Owners of private houses, in addition to cozy room arrangement, also have the task ...

|

|

For the arrangement of houses in areas with slopes or in places with problem soil ... |

The simplest and most affordable way to perform a black coating for premises any ... |

DIY roof insulation with your own hands

Low -rise houses with a residential attic are more common. This is primarily due to material benefit. After all, building a house with a residential attic is cheaper than with a full -fledged second floor, and the living area is equivalent. In other cases, the owners of the houses decide to make a room intended for year -round living from a non -residential attic. In the article, we consider what material, and according to what technology you can insulate the roof of the attic.

Content:

The importance of insulation of the roof of the attic

- The technology of insulation of the roof of the attic has its own nuances, since the room is directly under the roofing material, most often made of metal, and therefore heavily heated in the sun. Therefore, a layer of insulation should not only retain heat in winter, but also save from summer heat.

Insulation of the double -sized roof attic with an attic photo

- At its core, the insulation pie is no different from working on the roof of the attic. But higher requirements are presented to it, since in the future the slope from the inside is sewn with drywall and is faced with finishing material. So, it will be difficult to carry out any repair work.

- It will be especially difficult to do everything correctly with the exception of errors when it is required to insulate the attic with a broken roof. Due to the large number of joints, the probability of the formation of cold bridges or water leaks during operation of the house is high.

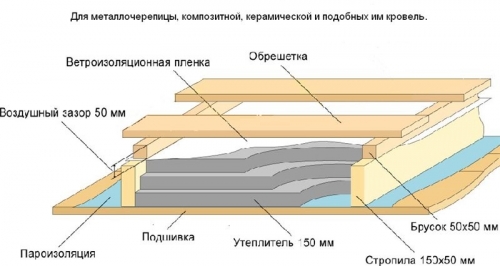

Regardless of the type of insulation used, the pelvis cake looks as follows:

- directly roofing material;

- crate;

- waterproofing layer (vapor barrier);

- insulation between the rafters;

- vapor barrier with gluing seams;

- finishing material.

When choosing a material for insulation of the roof of the attic from the inside, attention is paid to its indicators of thermal conductivity. The higher they are, the more thin the layer will need. In short, then the best indicators of polystyrene foam, basalt cotton, ecowan.

- As is known from the laws of physics, warm air rises up, which means that the highest heat losses occur through the roof of the attic. If the winter in the region is snowy and the roof is covered with snow, then it plays the role of an additional thermal insulator and holds the heat that has leaked through the boat of the attic. But due to a large load, the roof is always designed so that the snow cover does not linger on it and go on its own. But at the same time, ice crust should not form, it serves as an indicator that thermal insulation is carried out incorrectly and the roofing material heats up so much that the snow floods.

- The main difference between the usual roof of the full second floor and the attic is the size of the space for ventilation, which is necessary between the roof and the premises. So, if there is an unheated attic, then the ventilation there occurs naturally through the auditory windows or loose skin casing. In the roof of the living attic, a very limited space is left under the venture, most often not exceeding 15 cm.

- Ventilation is very important, as it eliminates the formation of excessive humidity under the roof, thereby leaving the entire structure dry and prolonging its operational period. In addition, this air gap, in the cold season, prevents the heating of the roofing, which avoids the formation of ice crust. And in the heat, on the contrary, it takes part of the heated air, excluding the overheating of the dwelling of the attic.

Roofing the roof of the attic video

Styrofoam

- When choosing a foam for insulation of the roof of the attic, the size of its sheets, thickness and density are estimated. If necessary, in the production you can order a cutting of material according to individual sizes. Most often, they do not even ask for an additional fee for this.

- But if you choose from what is presented in a construction store, then the foam is produced standard dimensions: 2x1m, 1x1m, 0.5x1m. If the roof is insulated with the rafters of 60 cm, then you will have to buy 1x1 m slabs and cut it off, which is why a lot of trimmings are formed.

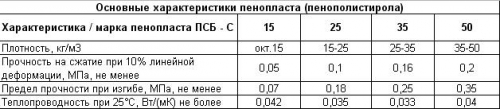

- The density of foam varies from 15 to 35 (these are those brands that are free). To warm the roof, you need to select 35, the material with lower characteristics has a more loose structure and low heat -protective qualities.

- The thickness is also different, from 20 to 200 mm. For the roof of the attic, it is most convenient to buy sheets with a thickness of 50 cm and lay them in a checkerboard pattern in three layers.

