The process of finishing the basement of the building is a rather important process that ...

|

|

The skirting board designed to lay wires has a special cable channel. AT... |

What roofing material to choose if complete tightness is placed at the forefront ... |

How to warm the floor with foam with your own hands

To save heat in the house, you need a whole range of works related to the insulation of walls, roof, windows and gender. Insulation of residential buildings allows you to save money, which are designed to pay for utilities, intact and safety. The paramount task during insulation is the coating of the heat -insulating material of the floor. A lot of insulating materials for gender are presented in the construction points network, but the most popular among domestic developers is polystyrene.

Content:

- Quality of foam as insulation

- Warfly insulation

- Warming of the concrete floor

- Warming with foam floor on the ground

Quality of foam as insulation

The warm floor, the lack of labor -intensive processing of insulation laying, significant financial costs, and, as a result, drafts are the main advantages of foam. Currently, more than 60% of foam in Europe is used for thermal insulation purposes.

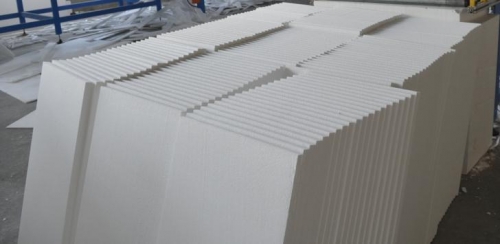

This material is a gas -filled white polymer, which consists of myriads (small particles of foamed polystyrene) and is best suited for use in the sex insulation system, which is quite successfully implemented in practice.

Some developers are deeply mistaken, because they believe that polystyrene is only granulated polystyrene foam, which is known since childhood to crumble into small balls. But this is not really. There are polyethylene foam, polyurethane foam, polypropylene foam, which belong to polystyrens and are profitable in price and good in practice.

The foam consists of 97% of the natural insulator of air bubbles. This insulation is produced in the form of sheets of various thicknesses and strength. It is recommended to purchase foam with profiled edges for floor insulation to get rid of the cold bridges in the future, which form in the cracks between the foam panels.

In the manufacture of the polystyrene, the water is overheated, which provides a high level of its moisture resistance. The good properties of pushing moisture are good to use to warm the floor in the house, which is located on a area with a high level of ground water.

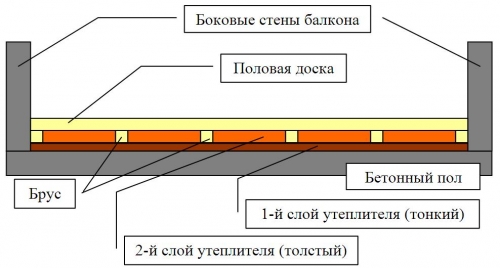

Warfly insulation

Warming of wooden floors is a rather serious issue when repairing an apartment, a country cottage, a country house or a bath. Wooden floors are very popular, because they give minimum loads on the floor stove regardless of the height to which the floor needs to be lifted.

Wooden floors are a combination of an air gap, which is formed between the overlap and bottom of the boards and layer of wood. The tree itself is an excellent thermal insulation material, not without reason in Russia huts were built from wood. The trouble only lies in the fact that at the junction of walls and ceilings, blown slots are formed that require insulation.

The insulation of the wooden floor with foam can do any owner of the apartment or private house. It is not difficult to cope with its styling, it is simply necessary to observe some conditions in the process.

To begin with, it is necessary to prepare the surface for thermal insulation material: clean it, thoroughly close the different cracks and cracks at the base through which parasites and insects penetrate, lay over 10 centimeters on top and densely thick film throughout the floor, providing good waterproofing. This layer will not let water into the middle of the floor.

Of course, you can purchase an ordinary plastic film, but it is better to use a special material that is made on a water -repellent basis and is distinguished by the properties of heat reflection. At this point, attach special importance, because the water insulation material enters the thermal insulation material and the useful life of the gender itself. After installing the waterproofing layer, fix the edges with tape.

Then you should watch a video about the insulation of the floor with foam and make a wooden crate from the lag, where thermal insulation material will be placed. With such a floor arrangement, loads are evenly distributed to the frame, therefore, as a thermal insulation material, you can purchase not only extruded polystyrene, but also foam in a traditional, granular form.

On the above film coating, it is necessary to send tightly to each other and to the walls of the dressing methodology sheets of foam. Pinch with foam all joints and various gaps. Another layer of waterproofing film on the foam is capable of ensuring the insulation of the floor from the possible penetration of the fluid on top.

At the final stage of insulation of a wooden floor with great caution, so as not to damage the film, it is customary to install a metal frame and perform a cement screed with a thickness of at least 5 centimeters. After such manipulations, you can safely engage in laying the main sex.

Warming of the concrete floor

The concrete floor in any case requires insulation. The best thermal insulation material is foam, as for the wooden floor. Remember that the technologies of floor insulation with foam are different for houses with a basement and buildings without a basement. Let us dwell on each of them.

Insulation of the concrete floor in houses with a basement

The owners of apartments that are located on the first floors of multi -storey buildings are faced with the problems of the presence of cold concrete floors. The flooring of the floor with foam will help to cope with them. It is better to cover concrete overlap with thermal insulation material from the basement. In this case, the plate is in a layer of warm air. After that, the cold stops making his way into the home.

To insulate the concrete floor with polystyrene foam, it will be needed by sheets of foam with a thickness of 5 - 10 centimeters. Now manufacturers produce sheets with chamfers, allowing to perform their installation qualitatively. In the process of work, masters may encounter the uneven walls, which is easily corrected using mounting foam and using different thicknesses of foam for floor insulation.

Foam fastening is carried out with special plastic dowels, which have a length of 120-140 millimeters. Start work with remote sections of the basement. Attach a foam sheet to the stove, drill a hole with a perforator through it, after planning the mounting location. Then remove the sheet and continue drilling the hole that corresponds to the size of the dowel. It is recommended for convenience to use 2 drills that have different diameters.

Before fixing the foam sheet to the place, apply glue for foam on the docking surfaces, which looks like an ordinary mounting foam to fill all the irregularities of the joints and ensure reliable thermal insulation of the joints. The sheets are attached to the concrete slab using dowels and fill the joints with mounting foam.

In the process of insulation of the concrete floor by foam from the basement, there are areas where it is not possible to use entire sheets of insulation. In this case, it is recommended to cut out pieces of the whole foam sheet in size and shape and lay them.

You can not leave the foam open, as it is a combustible, and it is easy to damage it. Therefore, it is necessary to plaster it. You can use glue to laying ceramics using a reinforcing mesh as a plaster mixture. As a result, you will get a thin, but durable layer.

Insulation of the concrete floor in houses without a basement

The concrete floor insulation procedure in this case will be somewhat different. Before starting work, it is necessary to carefully prepare the base. First of all, remove the old flooring and check the floor for visible chips and cracks, when detecting which you must again apply the adhesive composition for the installation of ceramic tiles.

Cracks are recommended to be sealed with a thick solution with a metal spatula, then proceed to the waterproofing of the floor. For such work, you can use special bitumen mastic or roll material. Remember that it is necessary to capture 10-15 centimeters of the walls. Put the reinforcing mesh on the film, you can take a conventional pantry.

After that, you can safely engage in insulation of the floor of the first floor with foam. The thickness of this material is different, it is best to choose a thermal insulation material with a thickness of 2-3 centimeters. Set the foam to the mixture tightly, in the end to prevent the formation of gaps and gaps, as well as get the best effect of insulation.

Knead to the average consistency using a mixer glue with an average spindle revolution and spread directly to the floor, or on foam every 10-30 centimeters. This is enough to carry out a reliable fixation of foam. After you have laid the sheets of foam, you can start installing the beacons.

For extreme lighthouses, make marks on the walls using a water or laser level, and the rest of the elements are usually mounted using a linear construction level. To fix the lighthouses, it is recommended to use the remains of the adhesive composition used earlier to install thermal insulation material. The distance between the guide beacons should not be more than 1.4 meters.

A solution of screed should be poured between the beacons, its excesses are removed with a flat rail or a rule that creates a perfectly flat floor surface. If in the future you are going to choose a parquet as a floor covering, then after drying the screed it is worth pouring half a thin layer (2-3 millimeters) of a self-burning mixture that eliminates the slightest irregularities of the floor.

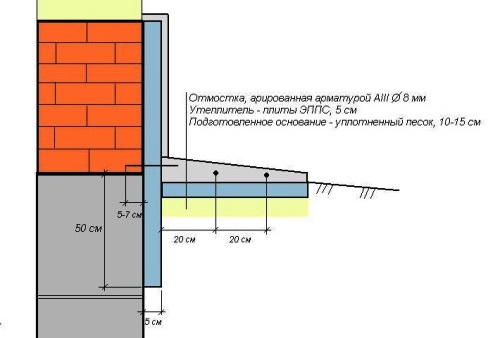

Warming with foam floor on the ground

In private houses, industrial and public structures, the floors on the ground should be isolated using an additional layer of thermal insulation, which has a minimum of one meter along the perimeter of the fit to the external walls of the floor. The floor, which is on the basis, does not make a load on the foundation, but contacts the ground, increasing the likelihood of the detrimental effects of groundwater. To protect the floor from moisture and you need to correctly design waterproofing.

The floor that is placed on the ground is higher or lower than the ground level. The floor insulation with foam in the house with a basement and building without it differs the thickness of the thermal insulation material used. In buildings with the basement, a layer of material can be thinner than in the construction without basements, since the floor is located below the level of freezing of the soil.

First, the foundation should be leveled. If the soil is loose, it needs to be compacted and allowed to settled for a month. Pour the pillow of crushed stone or gravel with a thickness of 10 centimeters and compact mechanically. Lay a layer of sand of similar thickness, tightly compress and cover with polyethylene. Sepable for insulation of the floor with foam for tiles should be dry, clean and not have significant irregularities.

Be sure to do the floors on the soil with waterproofing. As a moisture -proof layer, you can use a plastic film with a thickness of 0.2 millimeters or roofing material. Put the waterproofing strips with a lowering of 10 centimeters and the output of the walls 10 to 15 centimeters above the floor level.

It is customary to start laying foam plates from the corner, pressing tightly one to the other. Start the next row with half the stove to shift the seams between the plates. It is recommended to lay polystyrene in 2 layers with the creation of shift displacement in levels to avoid the formation of cold bridges. To completely prevent the penetration of the cold, it is worth using a foam with millstone edges of a spike-puzza.

Cut the last plates a little large in size and lay down with some effort. After laying the entire foam, it must be covered with a protective layer - with a plastic film with a thickness of 0.2 millimeters or roofing material and removed the edges above the floor plane up the wall. To increase the persistence of the floor on the ground, it is customary to reinforce the screed with a metal or alkaline net of fiberglass.

On the stoves of foam, it is customary to pour a solution of concrete on this way. Pouring should be a thick consistency and contain a filler, which has a diameter of up to 8 millimeters. Perform the screed from the cement of the brand 200. The minimum thickness of the screed should be 4 centimeters. Pour the solution between the guide rails and wipe it after hardening with a rare cement mortar. A horizontal deviation of not more than 5 millimeters is allowed.

The basis of the floor must be secured from the loads during the first three days. Behind the floor in the process of hardening, it is necessary to look after 10 days, moisturizing from time to time and avoiding drying out. The floors on the ground in rooms of over 30 square meters are customary to divide into segments of 10 square meters to avoid unwanted warehouses and deformations during the work.

Thus, with a do -it -yourself floor, insulation of the floor with a foam is a simple way to give a heat to the heat. In addition, the use of polystyrene plates is an excellent tool for reducing shock noise. The advantages of foam have long been appreciated by professional builders and private developers.

i am a well than thanks !!!

i am a well than thanks !!!

so conveniently very good !!!

so conveniently very good !!!

what nonsense are you

what kind of nonsense do you write, anonymous? Chukchi or what? :)

what nonsense are you

what kind of nonsense do you write, anonymous? Chukchi or what? :)

i used to have to sheathe the floor before

i used to have to sheathe the floor with a blue foam with joints, as our walls of houses are sheathed from the street, then on top of the yuzby and linoleum plate, but stsuko is expensive ...

legs in winter freeze even in

the legs in winter freeze even in three socks and slippers, despite the fact that concrete already lies a parquet, a brilliant insulation and linoleum with insulation, and one dick floors are ice like a bastard, you need to lay the pencil case.

Good and relevant article,

A good and relevant article, which will be useful for lovers who are gathered to warm the floor themselves, and experienced builders. I also insulated the floor myself a couple of months ago and I want to advise the Penoplast-MSK foam manufacturer. I ordered PSB-C 35 from them, just for floor insulation. The site is very convenient and simple. The material was high -quality and inexpensive. They brought it quickly. So the problem with gender insulation in the country has long been resolved. And the legs do not freeze even in winter \u003d)

test

test