DVP abbreviation woodenage material made of wood, ...

|

|

Plastic windows can be installed in any kind of design: stone, concrete, wood ... |

Almost every owner is concerned about the issue of preserving his crop, which is usually ... |

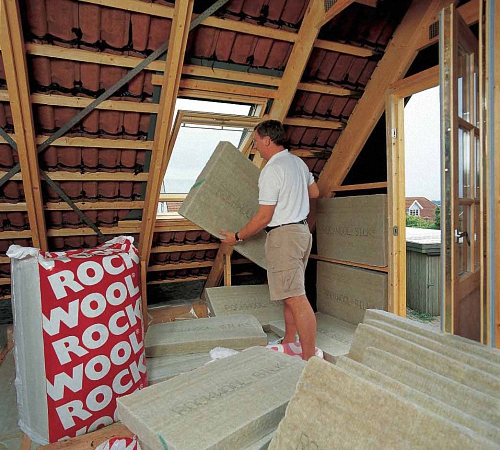

Rockwool insulation: overview of the material, installation instructions

Thermal insulation and sound insulation of the room in which it are installed depend on the quality of the insulation. Choosing Rockwool insulation - heating costs in the cold season are reduced by two or even three times. We will consider further about the features, advantages and installation of this insulation.

Table of contents:

- Production and characteristics of Rockwool insulation and characteristics

- Rockwool insulation: Advantages and scope of use

- Rockwool insulation overview

- Rockwool insulation instructions

Production and characteristics of Rockwool insulation and characteristics

The main component of Rockwool insulation is stone cotton wool, which consists of basalt and gabbro. Let us consider in more detail the process of manufacturing stone wool in order to understand its advantages as a heater.

First of all, the required amount of cotton wool that enters the cast -iron stove is selected. The main fuel material is the coke, due to which the air temperature in the furnace exceeds 1300 degrees. There is a process of turning mineral breeds into a substance of liquid lava. As a result of this process, a liquid is formed, which settles through gravity on special rapidly rotating disk devices.

Disks are engaged in breaking raw materials into small fibers resembling cotton wool. In the process of cooling, these fibers are accumulated in a special chamber, from where they already come out in the form of a cotton carpet.

When the fibers are formed to them, binder and hydrophobic products are added to them. Then there is a transportation of a cotton carpet from the camera to a technological station, where the fibers are divided into small parts and stone cotton wool is formed.

After that, a process called polymerization follows. Its essence is the heating of the cotton wool to a temperature of two hundred degrees and in the addition of a special resin. The material stabilizes before the production of its final processing.

The final stage includes cutting cotton into certain parts, depending on the size and packaging determined by the production plan.

The structure, size and weight of the stone wool Rockwool depends on the production line and the series in which it is released. In addition, the actions of some types of stone wool undergo secondary processing.

This process is absolutely non -waste, the material that remains after the production of mineral wool undergoes secondary processing.

Rockwool insulation: Advantages and scope of use

Consider the main advantages of using Rockwool mineral wool insulation during insulation:

1. Long -term strength - cotton wool, in the process of manufacturing which such rocks as basalt and gabbro are used, is characterized by a high level of strength and durability. And even for several decades, she does not lose her properties. Subject to proper installation and application, Rockwool stone wool does not provide shrinkage, is not subjected to deformation. In addition, this material is stable before moisture, temperature changes, mold and fungus are not formed on its surface.

2. An excellent heat insulator - in the cold season, in a building insulated using Rockwool stone wool, heat is much better preserved, and in summer - cold. Since cotton wool is practically not deformed, it differs in a stable size and elasticity, it tightly adjacent to the surface and does not form thermal bridges or cracks through which heat evaporates. Therefore, the use of Rockwool stone wool as a heat insulator can save significantly on the installation of expensive heating systems.

3. Fire safety is a significant dignity of stone wool. Thanks to the addition of special additives, stone cotton wool is not able to burn, secrete smoke and ignite. It also has fire -retardant characteristics, is not exposed to fire or high temperature

4. A high level of soundproofing is another useful characteristic of Rockwool stone wool. When warming the house, using this material, you do not need to install additional sound insulation, since stone wool very strongly lowers the sound tone in the room.

