Today, the popularity of the designs of suspended ceilings is undeniable. Such ceilings have ...

|

|

Tile coatings are considered one of the most resistant to natural wear and ... |

Any design of the building should effectively perform the main functions, including protection ... |

DVP on a wooden floor: installation features

When leveling the lower surface of the room, the most practical and affordable way is the laying of the fiberboard on the wooden floor. This method is appropriate when flooring on old tuberous floors, a plane with irregularities, defects or with some slope. Sheets of wood -fiber plates are most often lined on lags, but another method is possible. It is possible to lay them under linoleum or carpet with insulation. This material is not always appropriate, for example, with heavy loads, and all the features of the coating should be considered in more detail.

Table of contents:

- Basic conditions for laying fiberboard on a wooden floor

- Advantages of floors from fiberboard

- How to choose materials

- Choosing a bar for lags

- How to cut the fiberboard?

- Technology Laging Lag and FEP on the floor

Basic conditions for laying fiberboard on a wooden floor

Each covers for floors has its advantages and disadvantages, and the flooring for the wooden floor remains the simplest and most practical. Old boards do not always make sense to tear off the floor, especially in old houses and country buildings. They provide the integrity of the surface and give additional heat. However, the boards are deformed over time and require partial or complete replacement.

The alignment of the surface using sheets of plywood, fiberboard or chipboard (not to be confused), experts recommend making lags made of high -quality timber. However, the thin layers of these materials can not always withstand significant loads, for example:

- for working machines that give a large vibration;

- under thin metal legs of furniture;

- under heavy and bulky furniture, especially if the supports are not on the lags under the sheets of coating, but on the gaps.

The choice of materials for styling and how professionally performed work on their installation is very important. Whether the floors will subsequently depend on this:

- even;

- solid;

- durable;

- sustainable.

The horizontal surface is the fundamental criterion for the quality of work on the installation of the floor. Therefore, prepare the necessary tools in advance, including a universal building level, without which it is difficult to verify the accuracy of the geometry of the sexes.

It is equally important to properly prepare the old base:

- carefully clean and remove all construction garbage;

- remove the plinth, which prevents the basis of the basis for fiberboard;

- fill all the cracks in the floor for tightness;

- clean everything that peels and crumbles on the floor;

- note the lower horizontal levels at the walls along which the surface will be leveled;

- if in the floor of the cottage, a country house or structure it is supposed to enter the cellar, then it is better to start with its arrangements, and then lay the floors.

Attention: if the lags are perfectly exhibited, then poor -quality work on laying DVP sheets can ruin the whole impression!

DVP cannot be laid too tightly without a gap, otherwise, with fluctuations in the level of their edges, they will rise, splitting. From the walls, sheets should also retreat about 4-7 mm this edge will still go under the baseboard.

Experts recommend starting the layout of fiberboard sheets from the opposite wall to the front door. If there is no experience in how to put fiberboard on a wooden floor, experts recommend that the first layer immediately check the level for leveling when detecting inaccuracies. Each subsequent row is verified horizontally in the same method of rush with inaccuracies inappropriate. When gluing plates, it is advisable to lay the load on top of the seams, and if they are nailed, then it is not necessary. If the floors are lined for laying linoleum or carpet, then no more processing is supposed.

Advantages of floors from fiberboard

Wood fiber plates are quite common building and finishing material applicable for repair and cladding of various surfaces. DVP is used not only for the rough installation of various designs, but also for the floor. It is noteworthy that even those who do not know how to lay the fiberboard on a wooden floor give preference to this material due to acceptable cost and practicality. DVP sheets are indispensable:

- when aligning the old floor;

- under the black laying of linoleum or parquet;

- for facing surfaces (floors, walls, arches).

Main advantages:

- the simplicity of laying, but you need to be able to put the lags on the wooden floor;

- high strength of fragile in the type of material resembling wood cardboard;

- well tolerates temperature changes with moderate air humidity;

- durability (in the absence of excess moisture);

- environmental friendliness, due to which FEP, this natural material uses allergies with intolerance to chemical components in a living room;

- convenient packaging;

- affordable price.

At the same time, genders from FEP have its disadvantages:

- when leveling the floor, additional costs for a beam for lags as a basis are required;

- insufficient protection against water, although for a children's or bedroom this is a completely suitable material;

- with a large pressure or blow, a sharp heavy object can form a small break between the lags;

- weak fire resistance in fire;

- too easy to facing the view;

- without protective processing, the surface wear out quickly, especially with a large load and movement of furniture;

- in raw an unheated room, it can be spaced.

Attention: regarding environmental friendliness, a controversial issue, since the old form of release suggested another technology for gluing materials, therefore it is undesirable to use the remains of the fragrance department in the living room on the workshops and garages!

