Thermal insulation of any building, whether it is a garage, an apartment or a country house, requires ...

|

|

The wood is rightfully classic for decoration of the room. Before ... |

When building a new house or the device of an old, an important part of the repair work ... |

Wall insulation with polystyrene polystyrene wallpaper with your own hands. Advantages, disadvantages, manufacturers of polystyrene wallpaper

Along with rising energy prices, the issue of thermal insulation of housing is becoming more and more relevant. Manufacturers of building materials introduce new technologies and offer non -standard solutions. One of these methods is insulation wallpaper. Material can be used as a finish covering walls or act as a substrate for decorative cladding.

- Foams of polystyrene wallpaper: Pros and cons of polystyrene wallpaper

- Nuances of choosing wall rolling insulation

- Wall decoration technology by heat -insulating wallpaper

- Review of popular manufacturers

Foams of polystyrene wallpaper: Pros and cons of polystyrene wallpaper

To date, the polystyrene polystyrene wallpaper is rarely used. Innovative material is used as a warming substrate for decorative wall decoration or as a finish coating with thermal insulation qualities. The composition of the insulated wallpaper: polystyrene foam and paper layer from the outside.

Characteristics of a roll heat insulator:

- density of 200-300 g/sq.m;

- the thickness of the canvas is 3-10 mm;

- roll length 10-15 m;

- width 0.5-1 m.

The main advantages of wallpaper from polystyrene foam:

- Thermal insulation ability. Important quality of polystyrene substrate foam maintenance in the room. The effect of roll insulation with a thickness of 6 mm is comparable using a brick barrier of 12.5 cm.

- Noise pitch. The level of sound exposure from the side of the street or neighbors depends on the thickness of the insulation substrate of the noise effect is significantly reduced. The effect can decrease within 21 dB.

- Aligning effect. Preliminary wall cladding with heat -be) will hide minor surface defects.

- Environmental friendliness. The material does not contain a freon, butane and, as it is operating, does not emit harmful volatile components into the atmosphere. Additional plus the inappropriateness of rodents and insects.

- Availability. The thermal insulation of the walls with wallpaper will cost not expensive, and the expended funds will pay off by a noticeable savings economy.

The rolled insulation is simple in installation, the canvases of the polystyrene foam smoothly lie down on the walls and easily join each other, forming the structure persistent to ruptures. However, such a method of thermal insulation is not devoid of disadvantages.

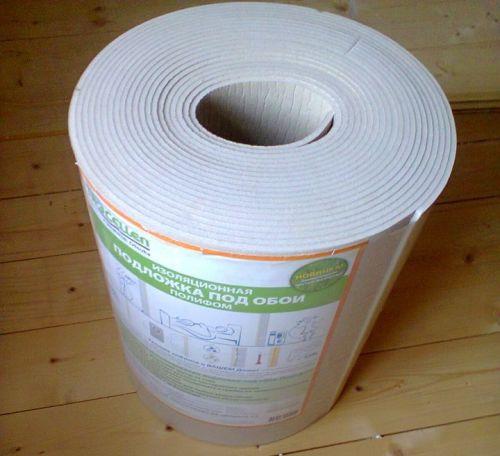

Wallpaper from polystyrene foam: photo

Cons of wallpaper from polystyrene foam:

- The probability of accumulation of condensate. Like any method of internal thermal insulation, the sticker of thermosos shifts the dew point in the direction of the room. This becomes the cause of the accumulation of condensate between the layer of insulation and the wall. To avoid freezing, it is advisable to provide additional external thermal insulation of the building and high -quality ventilation of the room.

- Ignorance. Foam polystyrene substrate of the fuel. However, the degree of ignorance and smoke formation depends on the qualitative composition of the material and the presence of anti -pireen impregnation. Some manufacturers are trying to minimize the fire hazard level, releasing a self -adjacent product.

Nuances of choosing wall rolling insulation

The construction market offers several types of thermal insulation substrate. The most in demand: polystyrene foam, polyethylene and cork materials.

