To save heat in the house, you need a whole range of works related to wall insulation ...

|

|

People have been erecting fences since a long time. The fence protected from predators and performed reliable ... |

With the help of a ceiling cornice, it is possible to divide the space between the wall and the ceiling ... |

Technology for decorating slopes on the windows with your own hands. Slopes for plastic windows: features and characteristics

To install plastic windows, specialists are needed. This is worth the means, but it is professional builders that will install the designs as expected. But to make slopes, you can do it yourself. To save money and do everything to your liking, you should carefully study the algorithm for performing slopes. To make the slopes of the power to any master, you just need to gain a little patience, prepare the necessary tools and confidently get down to business.

Table of contents:

- Slopes on the windows

- Varieties of slopes for windows made of plastic

- Features of plastic slopes on windows

- Characterization of slopes for plastic windows

- How to mount plastic slopes on windows

- Installation of slopes for windows

- The installation technology of slopes on the windows using plastic or drywall

Slopes on the windows

Finding a specialist performing this process qualitatively and consistently is not so simple. Because the mounting of the slopes is not only to make slopes, but also to correctly perform the finish of the plastic window. It is done first. With any type of slope, the seams between the window and the wall deserve special attention, it should be hermetically sealed, since this is the main cause of the subsequent heat leak. It often happens that the masters who install windows do not blow out the space with mounting foam and there are incomplete voids that lead to heat loss. If visually it is not visible how high -quality the cracks are blew, you can check the presence of a draft with a lighter or match. If the flame trembles, then there is an invisible draft and this must be immediately corrected. Repeated use of foam helps to seal the gaps. After a day or two, excess foam is carefully cut off with a knife. Now it is permissible to start finishing the slopes.

Prior to the start of internal work, work is underway with the outside of the windows. External slopes are closed in two ways:

- The final putty is applied to the starting layer;

- Only a solution from a mixture of cement and sand is used.

The choice between this way or another depends on the condition of the wall. If the surface is relatively flat, it is enough to apply a thin layer of putty, if there are chips on the wall, it is necessary to align the surface with a cement solution.

Varieties of slopes for windows made of plastic

In their location, internal and external slopes are distinguished. Select such slopes:

- plaster using a cement mortar;

- from drywall;

- foam;

- plastic;

- Wooden.

To choose the right option for the slope, it is necessary to analyze the following criteria:

- durability;

- availability;

- ease in mounting;

- Easy in subsequent operation.

Plassing of window planes was previously considered one of the most commonly used methods of finishing. The implementation of this type of work is possible for internal and external options. The disadvantage of this method is the low thermal insulation capacity of the cement layer. In addition, over time, the surface of such slopes is covered with grids of small cracks.

Plasterboard slopes made according to all the rules, with water insulation or polystyrene, have high thermal insulation abilities. But it can not always be used to install drywall on slopes on slopes only for internal work, after which additional decoration is performed. Provided that drywall is covered with primer and paint, slopes serve for a long period of time.

Plastic slopes are not only attractive in appearance, but also have high technical characteristics. It is possible to use such material for the manufacture of both external and internal protection. The installation of slopes from plastic material is carried out very quickly, in addition, the complete combination of the framework of the plastic window itself and the finish of the side surfaces gives an interesting harmonious view of the windows. Strong aspects of the use of plastic material, we can note the following:

- immunity to ultraviolet radiation;

- resistance to the scorching sun;

- the ability to withstand mechanical and chemical effects;

- environmental friendliness of the material;

- Seamless design;

- resistance to mold, fungus, decay.

Drugs made of wood are most often used for decoration of wooden surfaces, the installation of the material is carried out in grooves, which makes it possible to install quickly. Structures are attached with self -tapping screws, so there are no gaps and cracks.

Foam for such work is also suitable, but requires careful preparation. Foam polystyrene has its advantages: it is easily cut, simply mounted. To install this kind of window protection will be needed:

- a container for the preparation of the solution;

- Two types of spatula: simple and gear;

- electric drill with a mixer;

- building level;

- A special construction knife.

Of the materials, an adhesive solution, mesh, foam, corner will be needed. Having glued, the foam is allowed to dry, and then all the joints are processed and sealed.

Features of plastic slopes on windows

Among the wide variety of materials for the finish, special attention deserves made of plastic. This is a durable material that does not require additional actions, like painting or putty. The advantages of this kind of surfaces are as follows:

- durability of the structure;

- external attractiveness;

- excellent compatibility with window material;

- the ability to hide irregularities and defects under plastic;

- optimal cost of work and material;

- excellent thermal insulation abilities of the material;

- speed of work, the ability to finish per day;

- there is no need to invite repair teams, if there are tools, it is really possible to independently install slopes in a few hours;

- lightness and ease of care, the material is easily washed;

- high moisture resistant abilities;

- reliable protection against temperature changes and freezing of the surface of the window.

In the process of dismantling old wooden windows, window openings are very often destroyed, all irregularities, gaps or voids must be sealed to avoid heat loss in the cold seasons. Even if wide gaps are visually visually visible, the slightest gap can become a place for reproduction of mold or fungus, the reason for the flow of cold into the room. It is not difficult to achieve high thermal insulation indicators - it is enough to lay the insulation under the plastic layer until the frame is adjacent to the window opening.

The construction market offers an abundance of materials for insulation:

- strips of polystyrene;

- mineral wool;

- panels - sandwiches;

- fiberglass;

- Foam polystyrene.

