Brick fences today are one of the elite types of fencing, so it was in ...

|

|

Every year exponentially, the number of owners of apartments increases, ... |

Low -rise houses with a residential attic are more common. First of all ... |

Metal roof installation with your own hands

What roofing material to choose if complete tightness of the roof is placed at the forefront? Of course, a metal roof. This category includes corrugated board, metal tiles and sheet or roller iron. The corrugated board and metal tiles are mounted using a rather large number of through fasteners, which significantly reduces the tightness of the roof. But leaf and roller iron is attached using a folding connection, completely excluding the through holes in the roofing material. It is about the latest technology that this article will be discussed. The device of a metal roof has a number of undeniable advantages: full fire safety, light weight, aesthetics and durability. And on a smooth metal surface, rain water does not accumulate. Installation of such a coating requires the use of a special tool, and professional roofing brigades even come to the object with their machines, which significantly accelerates the work. But you can equip a metal roof yourself, for this you need to familiarize yourself with the technology below and take some tool for rent.

The design of the metal roof

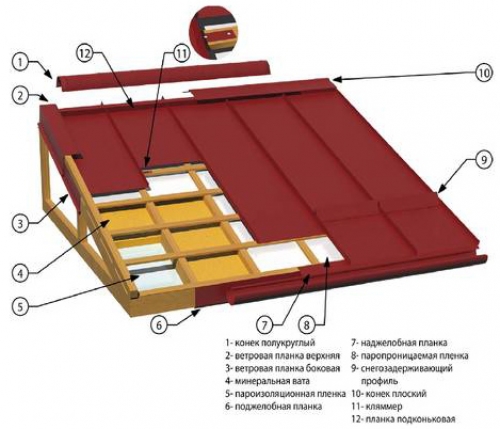

The metal roof is laid on the rafter structure with a fairly frequent crate. The distance between the neighboring slices of the crate should not exceed 25 cm. The slope of the roof slopes should be from 16 to 30. Metal sheets are laid on top of the crate, the edges of which are connected by the so -called fold connection.

A little terminology that is used when working with a folding roof:

Word falzmigrated to us from the German language, where Falz means gutter or groove. The edges of the sheet iron are wrapped, the edge of one of them, as it were, wraps the edge of the other, then the connection is compacted. The result is one of the most reliable compounds that exist at the moment. By the way, if you are still not entirely clear what the Falz is, remember the tin canning jar. The compounds of the fold roof is exactly the same as the edges of the tin can - strong and absolutely tight.

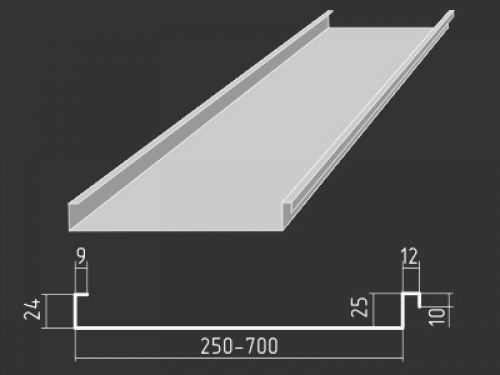

Paintings or cards These are sheets of iron interconnected along. The length of the picture is equal to the length of the slope from the skate to the overhang. For convenience and greater reliability, maps are not made longer than 10 m. Pictures can be scored from pieces of sheet iron, and can be whole, carved to the desired length of rolled metal. The latter option is more preferable. Firstly, because whole paintings are more convenient to use and fix. And secondly, the tightness of the roof increases.

Preparation of paintings by cutting to the desired size and bending of the edges to create a fold is better to do in advance, below, and the finished material that remains only to fix it to the roof. For the manufacture of cards, special equipment is used, which bends the edges (a machine for the manufacture of self -extensions of folds). So at the top it remains to plant one edge on the other and connect them together.

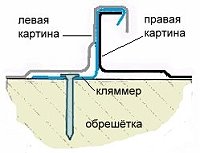

Klyimers To fix the metal roof to the crate, they are made of the same material as the paintings. This allows you to make the entire coating as durable as possible, the fasteners will not fail before the roof coating and will not corrode. Kleimers are a strip of metal, one edge of which is fixed by a self -tapping screw to the crate, and the second is started between the edges of metal sheets and bend into the folding connection along with the edges of the paintings.