Distinctive features of each species:

- Foam polystyrene. Not hygroscopic, affordable, durable and soundproofing. Due to the presence of air bubbles, the material absorbs vibrations well. The lack of use is poor adhesion with smooth walls. This quality is minimized in polystyrene foam substitutes with an outer layer of cardboard. The material is resistant to the humid environment and the effect of the fungus, but its thermal insulation qualities are inferior to the plastic substrate.

- Polyethylene. A panel from the filmed cells with air. Foamed polyethylene on both sides is laminated with paper. The elastic, light, plate material has a high density (30 kg/cubic meter) and low thermal conductivity (about 0.038 W/MK). The most common polyethylene substrate by the polyphus.

- Cork insulation. Natural heat -insulating material recommended for use in children's rooms and where people who are prone to allergic reactions live. Travel characteristics: density 100-120 kg/cubic meter, thermal conductivity is 0.04 W/mk, the thickness of the substrate for wallpaper 10 mm.

Camping thermal insulation increases the temperature in the house by 2-3C in the winter, and in the summer it helps to keep coolness in the room. Disadvantages of natural insulation: high cost and the need to use special glue.

The reusable application of wallpaper on roller heaters is permissible with the preservation of the declared properties of the heat insulator. Paper lamination substrates are well held on the walls, foil products are better reflected in heat.

Advice. High -quality insulation is elastic, elastic and dense. Before buying, the substrate should be felt and evaluated for gap if the material is easily torn, then it should not be purchased. Safe thermal barrels should not have a pungent odor

When buying a substrate, the color of decorative wallpaper must be taken into account. For light colors, it is better to choose a white insulation optimal base for wallpaper of any color.

Before choosing wallpaper from polystyrene foam, it is necessary to evaluate the required degree of thermal insulation. For decoration of adjacent walls, thermal wallpaper is enough 3-5 mm thick. The material will provide better noise reduction and better insulation.

Wall decoration technology by heat -insulating wallpaper

The procedure for installing thermosos involves mandatory preparation, primer of the walls, the choice of suitable adhesive composition and compliance with the methodology of gluing insulation.

Necessary materials and inventory

To perform finishing work will be needed:

- insulation substrate;

- glue is suitable for a composition designed to work with heavy wallpaper; When calculating the quantity, it must be taken into account that the glue will be applied twice on the pasted surface and wallpaper;

- the putty for aligning the wall is selected in accordance with the type of base;

- deep penetration soil warning the appearance of mold;

- spatulas of different sizes;

- tape for finishing the joints of thermo -barrel paintings;

- crush roller with a low pile;

- construction knife;

- measuring instruments (roulette, level);

- soft rag;

- glue roller.

If you need to remove old wallpaper, you can use a sharp knife or scraper.

Surface preparation

Preparatory measures can be divided into several composite stages.

Stage 1. Removing the old finish:

- Moisten the surface and leave for 15-30 minutes.

- Substantiated wallpapers to lift with a sharp tool and remove from the wall.

- If the measures taken are not effective, it is necessary to use special washing.

Stage 2. Elimination of defects. Apply putty to the surface with a wide spatula, smooth the cell. After drying the layer, the wall must be polished and discouraged. Evenly apply the primer in one or two layers (depending on the porosity and looseness of the base).

Subsequent actions must be proceeded after two to three days, provided that the primer dries completely. Optimal conditions for further work:

- temperature from +10C;

- humidity within 70.

Gluing the insulation substrate

Before starting the installation of thermosos, they must be prepared:

- Measure the height of the room.

- Dissage the insulation on the floor and mark the cuts of the cut. In this case, it is necessary to leave a supply of 2 cm for the final trim after gluing the wallpaper to the wall under the ceiling and floor skirting boards. To arrange acoustic and thermal insulation, the wall -floor laying method is used - the substrate strips are placed on a wall with a lowering of 15 cm. The finish flooring is subsequently mounted. This method reduces the likelihood of cold areas.

- After cutting, leave sheets of insulation lay down and straighten under your own weight.

