One of the most vulnerable places in the house where heat loss most often occur is ...

|

|

When installing or updating the heating system, it is important to correctly decide on ... |

Modern production technologies provide the opportunity to make ... |

How to make a wooden skirting board with your own hands

The wood is rightfully classic for decoration of the room. First of all, it is appreciated for environmental friendliness and high mechanical strength. The wooden skirting boards perfectly complement the floor from the parquet, harmonizing with it. There are a large number of purchased wooden skirting boards. Self -manufacture of skirting boards will not only save money, but also opens up the possibility of choosing the optimal shape and color of the skirting board. We will learn about how to make a wooden skirting board on your own.

Table of contents:

- Drill floor skirting board: advantages, features and characteristics

- Work with wooden skirting boards: Material for the manufacture of skirting boards

- How to install wooden skirting boards indoors

- How to make a corner on a wooden skirting board: installation of skirting boards

Drill floor skirting board: advantages, features and characteristics

Wooden skirting boards are recommended for use on natural floor decoration options. For carpet, linoleum, tiles, a plinth made of plastic is more suitable.

The white wooden skirting board is preferable in dry rooms, such as the bedroom, the living room, the nursery. They are installed on wooden or parquet floors. Among the advantages of such skirting boards are noted:

- environmental safety;

- naturalness;

- attractive appearance;

- High strength.

There are two main options for wooden skirting boards:

- massive;

- Openced.

The first option is more expensive. For its manufacture, valuable rocks of wood are used in the form of oak, beech, cherries, alder. Cheaper models are made of pine or spruce massifs. This skirting board is suitable for expensive flooring. It is characterized by a long service life, resistance to mechanical damage, the complexity of the installation, and high cost.

The veneered version of the baseboard is a cheaper option. For its manufacture, pine or spruce wood is used. Valuable wood rocks are applied to the base from above. In appearance, the skirting board is an identical massive, however, operational characteristics are at a lower level.

Another version of wood skirting boards is a flexible baseboard. As a basis for the construction of the skirting board is ash, oak, beech and other solid varieties of wood. Special wood processing technology allows you to obtain elasticity properties. To store such a skirting board, special packaging is necessary, the interaction of the skirting board with air leads to its solidification in a certain form.

The pricing policy of wood skirting boards is determined by the type of wood used in the process of their manufacture. The cheapest options are pine skirting boards, and the most expensive are oak ones. The best option is larch, wood has excellent performance characteristics, almost the same as oak, however, the cost of such a skirting board is not much higher than in pine.

After the installation of wooden skirting boards, they must be covered with varnish, which provides additional protection of the coating from moisture, temperature changes and other factors.

In addition, there are a huge number of types of skirting boards in relation to their shape. The most popular plinth that has a triangular cut. Using modern woodworking equipment, it is possible to create models of skirting boards with a variety of cuts, patterns.

Standard skirting boards have a base height of 1-2.5 cm. The height of the skirting boards themselves is not limited and is from 4 to 30 cm. Choosing the size of the skirting board, it is necessary to take into account the height of the ceiling in the room. High skirting boards are suitable for rooms with high ceilings.

Work with wooden skirting boards: Material for the manufacture of skirting boards

The classic solution is the manufacture of a skirting board from the same wood breed from which the floor is built. However, with the help of modern devices, it is possible to successfully combine several species of wood among themselves.

Coniferous rocks are used for the manufacture of cheap skirting boards. Most often, pine is used as material. Soft wood array is light in processing and cutting. Due to the presence of a light texture, the skirting board easily takes any coloring composition. Spruce plinths are rare, since this material is difficult to process.

The skirting board, for the manufacture of which the larch is used are the most popular, thanks to a successful combination of price policy and quality characteristics. This material is well opposed to moisture, is not rotted and is used even in the kitchen and in the bathroom.

Wooden skirting boards from oak are elite options. They have unique strength and the highest durability. The use of skirting boards from bleached or artificially aged oak rocks allows you to give the room sophistication and solidity.

Book has the same performance as oak, but differs from it in color. Book plinth has a pinkish texture that is not suitable for every interior.

If you want to get a pleasant brown color, we recommend that you make a walnut skirting board with your own hands. This type of tree has a special elasticity, suitable for making a flexible baseboard. It is such a skirting board that will allow you to arrange extraordinary in the shape of the wall. The composition of the nut contains iodine, which has a beneficial effect on the atmosphere in the room, improving it.

The light color of the olive can be obtained from ash. This type of tree, as well as the nut has high plasticity, the texture of the tree is clear and has veins.

The skirting boards from alder is not recommended to make, since this material has no plasticity and is afraid of excessive humidity. The presence of temporary dampness, instantly destroys the tree.

The original coloring of the red tree makes it popular in the manufacture of skirting boards. In addition, the array is durable and light. Although the cost of such wood is quite high compared to all of the above options.

For the manufacture of skirting boards for the bath, linden is best suited, as it is distinguished by good plasticity, resistance before moisture. Cherry is also highly popular. However, its only advantage is a gradual color change, during operation.

Keep in mind when choosing a skirting board without varnish coating, after processing it with a varnish composition, it will change the color. This fact should be taken into account. If you are going to open the baseboard with colorless varnish, then in order to find out what color the baseboard will get, soak it with water.

How to install wooden skirting boards indoors

Wooden skirting boards compared to plastic are more rigid, so the installation process has certain subtleties that you need to adhere to. In order to make a wooden skirting board yourself, you must have a certain experience with a carpentry tool. In addition, it is necessary to choose the right quality material for work.