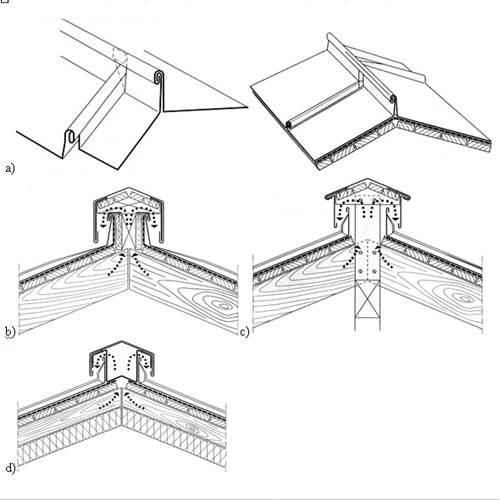

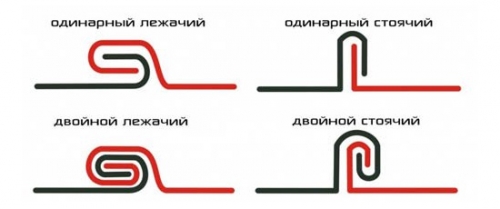

Falts compounds are lying and standing, as well as single and double. Lying fakes Used to connect metal sheets in the picture parallel to the cornice. Due to the fact that the folds are lying and pressed as much as possible to the plane of the roof, the water easily flows along the roof. Nevertheless, recently they have been trying to perform a falsetzer roof without horizontal compounds to make it perfectly smooth. This allows you to make a roll technology when a metal sheet is cut off immediately the required length. Thanks to the smooth, even surface, the water flows well and the snow is not delayed, but the very possibility of corrosion due to stagnation of water or its ingress inside the folding compound is minimized.

Standing fold joints Used in the seams between the paintings of the metal, parallel to rafters. The standing double fold is considered the most reliable compound that provides maximum strength, durability and tightness.

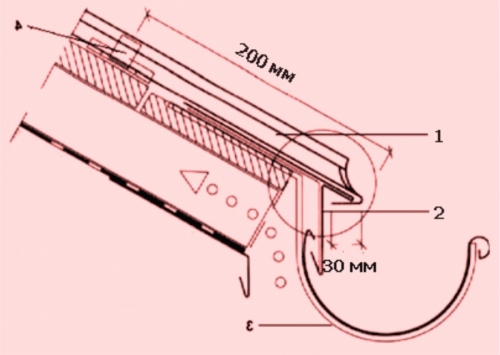

Roofing frames A special tool for wrapping the folding connection. A set of two frames allows you to make a double fold in two passes. Using a manual framework, you can work with sheet iron with a thickness of 0.5 0.8 mm. The capture width of each frame is 200 240 mm.

If the roofing framework is a handmade tool, then semi -automatic seating machines and electric folding machines are designed to minimize manual labor and increase productivity. They are used on large objects.

Crutches Wooden T-shaped elements, which at the very beginning of the installation of roofing material are nailed to the cornice and are used to hold sheets of metal on the roof. Simply, they do not let the paintings fall down.

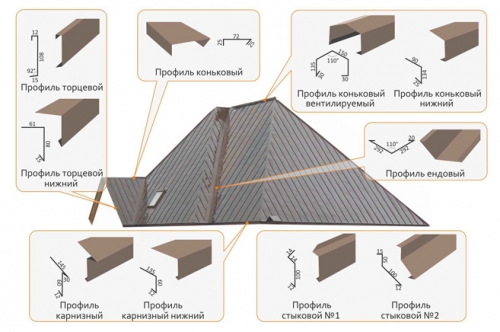

For lateral, upper and lower compounds of the metal roof are used continuous elements, for example, wind planes, pancreas, snow retainers and ridges. They must be made of the same material as the roof itself.

Types of metal roof

The folding roof can be made of various metals, which differ in properties and operational characteristics.

