Building a house on a high sand content is a rather complicated process ...

|

|

Roller shutters Modern solution in the field of security of commercial ... |

Even in the most provincial village houses, not to mention modern suburban ... |

Pillars for the fence - how to install, install, choose. Instructions

It is not difficult to build pillars for the fence with your own hands, here the observance of the technology and sequence of construction stages is of no small importance. Today, many manufacturers offer ready -made, rapidly vested supports from various materials. They are covered with a special composition that protects against adverse weather conditions, prevent corrosion to develop and have an original appearance. In the article, we consider how to choose and install pillars for the fence.

Content:

- Pillars function and the role of the foundation in the fence

- What are the pillars for the fence

- Methods for installing supports

- Selection of supporting pillars for combined fences

Pillars function and the role of the foundation in the fence

- The term of operation of the fence depends not so much on the selected material, but on the quality work on laying the base, competently established supports. In fact, the construction of the fence is the totality of the following components: pillars, transverse lag and crate.

- Pillars are of particular importance in these buildings, it is they who take the load of the entire fence and the higher it, the more stable they should be.

- Their installation is no less important, because competent installation determines the quality and durability.

- The depth and method of sealing increase the resistance to loads and allow you to maintain its vertical.

- The material from which they are made can correspond to the sections of the fence or create an original contrast.

Errors, when erecting pillars for the fence:

- incorrectly selected or not properly implemented by the foundation literally after 3-4 years can lead to the destruction of the stone (clinker) canvas;

- if, for some reason, the supports were simply buried in the ground, without filling with a concrete mixture, then this also becomes the cause of columns, up to the collapse of the entire fence.

Therefore, you should carefully familiarize yourself with the methods of their installation and the types of fences most suitable for one or another basis.

What are the pillars for the fence

Concrete pillars

- This material is valued for its reliability and special strength.

- Concrete opposes mechanical influences, corrosion, rot, does not require maintenance. Now manufacturers offer a huge assortment of pillars made of this material.

- Special fiberglass, metal or polyurethane forms for the manufacture of supports are also sold, a concrete mixture is poured in them, where it freezes.

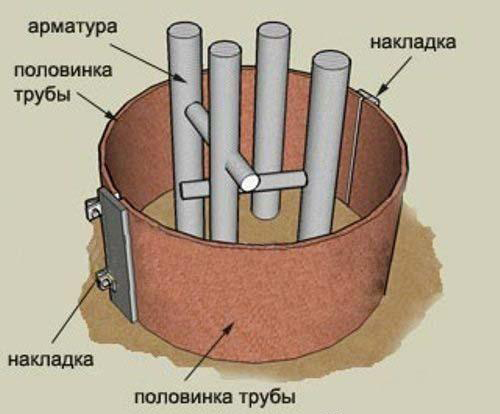

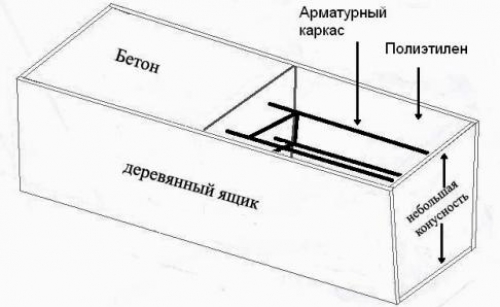

Form for concrete pillars with your own hands

But such forms are quite possible to perform on their own. For the speed of manufacture, you can make a multi -position matrix, which will cast at the same time 4 concrete supports.

You will need:

- 9 boards 30x250x2500 mm

- 2 boards 30x250x1000 mm;

- blacks on wood, screwdriver, tin sheets, reinforcement, 8 metal linings, waste oil, concrete mixture.

- Studge with a tin of 6 boards 2.5 m long on one side, in the same way to make a meter lumber. Three dividing boards are upholstered on both sides;

- collect the formwork using screws, which will make it possible to disassemble the design for their easier excavation;

- before laying concrete, the matrix must be lubricated by working out;

- tie and lay the reinforcement;

- pour a concrete solution, carefully leaving in full shape;

- measure the same distance on both sides and install metal inserts that will serve to fasten the frame;

- cover the matrix with a damp burlap, wetting it for a week.

