Lining is a rather popular finishing material, the service life of which is directly ...

|

|

The layout of modern private houses and cottages provides for the presence of the foundation ... |

Buildings and crafts made of wood occupy an important place in national culture, here ... |

Liquid insulation for walls: Features of material and thermal insulation technology

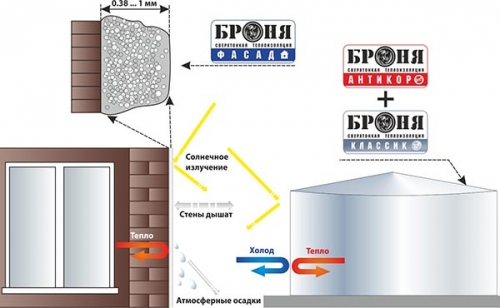

In order for living in a house or apartment to be comfortable at any time of the year, it is important to take care of good thermal insulation during development or repair. In standard apartments of high -rise buildings, nothing of the kind has been provided for, that's why there are now more and more people living on the upper or lower floors, as well as in corner apartments, the walls begin to insulate, trying to save the rooms and save on heating in the winter. The article will talk about a liquid insulation for walls.

Content:

- What is a liquid insulation for walls

- Liquid foam

- Advantages and disadvantages of liquid insulation

- Features of the material

- Warming with liquid insulation

- Additional Information

What is a liquid insulation for walls

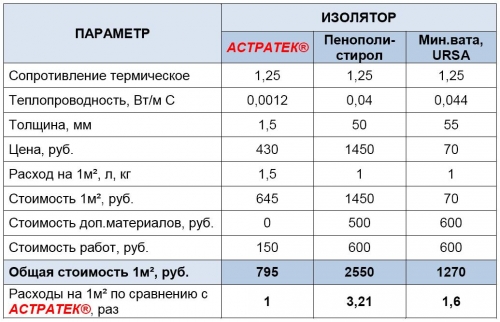

A few years ago, for this purpose, polystyrene, mineral wool and other solid thermal insulation materials were used. New, modern technologies made it possible to create a completely different type of insulation, which has a number of undeniable advantages in comparison with traditional liquid insulation for walls and roofs. What is it, what are its features and how to properly apply such thermal insulation?

- On sale, this thermal insulation material is available in packages resembling ordinary paint in plastic banks of various volumes. In appearance and consistency, it is also similar to paint, which is why the people often call it the insulation paint. Another name is liquid ceramics. In the first and second case, we are talking about the same material, the name does not change its qualities. Also on sale you can find liquid insulation in cylinders, its price will be higher, but it is also much more convenient to use it.

Liquid insulation corundure

- In terms of composition, liquid thermal insulation is the smallest capsules of glass or ceramics, which are filled with air or inert gas. Acrylic polymers are used as a binding capsule. In a percentage of at least 80 percent, microcapsules are made up, the remaining 20 acrylic polymer. The result is a mass in texture and consistency resembling dense dough. These proportions are maintained regardless of the type of insulation, brand and manufacturer.

Liquid insulation armor

Liquid foam

- There is also another type of liquid insulation for walls the so -called liquid foam. What is its difference from liquid ceramics? Liquid foam is a foamed substance that is applied using a hose or a pistol. Another name for this type of thermal insulation of the foam.

- Penoizole is ideal for filling the voids in hard -to -reach places, sealing the seams and, of course, thermal insulation of walls, floor, attics and basements. You can make material directly at the construction site, everything that needs equipment for foaming, raw materials, water and access to electricity.

Advantages and disadvantages of liquid insulation

Compared to mineral wool or ordinary polystyrene foam, Penoizole has a number of advantages:

- in addition to thermal insulation, Penosole provides excellent hydro- and sound insulation.

- this material is not toxic and environmentally friendly;

- penoizole has high fire safety;

- this type of insulation is durable, subject to all recommendations for the manufacture and installation, can last without losing its qualities up to fifty years;

- penoizol is resistant to various microorganisms on it, fungus and mold are not formed on it;

- liquid foam not only retains heat in the house and prevents moisture penetration, but also protects from the invasion of rodents and parasite insects, which is especially important when arranging cottages and private houses;

- the low weight of liquid insulation, due to which it can be used to process the surfaces of the building built on weak soils;

- this material is very easy to install the foam is simply poured into hollow structures or formwork and is left for solidification;

- universality with the help of liquid thermal insulation materials can be insulated with almost any rooms and buildings: rooms and entrances in an apartment building, private residential buildings and cottages, public and office buildings, shopping and sports centers, production shops, warehouses, hangars, etc.

- low price in comparison with other thermal insulation materials. Of course, the cost will largely depend on the manufacturer and brand, as well as on the batch of the purchased goods. But if you conduct an analysis of prices and clarify the current discounts, you can purchase a high -quality imported liquid heat insulator at a very favorable price.

However, this at first glance ideal material has its own disadvantages. Firstly, when pouring horizontal surfaces without pressure, liquid foam gives shrinkage up to 5 %. Secondly, immediately after the installation there is a not very pleasant smell of formaldehyde. Over time, the smell disappears, so this moment can hardly be attributed to significant disadvantages of the material.

- Another important detail: for the full and high -quality insulation of vertical surfaces, the foamolisol must be used in combination with other thermal insulation materials. He independently cannot provide the necessary level of protection against drafts, cold and moisture.

