The rafters serve as the basis of the entire roof structure, and their installation is one of ...

|

|

For each owner of the house, it is important to equip all rooms with special comfort ... |

Particular importance has recently been attached to an increase in the functionality of buildings with ... |

Buronabish stump foundation: Installation instructions

To arrange houses in areas with slopes or in places with problem soil, a brownish foundation is used. With its help, buildings are being built in settlements with dense development. We will consider further about the intricacies and features of the construction of the pile brownish foundation.

Table of contents:

- Buronaby foundation: features and advantages

- Construction technology and the arrangement of the foundation on bored stumps

- Buronabish pile foundation with grillage: procedure for creating a grillage

- DIY Brown Burian foundation: Basic construction processes

Buronaby foundation: features and advantages

If in the process of building the house there are problems of the availability of engineering communications or other structures near the building, then the use of a traditional strip foundation is impossible. In this case, it is recommended to build no less powerful - a brownish foundation on stilts. Since in such situations it is simply necessary to observe accuracy and not exceed the permissible threshold of vibration, which is able to affect the foundation of neighboring buildings. To avoid the destruction of neighboring objects, their deformation, which occurs after vibration pupils very often used the foundation from piles.

The installation of the foundation on bored piles helps to build buildings that are located in areas with special engineering or geological conditions or structures subjected to high load. The main advantage of such foundations is their low noise.

The construction of the foundation on bored piles involves preliminary drilling of pillar pits, into which a variety of metal -stone structures are immersed. After that, the pits are poured with concrete or cement-sand mortar. The drilling process requires the presence of casing pipes with a length of one to three meters. If the bypass pipe is absent, then the use of a sneaker is recommended. The casing is equipped with a cutting tip, which is located on the lower flanges of the first section. The drilling process using the siege pipe is due to the production of continuous rotational movements. The use of the first or second drilling option depends on the location of the foundation, area and properties of the soil on which it is built.

Among the advantages that highlight the foundation on brownish stumps from other types of foundation should be noted:

1. Ensuring the complete safety and integrity of buildings located near the building.

2. Reduced vibral indicators.

3. Low noise production.

4. Such a foundation does not need the delivery of certain components.

5. does not require a time to buy piles.

6. When arranging the foundation on bored piles, there is no need to get rid of excess soil.

7. In addition, such a foundation is characterized by high supporting characteristics, high performance and ease of installation.

8. This type of foundation is suitable for building buildings on soils of any type and complexity.

Construction technology and the arrangement of the foundation on bored stumps

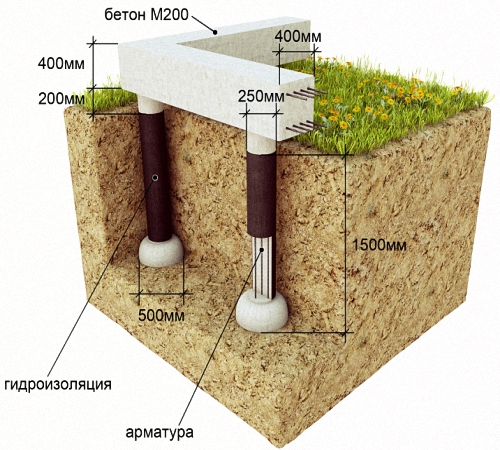

A brownish foundation is a design that is mounted directly on the construction site. The main component of such a foundation is pile, since it is on it that the whole load from the building lies. To calculate the installation of the pile, it is enough to calculate the depth of freezing of the soil and set it below this mark by several tens of centimeters.

As waterproofing, coating from roofing material is used, it covers the support in two layers. The connection of the upper endings of the supporting sections occurs using a radar. The foundation on brownizer stilts in the ratio with the type of radar can be of two types:

- hanging;

- buried.

To avoid the appearance of swelling on the object, it is necessary to leave a gap of 10 to 15 cm between the soil and the hanging raster. The lower section of such a radar is deepened into the ground by more than 20 cm. The foundation on bored piles with the presence of a radar is able to withstand a load of 1,500 kg.