Gluing technology:

- Knead the adhesive solution, observing the proportions recommended by the manufacturer.

- Apply glue to the inner surface of the strip, leave for 5-15 minutes for impregnation (the exact period is indicated on the packaging of thermal insulation wallpaper).

- Process the wall, capturing the area wider than the size of the panel.

- Apply the insulation to the wall, flatter, conducting a soft roller or plastic spatula in the direction from top to bottom. Remove the excess glue with a soft sponge.

- The level to check the verticality of the first strip on it will be placed the rest of the elements.

- The second canvas is added closely with the first cut, avoiding the appearance of hillocks.

- The polystyrene background foam bend at the corners cannot be connected to the wallpaper. The slots that appeared must be filled with sealant.

- The joints of the joints should be covered with adhesive tape or painting tape.

Finished decorative decoration

When choosing wallpaper to cover the insulated substrate, preference should be given exclusively dense options. Thin paper products are not suitable, as the joints can disperse over time.

Procedure:

- Cross wallpaper with a margin for circumcision.

- In terms of level or plumb line, repulse the vertical line for an even location of the first strip.

- Apply glue to wallpaper and wall.

- Apply the first canvas to the surface, leaving over the entire area and exposing the air.

- Cut the excess wallpaper, aligning the adjoining line with the wall and floor from above and below.

Review of popular manufacturers

A wide range of thermal substrates indicates the demand for the material. Among consumers, foreign and domestic brands have proven themselves well: Thermo-Tab, Eco-Tap, Eco-Heat, Globex, Polf.

Thermo-Tab. The insulated wallpapers of Izopan (Ukraine) are produced with a thickness of 3 mm, 5 mm and 6 mm. The basis of the material is polystyrene. The material is neutral not exposed to microorganisms and does not distinguish harmful substances.

Thermo-Tab insulation is suitable for the use of household and residential premises. Estimated cost is about 9 cu/roll 6 mm thick.

Eco-tap. The heat -insulating substrate for the wallpaper is produced with a thickness of 3 or 6 mm. The basis of the material is foamed polystyrene. The basic characteristics of the Eco-Tap at 6 mm:

- density of 20 kg/cubic meter;

- the middle class of thermal conductivity is 0.06-0.115 W/m*C (1 mm of the substrate corresponds to 20 mm brick, 10 mm foam concrete or 40 mm of a reinforced concrete wall);

- roll length 10 m, width 50 cm;

- estimated cost 3.5 cu/roll.

In addition to manufacturers of polystyrene wallpaper, polyethylene substrates are in demand:

- Ecohite. On both sides of the polyethylene foam, white paper is applied. The material is popular thanks to a number of undeniable advantages:

- strong homogeneous structure;

- universality is applicable to wallpaper of any color;

- increased level of moisture resistance;

- neutrality to solvents;

- the presence of antifungal impregnation;

- thermal conductivity in the range of 0.031-0.033 W/m*K;

- almost zero vapor permeability;

- it is possible to use for gluing a conventional PVA Clair;

- the duration of the service is about 50 years.

- Polit. The representative of the eco segment, produced by a thickness of 4-8 mm. The material is certified according to the complex system ISO 9001. The main characteristics of the canvas 5 mm thick:

- the end of thermal conductivity is 0.043 W/m*K;

- the weight of thermosobiev is 230 g/sq.m;

- density 30 kg/cubic meter;

- combustibility category - G4 (rapidly flammable material);

- the insulation reduces the cold radiation of walls, prevents the appearance/spread of mold and does not absorb moisture.

An alternative solution to the crying walls is the gluing of the foam (analogue of the polyfom). Wallpaper of the rack alcohol, alkalis, gasoline and other aggressive substances. A chemically sewn polymer is characterized by minimal deformation and low thermal conductivity.

Of course, the internal cladding of walls using heat -insulating wallpaper will give a proper effect and increase the energy efficiency of the house. However, to achieve a more tangible result, it is necessary to act in a comprehensive and additionally insulate the building from the outside.

Wall decoration with polystyrene foam wallpaper: video