Tip: The density of the polystyrene foam indicates such a parameter as the size of the air cavities between the granules of the foam. But in order to correctly calculate it and qualitatively insulate the roof of the attic with foaming, you need to know that the brand of material 25 actually has a density of 20 kg/m3, and the foam plate with a mark of 15 has a density of 10 kg/m3. For internal insulation, slabs with lower density are suitable, and for external work it is necessary more durable and hard, with a value of at least 25 kg/m3.

The quality of the material

- It is recommended to buy polystyrene foam for insulation of the roof of the attic only in specialized stores or construction markets. If the quality of the products is in doubt, or its density does not look like the declared, it is worthwhile to ask for a quality certificate. With the excessive looseness of the polystyrene foam, during its fitting, the edges of the edge will break and sprinkle in size. So, the heat -insulation of the undercarbon room will no longer be possible to conduct a qualitatively.

- You can determine the quality at first glance by the inner surface or by the cut. High -quality products should be a snow -white plain color with granules uniform in size. To calculate the unscrupulous manufacturer, it is enough to run through the material with your hand, if at that moment individual granules begin to leave and fly away from it, then you should not buy it.

- It is good if the polystyrene is stored on a warehouse protected from rain and sun, this guarantees the safety of all its characteristics.

Dressing the roof of the attic polystyrene

- The insulation of the attic always begins with the roof. If this room is already resident, then all furniture and those items that will interfere with the work are taken out of it. In addition, when cutting foam, a lot of garbage is formed, which is then very difficult to clean. Therefore, it is advisable to temporarily cover the ceiling and walls with a film and not arrange drafts that will contribute to the spread of the polystyrene granules.

- Next, check the condition of the rafters. If they are made of wood, then additional treatment with antiseptic compounds is carried out.

Tip: sometimes, with thermal insulation of the roof in summer cottages, the ceiling is not disassembled to the rafters, but a new crate for the insulation is made directly on top of the existing ceiling. This will save time and make the work simpler, but the living space will decrease by at least 12 cm and it will not be possible to check the wear of the rafter system.

- Next, the vapor barrier film is attached to the desired side inside (the manufacturer on the roll label always indicates which side is the front and which is internal). It must be pulled very tightly so that it will fit all the rafters without gaps and adjust to the crate of roofing material without sagging. It is convenient to do this with a construction stapler. The width of the roll on average does not exceed 1 m, so joints form in length. They should be done with an overlap of 10-15 cm and glue with tape. Manufacturers often recommend using reinforced tape, but you can use cheaper on paper -based.

- Now the turn has come to insert polystyrene. This is a light, but hard material that is simply cut by an ordinary knife (but the blades are quickly stupid, so you need to have several spare ones in stock). Work can be done to one person. The most important thing is to correctly and accurately fit each plate in size so that there are no gaps. The less they turn out, the more effective the thermal insulation will be, which means small heat loss. But sometimes rafters can have a curved shape, then gaps are inevitably formed. They will have to be dumped with mounting foam. If the second layer will be laid in the future, then you need to wait for it to dry, cut off excess and only then continue to work.

- Most often, the foam rises rigidly between the rafters and does not require additional fixation. But sometimes there are times when it will need to be planted on special glue.

- A vapor barrier film for internal work is pulled on top (manufacturers share them with different letter designations, sellers in the store will certainly tell you about this). It is also tightly pulled over the insulation and attached to the rafter first on the stapler. When the desired tension is reached, from above, right along the entire length of the rafters, a wooden rail is attached to screws or a guiding metal profile. This not only allows you to additionally fix the film, but will also become a frame for a future cladding. With this method, vapor barrier should be pulled immediately over the entire height of the attic roof.

- Thus, the thickness of the roof of the attic corresponds to the thickness of the rafters and is 10-15 cm depending on the purpose of the room and weather conditions of the region. If the work was carried out by polystyrene in one layer, then many joints are formed between the sheets, which are called cold bridges. To avoid this, it is better to take a thinner material and lay it with an overlap in the form of brickwork.

Mineral wool

If foam is often used to warm the attic in a country house, then it is recommended to choose a more environmentally friendly material for a house intended for year -round living. This is mineral wool. It differs in purpose, which depends on the density of mats.

Insulation of the roof of the attic photo

Dimensions can vary, but the most popular standards as: width 60 cm, length of 125cm and thickness 5 cm. Therefore, during the construction of houses, the project most often provides a step of the rafters of the attic roof of 60 cm.

