There are a lot of options for aligning the floor, for example, to lay the laminate. All...

|

|

Any private plot of land needs to be surrounded by a fence. Sometimes he performs ... |

It is not difficult to build pillars for the fence with your own hands, here's an important ... |

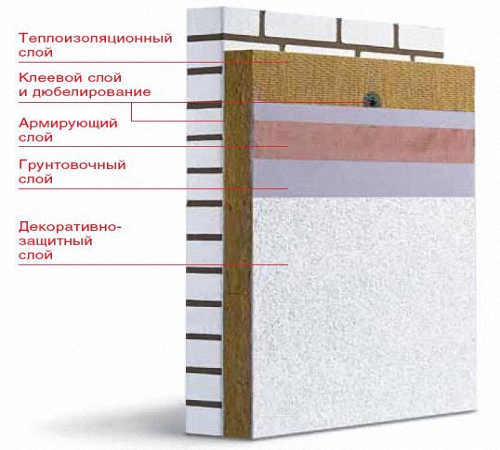

Insulation of the facade with mineral wool

Among several options for insulation of the facade, mineral wool is most popular due to the affordable cost, durability and efficiency. We will talk about how to insulate the facade with mineral wool.

Table of contents:

- General concept of mineral wool

- Advantages and disadvantages of insulation of the facade with mineral wool

- Varieties of mineral wool for facades

- Safety rules while working with mineral wool

- The choice of mineral wool and the cost of insulation of the facade of the house with mineral wool

- Insulation of facades with mineral wool: technology and features

General concept of mineral wool

Mineral wool is a material that is widely used in the process of insulation or thermal insulation of both the inside of the room and external.

Mineral wool varies between themselves with a structure and fibrousness. It has a fairly wide scope of use.

The process of production of mineral wool consists in melting rocks of metamorphic and magmatic type, as well as metal production waste and other similar substances.

The most popular type of mineral wool is a basalt -based cotton wool. It has a maximum water -repellent effect.

Thanks to the chaotic location of the fibers, this material is quite durable and stable before strong loads.

The scope of the use of mineral wool:

- thermal insulation of vertical, horizontal surfaces, areas of an inclined type in all buildings;

- insulation of the facade of the plastered building;

- intermediate layer in the system of the ventilated facade;

- in the process of insulation of sandals, metal casing or reinforced concrete panels;

- for thermal insulation of the water system and other industrial areas;

- thermal insulation of the floor or external thermal insulation of the roof;

- Thermal insulation of the bath, pool or sauna.

The thermal insulation properties of mineral wool have a direct connection with its thickness. The thicker the cotton wool, the better thermal insulation.

Mineral wool has a wide range of use, it is not affected by high temperature, moisture and fire.

Vata has a fibrous structure, therefore it is an excellent heat insulator. The fibers, interwoven with each other, form a holistic canvas that does not let noise, but is quite capable of passing the air.

Mineral wool is available in the form of a stove or mat. It is soft and hard. The first type is great for thermal insulation of the ceiling or wall space. And hard mineral wool is used as a heat insulator of a metal frame, in the form of a layer.

The basalt fiber is also a variety of mineral wool. This material is produced not only in plates, but also in rolls, which greatly facilitates its transportation and further installation.

Advantages and disadvantages of insulation of the facade with mineral wool

1. Mineral wool is an excellent heat insulator, the main advantage of which is the maintenance of heat in the room.

2. Work with mineral wool is more pleasant than with polystyrene, since not everyone is able to endure the sharp sound of the creak of this material. Mineral wool is perfectly cutting and easily laid on the facade.

3. Using mineral wool, small rodents will not bother the owner of the house, as they do not really like to live in it.

4. Mineral wool forms an excellent integral structure that has practically no cracks, which means the quality of insulation increases several times.

5. Due to the density of mineral wool, the effectiveness of insulation remains at a high level.

6. Mineral wool does not sit over time and does not lose size.

7. Minvata is fireproof material, as it is not able to ignite.

8. Mineral wool is resistant to mold, fungi and other microorganisms.

9. This material is resistant to chemicals, which once again proves its reliability.

10. Mineral wool not only does not ignite at the highest temperatures, but also prevents the spread of fire, therefore, when a fire occurs, mineral wool can protect property.

11. An excellent property of mineral wool is the ability to breathe, that is, to let air through itself, which means the lack of condensation and improvement of the properties of the facade.

12. Due to the property of air passing, the air in the room becomes more fresh.

13. Some types of mineral wool are absolutely safe for human health, they are harmless even for people with allergies, as they are made of environmentally friendly materials.

14. The water -repellent properties of mineral wool contribute to the lack of dampness in the room.

15. Mineral wool is an excellent sound insulator, it does not let extraneous sounds into the room, thereby providing its owner with comfort.

16. A variety of choice of mineral wool opens up to customers a huge selection of this material that is able to be used in different fields of insulation, belongs to different price categories and satisfies all consumer requests.

17. A long service life is another advantage of this material, mineral wool can serve as a facade with a heater for more than a dozen years, and over time it does not lose its properties.

18. Available cost makes this material one of the most popular among consumers.

The disadvantages of mineral wool include:

- The presence of saw, which when working with this material enters the air, so you should protect yourself with means of protection;

- Some types of mineral wool, when exposed to high temperatures, secrete harmful substances into the air, which negatively affects human health.