The process of erecting the supporting parts of the foundation involves preliminary work on the marking of the site. This procedure is carried out using fishing line or rope, level and additional tools.

After the marking is performed, proceed to digging the trench, its maximum depth is 40 cm. When the trench is ready, take marks at the future place of the pile location. Motoburg will help equip wells in places noted earlier.

To ensure high -quality waterproofing of the support and avoid its premature damage, it is recommended to put two layers of roofing material in the well before installation. Keep in mind that the size of the shirt from the roofing material must exactly coincide with the size of the well.

The technology for designing the foundation on brownibular stumps installed on the ground with high humidity involves the manufacture of piles using casing pipes. This design allows you to produce high -quality filling of the casing with a concrete solution. When the concreting process is completed, there is a dive into the well of the reinforced frame.

The type of frame depends on the proposed load read out during the calculations for the construction of the foundation. It is possible to install the frame around the entire perimeter of the pile or on a certain area. Another option for installing the frame is its installation on the upper section of the support, in this case, it serves as a component connecting support and grillage. When installing the frame, it should be noted that its contact with the soil is unacceptable, so its lower part is set above the supporting level. If the frame comes into contact with the soil that it will succumb to corrosion and will soon deteriorate. If the soil density is quite high, and the walls of the well are stable, the casing is not installed.

In the process of pouring with a concrete pile pit, be sure to seal the concrete mixture with a vibrator to get rid of air bubbles and improve the quality characteristics of the structure. The grillage is connected to the supporting part with the help of the reinforcement rods, which pre -display, at a distance of 2 to 5 cm. The version of the construction of a monolithic grillage is possible, in addition, when building a grillage, materials are used in the form of concrete beams. In this case, the rod is concreted in the upper sections of the support. It turns out a design that resembles the letter T. In addition to this, the horizontal section of the structure is equal to the width of the support section, and the vertical - is compared with the size of the beam that will be laid. After the process of laying the beam is completed, joints are concreted, and horizontal sections of the rods are qualitatively welded to the loop of the installed components.

It is possible to use bottle -to -concrete bored piles. The process of installing such piles has its differences, namely: during the period of filling the foundation with concrete solution, it is filled with stones. Thus, the strength characteristics of concrete increase, and its consumption decreases. When constructing a brownibular foundation using such piles, it is necessary to condemn the pillar pits, the depth of which is half a meter. Since such supports are less stable before exposure to a vertical or horizontal force.

Buronabish pile foundation with grillage: procedure for creating a grillage

When constructing the foundation on bored piles, the creation of a grillage acts as a mandatory process. If we talk about its constructive features, then they are equated to the equipment of the strip type foundation. Since the grillage has the form of concrete tape, which acts as a connector of the tops of the supporting parts. If we are talking about the foundation of the slab type, then all supporting components are combined using the grillage.

To create a grillage, the presence of:

- reinforced concrete solution;

- steel reinforcement;

- wooden structures.

One of the most popular types of grillage is its construction with reinforced concrete. This design is durable and monolithic. To build such a foundation, a pre -installation of formwork is required, while its reinforcement is a mandatory process. In the absence of reinforcement, too much load from the building will lead to bends. Therefore, it is required to lay out the reinforcement with two belts, while one belt has the form of a mesh that is welded from reinforcing bars with a 200-400 mm styling step.

The connection of two belts occurs using special equipment in the form of vertical rod rods. The reinforcement, in no case, should not touch the formwork. To avoid this, use the lining boards that are installed under the lower belt. In order to prevent the shift of two belts, carefully attach them to each other.

In order to avoid the appearance of damage on the foundation during the period of reinforcing the soil, you need a small opening of 200-300 mm, which will be located between the soil and the foundation. This gap is left during the period after installing the grillage and laying the foundation.

