The active development of technology allows today to create unique construction ...

|

|

Let many people put PVC windows in their homes today, but most people, especially in ... |

When arranging a dwelling, it is not the last place to vapor barrier of the walls and ... |

DIY waterproofing waterproofing

The concrete floor, along with other types of flooring, needs waterproofing. The concrete itself has some water resistance, but with prolonged contact with moisture, it begins to collapse, and unprotected joints between the floor and the wall can provoke a number of serious problems.

For waterproofing concrete floor, both traditional and more modern methods are used. Consider the technologies of their application, and analyze the features of the floor protection depending on the type of room.

Content

- The need for waterproofing concrete floor

- Materials for protecting the concrete floor and the specifics of their application

- Features of the waterproofing of the concrete floor in different rooms

- DIY waterproofing waterproofing

The need for waterproofing concrete floor

Concrete floors are often used in the arrangement of residential and non -residential premises. They are a good basis for laying all kinds of flooring: linoleum, laminate, parquet.

Concrete hygroscopic material, gradually absorbing moisture. In order to protect expensive flooring from contact with moisture, a layer of a protective barrier is installed on top of the concrete floor (in front of the screed). Waterproofing material prevents the contact of finishing materials with water steam.

On the first floors of industrial structures and basements, a waterproofing layer should be laid on top of sandy, well -tamed, pillows.

The waterproofing of the concrete floor significantly reduces the risk of a number of problems, namely:

- the appearance of leaks between the wall and the floor;

- deformation of the flooring;

- damage to the interior decoration of the room due to high humidity;

- foundation destruction;

- the appearance of fungus and mold on the walls.

Materials for protecting the concrete floor and the specifics of their application

There are various methods of waterproofing concrete floor. Price, application technology, service life and technical characteristics of the protective layer depend on the material used.

Rolled waterproofing. The most common method in which roller materials on a bitumen basis are used. They come in two types: floating and self -adhesive.

The advantages of floating materials, such as roofing material, include their durability and availability at a price. However, they have significant drawbacks:

- the need to use a gasoline or gas burner during installation, which is not always convenient and acceptable (especially in small rooms);

- when heated, an unpleasant odor and harmful smoke stand out;

- laying roofing material requires the subsequent filling of an additional screed. This increases the load on the foundation and reduces the height of the ceilings.

A worthy alternative to the traditional roofing roofing material on an adhesive basis. They are more convenient in styling and create a high level of moisture protection.

Crystal waterproofing. This method gradually displaces roll waterproofing. Various bitumen-polymer, cement-polymer and bitumen-teddy mastics are used. Thanks to plasticizers and special fillers contained in the mastic, the waterproofing layer is durable and elastic.

Some manufacturers add components that prevent the development of fungus and mold growth.

Before applying mastic, it is advisable to process the floor with a special primer, this will increase the adhesion of the waterproofing layer with a concrete base

Often protective mastic is sold with a primer (their composition should have the same main component).

The main advantages of coating waterproofing are efficiency and ease of application of material.

Cement-polymer mastic can be laid on a reinforcing mesh, as a result you get a layer of waterproofing and screed at the same time

Penetrating waterproofing can be used as an additional or main measure of concrete floor protection. There are the following subgroups of penetrating waterproofing:

- The concrete allows you to increase the density, strength and frost resistance of the material. Used as an additive in the manufacture of waterproof concrete structures or to create a protective reinforcing layer.

- Polymer -cement can be used to process concrete, wooden and brick floors. The material is characterized by high adhesion with the surface, environmentally harmful and easy to use.

- Cement inorganic waterproofing is used to process the concrete floor and walls (relevant for pools, baths, bathrooms).

Ceramic tiles can be laid on a layer of penetrating waterproofing

Folding waterproofing It is used to protect the foundation or floor in wet rooms. Fanding material is poured into the pre -built formwork. As a filler, you can use: perlite sand, ash, mineral cotton wool, concrete (when moisturized it turns into a waterproof gel).

Folding waterproofing is reliable, has a long service life, but its installation is quite laborious and expensive.

Features of the waterproofing of the concrete floor in different rooms

Protection of the concrete floor in the house and bathroom

When waterproofing the floor in the living rooms of the house or apartment, paint or coating technology is used. This will be enough to provide the flooring, and the room as a whole, protection against excess humidity.

You can apply waterproof paint to the floor surface, which contains polymers that can clog concrete pores. To increase the efficiency of the waterproofing layer, it is advisable to apply paint to 2-3 layers.

Waterproofing work should be carried out in a well -ventilated room, since the paint has a strong smell

Since the bathroom is a place with high humidity and high risk of leaks, it is better to use glow or coating waterproofing it is more durable and reliable.

For such work, self -adhesive roll material, bitumen or synthetic mastics are well suited.

Video waterproofing concrete floor in the bathroom is presented below

Waterproofing of the floor in the garage and basement

The waterproofing of the concrete floor in the garage must be especially carefully carried out, since the constant excess of humidity can lead to rotting and damage to transport. Ventilation, but not for long.

Types of waterproofing of concrete floor:

- soil device;

- crossing device.

The soil waterproofing is performed at the time of arranging the base for the floors. A roll material (polymer membrane, bitumen roofing material or polyethylene, with a thickness of about 1 mm) is suitable for work. When laying out the material, the overlap on the walls should be at least 10 cm. The waterproofing layer should lie down evenly, without the formation of waves and ruptures.

