Laminate is a strong and stable coating, but over time the surface can ...

|

|

We warm the bath with our own hands. Tips from the master for the installation of thermal insulation

As you know, every year energy is becoming more expensive. What to do to the owner ... |

Installation of tiles is quite a laborious process that takes a lot of time and requires ... |

The use of fiberboard during repair and construction work. Features of the material, scope and advantages

DVP abbreviation of wooden material made of wood, polymer and adhesive materials. The described products refers to the materials of the economy class. DVP serves for the manufacture of furniture, in repair, construction, in industrial production. It can serve as a replacement for expensive materials of natural origin, replacing expensive, but not inferior in quality.

Table of contents:

- Features of the material fiberboard

- DVP marking and dimensions

- The scope of use of fiberboard and the advantages of the material

- Laminated fiberboard advantages and disadvantages

- Use of fiberboard for floor, walls or doors

- Necessary tools for installation of fiberboard

- Tips for those who buy fiberboard

- How to properly process the fiberboard sheets with your own hands when painting

- Using FEP for external and internal work

- Plywood or fiberboard features of the material

Features of the material fiberboard

For the manufacture of fiberboard, wood waste is most often used, but natural raw materials are used for expensive sheets. Using hot press, wood waste, antiseptics and synthetic resins are mixed to achieve the desired thickness and density. Based on the quality of pressing, such types of material are distinguished:

- The soft this option is used for ceilings and cladding, has a density of one hundred kilograms per cubic meter. It is a competitor to drywall.

- The half -hardness has a density of four hundred kilograms per meter cubic, furniture is made from it.

- The solid has a density of eight hundred and fifty kilograms per meter cubic, irreplaceable in construction.

- The superhand is inherent in a thousand kilograms per meter cubic, universal option for use in car construction, furniture.

- The insulation has low density and is used in the field with minimal mechanical voltage.

- The finishing side has a laminated side and is used to decorate a dwelling or furniture, has a low density, is not applicable for strong mechanical loads.

DVP marking and dimensions

When choosing the material of the fiberboard, you need to pay attention to the labeling of products and many other criteria. For example, soft panels are divided into three varieties with the letter m and numbers from one to three. As for solid panels, they have the following designation:

- T the usual solid dvp panel;

- TP is a solid panel with a coating on one side;

- TS solid panel with the front side of the chips;

- TSP is a solid panel with the front side covering and with the addition of chips;

- ST super -hard panel is ordinary;

- STS is a super -hard panel interspersed with chips on the front side.

Any type of fiberboard has a thickness of three centimeters and two millimeters. The length ranges from two meters fourteen centimeters, up to two meters seventy -five centimeters. The width of sheets is one meter twenty -two centimeters and one meter seventy centimeters.

The scope of use of fiberboard and the advantages of the material

To date, FEP is a very popular material that serves for wall decoration, manufacturing flooring and furniture. The wood composition of the panel preserves heat very well, has high soundproofing abilities, and helps create comfort. The material has a low cost, which favorably distinguishes it from other similar options.

The strengths and weaknesses of the material directly depend on indicators such as thickness and density. Depending on the targets, the soft and various hardness of the product is chosen. The required sheet size and color scheme are also selected.

The material is well cleaned, it is enough to wipe the sheet with a damp cloth, but it is worth keeping in mind that it is impossible to strongly wet the surface of the sheet, synthetic detergents cannot be used.

If it is necessary to sheathe the surface of the walls with the material of the fiberboard, it is not necessary to align the wall specifically for this, the main requirement of the dry surface.

The material has high operational indicators and is durable, and the acceptable cost of sheets makes the purchase of a priority fiberboard.

The surface of the product can be painted or repainted, updating the appearance or to give novelty. The use of decorative plaster is also applicable, which in no way will affect the quality of the material.

DVP belongs to those few materials that have practically no shortcomings. Only one minus of the material is insufficient thickness can be noted. The longitudinal load does not have any effect on the panel, but the transverse will definitely violate the integrity. This requires special accuracy and thoroughness when mounting sheets on the wall. It is extremely important not to leave the fiberboard between the sheet and the wall of the air gaps, because the panel can be damaged in the process of facing.

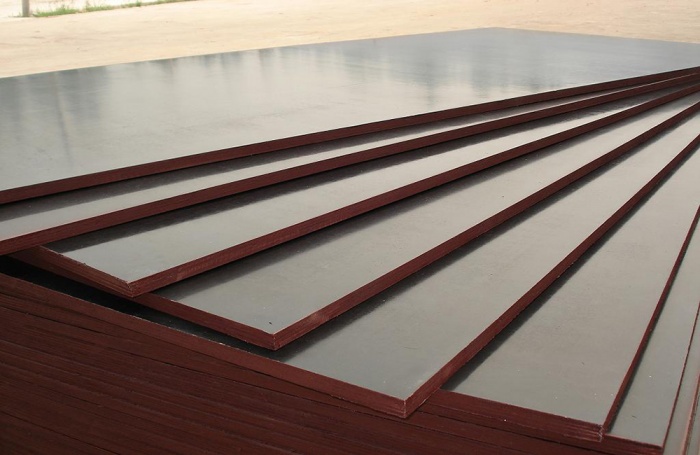

Laminated fiberboard advantages and disadvantages

Laminated sheets of fiberboard are attractive and multifunctional. They are used for furniture production, in construction, during finishing work. The material is made in various color solutions and different textures. The material has a small thickness, very flexible, if you compare it with a sheet of chipboard of the same performance.

The laminated fiberboard panels can be cut into the necessary parts in shape and size. This does not need special equipment. It is enough to use the usual jigsaw, but for speed, it is ideal to apply an electric tool.