You can use another option

- Dig a well with a depth of at least 1.2 meters, install a plastic sewer pipe into it, the diameter and length of which is selected according to the necessary support parameters.

- The pipe is covered with soil, the vertical is aligned and finally fixed. In the pipes to install a tied wire for reinforcement and pour the pipe with a concrete mixture.

- It is not recommended to fill the solution in parties, it is better to perform this procedure in one technique. After 7 days, the pipe is carefully removed.

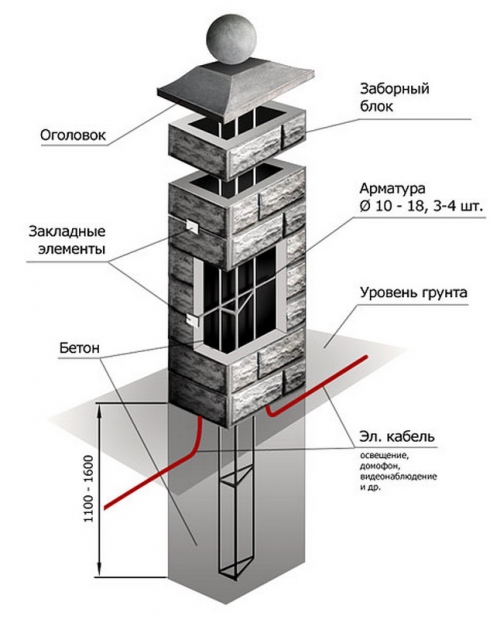

Decorative setting pillars made of concrete

A good alternative to a concrete pillar can be a sketch analogue. It is made by blocks that can be painted at will. It is also carried out with imitation of clinker, lamp masonry. This type of support allows you to choose the optimal height of the fence itself along the work.

- To install them, a well of the required depth is rummaged and poured with concrete solution. Here you need to vertically install steel reinforcement, which leaves the soil by 30-40 cm. If necessary, it is lengthened by a welding way.

Tip: blocks are rotary, passing and finite, therefore, when calculating this material and its assembly, you should be extremely careful.

- Blocks are put on rods, a concrete solution is used for the strength between the settled parts, where the seam should not exceed 12 mm. The internal space formed by these components is poured with the same mixture.

- The inner cavity of the blocks allows an electric cable, for example, for alarm, video surveillance, street lighting, intercom.

Wooden supports

They are valued due to their natural material, price availability, appearance. However, the operational terms are quite short, such pillars will stand for no more than 12 years. Although, if you use an oak barrel as a support (not a beam!), Removing only a bark from it, then it can stand at least 20 years.

Tip: Wooden supports are not recommended to be poured with sand -cement mortar.

- It is best when, before installation, the lower part of the pillar is burned, and then plunged into hot buzzing, a liquid roofing material or resin. For greater reliability, they can be wrapped with polyethylene or the Toli.

- Next, pits are prepared for pillars, here the recommended depth is at least 1.2 meters. The support is fixed, aligned with a vertical plumb. For filling, sand is used, which is moistened and rammed.

- You can extend the life of such supports if you minimize contact with the soil by performing their installation in previously concrete metal pipes.

Screw pillars

- Such a pile is equipped with blades and a pointed end, in general, the whole structure resembles a drill.

- The height of the entire pillar is 3 meters, where the lower part included in the ground is 1-1.2 m and has a round section.

- The support itself remaining above the surface can have both round and square (rectangular) profile.

- Polymer coating protects the base and makes it possible to choose the desired shade.

- Using a special gate, it is easy to mount it in any soil in just 10 minutes, but there is also a limitation of rocky soil.

- The upper part of the pile is closed with plastic plugs that prevent the penetration of moisture into its cavity.

- For weak soils, two -lobed piles of large diameter (section) are used. Of course, when tightening them, it is necessary to make maximum efforts, but the final result will justify itself to create the impression that this support is concreted.

- Another advantage is the screw piles of light dismantling. If for some reason they need to be removed, then such work will be carried out without difficulty. To do this, just scroll the piles in the opposite direction, that is, simply unscrew.

- With screw support pillars, spans from a net, a profiled sheet, a Euro-stack and inserts with forged elements will perfectly harmonize.

