Until recently, a chandelier was used to light the room, proudly ...

|

|

How to make repairs in the bedroom to observe the harmony of aesthetics and practicality? ... |

The architecture of modern buildings involves a wide variety of aesthetic ... |

We warm the bath with our own hands. Tips from the master for the installation of thermal insulation

As you know, every year energy is becoming more expensive. What to do the owner of the bath under construction in order to further be able to enjoy the steam room and save on its content? The competent insulation of all structural parts of the bath will help solve this issue: floor, walls and ceiling. This rule is applicable to any residential buildings, but when warming the bath there are secrets that will be disclosed in this article.

Table of contents:

What materials are used to warm baths. Their pros and cons of

Particular attention must be paid to:

- the choice of materials for insulation of the bath;

- determining the scheme according to which it is necessary to thermal insulation of the steam room;

- consideration of various technologies applicable to baths erected from different building materials.

Preparation for insulation of the bath begins with the choice of insulating material. Which one should you choose a choice? The answer lies mainly with the purpose of this building, namely maintaining a high temperature and a created healing atmosphere inside the steam room. Therefore, the use of only environmentally friendly and biologically inert materials is allowed, both for building and for insulation of this structure. Those samples of heat insulators that do not withstand high temperature conditions can distinguish unpleasant odors and gases, spray small particles, are not allowed to use. When we choose thermal insulation for the bath, these factors must be taken into account.

Insulation, the use of which is optimal during the construction of a bath, can be divided into two classes:

- reflecting, which do not release heat outside the room, reflecting the infrared spectrum of radiation back;

- holding that they retain the temperature of the interior, thanks to their own low thermal conductivity.

The insulation of the walls of the bath requires a thorough analysis of existing materials so that the price-quality ratio is most justified.

There are several materials ideally suitable for extreme conditions of the steam room. They will talk about them later.

1. Stone cotton wool

Stone (or differently mineral, basalt wool) is a leader among insulation, which is practically no lack of a rather large volume. It must be taken into account when planning the structure.

Minvat is an environmentally friendly material made in the processing of basalt breed. It does not harm human health or the environment. The finest fibers are formed into layers of various densities and masses. This insulation has truly unique characteristics, thanks to which it has become one of his favorite species among experienced builders.

For the first time, residents of the Hawaiian islands, similar to thin fiber threads after the eruption of one of the volcanoes. The basalt breed was melted in the germ at a temperature of more than 2000 degrees. Later, the conditions of the natural formation of stone fiber were repeated in production. Molted in the stove up to 1,500 degrees of the breed passing through air flows, turns into hard thin fibers. After applying special binders, at 300 degrees and pressure they are pressed into plates.

Technological characteristics of stone wool:

- Many small air pores formed among randomly located cotton fibers determine a high degree of thermal insulation. It ranges from 0.038 0.045 W/K*m.

- If moisture gets on the basalt wool, it does not absorb it, that is, this material has hydrophobic. Also, condensate particles are not formed among the fibers.

- The material belongs to the category of non -combustible. Since it begins to melt only at temperatures exceeding the threshold of +1114 degrees Celsius.

- Street noises will not penetrate the room if the cotton wool is located in the outer skin of the building, since the material has excellent soundproofing qualities.

- Even over time, the mineral wool slab practically does not change the shape, with the right installation they do not sag and retain their original characteristics for many years.

- The chemical and biological inertia of the material ensures its safety from the influence of foreign substances, mold infections and fungi, rot. Although formaldehyde resins are used to fasten the fibers, their content is so scanty that they do not stand out into the surrounding space. In addition to everything, unlike glass wool, the fibers of this material do not irritate the skin and mucous membranes, it is also safe for allergies.

One of the disadvantages of mineral watts, including basalt, is the possibility of settlement of rodents in them.

2. Glass

The structural structure of this material is identical to stone cotton wool. Many small fibers from inorganic glass, intertwining, form air chambers, which perfectly hold heat. At the same time, the vapor permeability of the glass wool remains excellent. The material is available, both in rolls and plates of various thicknesses and sizes.

