Nowadays, the sphere of building materials develops very quickly and gives the world everything ...

|

|

The concrete floor, along with other types of flooring, needs waterproofing. Concrete itself ... |

Repair of a removable formwork is an important process that must be carried out regularly ... |

DIY floor insulation with your own hands

The bathhouse or sauna has already been built, and the heat consumption is too large? Would you like the room to warm up faster and warmer to last longer? Or construction is in full swing, but the tasks are the same. The ceiling, walls, floor - all parts of the structure of the bath in both cases need to be insulated. Although, there is an opinion that the insulation of the floor in the bath is a waste of time and money. Moreover, due to insulation, the floors begin to rot and are quickly destroyed. There is a share of truth in this, but modern materials and proper insulation of the floor of the bath allow you to avoid these troubles and make the room even warmer, and the washing process itself is much more comfortable.

The process of insulation directly depends on the flooring. Two options are possible: concrete or wooden floors.

Concrete floor in the bath

Wooden floors in the bathhouse

In any case, the insulation of the floor of the bath with your own hands with the correct sequence of actions is quite real and does not require mandatory contacting specialists.

Concrete floor insulation in the bath

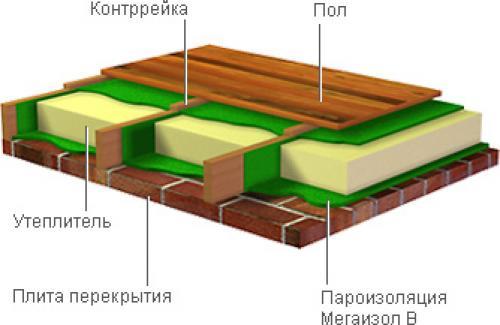

If you decide to equip the concrete floor, it is assumed that at first the foundation is poured on which the concrete floor slab is placed, the third layer is waterproofing, on the top of which the insulation is laid, then a screed with a reinforcing mesh, the sixth layer of the underlying system, the latter is laid by ceramic tiles. Since the tiled floor is slippery and cold, it is advisable to additionally cover it with a wood grill, which, if necessary, can be removed and dried.

When warming the concrete floor in the steam room, perplit, glass wool or expanded clay are most often used as a heat insulator. The layer of insulation is laid between two layers of concrete. An exception is expanded clay, which is kneaded directly into concrete. If perlite is selected as a heater, then in the process of working with it it is necessary to close the room, because Because of its lightness, the material can easily fly up. However, due to low thermal conductivity, perlite is often used to achieve the goal. First, it is necessary to mix perlite with water, in a ratio of 2: 1, cement is added to the resulting solution. The mixture is thoroughly mixed to a homogeneous mass, and then approximately 0.5 liters of water and an additional perlite bucket are added to it. In the resulting insulation solution, water should not be released. The finished mixture is laid out with a thin layer on a concrete plate. In order for the solution to completely dry, it will be needed for about a week, after this period the second concrete layer is poured.

A modern alternative to mineral wool and bulk insulation is polystyrene foam. In the process of insulation, slabs with a thickness of 10 to 25 cm or sprayed material are used. The recommended thickness is 10-15 cm. The most popular brands:

- Natur-III-PZ;

- STYRODUR;

- Ursafoam/glascofoam;

- URSA XPS Natur-III;

- Penopropliex.

This material has a lot of positive qualities, namely: lightness, wear resistance, excellent thermal insulation, economy in use.

However, some difficulties may occur in the process of floor insulation in the bath using foam, because A perfectly flat base is required. The process of insulation using polystyrene foam is similar to the above.

Wooden floor insulation in the bathhouse

Although the concrete floors will last longer and are more convenient to operate, many lovers still stop their choice on wooden floors. In addition to the fact that such floors are environmentally friendly, they, unlike cold tiles, retain heat for a long time. The most suitable wood of wood are larch, fir and pine. Boards from oak, linden, aspen and poplar are not suitable. It is believed that the tree in the bath begins to rot quite quickly, but with the right approach and treatment with an antiseptic, the floors can be protected both from decay and from the fungus. It is not recommended to treat the floor directly in the steam room or other substances, since harmful evaporation negatively affect the skin and lungs. In this room, it is enough to use well -dried boards that do not rotten, but darken over time.

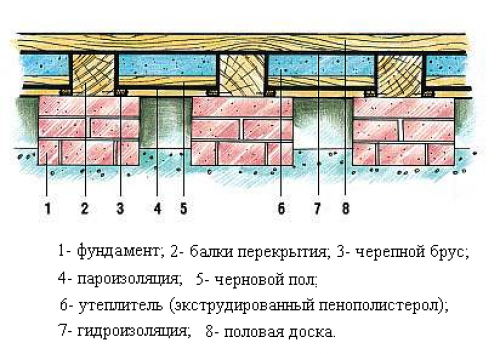

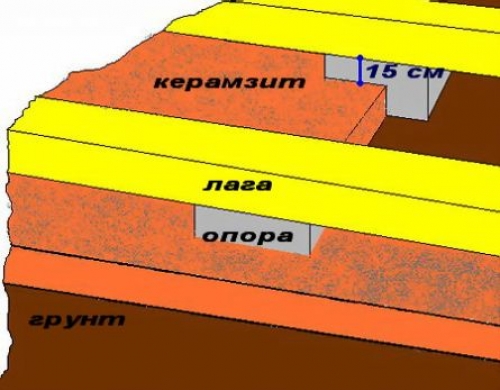

The design of the wooden floor in the bathhouse is not much different from the concrete, only instead of the floor slab, beams are placed, and on top of them a skull. Directly the insulation goes above the draft floor. As a heater in this case, you can use the same expanded clay, sand, slag, fiberglass or mineral wool mats.

The vapor barrier is most often performed by Permamine.

When laying the floor in the bath, one must not forget about the drainage of water. Lovers of steam rooms sometimes do not nail the wooden floor boards using nails, using the so -called removable floor. As soon as the boards are wet, they are removed and put on drying, and spare are applied to the floor. There is also a special technique for drying a wooden floor.

Whatever option for the floor for the bath you choose, it is better to insulate it during the construction process. How to do this with the help of stone wool Rockwul, look at the video.