- Meanwhile, the foamyizol is much more economical than the usual foam or mineral wool as a heater. The ten -centimeter layer of liquid foam provides the same quality of thermal insulation as a layer of solid foam thirty centimeters thick, a layer of mineral wool with a thickness of twenty centimeters, brickwork two and a half meters thick or concrete masonry with a thickness of three meters.

Features of the material

- As was said, the main difference between liquid foam is that it can be made directly on the construction site. The raw materials are connected to the water in the proportions indicated by the manufacturer, after which it is foamed to a pasty state in a special machine.

- Further, the material is already completely ready for use. It is most convenient to apply it with a hose with a diameter of 30 mm. Inaccessible sections of a small area are filled through a special pistol. It is also the perfect material if you need to thermal insulation on the designs of the wrong and complex geometric shape.

- Interesting information: There is evidence that this type of thermal insulation materials was originally developed for spacecraft. He had to maintain heat even with absolute zero in outer space. How reliably this is not proven. But liquid foam really has unique characteristics, resistance to atmospheric influences, ultraviolet light, temperature difference, organic solvents and mechanical damage.

Warming with liquid insulation

The technology for applying liquid ceramic insulation and liquid foam is different.

Astratek liquid insulation

In the case of installation of ceramic thermal insulation material, work is carried out as follows:

- first, walls are prepared or other surfaces are aligned, plastered, polished and primed. If there are no special irregularities on the surface, it is enough to simply close up cracks and hollows;

- ceramic liquid insulation in banks is already completely ready to work. It is applied like paint, using a roller or brush. At first, one layer should be applied and let it dry. Then repeat the procedure;

- if a thin wall is insulated in one brick, you need to sequentially apply 4-5 layers of liquid material, each time letting it dry well;

- when warming thick walls from shell or concrete, it is enough to apply a heater in two or three layers;

- the drying of each layer, depending on its thickness and the brand of the material used, will take from 1 to 10 hours. It is not recommended to rush, as this is fraught with subsequent relaxation of the heat -insulating coating. At the end of the thermal insulation work, the walls or floor can be painted at your discretion or decorated with any other finishing materials.

But how is the liquid foam is applied for insulation:

- first, the formwork is mounted on the surface pre -cleaned from dust and garbage;

- then thermal insulation foam is prepared in accordance with the instructions. In order to fill out all the voids qualitatively, it is important to make an accurate calculation of the required amount of material. Liquid foam has the ability to increase in volume when applied under pressure. On the cylinders with the finished mixture, the area in cubic meters is indicated, on the coating of which the contents will be enough;

- the composition is applied on the surface, after which it is left for complete solidification.

There are three ways to pour liquid foam for wall insulation.

- Pouring between the inner and outer wall of the already built house. Thus, you can insulate the building only if there is a gap of 3-5 centimeters between two pieces. Then holes are drilled in the outer wall, the diameter of which is 3-3.5 centimeters. The distance between the holes should be approximately one meter, they are located in a checkerboard pattern. Then the finished composition with the help of a hose under pressure drives into the hole until the foam appears in the hole next door. Work is carried out in the direction from top to bottom.

- Pouring between the walls of the building under construction. Then the liquid insulation is applied in layers depending on the material of the walls.

- Application of insulation between a stationary wall and a false-walled siding, corrugated board, drywall, etc.

Necessary equipment for liquid insulation

- If the work is carried out by the team of a construction company, then they have to have all the necessary equipment. If the insulation is carried out independently, then you will need:

- a device for mixing gas, raw materials and liquids. In this case, you need to choose the unit that can produce raw materials in the required volumes;

- compressor for applying the finished composition.

Additional Information

- A liquid heat insulator is suitable for both internal and outdoor insulation of rooms. With this material you can work at temperatures up to 5 degrees of heat, which is an additional advantage that affects the speed of development or repair.

- After the heat insulator completely dried, the walls and surfaces look as if they were painted with white paint. To date, no manufacturer produces liquid heaters with any shade, so the dye in the composition of the material significantly affects its thermal insulation qualities. If there are no special design ideas, then you should not worry more about the additional finish coating. But if desired, painting or pasting with wallpaper is acceptable.

- If it is desirable to save money as much as possible, you can do all the insulation work yourself. But often, with the simultaneous purchase of thermal insulation material at the company and ordering its installation, the company offers a good discount. Perhaps it will not be possible to save financial resources, but there will be no hassle with delivery and applying the heat insulator, and the freed time can be spent on other tasks.

- To carry out repair work of a small scale at home, it is more advisable to purchase a finished mixture in the cylinders, so the preparation of the mixture independently requires not only the presence of special equipment, but certain skills.

- It is noteworthy that liquid foam is widely used not only for wall insulation, floor and ceiling of residential premises. It is also used to maintain refrigerated refrigerators of industrial refrigeration units, conservation of waste of various types.

- A great advantage of liquid foam is its high vapor permeability - in contrast to solid insulation. If excess moisture accumulates in the room, it will quickly go through the pores of the material, which is why fungus and mold are not growing on the walls insulated with this material.

- When choosing the thermal insulation material, many buyers are embarrassed by the specific smell of liquid foam may seem that the composition of the heat insulator contains substances that can harm human health. But this is completely wrong. Liquid foam is completely non -toxic and completely suitable for use in residential premises.

Liquid insulation video

Summary: liquid insulation is a great way to save several times the costs of energy in the house and at the same time give the walls, ceiling and floor a neat, aesthetic look.