When arranging the floor in the garage above the basement (overlapping), a layer of roofing material or bitumen mastic can be used as protection. However, if the plans have the manufacture of the observation pit in the garage, then there will be no meaning from such waterproofing.

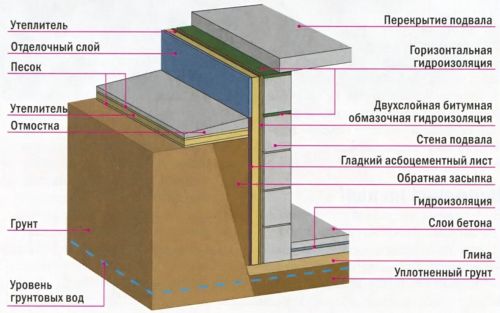

If there is a basement in the garage, the only true way to make waterproofing the concrete floor in the basement itself.

There are three types of flooring in the basement:

- anti -capillary floor protection from capillary waters;

- non -pressure protection against floods and rains;

- anti -naval protection against groundwater.

You can perform high -quality waterproofing of the floor in different ways. One of the most reliable laying of the pie, in which the floor level rises to a height of about 50 cm.

The sequence of laying layers is as follows:

- crushed stone (layer thickness of about 2 cm);

- fat clay;

- thin layer of concrete;

- layer of waterproofing mastic;

- rolled waterproofing (2 layers in a row);

- thin layer of concrete;

- reinforced concrete screed.

For waterproofing the concrete floor in the basement, it is not recommended to use membranes and films are not able to withstand the foundation on the foundation during the seasonal shift of the soil, and they will not cope with pressure soil waters

Concrete floor protection in the bath

Some believe that in the bath it is not necessary to make waterproofing of a concrete floor, since the air temperature is very high and the humidity itself will evaporate. However, it is not. Very often, due to incorrectly performed penetrating waterproofing of concrete, the floor in the bath does not warm up. In addition to discomfort, this can lead to the destruction of the flooring.

To protect the concrete floor, excess moisture can be used to apply penetrating waterproofing. To do this, it is necessary to clean the floor surface well, align it, grind and cover it with cement, polymer -cement or concreting waterproofing composition.

Properly performed waterproofing of the concrete floor in the bath will protect the elements of the structure from premature destruction and improve the microclimate in the steam room.

DIY waterproofing waterproofing

Preparatory stage

For waterproofing work, it is necessary to pre -prepare the room, namely:

- complete all dirty work and install/replace all pipes;

- free the room from furniture;

- to align the floor and walls, compliance with this condition is important for rolled waterproofing;

- grind the surface of the floor;

- fill all cracks in the floor and joints (you can use the usual cement mortar);

- it is advisable to install reinforcing nets on large cracks;

- prepare tools and materials necessary for laying/applying a protective layer (brush or roller for coating waterproofing; construction knife, level and burner for roll).

Rolled materials coating technology

For rolled waterproofing, the smoothness of the surface is very important, so before work it is necessary to check once again so that the gap between the level and the floor does not exceed 2 cm.

The sequence of work is as follows:

- Make inclined joints between the wall and the floor at an angle of 45. You can use a cement-sand solution (1: 3 ratio).

- Clean the surface of the floor and cover with bitumen mastic.

- A film or roofing material before laying to the floor should lie in a detailed state for a day, this will prevent bloating when gluing.

- Cut the material into segments of the desired length and roll into the rolls in the inside.

- Mote the markup where the waterproofing will be laid.

- Make the lower edge of the canvas with bitumen mastic and start the layout on the floor. It is better to do work together.

When laying out waterproofing material, it is necessary to ensure that the overlap between the canvases is at least 1 cm

If when laying the roll went to the side, it must be cut and leveled with a new cutting of the canvas. When the bubble is formed, it is cut, the air is released, spread with mastic and glued to the concrete base. The restored place of bloating must be smoothed with a spatula.

Seamless waterproofing technology (coating)

On your own and in a short time you can make coating waterproofing of a concrete floor. The technology of applying mastics does not require a perfectly flat surface the floor is enough or sprinkled. It is undesirable to make wet frill.

The procedure for applying waterproofing mastic:

- Apply 2-3 layers of primer to the floor (the surface should be completely saturated).

- Slide the joints of the floor with the walls and the corners with a special ribbon with hermetic properties.

- Put on the pipes rubber seals, and glue their joints with a floor with a tight ribbon.

- Dilute mastic according to the instructions attached to it. Its consistency should resemble warm plasticine.

- Apply mastic with a hard roller, it is convenient to use a brush in the corners.

- The walls must be treated with mastic to a height of at least 20 cm.

- Leave the surface until completely dry (about a day).

During the drying of the waterproofing layer, moisture, dust and extraneous objects should not fall

The flooring can be laid on dried waterproofing: tiles, porcelain tiles, linoleum, etc.

As you can see, you can protect the concrete floor from moisture yourself, the main thing is to choose the right waterproofing material and adhere to the technology of laying it.

Thanks for the detailed

Thanks for the detailed information. To get more information about concrete waterproofing, you can read the following blog: https://penetron.az/beton-hidroizolyasiyasi/