5. The vapor permeability is the fibrous structure of the cotton wool, despite the fact that it does not pass noise, allows the walls to breathe. Therefore, dampness and mold in insulated walls do not appear.

6. Moisture resistance - fluid processing using special hydrophobic impregnations, makes it stable before water. Rockwool stone cotton wool is able to absorb the liquid at the minimum level, so it takes unnecessary moisture from the air, thus regulating the microclimatic conditions in the room.

Rockwool will constantly improve, therefore, the scope of its products is expanding. Consider the main areas of application of stone wool Rockwool:

1. In the process of construction insulation - stone cotton wool is able to create thermal, soundproofing and fireproof isolation in public, residential and industrial premises. Rockwool mineral wool is used to improve the heat -insulating properties of a flat or beveled roof, both external and external walls, ceiling systems, floors or chimneys.

2. Rockwool stone cotton wool is used as technical isolation, for example, in the process of insulation of equipment, ventilation system, air conditioning, smoke removal, heating equipment, as well as for thermal insulation of boilers or industrial installations. These products are used for thermal insulation of devices operating with any temperatures.

3. It is used to increase the fire resistance of construction structures, such as ceilings, steel structures, ventilation or chimneys, thus increasing the level of fire safety of the building.

4. In addition, stone cotton wool is widespread in the shipbuilding industry. Since in this area there are risks of the appearance of high fire or explosive danger, the correct fire -insulation, performed by stone wool, is of great importance.

5. Rockwool insulation, which is made on the basis of mineral wool, is also used to warm the suspended ceilings.

6. Rockwool is engaged in the manufacture of facade panels that differ in moisture and fire resistance, and are used in the process of lining of facades of buildings for various purposes.

7. With the help of stone cotton wool, devices are made that control noise or vibration. Thanks to the use of acoustic screens or mats, buildings or certain objects are protected from excessive noise or vibration.

8. In the automobile region, stone wool fibers are used for the production of various parts.

9. The use of stone cotton wool Rockwool has found application in the field of agriculture. Stone cotton wool is part of the soil on which plants are grown in greenhouse conditions.

To buy Rockwool insulation, you should contact a construction store or to the supplier of these products. For Rockwool insulation, the price depends on the option of the material, its functional purpose, the purpose of installation and the number of products.

Rockwool insulation overview

1. Mineral wool Rockwul alfarc - products are available in the form of mats, which on the one hand are covered with an enhanced film made of aluminum. Its functional purpose is to enhance the design and decoration of thermal insulation.

2. Rockwall endli - produced in the form of plates or shaped products, there are two types of such plates:

- with the presence of aluminum cladding;

- without her.

It is possible to make such plates with a special finishing layer of fiberglass. The material is used in fire protection of metal structures, such as columns, chimneys, beams or ventilation pipes. Additionally, you should purchase a special glue of the crap, which fixes the plates on the surface of the insulated structure.

3. Rockwood Dachokro Max - is a non -combustible insulation, which allows thermal insulation of the ballast or linable roof. It is characterized by high strength, practical lack of shrinkage, a low level of deformation.

4. Rokvul Dachrok Prof - insulation, which thermal insulates the coatings and roofs of special purpose. It is a non -combustible product, has a high level of moisture resistance.

5. Rockwool Demo - allows not only to insulate the surface, but also an excellent sound insulator. It is used for ventilation of coatings or attic premises with the presence of ventilation, also installed on beam ceilings, suspended ceilings or partitions. Rockwul represents a new method of packing rolls of these products, Rockpack - holds twenty rolls.

6. Rockwool Fasrock - is distinguished by the universality of use in the field of insulation of external and frame walls, as well as ceilings in basements, garages or crossings.

7. Rockwool Fire Doors - use for thermal insulation of doors. This material perfectly protects the doors from fire and does not miss extraneous sounds. The plates differ the same size, made in a rectangular form. On the ribbed surfaces or angles of the plates there are no damage.

