Si, recientemente, los puntos húmedos comenzaron a aparecer en el techo, que después de un tiempo ...

|

|

Die wichtigsten und mühsamsten Reparaturaufgaben gelten als ausgeglichene Arbeit ... |

Día a día, la popularidad de los techos estacionados está creciendo. Quizás simplemente no existe en ... |

DIY vapor barrier

A wooden floor is quite demanding to use and puts forward strict requirements for its protection from the negative effects of various external factors. First of all, you should think about the level of humidity, since wood is very susceptible to it. But thanks to modern technology, we have been presented with all kinds of floor vapor barrier materials that can cope with this problem.

Περιεχόμενο:

The need for floor vapor barrier

Increased humidity in the house has a negative impact on wooden coverings. The steam that accumulates inside living quarters - during showering, washing or wet cleaning, from cooking and the breathing of people themselves - seeks a way out. Since the pressure of such steam is much greater than atmospheric pressure, it puts pressure on the ceiling, walls and floor, which, together with the temperature difference, leads to the appearance of condensation.

Water, which gradually penetrates the insulation and wooden structure of the floor, destroys them over time. Building materials begin to rot, their original technical characteristics deteriorate, and mold and mildew appear. In addition, the comfort of the people staying in it will directly depend on the temperature and humidity conditions in the room.

To avoid the slow but irreversible destruction of the floor structure, it is necessary to install a vapor barrier layer that prevents the harmful effects of moisture on wooden coverings. At the same time, the air goes outside, and normal circulation is created in the room.

As for concrete floors, condensation also accumulates on them, although it does not harm them. But it is recommended to do a vapor barrier in cases with a concrete floor, since the air humidity in the house will still be high. This is why a floor vapor barrier is needed.

Types of vapor barrier materials

Until the beginning of the 21st century, glassine, roofing felt or roofing felt were mainly used as vapor barrier materials. Today, the market can boast of different types of vapor barriers, many of which successfully protect against the effects of water. Breathable membranes and films are most often used as a vapor barrier layer for a wooden floor. Of course, there are other types of vapor barrier materials, for example, such as liquid rubber and bitumen-polymer mastics, but they are more suitable for walls and roofs than for floors.

Polyethylene film

This type of vapor barrier is quite common and affordable. You can find two types of vapor barrier polyethylene films on the market: non-perforated and perforated. It is believed that perforated film is better used for waterproofing, and non-perforated film for a vapor barrier layer. This is explained by the presence of microholes in the film and the level of vapor permeability. Perforated film has higher vapor permeability.

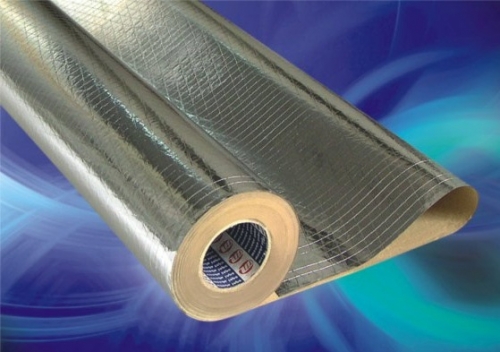

Today, thanks to the rapid development of technology in construction, another type of polyethylene films with a reflective aluminum layer has appeared. The vapor barrier of such films is much higher, so they are usually used in rooms with high levels of humidity and temperature, such as kitchens, baths and saunas.

The main disadvantage of polyethylene film is that it tears quite easily, which requires special care during installation. Even if polyethylene film with reinforcing mesh is used, its durability and strength will not be very high. Also, when installing a vapor barrier on the floor using film, it is necessary to create a ventilation gap.

Polypropylene film

Compared to polyethylene film, polypropylene film is more durable and resistant to various atmospheric conditions. At first, this material was made exclusively from polypropylene, but it was discovered during operation that condensation formed in the films on the insulation side, disturbing the temperature-humidity balance and causing rapid wear of the insulation.

Today, a special layer is rolled onto polypropylene reinforced films, which consists of viscose fiber with cellulose. It absorbs well and retains large volumes of moisture, preventing drops from forming. When vaporizing the floor in an apartment, such films are placed with the anti-condensation layer down, and a ventilation gap is created between the insulation and the polypropylene film.

Diffuse membranes

Diffuse breathable membranes are one of the highest quality and most expensive vapor barrier materials. The vapor permeability coefficient of diffuse membranes is very high and is achieved thanks to the microstructure of the material, which is a non-woven material made from artificial fibers.

Breathable membranes are designed to protect against moisture and control its level due to the ability to pass air from two or one side. Based on this feature, diffuse membranes are divided into one-sided and two-sided, which leaves a certain imprint on the method of their installation, because when installing a one-sided breathable membrane, you have to pay attention to which side of the material will face the insulation.

Breathing membranes are also divided according to the number of layers. They come in three, two and single layers using a special anti-condensation layer that can accumulate moisture and then gradually evaporate it. Among the multilayer diffuse membranes are the so-called intelligent ones, which combine the qualities of heat, hydro and vapor barrier, and are independently capable of regulating vapor exchange based on the temperature and moisture level in the room.

Another advantage of diffuse membranes is the absence of a ventilation gap between the thermal insulation and the membrane. Perhaps the only drawback of this vapor barrier material is the high price of floor vapor barrier. However, all the advantages and positive qualities that it gives, this disadvantage is reduced to zero.

