Often, when in old houses it is necessary to insulate walls inside the apartment ...

|

|

The height of the ceilings is usually designed even before the start of construction, but what ... |

Many people want to make their apartment much quieter and comfortable by glazing ... |

Installation and installation of fence from corrugated board with your own hands

Any private plot of land needs to be surrounded by a fence. Sometimes it performs an exclusively decorative function, but more often it is installed for the safety of a country house or cottage. It also allows you to close from prying eyes and adds comfort to the site. There are a large number of building materials, but the optimal combination of price and quality is corrugated board. Often the price of work on installing fences from corrugated board is quite high, and scares away many. The output will be his own installation, which is not so difficult.

Content:

- Which corrugated board to choose

- How to calculate the corrugated board for the fence

- Necessary materials and tools

- Technology for installing a fence from corrugated board

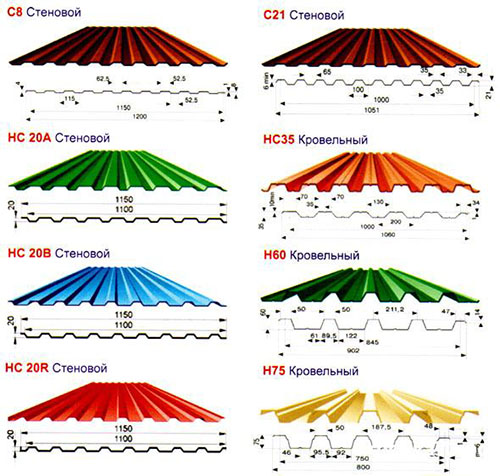

Which corrugated board to choose

In total, there are several varieties of corrugated board, consider the main ones that will affect the operational qualities of the fence and its appearance.

Corrugated board with polymer coating. Its coating is a polyester composition that provides the reliability and durability of the metal. Sheets, with this coating, have the highest anti -corrosion characteristics. In addition, they are resistant to the negative impact of the environment, which allows you to extend their service life, without additional care, up to fifty years.

It has a large color scheme, which is very important for a harmonious combination with a common design of buildings on the site. A polymer coating can be both on one and on both sides (the second option will be much more expensive). It is widespread as roofing material, as well as for external cladding of hangars and industrial facilities.

Galvanized corrugated board. Its main advantage is a low price. This is due to the fact that inexpensive raw materials are used for manufacturing. But it has low resistance to the influence of external factors. In addition, next to it it is not recommended to plant plants that can burn out from overheating on sunny days. Most often, galvanized corrugated board is used for temporary fencing of construction sites.

In addition, it is divided by the height of the profile and the thickness of the sheet into: roofing, carrier and fence (wall).

How to calculate the corrugated board for the fence

In order not to buy the material in the future, it is necessary to initially calculate everything accurately. This will reduce the time of the construction process and financial costs. It is necessary to take into account not only the sheets of the corrugated board, but also the supporting pillars, transverse lags, fasteners and the number of cement-sand mortar for pouring the support. In addition, any fence is required to be equipped with a gate and gates.

Typically, for the fence, corrugated board with a wave height of 10-20 mm with a polymer coating or galvanized is used.

For supporting pillars, a square profile pipe is used. Its cross section directly depends on the height of the future fence.

Calculation scheme

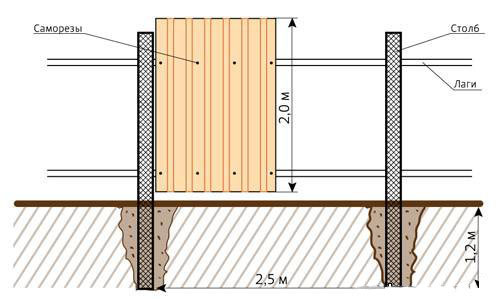

The corrugated board is a strong material, fences from it can reach 8 meters in height. The number of lags that profiled sheets will be attached to can be different, but most often there are two of them. You will also need metal screws and rivets for joints.

Calculating the total number of supports is easy. To do this, we divide the total length around the perimeter by the distance between the supports, and add 3 more poles to the resulting result (one pillar on the gate and gate, and one to the turn).

The corrugated board is calculated on the basis of the working width of the sheets. The total meter of the perimeter of the future fence is divided into a working width, thus, we obtain the required number of sheets. But it is advisable to buy 1-2 sheets for a reserve.

Calculating the length of the lag is also simple. To do this, the total length of the total perimeter is multiplied by two, the necessary meter for the manufacture of the gate and gate is added to the resulting number. And if the total number of profiled sheets is already known, then we multiply their total length by 2 and also add the necessary length of the pipes for the manufacture of a gate and gate.

The sizes of corrugated board for the fence can be made for your individual order. But on average, its width is 100-130 cm, and a height is 180-200 cm.

The following is a scheme that will allow you to correctly calculate the number of all materials for the construction of a fence from corrugated board.

Necessary materials and tools

Pillars.The best option for supporting pillars will be a metal profile pipe, which has a square or rectangular section of 4x6 or 6x6 cm and the thickness of the walls from 2 mm. To give the design of stiffness and flexibility, the distance between the supports should be 2-2.5 m.