This material is used much longer than basalt wool, and costs many times cheaper, but technical characteristics are slightly lower. A significant minus of glass wool is its influence on allergy sufferers. Small particles of fiberglass in contact with the skin or mucous membranes can cause itching, burning and other unpleasant consequences. Although it is difficult to work with glass wool, it is necessary to isolate it very well from the penetration inside the room, and in some points it is quite dangerous to health, an indisputable plus of this prickly and not very pleasantly smelling material is the fact that mice do not want to live in it.

3. Foam

Refers to the holding heat to insulators. This is a porous material that, due to the lightness, moisture resistance, inertness to the processes of decay and the reaction to alkali and acid, is actively used as a heater. But it is worth noting that already at 80 degrees Celsius, this material can begin to melt, so it is impossible to use it inside the room of the bathhouse. In addition to everything, rodents love foam very much.

4. Reflecting heat isolators

Foil thermal insulation is widely used for insulation of premises, including baths. There are several of the most commonly used materials with aluminum coating or a metallized film made of polypropylene, which reflects infrared radiation, that is, heat. These are polyurethane foam, polyethylene stoves, mineral wool with foil coatings.

The use of the reflective layer increases the level of thermal insulation capabilities of the material by many times, and also increases its life, since it prevents the ingress of water vapors into the insulator material. The level of soundproofing, resistance to temperature differences, due to which most insulators become unusable, increases.

Attention! A distinctive characteristic of foils is counteracting radiation radiation. You can also not use additional measures of chemical processing of materials.

5. Ecological alternatives

Warms made of glass, peat and paper unified heat -insulating materials. Consider their characteristics in more detail.

- Foam glass is performed at high temperatures. The foamed glass is non -combustible, completely harmless to human health and the environment, has stable forms. With good performance, among its shortcomings there is too much weight and high cost. These factors make foam glass not very popular material.

- Peat blocks have a high degree of heat and sound insulation. With that, this material is completely environmentally friendly, since peat, sawdust and straw are used for its production. Peat blocks do not rot, as they have a bacteriostatic effect. High temperatures and humidity of this thermal insulation material are also not terrible. New material is quite common in production.

- Ecowata is made from waste paper, this is a product consisting of treated cellulose fibers. It is environmentally friendly, but it absorbs moisture strongly, so using it for insulation of the bath is not rational.

It is important to remember that for use in the insulation layer of the bath requires a material that will be environmentally friendly even at extreme temperatures. Therefore, the use of polystyrene foam (foams of various modifications) is strictly prohibited in baths and saunas. When heated, this material can distinguish toxic substances and melt.

Many eco-materials based on natural components (moss, reeds, straw, etc.) are also not recommended, due to the danger of fire or mold formation.

DIY Bath insulation

The installation of heat -insulation with your own hands in the bath requires compliance with certain rules:

- Apply insulation in accordance with the used material when erecting walls.

- Install the foil insulator with a metal film inside the room.

- Propine all the joints of the foilizol and tightly invest insulating plates. This is necessary so that there are no cold bridges.

- The thickness of the insulation layer should not be more than the thickness of the bars of the crate.

- Do not violate the procedure for installing the thermal insulation layer of the walls of the bath.

Any construction, including the bathhouse, can be insulated outside and inside. The purpose of these works is different.

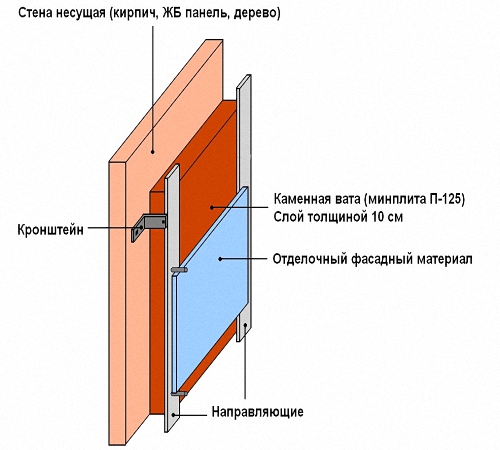

1. External insulation. It helps to preserve the wall of the bath in its original form, does not allow the walls to dive, prevents the appearance of fungi and mold.