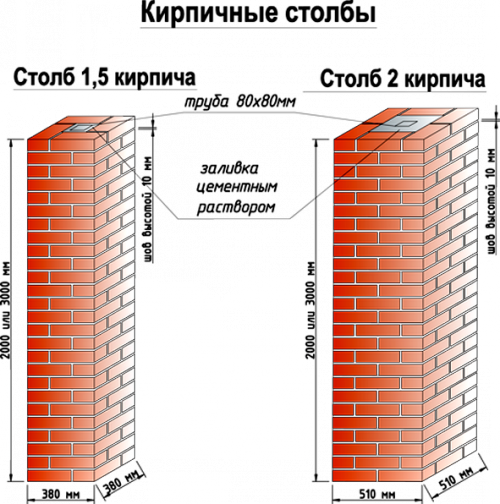

Brick pillars for the fence

Such supports have a high level of strength, in addition, they give the fence a respectable appearance. But their installation requires a thorough foundation, since they have an impressive weight.

As the basis of a brick column is used:

- a metal pipe with 100-150 mm. The depth of the pit is selected depending on GPG and can be up to 1800 mm. Pillars are exposed on strict vertical and fixed with wooden wedges or tamped soil. After installation, the pipe is covered with protective alkyd paint;

- reinforcement can also be performed by increasing metal rods of 8-14 mm, for this, when constructing the base in concrete, the reinforcement should be vertically laid. The rods can protrude 30-40 cm on the foundation, then they are extended with a welding machine. In this case, the resulting well of the masonry is filled with a thick sand-cement mortar;

- the base can also be performed as follows - a roll roofing material is taken, folded and dressed on rods, forming a barrier between them and clinker masonry. Here, pouring the resulting pipe is carried out with a liquid solution;

- you can also carry out a concrete base:

- it is necessary to dig a ditch, the depth of which can vary from 40 cm and deeper, and the width of at least 25 cm, these parameters depend on the height of the fence and the width of the brick (stone) masonry;

- metal support points are marked, a well of the desired diameter is drilled here. The bottom and walls of the recesses are covered with roofing material and pillars are driven;

- then they are aligned in height and verticals are exhibited with a plumb line;

- around the supports a reinforcing belt is installed;

- then the sand is poured, which is abundantly watered and compacted;

- the formwork is established, it should be borne in mind that if the presence of a basement is planned, then the formwork height should be higher than the ground level by 30 cm or more;

- the formwork can be made from lumber or use a removable structure;

- a clinker or laughter stone is laid out on a sand pillow and a reinforcing mesh is placed on top of it;

- the trench is filled with concrete mixture, for this a solution of M100 or M150 is used. It is necessary to wait at least 7 days so that the reinforced concrete structure gain strength;

- after removing the formwork, waterproofing is performed. Most often used: bitumen mastic, polymer mixtures, roofing material.

- For greater reliability, metal supports can be poured with a concrete mixture, before this procedure you should check their height. If the soil of the heaving type, then it is recommended to weld the plate to the pipe, it will serve as a kind of obstacle when squeezing the pillar.

- Before the masonry work, a waterproofing of the concrete base is performed, and only then they proceed to laying the clinker. In order for the seam between the rows to be the same, you can use 10 mm reinforcement, which is located around the masonry perimeter. When working, the level is checked by the horizontal and vertical of each row. With a rubber hammer, the location of this material is trimmed.

- The top of the column can be made in the form of a four -sided roof, pyramidal in shape or covered with decorative lids of any shade. They can be geometric shapes (ball, star) or have a decoration on the upper part (for example, the head of a lion).

DIY metal pillars

This is the most popular type of supporting pillars in the construction of inexpensive fences from a grid, corrugated board or wood. Next, we consider how to install metal pillars for a do -it -yourself fence.

- Initially, the boundaries of the site are noted, using pegs and a stretched rope.

- The supporting pillars are recommended to be installed at a distance of not more than 3 meters. Metal pipes with round (50 mm) or rectangular cross section (30x50 mm or 50x70 mm), the thickness of which can be 2-3 mm, are ideal as supports.