Cink Steelit has relatively high anti -corrosion resistance and is able to last at least 30 years as a roof (30 50 years). When working with this material, it is necessary to tirelessly ensure that in no case do not damage the zinc coating, otherwise corrosion cannot be avoided. To extend the service of galvanized steel, a paint for a metal roof is used, which is covered with a roof every 3 5 years (the first time after 7 10 years).

Galvanized steel with polymer coating More protected from the influence of negative atmospheric factors. For example, such a coating as Pural has already become a household name. Pural is a coating of polyurethane and polyamide and has increased strength, as well as resistance to ultraviolet rays. In total, there are about 17 color decisions of Pural coatings, among which there are matte, giving the roof a unique soft shade. In addition to the pool, galvanizing is covered with polyester and plastisol. With such a roof, you need to be as careful as possible and try not to damage the coating during installation.

Aluminum A little more expensive than galvanized steel, but is used to cover the roof due to the fact that it does not lend itself to corrosion, does not change color over time and is very plastic. Due to the unique plasticity of aluminum, it is easy for them to cover the slopes of a complex shape, the material is easily bends in the places of profile fractures. The service life of an aluminum roof is about 100 150 years.

Copper It is considered the most durable and expensive material, which can be used to cover the roof. Over time, patina appears on the surface of the copper, the result of the oxidation of the metal, protecting the metal itself from the influence of the environment. The color of the patina changes over time. Therefore, the copper roof is at first fiery red, and over time acquires a matte greenish tint and even dark loudness. It is precisely for this aesthetic property of the chameleon that copper love to use to cover architecture monuments and significant structures. The service life of a roof from copper can be from 100 to 200 years, and the maximum recorded period is 700 years.

Titan-zincThis is modern development, used for the roof relatively recently. Despite the fact that zinc is well opposed to corrosion, it has a lack of fragility. This does not make it possible to use galvanized steel in complex forms or nodes, where plasticity is needed. The material called Titan-Tsink consists of 99.95 % of zinc, 0.03 % of copper and aluminum, 0.02 % of titanium, which gives the metal strength. The service life of a tank-zinc roof is approximately 70,100 years, under more aggressive conditions, for example, near water bodies 50,70 years. But in the process of installation with a titanium tie, you must be extremely careful: you can’t walk, scratch or knock on it. Also note that this material does not like the neighborhood of other metals and some wood species.

To cover the roofs, metal is taken with a thickness of 0.5 1.5 mm. It is easier to work with more thin materials, since it is easier to bend and wrap them, without leaving cracks. If it is planned to make additional elements from the same metal, then the recommended sheet thickness is 0.6 0.8 mm. More detailed requirements for various cases can be learned from SNiP II-26-76. By the way, building codes do not prohibit changing the shape of the metal for the roof, for example, bending and making curly elements. But a change in the shape of a galvanized sheet is not recommended, as this can violate the monolithic of the zinc coating.

As already mentioned above, the folding roof is laid mainly on slopes with an angle of inclination from 16 to 30, but a flat metal roof is also possible. This imposes certain restrictions and slightly changes the technology of laying the material, since it is necessary to equip a high -quality drain from the entire area of \u200b\u200bthe roof. Also, in the process of wrapping the folder connection, a sealant for a metal roof is used to secure the connection from leaks as much as possible.

Installation of a metal roof

Falts roof is the type of coating, the arrangement of which must be entrusted to professionals. And not just to roofers, but only to those brigades who have experience with a folding metal roof. This is due to the mass of the nuances, as well as the need for professional equipment that facilitates installation.

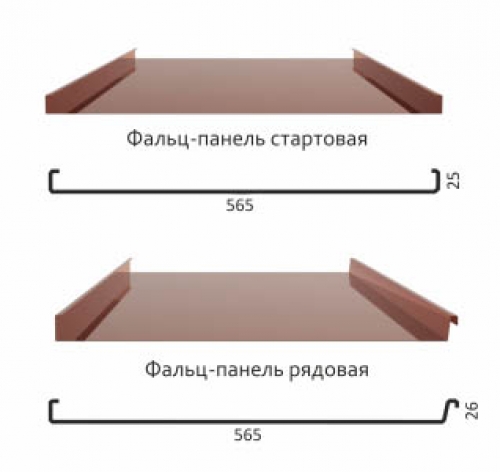

The modern market can offer ready -made metal sheets with edges of a standard length of 2.5 m or more bent for a fold. After acquiring them, it will only remain to be interconnected. But this method is not the best.