2. Internal insulation helps to improve the effect of external insulation, and also holds heat inside the steam room.

In addition, when building a bath, it is necessary to perform an independent installation of the insulation on the floor and the installation of insulation on the ceiling.

1. Wall insulation

Consider how the insulation of the bathhouse is arranged from the inside. The scheme is similar to external insulation, but has certain differences.

- Metal profiles, or bars of the required thickness, are attached to the wall, so that the insulation is freely laid into the frame. But there should not be cracks between his mats. Ideally, the step of the crate should be 2 cm less than the width of the insulation.

- It is better to use nails, not self -tapping screws for attaching crate in wooden houses.

- The frame of a metal profile is a little more difficult than wooden, but the result will be much better. In conditions of humidity and fever, it will last longer. If wooden bars are used, they are recommended to be treated with special impregnations.

- For internal thermal insulation, it is important that the foil part is located inside the room. If material is used without an aluminum layer, then a vapor barrier film is laid on top of the insulation.

Important! The vapor barrier layer or foilizol should be carefully glued with metallized tape over all seams so that moisture does not get into the thermal insulation.

- On top of the insulation layer, the elements of the finish are attached. The best option for baths is the lining. It should be remembered that there should be a small air layer between insulation and external trim (about 1 cm will be enough for air circulation).

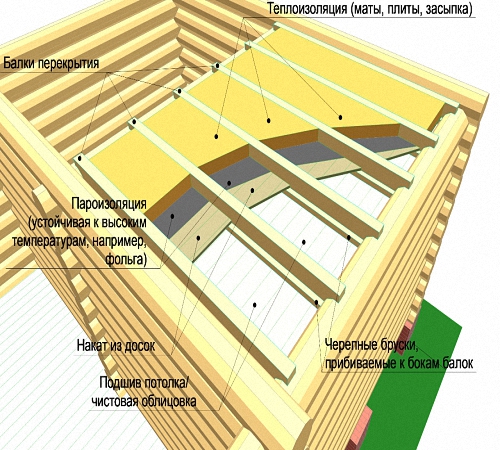

2. Overlapping

Since the maximum amount of heat goes through the ceiling from the steam room, it should be isolated most carefully. If possible, laying the heat -insulating layer can be carried out at the top of the ceiling. From the inside it will be necessary to place a layer of vapor barrier or thin foilizol. If the roof of the bath does not allow work on the ceiling overlap, all stages of isolation are repeated in accordance with the insulation of the walls.

A larger layer of thermal insulation must be laid on the ceiling. Fixing it from the inside, it is advisable to use fungi mounts, since the optimal thickness for mineral watches is 20 cm.

3. Warming of the floor

Cozy and stable warmth in the bath can be achieved if you devote the insulation of the floor, doors and windows enough attention. The following work is carried out for the insulation of the floors:

- the aligned and compacted earthen floor is filled with screed;

- the next layer of waterproofing (usually roofing material or dense polyethylene, which must be overlapped and seams glue);

- laying the heat insulator (expanded clay or sheet, fibrous heater);

- another layer of waterproofing is laid on the same principle;

- the finish layer of screed is poured.

Important! The floor in the bath must be arranged with a small bias and laid out the originally drainage system. It is also necessary to pay special attention to the quality of the finish fill so that water does not fall into the insulation.

There is no particular difference in principle of isolation of the internal surfaces of the bath. When using expanded clay for floor insulation, the calculation is made depending on the thickness of the walls. So, a layer of insulation should be at least twice as much as the thickness of the walls. But if possible, you can make it more.

You can familiarize yourself with the features of the thermal insulation in more detail by watching the video: We warm the bath with our own hands, which is at the end of the article. The video describes in detail all the stages of insulation of each structural element of the bath.

During the construction of the steam room, it is necessary to think about external insulation. Its features will depend on the material of the construction of the walls. The best option will be the systems of ventilated facades with the installation of thermal insulation materials, which have already been mentioned above.

Having conducted high-quality insulation of the bath with your own hands, both from the inside and outside, the owner will be able to truly enjoy healing bath procedures, relax with the body and soul in a cozy and warm bathhouse.