On sale there are several brands of mineral wool, consider the most popular of them below.

- Mineral wool P-35. The number means the density in kg/m3. This is a rather loose material that is suitable for insulation of the floor on the attic or for the upper straight part of the roof located under the trump of roof.

- Mineral wool P-50. This density is enough to warm not only the floor, but also the walls, as well as the slopes of the attic roof. For central Russia, it is enough to make 3 layers (15cm). This is one of the inexpensive types of this material, so often consumers opt for it.

- Mineral wool PZh-175. It has not only high density, but also additional rigidity. This is especially important if the insulation work is carried out from the inside. Such mats are very tight between rafters or guide frame, which allows one person to work. But their cost is already significantly more than the above analogues.

- Mineral wool PPZ-200. This type is selected in the case when special requirements for fire safety are set to the room. Thanks to such density and rigidity, it can restrain the spread of fire for a while.

Despite all the popularity of this thermal insulation material, it has a number of disadvantages:

- although when touching the mineral wool there is no sensation of discomfort, but small particles stick to the skin and cause severe itching, which cannot be washed off with water for a while. It is especially important to warm the attic to protect the eyes and nose from the hit of these particles, which crumble when laying the material into inclined and horizontal surfaces;

- minvata absorbs water, after which its characteristics are sharply reduced. Therefore, it is important to make the right insulation cake using special vapor barriers.

Tips for the choice of mineral wool for the insulation of the attic

- First of all, you need to rely on the manufacturer. The highest quality and proven products in the Russian construction market are such European companies as Rockwool, Ursa, Paroc, ISOVER. If their price is too large and does not fit into the estimate, then a good domestic manufacturer produces mineral wool under the brand of Technonikol.

- Mineral wool combines several varieties of materials. For example, glass wool and slag. But unlike mineral wool, they have lower indicators for soundproofing, less environmentally friendly, and the first option is dangerous when working with it.

- The heat -insulating characteristics of the slabs also depend on how its fibers are located. With their vertical arrangement, the material has higher noise and heat-protective qualities. But with a chaotic, the mat is very stringent, capable of withstanding a serious mechanical effect. It cannot be determined independently, but the consultant in the store is able to answer this question.

Insulation of the roof of the attic from the inside with your own hands in mineral wool

- They insulate the attic with mineral wool both outside and inside. In the first case, this is preferable in the construction of a new house, but when work is carried out as a repair, there is no choice left and insulation occurs from the inside.

- The thickness of the insulation layer depends on the width of the rafters, and as a rule, is 15-20 cm. So the mineral wool is laid in 2-3 layers, which allows you to displace the rows in a checkerboard pattern and block the joints of the joints with subsequent sheets.

- As already mentioned above, thermal insulation material is selected by high density, which provides it with the desired density and the necessary indicators in thermal conductivity. If the rafters are mounted with a step of 60 cm, then the material is convenient to go to bed and fit tightly between them. Otherwise, it will have to be customized. When warming with rigid slabs, at first roulette, they measure the desired size, then cut them with a knife on the floor and the ready -made are inserted into place. When working with soft material, it is simply inserted between the rafters and the excess of the bent edge is cut off in place with a sharp clerical knife.

Tip: all scraps that remain from the material should not be thrown away, they may have to warm small cracks that form at the junction of an attic slope and walls.

- Work is more convenient to carry out together and in special protective equipment, such as a respirator and a mask. This is due to the fact that insulation is carried out above the head, and inevitably small particles of the mineral wool will fall on the face, causing severe irritation and itching.

- First, all layers are laid in one strip of the frame from the rafters and immediately pull the vapor barrier film. It allows you to tightly press and fix the insulation. Such fabric is attached to wooden rafters using a construction stapler. Its length is recommended to measure in advance along the entire length of the wall.

- Often, when using expensive hard slabs, they insulate the entire area of \u200b\u200bthe attic and only then close it with vapor barrier.

- After insulation of the scatter of the attic, they proceed to thermal insulation of the walls. If it was previously cold, then at first they equip a frame of boards with a width of 15-20 cm, which will ensure the installation of the required layer of mineral wool. The guides are put only vertically, with an indentation from the corner to avoid the cold bridge. When warming, it is recommended to lay one layer (the latter or outside the house) so that it overlaps the wooden frame.

- On top, vapor barrier with overlap and gluing all seams is also very tight.

Proper insulation of the attic

Proper insulation of the attic http://www.enterinvest.ru/2018/08/uteplenie-msardy.html