Buying will be much more preferable rolled galvanized steel, the same purple, for example, or copper. Directly at the facility, it will be necessary to cut the sheets of the required length equal to the length from the skate to the cornice plus 50 100 mm, necessary for arranging the folds in the place of the ridge and under the cornice overhang. On a special folding machine, you can wrap the edges of the sheet for their further connection with each other.

The following is a unified technology for the installation of a fold roof.

Arrangement of rafters and crate for a metal roof

The arrangement of the rafter structure for the folding roof is no different from the standard technology. It makes no sense to put the rafters too often, since the roofing material is very light. But the crate must be performed with a step of 200 250 mm from a beam of 50x50 mm or 50x100 mm. Such a frequency is necessary in order to minimize the deformations of the roof metal during operation, installation and repair. So the roofer’s legs will always step on the place where the craft boards are located under the metal, and the metal will not bend and deform.

If the roof is flat, then the crate must be made continuous.

The horse is made of two boards that converge at one point in two edges. And the cornice must be made continuous, of 3 4 knocked down boards.

Waterproofing of a metal roof

To minimize the appearance and accumulation of condensate on the back of the roofing material, the roof must be waterproofed. If the roof was insulated, the crate is nailed on the rafters, and a waterproofing superdiffusion membrane is attached on top of the crate, which does not pass water inside, but releases steam from the inside. Waterproofing begins to be fixed from the bottom up, the joints are made with an overlap of 100 150 mm and glued with construction tape. The film should be fixed with a small sag, so that in the event of severe frosts, it does not break due to the fact that it is very narrowed and pulled between the mounts. By the way, you can fix it with self-tapping screws and dowels with a wide hat.

On top of the waterproofing membrane, a double -indicated -mentioned step is packed. So two ventilation gaps will be formed: one between the insulation and waterproofing, and the other between waterproofing and roofing metal.

Fastening of a metal roof

Installation of roofing iron begins with the installation of crutches. They are nailed to the cornice with a step of 70 cm, they will hold the paintings of the metal so that they do not fall during the installation process. Wooden crutches can be replaced with a steel corner of 50 60 mm, which is attached along the cornice overhang. This method is even somewhat more convenient, since there is no need to verify crutches so that they are evenly located on the same line.

He rises up the first picture with ready -made bent edges. It is laid next to the pediment so that an overhang is formed 40 50 mm. The sheet is leveled so that the edge of 30 mm remains to cross the horse (the edge of the edge should be 60 mm on the opposite slope).

Klyimers They are attached from the side where the second sheet of metal will be applied. The cowl is fixed to the crate with a 4x50 mm self -tapping screw in the place that is overlapped with a sheet of metal. As a result, it should turn out so, the bent edge of the metal should be in the immediate vicinity with the vertical edge of the Kleimer. All Klyimers are attached with a step of 500 600 mm.

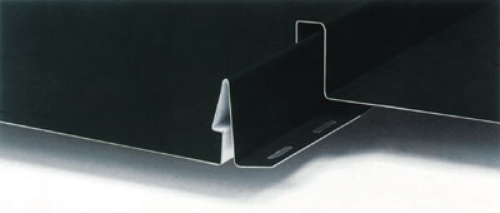

Rises the second picture And it is installed next to the first so that its bent edge is put on the bent edge of the first picture (for self -adjacent folds). If the edges of the paintings are even, not self -adjacent, then the edges of the first and second paintings should simply be located in the immediate vicinity, a Kleimer should be clamped between them. Further, using a roofing framework or other professional tools, a fold is performed. Usually it takes two passes with a hand tool, back and forth.

Inside the fold, a cowl bends, so the connection is very strong.