8. Rockwool firock - are used in the process of thermal insulation of fireplaces that have cast -iron liners. They are able to withstand a constant temperature up to 600 degrees.

9. Rockwool flexorock - the material is available in the form of elastic cylinders that have aluminum coating and self -adhesive bookmark, which isolates networks with central heating, hot water supply or heating mains, and prevents condensation. Perfectly insulates the knees and bends of pipelines. The adjustment of each cylinder is carried out individually, in relation to the selected place of installation. The advantage of using this material is to accelerate the installation of thermal insulation in the pipeline system.

10. Rockwool Industrial Battsblack - are low -temperature plates that thermo- and soundproof the inner surfaces of the box for ventilation. They are used in the process of soundproofing of muffle muffle or chamber type.

11. Rockwell Lamella Mat - used for thermal insulation, noise punching and preventing the formation of condensate in the channels of the ventilation or air conditioning system. Low -temperature pipes, small tanks, oval surfaces and reinforcing devices are capable of thermal insulation.

12. Rockwul Megar - is an excellent insulation of attic, balcony, suspended ceiling, pitched ceiling or attic.

13. Rockwool Montrrock Max is a heat insulator that is used in the insulation of flat roofs having a corrugated or massive overlap.

14. Rockwul Montrrock pro - creates thermal insulation with a flat reinforced concrete or metal roof. It is used for thermal insulation of the roof with increased thermal requirements.

15. Rockwool Panel Rock - heat and soundproofing the outer walls on which facade cladding with panels or other finishing materials will be produced.

16. Rockwool Rockmatian - isolates pipelines, heating networks, tanks, furnaces, flat surfaces, reinforcement, the temperature of which does not exceed 400 degrees of heat.

17. Rockwool Rockmine - materials that thermal insulation of floors and attic rooms with ventilation, wooden floors from beams, suspended ceilings, and lag floors.

18. Rockwool Ro rack - insulation and sounds the walls of several sobs, attics or attic houses, beam floors and floors on the lags.

19. To create non -combustible floor insulation, which are built on a soil basis or ceilings on a concrete basis use the Rock -Rock Stroke heat insulator.

20. Stone cotton wool supercro - insulations of floors and attic premises, wooden floors from beams, multi -layer external walls, frame walls, and floors on the lags.

21. Rockwool Technocrac - is produced in the form of mineral wool plates, which heat and sound insulate flat surfaces of the horizontal and vertical direction, walls of large tanks and cassette metal structures.

22. Rockwall of the Max Fan - is used in the process of thermal insulation of external walls or high partitions.

3

24. Rockwool Light Butts insulation - is produced in the form of light water -repellent heat -insulating plates. Rockwool basalt insulation is characterized by a high level of recovery, lack of shrinkage, low thermal conductivity and ease of installation. Do not form the cracks and retain a comfortable temperature in the room.

Rockwool insulation instructions

The main subtleties of installing the Rockwall insulation depend on the place of its installation. Consider the option of installing insulation in the attic.

The recommended insulation thickness is 20-35 cm. To begin with, using a roulette you need to measure the distance between the beams in which thermal insulation material will be laid. Further, the mineral wool is cut into the help of a knife to the appropriate parts.

It is recommended to exceed the length of the mineral wool sections by two centimeters so that it easily retains between the beams on its own. Lay the first layer of insulation, pay attention to its adjacency to the edges of the beams. Next, a metal frame is installed, which will become a separator between two layers of insulation.

After the metal frame is assembled, install the pre -carved parts of the second layer of insulation. If necessary, install vapor barrier, lay it over and fix it with a tape. Next, the attic is finished in accordance with the individual requirements of the owner of the room. Installation of Rockwool insulation will save on the heating of the attic in the cold season.

Tips on the insulation of the attic:

- installed slabs should have the same thickness;

- If several layers of plates are installed, then their seams should not match;

- press thermal insulation material as tightly as possible to avoid the formation of cracks;

- With improperly laid thermal insulation, cold bridges form, which lead to condensate, increase heat loss and significantly affect the duration of the use of insulation.