If there are any doubts, see the advice of experts: how to lay the fiberboard on the wooden floor of the video at the end of the article.

How to choose materials

Buying sheets of fiberboard is a responsible business, and a large list of building materials from different manufacturers not only gives more choice, but, to some extent, brings confusion. Today there remains the risk of acquiring poor -quality or inappropriate goods.

1. If the alignment of the floors is done for painting, it is better to purchase a decorative plywood that can be laid out with patterns, like a parquet or laminate of high -quality floors will cost much cheaper.

2. If the appearance is not so important, since the flooring for the wooden floor is planned for laminate or carpet, then the visual parameters are not as important as the technical characteristics. Sheets of wood -fiber slabs are different, soft and hard, and are classified according to their standardization scale:

- brand T with a conventional front surface;

- T-C has a front layer with a thin-dispersed mass of wood fibers;

- T-P has the color of the front surface;

- T-SP Suborodispersed Personal layer is tinted;

- T-V has increased water resistance without tinting;

- NT semi -hard sheets;

- ST super -hard sheets with a conventional front surface;

- STS-s super-hard sheets with a thin-dispersed facial layer.

Quality groups A and B have hard stoves of the brand T, T-P, T-C, T-SP, and their front surface involves the 1st and 2nd variety. The density of soft sheets varies: M-1, M-2 and M-3. Separately, emergency chief of the fiberboard of the brand T, which is produced in a wet way. It is used for various purposes:

- insulation and decoration;

- sound insulation and thermal insulation of the floor;

- construction of internal partitions;

- wall sheathing;

- subway for parquet, laminate, linoleum;

- for decorative cladding of various shield structures.

Tip: When buying, pay attention to the appearance of the organ. They should be without defects, have the same thickness around the entire perimeter, with the same shade of the surface of the sheets in one pack (party).

The main quality indicators:

- the same sizes of sheets;

- a single thickness of the fiberboard;

- uniform homogeneous front surface.

Choosing a bar for lags

When choosing a beam for lags for styling, it is important to adhere to some recommendations:

- wood, laid under the fiberboard on a wooden floor, should be dry (light beam dry);

- do not purchase it in advance and exhibit it in a raw room, it will be warmed up and will become unsuitable;

- use wood with processing with special antiseptics of the 2nd or 3rd varieties from healthy wood without knots made of conifers;

- the cross -section of the beam is recommended at least 40mm and up to 70mm;

- hubby will lead the lags later due to the heterogeneity of wood, but you can use trimming without these defects;

- a small amount of cracks is permissible, since for wood bars this is a natural state;

- * lack of fungi and sprouted in damaged areas of wood (quality indicator);

- it is better to immediately roll the crumpled or winged bars or use scraps in short areas of the lag crate.

Attention: you can check the wingedness (screwing the crumpled beam) can be a plumb or thin elastic cord stretched along any wood rib.

How to cut the fiberboard?

When laying sheets of such facing materials as organ or plywood, one has to face the need to cut, especially in the extreme rows. Construction supermarkets offer such services, but the exact dimensions of the room with its deviations from the norm are needed, for example, not all angles of 90.

Attention: Remember that it is better to make the sheets in short they will go under the baseboard, but it is very difficult to cut excess.

When cutting by the machine, cutting sheets is performed most evenly and with a high -quality edge. If there is no such opportunity, you have to do it yourself:

- electrician;

- disk saw with a laser guide and disks for work on an organ;

- universal construction tool for cutting building materials;

- a grinder for accurate marking.

Tip: It is better to use a special home -made machine holding a grinder. The scissors for metal will help to remove the edges a little. In the absence of experience, it is better to train on an unnecessary piece, before studying the video at the end of the article.

Often you need cutting sheets for the seizure for pipes for radiators and water supply, niches or wall protrusions. Special holes are made by an electrician, a universal tool or a reliable sharp knife. Take care of this tool in advance, for example, take rent. Close the template from the cardboard and check everything in place if everything is accurately transferred to the fiberboard.

Technology Laging Lag and FEP on the floor

DVP and timber slabs are unacceptable in a raw room, it is best to put the beam on the floor horizontally, and the sheets vertically along the wall at room temperature are close to room temperature.

Lags are laid on pre -prepared surfaces, a self -leveling mixture or old wooden floors. As a rule, the technique of how to lay the fiberboard on a wooden floor is applicable both for aligning the surface and to update the surface. If there are small curvatures, floor levels from east to north or west to east, noticeable slope or obvious bumps, then you should try to either eliminate them or close them.

If there is no experience in how to lay the fiberboard on a wooden floor, then you can seek advice on the video. In many cases, for the arrangement of the lag, you can contact specialists, and lay sheets of fiberboard yourself. However, there is nothing complicated if there is a tool, patience and experience with wood. It is necessary to carefully examine the entire surface of the old floor, and if a fungus or mold is detected there, you cannot leave under the sheets of fiberboard, otherwise they will eat all new floors over time. The remaining areas are treated with a special fungicidal primer or a building antiseptic for wood and other surfaces.

Tip: It is also worth removing those boards that creak do not think that something will change under the weight of new sexes. Sometimes, due to defects, it is necessary to clear a significant part of the old wood flooring. Do not worry all this will hide under the lags and new cladding!

1. If the old floors are relatively smooth, but it is required to update the surface, it is enough to polish them and then glue the sheets of high -quality fiberboard orlite. With this method of laying, the old base is necessarily carefully cleaned after grinding for the primer. It should dry at least 8-12 hours, depending on the composition and temperature of the air. Only half of this is the glue and apply the orlite sheets, crushing goodness in the corners and edges.

2. In the design of the lag, special galvanized locknuts with a nylon ring are usually used, which prevents the displacement of the nuts along the thread.

Devices do not allow them to unwind and loosen the structure. When tightening the upper lockheads that fix the lags in the position that is required in this section of the floor, they are slightly deepened into the wood structure. Because of this, the surface level may be slightly lower than the alleged. Tightening the upper counter -gaming, monitor the laser level, given this error. Experts also sometimes display 2 levels, additional under the locknut.

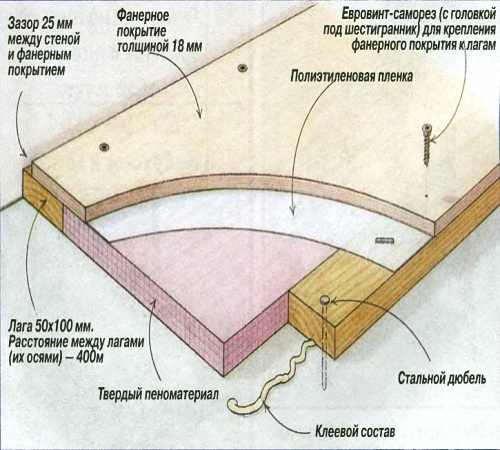

3. All lags fit in this way see the scheme:

Preliminary calculations in the interval between them and the floor level correlate:

- with the cross -section of the beam;

- the slope of the floor;

- sizes of orgal sheets.

The bars are mounted directly to the old wooden base, and where there are no boards at the base, instead of them, segments of the corpuslet or other pieces of wood are installed under the lags. It is not recommended to make a partial crate from the lag or leave gaps under them in the floor before lining the fiberboard. Before laying them on the floor, it is worth recalling that for the draft floor, as a substrate for linoleum, parquet or carpet, they use less expensive plates with a small thickness, and for the finish, high -quality hard organiter.

Attention: purchased sheets of fiberboard are exposed for 2-3 days in a living room for acclimatization for 2-3 days. Before the sticker, you can slightly sprinkle the back of the spray gun or treat with a primer for better adhesion. When installing with nails, this is not necessary.

Features of the FEP of FEP on Lagi:

- the sheets on the lags are laid out so that the seams converge on the bars;

- orlit (DVP sheets) is nailed with screws, self-tapping screws or nails with a step about 100mm along the edge and after 120-150mm in the center;

- the next row adjaches freely, with a small gap of about 2-3 mm;

- all sheets on parallels are laid in the same way.

Features of FORTION OF DVP for glue:

- installation glue is applied to the entire surface of the sheet and is well distributed without subtexts,

- the sheet should be saturated for 25-30 minutes;

- glue is applied on top of the primer on the floor;

- the sheet is crushed and checked horizontally.

Features of the finish processing of the floor:

- it is important to remove all the remnants of the glue that performed in the gap;

- large gaps between the sheets are sealed with putty or glued with a reinforcing ribbon under the draft floor;

- the surface of the fiberboard can be varnished or painted.

Talk about the fiberboard, and on

Talk about the fiberboard, and in the pictures of the plywood ...

the asshole is stupid!

the asshole is stupid!

i was also upset

i was also upset by the content of the article. Blah blah blah. In vain spent time. A bunch of water, as in a diploma at the humanitarian.

If only in one image

If only on one image in the article to see the FEP!

EPT, adhere to what you

EPT, adhere to what you cover -with a faner or fiberboard for a new base/ lags/ or on an old plank hut, they mixed it !!

DVP is on plywood, specialists

DVP is on plywood, specialists of hellish

Dumb bastards in pictures

Dumb bastards in the pictures everywhere plywood are spinning and fucked about fiberboard. DVP Fuck this wood fibrous plate, it is thin and used as a coating instead of a laminate for example, and chipboard is used just for what you write.