If, as a result of such a selective inspection, you have a suspicion that the parquet does not meet the standard, you need to check the whole batch. If you have collected a parquet without much effort, there are no large cracks and significant changes in height between the parquet, then such a coating is good with the quality of geometry.

- Parquet thickness. The market has the most parquet, which has a thickness of 15 - 16 millimeters, but there is also piece parquet, which has a thickness of 22 millimeters and is designed for rooms with large mechanical loads. When choosing the type of piece parquet, consider the differences in the thickness of the working layer (that is, between the spike-pasis and the upper part of the dick). At a thinner parquet coating, the working layer reaches 7 millimeters, in Tolstoy is 11-12 millimeters. This indicator is responsible for the durability of the parquet, because with a thicker working layer, the parquet withstands more grinding cycles.

- Parquet sizes. When laying parquet, it is recommended to use a coating with strips, which have a length of 400 - 500 millimeters and a width of 60 - 70 millimeters. The half -smaller format will look small and have more joints, which affects the strength characteristics of the coating and its durability. A large -format parquet floor, in addition to deck drawing, forms disproportionate and large modules that look rude. As a rule, parquet is made with a multiple length width with a coefficient of 3, 4, 5 or more. The ugly ratio of width and length reduces the number of options for drawings that can be laid out of the dies.

And finally, pay attention to the problematic species of wood. The piece parquet, which is represented on the market, is made mainly from different breeds, in the list of which oak, ash, nut, tic, maple, wenge, mergau and others. In the general list there is the so -called problem wood, it includes ash, beech, grab, maple and Kemas. For this wood, special measures are required related to the protection of its moisture. In addition, it is not recommended to use parquet varnishes, primer and water -based glue, which can provoke swelling and subsequent deformation of the parquet.

Awesome article. Thanks

Awesome article. Thanks a lot!

Good article

Good article