Liquid rubber

Today, liquid rubber is already a fairly common material for creating a vapor barrier layer. Liquid rubber is a cold water-based bitumen-polymer emulsion. It is conveniently applied, quickly sprayed over the base, even if it has a complex topography, forming a seamless monolithic rubber carpet after hardening, which is irresistible to liquids and gases and is characterized by additional hydro, heat and sound insulation.

Modern liquid rubbers come in several types:

- An emulsion that is applied in an automated way and is mainly used for vapor barrier of floors, which have a large area of \u200b\u200bhundreds, thousands of square meters.

- An emulsion that is applied manually to the floor, the area of \u200b\u200bwhich is no more than several tens of square meters.

DIY vapor barrier

1. Preparing the surface for installing a vapor barrier

During the initial construction of a private house with a vapor barrier for the floor, there will be less hassle. To begin with, it is recommended to treat all floor boards with a special compound against rotting, insects and pests. Particular attention should be paid to the subfloor and joists, as they are located in close proximity to the ground. Reinstall the joists and install the subfloor. A layer of vapor barrier material will have to be laid on it.

The technology of floor vapor barrier for an already built house will be different. In the case of creating a new vapor barrier or overhauling an old one, first remove the floor covering, remove the subfloor, and remove the vapor and thermal insulation. The screed should be thoroughly cleaned using a vacuum cleaner or broom.

Then inspect it for defects: potholes, through and small cracks, as well as large irregularities. If there are a large number of these, then some repairs will be needed. It is necessary to straighten the screed to prevent direct penetration of moisture from the soil through through cracks. As an additional protection against the effects of water, you can install waterproofing: if you use waterproofing material in rolls, then it is laid overlapping, the joints are taped with special tape or regular adhesive tape.

After this, install the logs in the design position. Check the level of each joist so that it is perfectly horizontal. In this case, it is necessary to treat all wooden elements with an antiseptic, which protects the wood from the appearance of fungus and mold, as well as damage by insects. Then you should thoroughly clean the surface from dust and debris. And only after that you can lay a layer of vapor barrier.

2. Laying vapor barrier material

No special knowledge is required when installing vapor barrier material. To vaporize a floor with your own hands, it is customary to use mainly film materials, representatives of which are the Izospan membrane and the Izospan V floor vapor barrier. The vapor barrier is laid on a supporting frame, and it is necessary to ensure that the film sheets overlap each other. The overlap width should be 15 - 20 centimeters.

The vapor barrier layer is secured with galvanized nails or a construction stapler, but most manufacturers recommend using special adhesive tape, which allows you to create a coating that is completely free of any cracks. To avoid problems with the mounting method, this must be clarified in advance when purchasing a vapor barrier material.

It is better to treat hard-to-reach places, parapets, abutments and other raised areas with bituminous coating materials, since it is difficult to properly install and securely fasten film vapor barrier in these places. After laying the vapor barrier layer, place insulation on top of it. You can use any thermal insulation material: mineral wool, polystyrene foam or polystyrene foam. The main thing is that this material fits tightly to the joists, leaving no gaps or cracks between the insulation and the joists.

On top of the insulating layer, another layer of vapor barrier membrane should be laid in the same way, which will prevent moisture from penetrating into the insulating material from inside the room. Be sure to ensure that the vapor barrier material overlaps. After this, you can glue the joints and safely begin the process of laying the main floor. When installing floorboards, keep in mind that a gap of 1-2 centimeters must be left from the vapor barrier to the floor.

3. Correct location of vapor barrier

To decide which side to lay the vapor barrier on, you need to understand where the steam is coming from:

- If you use such a two-layer film when installing, then strictly follow the instructions for the floor vapor barrier and lay it with the smooth side, which does not allow moisture to get into the insulation, to the heat-insulating material, and the rough side, which retains moisture, into the room.

- In the case of installing a foil vapor barrier, it is necessary to take into account an important point: it should be placed with the metallized side up so that heat is repelled into the room, lay it end-to-end, gluing it with aluminum tape.

- The polypropylene vapor barrier, which has a one-sided laminated coating, is placed with the smooth surface facing the insulation and the wicker surface facing out.

- If you use a three-layer film with a reinforced mesh that is laminated on both sides with polyethylene film, then the material should fit tightly to the heat insulator and have ventilation gaps of 2-5 centimeters.

4. Vapor barrier with liquid rubber

A polymer-bitumen material for floor vapor barrier called liquid rubber is applied to the surface as shown in the video about floor vapor barrier. First, open a bucket of mastic, then mix the contents and apply it to the base using a brush or roller. When dry, this material forms a rubber film on the floor, which is firmly glued and completely follows the surface topography.

The coating does not allow moisture to pass through in any form: in the form of water from above, in the form of steam from below. The consumption of liquid rubber to create a vapor barrier layer on a wooden floor is 1 - 1.5 kilograms per square meter. For waterproofing purposes, it is recommended to increase its consumption to 3-4 kilograms per square meter. The thickness of the film is approximately 0.7 millimeters.

Thus, if you properly install the vapor barrier of the floor, following all the simple installation technology, as well as protecting the insulation from mold and rot, then you will be able to avoid significant heat loss, and the thermal insulation performance will be excellent. Such a sandwich will provide your home and its occupants with comfortable conditions and will significantly extend the life of your floor.

Vapor barrier 3 price

Vapor barrier in 3 price segments (Brane. Texbilt. Rainex). Wholesale and retail. Call us for advice 89851545832