For example, the optimal moisture of the board should be 17%. Raw wood is poorly polished and milling. Choosing wood should also pay attention to its appearance. If knots are present on the boards, chips, deformations, then it is better to refuse their purchase.

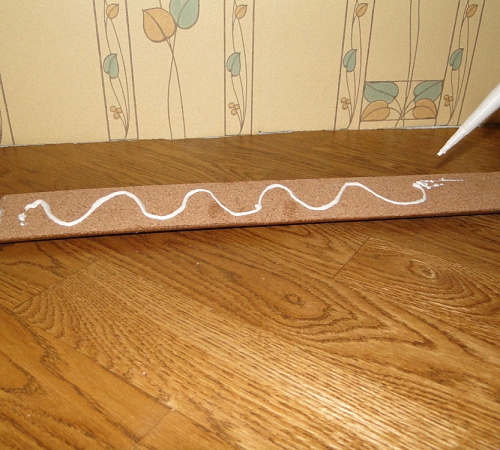

The main type of wood processing before the manufacture of a skirting board is its milling. At this stage, special equipment will be required - a milling machine, and skills in working with it. To make wooden skirting boards with your own hands is quite costly both in time and money. However, the only advantage of this process is to obtain an individual skirting board that will satisfy all the preferences and desires of the owner of the room.

Before fixing wooden skirting boards, it is necessary to determine the amount of material necessary for the room. To do this, determine the length and width of the room, multiply the amount of these values \u200b\u200bby 2 and add a supply of 20-30%. The supply is necessary to compensate for trimming and docking.

I begin to install the floor up wire wooden wooden flooring from the corner located next to the door. Next, continue moving by clockwise. Keep in mind that, unlike plastic skirting boards, plugs are not installed on wooden, hiding defects in the joints of the planks among themselves. Therefore, an important role in the further aesthetics of the coating is played by a qualitative docking of skirting boards. In the presence of perfectly even corners in the room, use the stupid for pruning skirting boards. With its help, cut two strips at the angle of forty -five degrees and dock them together.

If the corners in the room are uneven, then it is necessary to attach two plinth planks in the corner. Next, monitor the line of their intersection, make markings on it and cut the skirting boards along the previously intended line. In order to make joints between the straight segments of the skirting boards invisible, it is necessary to cut them in compliance with a certain angle of inclination.

To fix the planks, use screws with which clips are installed. The bar is mounted on the clip and holds on it. In order to hide holes for self -tapping screws, use wood putty, the color of which exactly coincides with the color of the skirting board.

The interval between the installation of the clip is about 50 cm. There are several options for these fasteners, the principle of which is the same. In any case, self -tapping screws are used to fix clips on the wall. The clip is installed on the bar, holding it.

How to make a corner on a wooden skirting board: installation of skirting boards

The ideal angle in the process of connecting the wooden planks of the baseboard can only be obtained when the angles in the room are located at right angles. In this case, the first bar is processed at Stusl at an angle of forty -five degrees.

Next, you need to install it to the wall and attach the second bar. Mark the marking according to which the skirting boards will be interconnected without the formation of cracks. If the corner of the cut of the second bar is not forty -five degrees, then the angle in the room is uneven. In any case, adhere to the previously performed markings according to which the cut is performed.

In the presence of a gap between the strips, hide it with a putty on wood. To remove a large gap in size, use a grinder with a special nozzle, with which the skirting boards are made. Next, fix the planks on the wall.

There are situations when the skirting board is installed not only in internal, but also in the external corners. In this case, the main thing is to decide on the side of the cut. First, saw the first bar, attach it in the corner and make the marking according to which the cut of the second skirting board is performed. Follow the absence of cracks.

Massive profiles are fixed on the wall in two ways:

1. Self -tapping screws.

In the process, the presence of a drill or perforator will be required, which will help make holes for the dowel. Attach the baseboard to the wall and mark under the screws, the interval between the fasteners is at least half a meter, if the walls are curved, then it should be reduced.

If the wall is made of concrete, then the diameter of the drill is six millimeters, on the walls of porous materials, it must be reduced. If the walls are made of drywall or wood, then we recommend using wood screws.

Fix the skirting board using self -tapping screws on the wall in order to hide the recesses under self -tapping screws, use wood putty.

2. The use of liquid nails.

This method of installation of wooden skirting boards is less laborious. However, for its execution in the room the walls should be perfectly leveled. Apply liquid nails to the skirting boards with a special gun and fix it on the wall, holding for several minutes.

After completing installation work, it is necessary to go to the putty of the skirting boards. To do this, wipe them with a damp cloth in order to remove dust. The tone of putty should completely coincide with the tone of the baseboard itself. Keep in mind that after drying, putty will change the color. Therefore, apply a little composition to the remains of the baseboard and wait for its drying. Bend the baseboard two or three times, before the start of each putty, make sure that the skirting board is completely dry. Next, the plinths and their wiping with a damp cloth are grinded.

The next processing process of plinths involves the implementation of its varnishing. To do this, install a painting tape on the floor and on the walls, which will prevent varnish on other surfaces. Apply one layer of varnish, wait for its drying and repeat the process again. In the process of drying the varnish, do not allow drafts and sharp changes in the temperature regime in the room. Unevenly dried varnish will adversely affect the duration of the operation of skirting boards.

If you used a purchased skirting board, then it must be painted in a certain color, since most often purchased options for wooden skirting boards are white. The paintwork paint should be designed to cover wooden products. It is applied in several layers. At the same time, after staining, apply one layer of protective varnish on the baseboard, which will prevent its destruction under the influence of moisture and other destructive factors.