DIY Brown Burian foundation: Basic construction processes

The main difference between the brownish foundation from its other types is that the piles do not require installation in the ground and at the same time do not damage its integrity. They are made in it, since after drilling a well, a wooden formwork or a metal pipe is inserted into it, into which a solution forming the base of the pile is poured.

The use of such a foundation on weakened soils is especially relevant. Since ordinary piles should lie down on the hard layers of the soil, which are outside the lower point of freezing, it is not always possible to install such piles, since the depth can be very large. Unlike a boiled foundation, for the construction of which a well and a solution are required, which allows to build a solid base.

The use of a pile of brownish foundation with insulation becomes quite popular. In this case, the use of polystyrene foam is recommended, since it is its rigidity that allows you to interact with the soil. Its fixation is carried out directly on the waterproofing layer. In addition, the use of polystyrene polystyrene avoids swelling of the soil.

Even the construction of a strip foundation using brownish piles is not capable of violating the located communication systems near, since it is not installed deeply, and its service life reaches a hundred years.

The procedure for performing construction work on the equipment of the foundation on brownizer piles is performed at any time of the year. The main condition for its quality is the correct observance of all technologies.

Conducting a calculation of a brownish foundation directly depends on the thickness of the walls of the future building. For uniform load distribution, it is necessary to make the foundation 25-45 cm larger than the wall of the structure.

The next stage is marking. It involves the uniform location of the piles on the site, while the owner of the pile is selected by the owner or builders performing work. It is recommended to install piles in the places of the walls of the walls, and around the perimeter of the supporting structure.

For deep well drilling, special equipment in the form of a pitcher is used. With their help, the process of building the foundation increases several times, and one well is made within one two hours.

With insufficiently dense soil, which is prone to scree, it is recommended to equip the formwork. If the soil has good dense characteristics, concrete is poured directly into the well. Also, as a formwork, in addition to wood, a pipe is used from a twisted roofing material.

The process of choosing piles is quite important, since the duration of operation of the foundation depends on their quality. The basic requirements for piles are strength and durability.

The option of building piles is possible, with an extended base of up to 500 mm. Such a pile is able to withstand a huge load exceeding five tons. The material of the manufacture of piles directly depends on the characteristics of the soil. When installing piles in clay and moist soil, strengthening in the form of casing pipes is required.

The mandatory component in the construction of a brownish foundation is the construction of the pillow. In this case, various materials are used in the form of crushed stone, concrete or stone. This is followed by the process of tamping the pillow and its filling with the main materials.

To ensure additional design strength, a reinforcing structure is used. They are installed in the formwork to ensure the integrity of the pile.

This is followed by the process of installing piles, the length of which is determined using a motorcycle. But, keep in mind that the minimum depth of the pile after the lower point of freezing of the soil is 100 cm. To find out about the depth of freezing of the soil in a certain area, you should resort to consultation of specialists or study the geological map.

The piles protrude behind the surface of the Earth by 30-50 cm. These areas are filled with concrete solution, finished using roofing material and combined with a strapping.

To prevent the soil of cement milk in the soil, you should think in advance about the waterproofing. Therefore, all the walls of the well are pre -evicted by a waterproofing film or roofing material. When using the first option, it is recommended to resort to the welding of the film in the form of a cover that is dressed on the piles.

This method is used exclusively on strong soils. Otherwise, the formwork should be wooden, cardboard, metal or asbestos.

And the last, final process is to fill the foundation with concrete solution. It is most convenient to carry out this work using the mixer. As a solution, fast -hardening cement is used, which is gradually preparing.

In addition to concrete, it is possible to use stones, cobblestones, limestone or sandstone. The main requirement for fillers is the strength and evenness of the stones. To create mechanical vibration and concrete seal, the use of a special drill is recommended. Since even the smallest air accumulations should not be present in Swai.

Buronabish foundation video:

Interesting and useful! Thanks,

Interesting and useful!

Thanks guys.