- The pipes are installed to a depth of 60 cm, their vertical is necessarily aligned with the help of cargo or level.

- It is also necessary to monitor the height of the pipes, if the pipe has drowned a little - you need to sprinkle sand or gravel to the bottom of the hole and compact.

- In the case when the support height exceeds the required parameter, then you can use a sledgehammer. But direct contact should be avoided directly with a metal pipe. When performing these manipulations, there is a likelihood of deformation, as well as a violation of the polymer coating layer. To prevent such damage, a dense fabric folded in several layers and a wooden or metal bar is used in the place where it will have the whole blow.

- Next, pouches are poured with a concrete mixture or sand -cement mortar. In order for concrete to gain strength, it is necessary to wait for at least 5-7 days. Galled pillars are painted with anti -corrosion paint on a alkyd basis, this will extend the life of metal products.

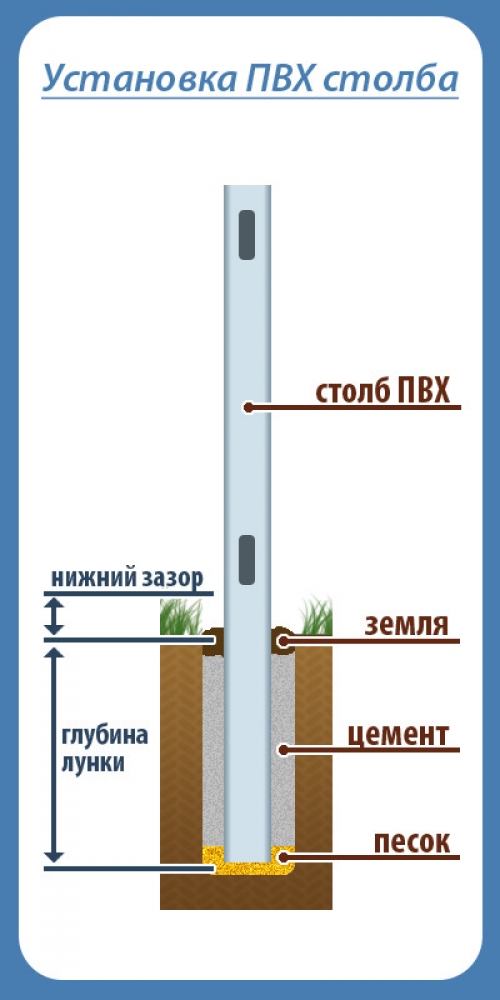

Plastic supports

- Polyvinyl chloride supports have a high degree of corrosion resistance and seasons (rain, snow, frost), do not require annual maintenance.

- The latest technologies allow them to make them in various shades and various shapes, models.

Installation is possible in 3 ways:

- installation points are marked, wells are drilled with depth of 1/3 from the length of the support. Sand and gravel are poured to the bottom of the pit, this mixture must be moistened and tamped. Next, a plastic pillar is installed and covered with soil residues, during the installation process it is important to monitor its height and vertical evenness;

- if the fence has a height of more than 1.5 meters, then these poles can be additionally strengthened using spot fixation. For this, the supports are poured with a concrete or sand -cement mixture;

- on plastic pillars of some models, there is a shoe (metal support), which already has working holes. The fasteners are made to the foundation by means of anchor bolts. The holes in this base are drilled with a perforator, the diameter and length of the drill are selected depending on the parameters of the metizes.

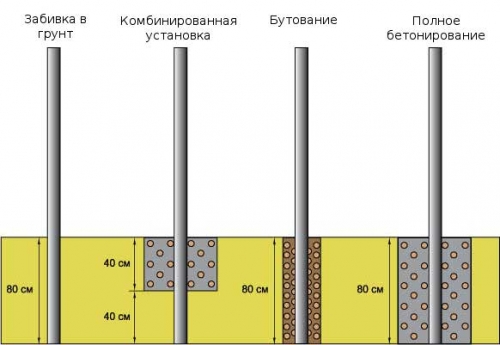

Methods for installing supports

There are several options for installing poles, each of them is selected based on the material from which it is planned to build a fence, sections and type of soil.