The choice of the material of the insulation depends on the width of the gap and the general condition of the surface of the window opening.

Characterization of slopes for plastic windows

And although the previous options for slopes can be very diverse, the leading new technologies and those materials that are distinguished by the best technical characteristics are leading. Proceeding, hesitation fades into the background since new and modern materials are not pushing quite high-quality and convenient in mounting and care. Among the most popular, the following can be distinguished:

- white plastic material;

- plastic material of various colors;

- slopes using gypsum fiber panels.

Plastic slopes are made in the form of a sandwich inside of which a heater is already installed, as a rule, this is foamed polystyrene foam. The success of using such a material can be distinguished:

- slight weight of the structure;

- high thermal insulation abilities;

- thanks to stiffness, such a design holds its shape perfectly;

- external attractiveness;

- ease of care.

Color plastic slopes have the same characteristics, but have a wide field for creativity and imagination. Such materials can be selected for the main color prevailing in the room or making this area a brighter spot. In this case, the owner himself decides how his slopes will look. Color plastic can be a matte or glossy texture.

As for the slopes of gypsum fiber panels, such material reaches more and more popular due to the following features:

- the ability of the material bending, becomes an ideal solution for arched windows;

- environmental Safety;

- thanks to the rigidity of the material, the design does not change and does not lose the given shape;

- high resistance to moisture;

- high sound and thermal insulation capabilities;

- the ability to perfectly plunge the surface and give the desired color by staining.

How to mount plastic slopes on windows

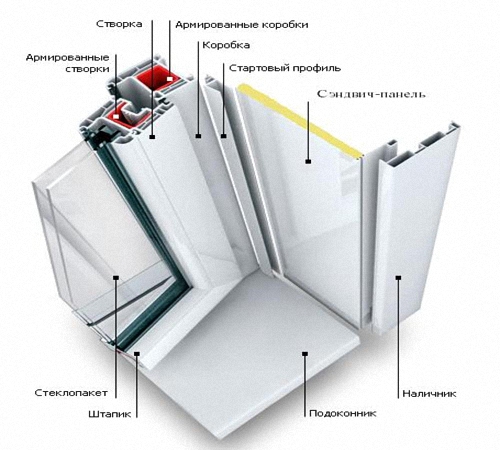

The first step before installing plastic slopes is to measure the surface. The height, the width of the plane is measured in order to have an idea of \u200b\u200bthe size of the sandwiches - panels. After the preparatory work is completed, we remove the protective film from the window profile and begin to mount the slopes.

First of all, side planes are mounted. The starting profile is cut off in size and attached to the window profile with self -tapping screws at a distance of fifteen to twenty centimeters. After this, wooden rails are attached along the edges of the window opening. It is necessary to control the evenness of the attachment using the construction level .. It is not recommended to rush at this stage. The next step will be the attachment of corners, that is, side slopes. It is recommended to use a special construction stapler for these purposes.

Sandwich - the panels should be cut taking into account the required length, width and angle of inclination. The plugs are put on the panel, inserting one part of the sheet into the corner, a thin layer of mounting foam is applied between the sheet and the wall plane and the second part of the sheet is inserted after that. The upper part of the sandwich is also mounted. At this stage of the work, it is necessary to ensure that the angle in the joints is at forty -five degrees. Shvas are sealed with glue, excess amount is removed immediately.

Installation of slopes for windows

Installation of slopes requires preliminary measurements. During measurement, the height, width and depth of the window opening are clarified. This is necessary to calculate the cost of work and the amount of material required. For independent work, it is necessary to carefully prepare. In addition to studying the theoretical side of the issue, you need to prepare a tool. For work, you will need:

- start profile in the form of the letter P;

- profile in the form of the letter F;

- fifteen -centimeter rack made of wood;

- insulation;

- self -tapping screws;

- bug screws;

- sealant to the color of the material.

The installation technology of slopes on the windows using plastic or drywall

For installation work, several consistent stages are carried out. A wooden rail is attached around the entire perimeter of the window, fastening is carried out by self -tapping screws, it is necessary to control the correctness of the vertical and horizontal base all the time. The rail also performs the function of the working surface for mounting sod panels. The starting profile is attached using self -tapping arapy and installed as close to the window as possible. A profile in the form of the letter F will join the rail after the work done, insulation is carried out around the perimeter of the window area. Most often, thin foam and mineral wool are used for insulation. Having done this work, it is necessary to begin directly to the installation of material for slopes. If this is plastic, the work ends with this. When using drywall, the surface is putty and painted.

As you can see, there are many options for performing the slope installation. Everyone chooses the right one, taking into account the individual characteristics of the window. To install the slopes with your own hand, it is quite possible for any home master: a little dexterity, accuracy, the presence of tools and following the recommendation of masters, will help to make high -quality and outwardly attractive slopes. If you have any questions about installing slopes with your own hands, watch a video that tells the rules of work in detail, recommendations are given and the algorithm for conducting sloping technology on plastic windows with your own hands is reflected.

8 (903) 715-91-15 steel

8 (903) 715-91-15 Steel lattices in Moscow http: //wwww.mosreshetki.tt34.fu metal grilles in Moscow and the region. Steel protection !!!

Steel lattices in Moscow

Steel lattices in Moscow

8 (903) 715-91-15 Steel lattices in Moscow http: //wwww.mosreshetki.tt34.fu metal grilles in Moscow and the region. Steel protection !!!