The laminated fiberboard sheet is environmentally friendly material, with high technical characteristics, it can serve as a raw material for processing. The cost of the panel is quite affordable, and excellent characteristics allow us to say that the material is a priority for use in construction and repair.

Sheets of DVP laminated have standard sizes, but differ in thickness. The strengths of the materials include its resistance to mechanical influences, a wide range of colors and textures, an excellent imitation of trees of different breeds, immunity to thermal effects. On the surface of the panel you can safely put hot objects.

Summing up, we can say that the advantages of a laminated fiberboard are:

- water resistance;

- ease of processing;

- optimal price;

- homogeneity;

- high strength.

But the material also has disadvantages. The main and serious disadvantage of the panel is the content in the material of formaldehyde resins.

Use of fiberboard for floor, walls or doors

DVP sheets are widely used for wall lining, finishing flooring or making furniture. Before carrying out a particular work, you should prepare correctly: take measurements, think through the nuances.

Whatever you plan to do with the help of fiberboard panels, answer important questions:

- what amount of money can be spent on the purchase of materials;

- make a drawing and calculate the required amount of material, if it is difficult to do it yourself or in order to correctly ask professionals or calculate online using special calculators on construction sites;

- do not rush to purchase the goods here and now, monitor the construction market, you can come across promotions and sales of residues;

- try to use the discount from wholesale purchases, purchase everything at the same time, this will help save on delivery;

- it is not necessary to buy a tool for work, especially if this is a single job, look for friends or rent.

DVP sheets can be attached in several ways: to fixers, mastic or nails. This type of activity does not require special knowledge and can do any home master. The material cannot be mounted immediately after the purchase on any surface. First, the panels are unpacked and lie about two days at room temperature. They should adapt to the humidity of the room. It is not necessary to specifically level the walls, but if they are very crooked, then some manipulations to give them the present -type will still have to.

There are various options for attaching the material, one of the most popular is the use of clamps-zombies. Glue is also used to attach material to the basis. The material can be attached to the frame with nails. What is preferable to choose, you decide, and it is better to get a consultation of a person who is versed in the issue of mounting fiberboard.

Necessary tools for installation of fiberboard

You can prepare a huge variety of items from DVP panels. To do this, you need to collect a set of tools so that nothing distracts from work. The main materials and tools are:

- a plumb line on a kapron rope;

- building level;

- electric drill with various drills;

- screwdriver;

- screwdriver;

- long measuring roulette;

- triangle for handling sheets of fiberboard;

- a felt -tip pen or marker;

- roller;

- strenger for work on top.

For a single work, nothing needs to be bought, you can take from friends or at construction bases renting a tool. But nothing super -reduced for the installation of fiberboard panels is needed. Almost everything is found in the storehouse of a home master.

Of the consumables, you will need:

- panels;

- reiki for the crate;

- final corners;

- fasteners;

- liquid Nails;

- antiseptic solutions;

- primer;

- scotch folga;

- insulation (if necessary);

- putty (if necessary).

Tips for those who buy fiberboard

If you want to make a beautiful and unusual floor, buy decorative material. If you put the material with the prospect of using the upper layer of laminate, parquet and similar, the appearance is not important, you can save on this. When purchasing the material, pay attention to the following points:

- the coating should have the same size;

- there should be no difference in thickness;

- the surface of the sheet should be uniform and homogeneous.

How to properly process the fiberboard sheets with your own hands when painting

In order for the material to serve for a long time, it is necessary to correctly carry out all the preparatory work:

- the surface of the fiberboard must be covered with a primer, let the surface dry, and this is necessary only once;

- the structure of the panel is heterogeneous, so making the coating of paint with the help of a brush is problematic, it is necessary to apply a roller or a spray gun.

If the material requires cutting, you need to practice in small pieces. Only after that they start working on large sheets. Cutting sheets of fiberboard is not easy, some work skill is needed.

Using FEP for external and internal work

DVP is used both in private and in production. The scope of use is diverse:

- insulation;

- soundproofing;

- thermal insulation;

- raising formwork;

- manufacturing doors;

- wall decoration;

- manufacturing of various types of furniture;

- for decoration of ground and underground modes of transport;

- floor decoration;

- manufacture of shields;

- production of boobs.

Very often, the material is used for the manufacture of arches and installations of walls.

Plywood or fiberboard features of the material

The dispute about which material continues to the present. Each product has its own strengths and weaknesses and therefore there is no objective answer. You can use each of the materials, replace with analogues.

Plywood serves for many goals, as it is a universal material. For example,

- wall sheathing;

- floor arrangement;

- roof sealing;

- furniture manufacture;

- mechanical engineering;

- manufacturing of containers;

- shipbuilding.

Sheets are made from various species of trees: birch, aspen, linden, alder, coniferous, maple.

There are two types of plywood: laminated and polished.

The advantages of the material are its properties:

- plywood is an environmentally friendly material;

- has excellent air supply abilities;

- allows you to create excellent sound insulation;

- it has a low weight and does not create a load on the structure;

- it has an attractive appearance, this allows you to make a beautiful decor of the room;

- simple installation system.

As you can see, such material as fiberboard is widely used in construction and repair. The high characteristics of the DVP panels allow you to use the material multifunctionally. If there are a video, what are the main options for using fiberboard, watch a video in which you will find a lot of important and useful information.

Garage Gate Pushkino

Garage Gate Pushkino http://www.vorota.tt34.ru Production of steel garage gates in Pushkino.

8 (903) 715-91-15 Pushkino garage gates for GSK.

Steel gates at the Pushkin Gate with trim under the lining.

8 (903) 715-91-15 Metal gates in the Pushkin Gate with Castian Castles.

The city of Pushkino Gate Garage Steel Gate in Pushkino.

http://www.vorota.tt34.ru garage gates in Pushkino 8 (903) 715-91-15.