Varieties of mineral wool for facades

Depending on the material from which mineral wool is made::

- glass wool,

- Basaltic mineral wool,

- slag.

Glaud is a material that is made of fiberglass. In the process of manufacturing, sand from quartz or glass battle is melted. This material is inflated on small fibers that form the structure of the fiberglass. The characteristic color of glass wool is light yellow. It is not particularly common in the field of insulation, as it differs in the presence of a very large shrinkage. A year after installation, the plates are compressed and lost in shape. The occurrence of this process is affected by moisture and temperature changes.

Basalt cotton wool is the most expensive material, as it has high -quality technical characteristics. In the production process, rocks are used, which are also melted. A characteristic color of basalt wool is yellow-brown or slightly greenish color. This material is fiery resistant, resistant to chemical and mechanical influences. Basalt cotton wool belongs to the materials of non -combustible type. It is durable, resistant to deformation and easy to install.

The modern production of mineral wool based on basalt has further improved these characteristics, so this material is the most popular in the field of insulation. Basalt wool is distinguished by the presence of a neutral environment, which improves its anti -corrosion properties. The use of mineral wool based on basalt can significantly reduce heating costs in the cold season.

Slag - material on the basis of the manufacture of which is slag. The production process of this material includes the melting of slag, which is blown with a specially directed stream of hot air, on small thin mineral fibers. For its manufacture, sour, domain slags are used. Dangerous for human health are additives from iron oxides, manganese or sulfur. The composition of such cotton wool includes slag impurities, in the form of balls. Their number significantly worsens the quality of this material. The slag is practically not used in the process of insulation of residential premises, although its cost is much lower than that of other types of mineral wool.

Mineral wool is distinguished in a ratio with the type of security:

- the first category - which include materials, are potentially safe for human health;

- the second category - minvat based on ceramic fiber, which is also unsafe;

- the third category is Minvat, which was not studied at all, so its influence is unknown;

- The fourth category is basalt mineral wool that does not contain carcinogens.

Safety rules while working with mineral wool

1. The process of insulation of the facade with mineral wool should end with the complete isolation of this material from direct contact with a person.

2. During work with mineral wool, be sure to use protective equipment: mask, respirator, rubber gloves, overalls.

3. Do not work with mineral wool in places where food or drinking water is located.

4. It is impossible to allow direct contact of mineral wool with children, this material causes instant itching, irritation, and allergies on the skin.

5. At the end of work with mineral wool, the room should be cleaned.

6. To cut mineral wool, use a pre -stolen knife.

7. If the work is carried out indoors, it must be well ventilated.

8. After working with mineral wool, you need to rinse your hands and face with cold water.

The choice of mineral wool and the cost of insulation of the facade of the house with mineral wool

1. Pay attention to the main technical characteristics of the mineral wool, such as strength and density. The higher they are, the product is better there.

2. The smaller the weight of mineral wool, the better its thermal insulation properties. To achieve high density, some manufacturers use a binder resin, and this is reflected in weight and quality of material. Therefore, choose that minvat, which is easier.

3. For insulation of the facade with mineral wool, the price depends on the volume of work, as well as the quality of the heater used.

4. The best option for insulation of the facade is a mineral wool of stone or basalt type, although its cost is slightly higher than, for example, the price of glass wool, but the quality of thermal insulation will be much better.

5. It is forbidden to work with mineral wool, at a temperature above 30 degrees, since at this moment the material expands, and at a lower temperature it will squeeze and the shrinkage forms.

Insulation of facades with mineral wool: technology and features

The preparatory stage of work includes the preparation of the surface for insulation. To do this, remove all unnecessary details from the facade, clean the surface of dust and dirt. Also remove the storm system and stock devices. Their installation is carried out at the end of all work.

There should be no metal objects on the facade, since they will form condensate and gradually reduce the qualitative characteristics of the insulation, and this will affect the appearance of the facade, even the appearance of dark spots is possible.

In the process of preparing the facade, remove the excess old plaster silt. Before work, the surface should be clean and dry.

This is followed by the installation of leders - durable cords that will help to install the minvat correctly. Before this, the facade part is divided into a certain number of zones, then the legends are installed: vertically, horizontally and diagonally.

The ledge of the leather is underway not to exceed 1 cm.

The next stage is the installation of mineral wool on the facade. Before this, guide profiles are installed, in which mineral wool will be installed.

They are installed using the level and preliminary marking by legends. To attach guides use dowels. Follow the reliable fixation of the planks, their loosening is not allowed.

Then prepare the glue for working with insulation. It must indicate a work permit precisely with mineral wool.

Apply glue to the inner part of the mineral wool, monitor the mark of the edges, corners and middle. Now attach the sheet to the wall and fix it in the guide.

This should be done with all sheets. Then, using a spatula, apply a reinforcement layer that will make mineral wool even stronger and will not allow shrinkage. To do this, use a thermosetle, which is covered with glue on both sides.

For the durability of the insulation, the surface of the surface with a special facade mixture should be made. This process will improve the appearance of the facade and preserve the insulation.

Insulation of facades with mineral wool video: