The front door is a business card of any house. Interior doors, also ...

|

|

The cellar is an obligatory extension at the cottage or near a private house. In that... |

In search of diversity, when decorating the ceiling, installation will be an excellent option ... |

DIY vapor barrier

The wooden floor is quite whimsical in operation and puts forward strict requirements to its protection against the negative impact of different external factors. Thinking first of all about the level of humidity, since wood is very susceptible to it. But thanks to modern technologies, we presented all kinds of materials for vapor barrier of the floor, which are able to cope with this problem.

Content:

The need for vapor barrier of the floor

Increased humidity in the house has a negative effect on wooden coatings. The steam that accumulates inside the living quarters - during a shower, washing or wet cleaning, from cooking and breathing of people themselves, seeks out the way out. Since the pressure of such a pair is much larger than atmospheric, it presses on the ceiling, walls and floor, which leads in conjunction with the difference in temperature to the appearance of condensate.

Water, which gradually penetrates the insulation and wooden structure of the floor, destroys them over time. Building materials begin to rot, their original technical indicators worsen, mold and fungus appear. In addition, the comfort of the people who are in it will directly depend on the temperature and moist regime in the room.

To avoid a slow, but irreversible destruction of the floor, it is necessary to equip a vapor barrier layer, which prevents the pernicious effect of moisture on wooden coatings. At the same time, the air comes out, and normal circulation is created in the room.

As for the concrete floors, condensate also accumulates on them, although it does not harm them. But vapor barrier is recommended in cases with a concrete floor, since air humidity in the house will still be high. This is what the floor vapor barrier is needed for.

Types of vapor barrier materials

Until the beginning of the 21st century, permamine, only or roofing material were mainly used as vapor barrier material. To date, the market can boast of different types of vapor barrier, many of which are successfully protected from water exposure. As a vapor barrier layer of a wooden floor, breathing membranes and films are most often used. Of course, there are vapor barrier materials of a different type, for example, such as liquid rubber and bitumen-polymer mastics, but they are more suitable for walls and roofs than for the floor.

Polyethylene film

This type of vapor barrier is quite common and affordable. On the market, you can find two types of vapor barrier plastic films: non -certified and perforated. It is believed that it is better to use a perforated film for waterproofing, and unprogramed for a vapor barrier layer. This is due to the presence of micro -focus in the film and the level of vapor permeability. The perforated film has a higher vapor permeability.

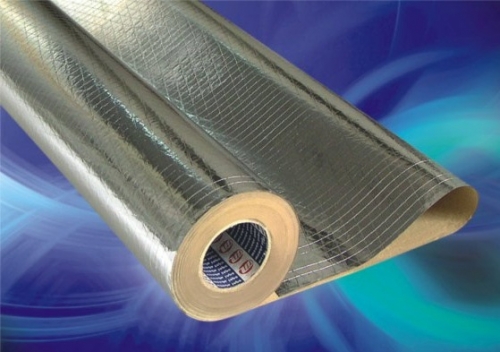

Today, thanks to the rapid development of technology in construction, another variety of polyethylene film films with a reflective aluminum layer has appeared. The vapor barrier of such films is much higher, so it is customary to use them in rooms with a high level of humidity and temperature kitchens, baths and saunas.

The main drawback of the plastic film is that it is easily torn, which requires special accuracy during installation. Even in the case of using a polyethylene film with a reinforcing grid, its durability and strength will not be very high. Also, when setting a vapor barrier, the floor using a film must be equipped with a ventilation gap.

Polypropylene film

In comparison with polyethylene film, polypropylene film has greater strength and resistance to various atmospheric phenomena. At first, this material was produced exclusively from polypropylene, but it was found during operation that condensate is formed in films from the side of the insulation, which violates the temperature and humidity balance and provokes the rapid wear of the insulation.

Today, a special layer rolls on polypropylene reinforced films, which consists of a viscose fiber with cellulose. It absorbs and holds large volumes of moisture well, not allowing you to form drops. Such films with a vapor barrier of the floor in the apartment are placed down with an anti -condensate layer, and a ventilation gap is equipped between the insulation and polypropylene film.

Diffuse membranes

Diffuse breathing membranes are one of the highest quality and expensive vapor barrier materials. The vapor permeability coefficient of diffuse membranes is very high and is achieved thanks to the microstructure of the material, which is a non -woven material made of artificial fibers.

Breathing membranes are designed to protect against moisture and control its level due to the ability to pass air from two or one side. On this basis, diffuse membranes are divided into one- and bilateral, which leaves a certain imprint on the method of installation, because when laying a unilateral breathing membrane, it is necessary to monitor which side the material will be facing the insulation.

Separation of breathing membranes is also performed by the number of layers. They are three, two and single -layer using a special anti -condensation layer that can accumulate moisture, and then gradually evaporate it. Among the multi-layer diffuse membranes, the so-called intellectual are represented that the qualities of heat, hydro- and vapor barrier are able to independently regulate vaporization, based on the temperature regime and moisture level in the room.

Another advantage of diffuse membranes is the absence between thermal insulation and the ventilation gap membrane. Perhaps the only drawback of this vapor barrier is the high price of vapor barrier of the floor. However, all those advantages and positive qualities that it gives, this drawback is reduced to zero.

Liquid rubber

To date, liquid rubber is already a fairly common material for creating a vapor barrier layer. Liquid rubber is a cold-based bitumen-polymer emulsion. It is conveniently applied, quickly spraying at the base, even if it has a complex relief, forming a seamless monolithic rubber carpet after solidification, which is insurmountable for liquids and gases and is characterized by additional hydro-, heat and sound insulation.

Modern liquid rubber are several types:

- The emulsion, which is applied in automated and is used mainly for vapor barrier of the floor, which has a large area of \u200b\u200bhundreds, thousands of square meters.

- The emulsion, which is applied manually to the floor, the area of \u200b\u200bwhich is no more than a few tens of square meters.

DIY vapor barrier

1. Preparing the surface for the installation of vapor barrier

With the initial construction of a private house with a vapor barrier of the floor, the trouble will be less. To begin with, it is recommended to process all the floor boards with a special composition against decay, insects and pests. Particular attention should be paid to the black floor and lags, since they are located in the immediate vicinity of the ground. Install the lags in place and equip the black floor. A layer of vapor barrier material has to be laid on it.

The technology of vapor barrier of the floor with an already built house will be different. In the case of the creation of a new vapor barrier or overhaul of the old, initially remove the flooring, remove the black floor, remove the steam and thermal insulation. The screed should be carefully cleaned using a vacuum cleaner or a broom.

Then inspect it for defects: potholes, through and small cracks, as well as large irregularities. If such are available in large quantities, then some repairs will be needed. It is necessary to straighten the screed so that there is no direct hit of moisture from the soil through through cracks. As an additional protection against water exposure, waterproofing can be installed: if you use waterproofing material in rolls, then it is on the overlap, the joints are glued with special tape or ordinary sticky tape.

After that, set the lags in the design position. Turn out the level of each lag so that horizontal is ideal. In this case, it is necessary to treat all wooden elements with an antiseptic that protects the wood from the appearance of the fungus and mold, as well as its damage to insects. Then you should thoroughly clean the surface of dust and debris. And only after that you can lay a layer of vapor barrier.

2. Laying vapor barrier material

Special knowledge when installing vapor barrier material is not required. For vapor barrier of the floor with your own hands, it is customary to use mainly film materials, the representatives of which are the isospan membrane and the vapor barrier of the floor of the isospan V. The vapor barrier is laid on the supporting frame, while it is necessary to ensure that the film canvases are overlapping. The width of the overlap should be 15 - 20 centimeters.

The vapor barrier layer is attached with galvanized nails or a construction stapler, but manufacturers for the most part advise using a special adhesive tape, which allows you to create a coating that is completely devoid of any cracks. In order not to have problems with the mounting method, this must be clarified in advance when buying vapor barrier material.

Inaccurate places, parapets, adjacents and other embossed areas are best treated with coil -based bituminous materials, since it is difficult to put and reliably fix the film vapor barrier in these places qualitatively. After laying the vapor barrier layer, place the insulation over it. You can use any thermal insulation material: mineral wool, polystyrene foam or polystyrene. The main thing is that this material fit tightly to the lags, leaving no gaps and cracks between the insulation and lags.

On top of the insulation layer, another layer of vapor barrier membrane should be laid in the same way, which will prevent the penetration of moisture into the insulation material from the inside of the room. Be sure to make sure that the vapor barrier is overlapping. After that, you can glue the joints and feel free to proceed to the process of flooring the main sex. When installing the floor boards, keep in mind that from a vapor barrier to the floor it is necessary to leave a gap of 1-2 centimeters.

3. The correct location of vapor barrier

To decide which side you need to lay vapor barrier, you should understand where the steam comes from:

- If you use such a two -layer film when laying, then strictly adhere to the instructions of the vapor barrier of the floor and lay it with the smooth side, which does not allow moisture to get into the insulation, to the thermal insulation material, and the rough, holding moisture, inside the room.

- In the case of installation of foil vapor barrier, it is necessary to take into account the important point: it should be placed upward with the metallized side so that the heat is repulsed into the room, laying it out in the locomotive, gluing with aluminum tape.

- A polypropylene vapor barrier, which has a one-sided laminated coating, is placed in a smooth surface to the insulation, and weaved out.

- If you use a three-layer film with a reinforced mesh, which is laminated on both sides with a plastic film, then the material should fit tightly to the heat insulator and have ventilation gaps of 2-5 centimeters.

4. vapor barrier with liquid rubber

A polymer-bitumen material for a vapor barrier of a floor called liquid rubber is applied to the surface as shown in the video about the vapor barrier of the floor. To begin with, a bucket of mastic is opened, then the contents are mixed and applied to the base with a brush or roller. Drying, this material forms a rubber film on the floor, which is glued tightly and completely repeats the surface relief.

The coating does not pass moisture in any form at all: in the form of water from above, in the form of steam from below. The consumption of liquid rubber to create a vapor barrier layer on a wooden floor is 1 - 1.5 kilograms per square meter. For waterproofing purposes, its flow rate is recommended to increase to 3-4 kilograms per square meter. The thickness of the film is approximately 0.7 millimeters.

Thus, if you properly arrange a vapor barrier of the floor, observing all the simple laying technology, as well as protecting the insulation from mold and decline, then you will be able to avoid significant heat loss, and thermal insulation indicators will be at a height. Such a sandwich will provide your home and its residents with comfortable conditions and significantly extend the life of your gender.

Vapor barrier 3 price

Vapor barrier 3 price segments (Brane. Texbilt. Rainex). Wholesale and Retail. Call we advise 89851545832