It will allow the fence to withstand heavy snow, heavy wind and not break. The length of the pillars will depend on the size of the sheet of corrugated board, as well as on the characteristics of the soil. In clay soil, pillars are buried 80-90 cm, if the soil is sandy or there are high groundwater, then the minimum recess for supports is 100-120 cm.

Lags. For them, a profile rectangular or square pipe is also used, but with a smaller cross -section. It will be enough 4x2 cm with a wall thickness of 2.5 mm.

Profileists. For installation of a fence from corrugated board, profiled sheets with a rowing height of 2 cm and a thickness of 0.5 mm are best suited.

Fasteners. For fastening, it is advisable to choose self -tapping screws for corrugated board (they have EPDM - gaskets that ensure sealing fasteners) or special rivets. This is due to the fact that ordinary screws can cause metal corrosion.

Tools

Tools for the construction of a fence from corrugated board with your own hands will depend on the characteristics of the soil. On light sandy soils, you can do with a simple manual drill and sledgehammer, and on heavy clay and rocky, a gasoline Yamobur will be required.

But in any case, there is a list of main tools:

- roulette;

- boer;

- sledgehammer;

- level;

- cord;

- welding machine.

Technology for installing a fence from corrugated board

Installation of pillars

Before installation, all the pillars should have the required size. Their length is calculated from the height of the fence and the depth of the underground part of the pillar, which is approximately 30% of the height of the aboveground part of the structure.

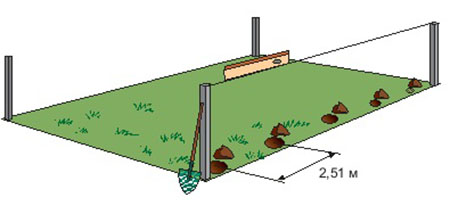

Initially, marks are installed in places where pits will storm under the supports. To do this, you need a roulette or a lace, the length of which is equal to the distance between the pillars.

As soon as everything is marked, the drilling of wells begins with a drill. In the event that the work moves quickly, they can be drilled at once. But if the pits are dug up manually and slowly, it is better to install a few pillars in them and cement.

The first corner supports of one row are the first to be mounted and fixed using wooden wedges. Between them, at the top, the cord is pulled in a strictly horizontal position. If there is a skew, then the height of the pillars can be adjusted by pouring the soil into wells or, vice versa, digging up. After everything is leveled, the intermediate pillars are placed focusing on the outstretched cord and are also fixed with wooden wedges. Further, a stone, crushed stone, chopped brick or large fractions of gravel are poured into the pits to the support pillars and is carefully compacted. Sand is poured on top and spilled with water.

A cement mortar is diluted with small volumes, designed for 5-6 wells. Therefore, it is not necessary to use an electric concrete mixer, it is quite possible to do with a small container. For its preparation, a proportion is used: 1 part of the cement, 4 parts of sand and 4 parts of water and crushed stone.

For the additional strength of the supporting racks, each of them is welded with a reinforcement of 15 cm long. They should be placed on the underground part across the pillar and cross-steam in relation to each other.

Installation of transverse lag

The transverse lags are attached to the finished racks using electric welding. The number of rows depends on the height of the fence. If it is up to 2 meters, then two is enough, and if higher, then the lag must be made 3 rows.

Tip: It is important to observe the distance from the lag to the edges of the profiled sheet, which should be strictly 20cm.

When all the lags are welded, they are thoroughly cleaned with a metal brush, after which everything is covered with paint.

Installation of corrugated board

The installation of corrugated board with your own hands is simple. It is attached to the lags using self -tapping screws with plastic or rubber washers. There is no need for a large number of mounts, it is enough to fix the sheet at the edges and in the center.

Each sheet is attached only after it is turned horizontally and vertical, which will prevent the formation of cracks. First, the first sheet is mounted, the second is installed on it so that it lay down, overlapping one wave.

Often, when on the corner you have to cut it in the required size. This is done using metal scissors without using a grinder and abrasive tools.

The final stage of installation of the fence from the corrugated board is the closure of the upper part of the supporting pillars to protect them from precipitation and, as a result, from corrosion.

Tip: if scratches appeared in the process of work on the sheets, they should be immediately painted with paint from the spray can. To give the fence of greater aesthetics, the supporting pillars can be lined with stone or brick.

In conclusion, it is worth adding that the edges of the profiled sheet are quite sharp and can injure the skin. Therefore, before starting to make a fence from corrugated board, take care of protecting your hands.

Thus, the process of erecting a fence is not very complicated and even unprofessional. By attaching zeal and hard work, you can save the family budget.

1

1

The fence from the profiled sheet we

A fence from a profiled sheet

We carry out corrugated board, and also carry out work on the creation, installation of fences from corrugated board

http://metallicheskie-zabori.ru/iz-profnastila/

Nothing is said about

Nothing is said about the use of concrete substitutes. For example, Canadian fast2k. Why? They, substitutes, have been more broader and wider in recent years in the Russian Federation.