Important! If the house will be operated in a wet climate or near reservoirs, then all compounds can be additionally seized using a sealant for a metal roof. This can be, for example, Tytan silicone sealant. It is most convenient to apply it on a strip of fiberglass, a width equal to the width of the bent edge, and glue this strip to the edge of the metal before performing the folder connection.

Kleimers are also nailed from the second edge of the second picture, then the third picture rises and the procedure is repeated.

A special element is attached to the enclosures of the paintings to the pediments the wind bar is lateral, and then the side bar is upper. These elements can be fixed through both self -tapping screws and with the help of folds (the latter is very difficult).

After all the paintings on both slopes are laid and fixed, performed horsethat can be ventilated and non -pre -premium. How they are executed can be viewed in the photo. Also pay attention to how the skate ventilation is performed differently.

Lastly, they are performed cornice overhangs and the gutter is attached for rainwater drainage. The edge of the Faltsa picture turns down so that water is easily drained.

Installation of snow retainers on a metal roof

The installation of fences and snow retainers on the folding roofs is required and regulated by clause 8.11. SNiP 21-01-9. Snow holders are necessary so that the snow does not leave the roof an avalanche -like, rumbling on the roof. In addition, there is a great probability of injury to a pedestrian located below. Elements of snow retainers are attached to standing folds with the help of self -tapping screws or screws. Fences are made of profile pipes.

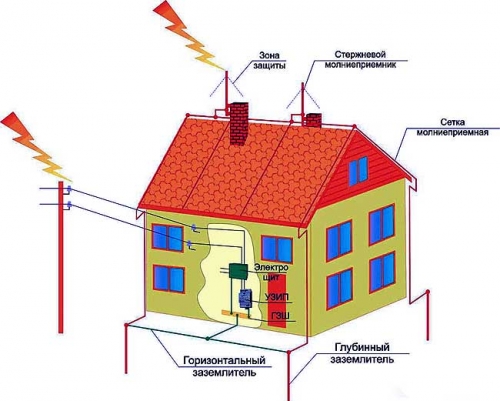

Lightning protection of a metal roof

Due to the fact that the metal roof is conductive and attracts lightning discharges, it must be grounded and equipped with lightning protection. The fact is that when lightning enters the metal roof, all the electrical appliances will not only fail, but the roof itself will also be repented, and a wooden crate will overheat under it, which can lead to an inevitable fire.

At the highest place the roof is fixed lightning receiver. It can be:

- Metal pin;

- Metal cable stretched along the skate of the roof;

- Special lightning grid.

It is best to use a metal pin with a height of 0.2 1.5 m, with a cross section of 100 mm2, with a diameter of 10 mm. The pin is installed vertically and should be made of copper, aluminum, and duralumin, which is steadfast to corrosion. Metal cannot be placed with paint and varnishes.

Tokoowood It is used to divert lightning from lightning to the ground. It can be a steel wire with a diameter of 6 mm, which is welded to the lightning receiver and lowered down the walls. At the same time, it is worth avoiding places next to the windows and doors and in no case bend the wire, this can lead to the appearance of the charge. To the walls of the current is nailed with special brackets.

Grounding A metal roof can be a grounding contour of metal pins, driven into the ground to a depth of 1.5 2 m and interconnected into the circuit. It is necessary to place such grounding at a distance of 1 m from the house and 5 m from the paths, porch and other places where people go. The pins should have a wall thickness of at least 3 mm and be made of steel or copper. Steel rods quickly rust, so once every 3 years they must be checked and replaced as necessary. By the way, do not forget, the more humid soil, the better for grounding, so in too hot arid weather it will not be superfluous to water the grounding circuit from the hose.

The arrangement of a metal roof only seems very simple, it is better to entrust its implementation to professionals who know all the subtleties. Indeed, in the event of an error on your part, if you still decide to perform installation yourself, after a short time the roofing material may fail. Given the lowest cost of roofing metal, these losses will be greater than the cost of the work of specialists. Do not skimp contact professionals.

Smiled (crutches are needed for

It smiled (crutches are needed so that the roof does not go down)))))). The crutches are kept by the groove so that it does not tear it off the wind and the crutch and an veterinarian, these are two different details. Teshka is needed for a cornice over that it is also not so that it is also not lifted and uncomforted from the wind