Dry way

A pipe is inserted into the prepared well and filled with sand and gravel. The soil is abundantly wetted and thoroughly compacts. This method is effective if a light, low design is mounted, without additional heavy elements.

The following varieties of fences can be performed from such material:

- the picket fence for the most part is bars mounted to the carrier. They can be attached with a different step, which allows you to make a fence of both deaf and discharged type;

- the plank fence is based on Tes, and their fastening is carried out to vertical supports.

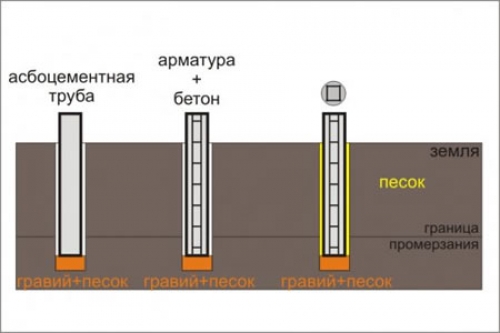

Columnar foundation or point method

Budget, but at the same time an effective option for attaching pillars for metal structures.

Manufacturing technology

- The well is digged with a depth of 1-1.5 meters, while the diameter should be larger (about 20 cm) than the diameter of the support. Such work can be performed with a shovel or use a garden drill;

- the bottom of the well is filled with sand about 30 cm, to protect the lower part of the pillar, a sleeve made of roofing material is used;

- for pouring, a concrete mixture of M150 (M200) is used mixed with gravel or broken brick. At this stage, it is necessary to check the support vertical;

- the flight between the supports can vary from 1.5 to 3 meters, these parameters are determined by architectural ideas;

- the walls of the funnel are strengthened by pruning the pipe, and if the diameter of the well is large, then you can use a bucket of which the bottom is pre -cut off.

If after drilling the well was filled with soil waters, then it is advisable to perform the following actions:

- dip the end of the pillar into a liquid roofing material where the height of the processing is equal to the depth of the well;

- after solidification, put on a plastic plane;

- insert the support into the pit, so as not to damage polyethylene and then straighten the edges;

- fill the distance between the film and the pillar with a concrete mixture.

The value of the concrete columnar foundation for the fence lies in its thoroughness, and this is due to a high degree of resistance to mechanical influences and temperature changes.

It is perfect for both heavy designs and light fences from a net grid.

Ribbon foundation

- For the fence, this is the most effective, but at the same time a rather expensive way to build a base, accompanied by painstaking work. It is more suitable for installing capital structures.

- Often this type of support is used for fences from clinker or decorative brick, natural or bottle stone. Its synonym is reliability and solidity.

- To protect the top of the fence from the effects of precipitation, it is recommended to use a decorative element.

- The fence can look like a whole wall, but more often concrete is used only for building supports, spans between them are made separately from wood, metal rods or concrete panels, which, due to their stylistic and color diversity, allow us to give a stylish appearance of any territory.

Selection of supporting pillars for combined fences

Sections of such fences can be recorded on both profiled pipes and brick or concrete supports. Therefore, the base is selected depending on the material from which the pillars are performed, and the insert may be as follows:

- of the forged elements, for example, made according to an individual sketch, which will give the site a unique style. As a decoration, art casting (monogram, leaves, etc.) is used. It is recommended to put such a fence if the territory is densely planted with shrubs or trees. For him, supporting pillars made of brickwork are perfect;

- the profiled sheet is most often used in the construction of a protective structure. It is easily and quickly installed, and the color palette allows you to choose for some parts of the house (to the color of the roof). Depending on the budget, it is performed either on metal supports or on brick posts;

- innovative technologies and elasticity PVC allow you to perform opaque sections in the form of a plank fence or wattle fence. The color scheme of the fence is very diverse, they can be standard white, and reproduce the structure of marble, wood and other material. It goes well with brick supports, decorative stone, metal profiled pipes.

The fence is an important component of the land and the final element of the landscape. Therefore, it is recommended to carefully approach not only the choice of material for pillars, but also correctly calculate its height. You should also take into account the type of all fence and competently choose its stylistic solution. After all, this structure will represent your possessions for more than a dozen years!

Forms for typepound pillars,

Forms for typepound pillars, forms of pillars for fences and forms of grape pillars can be found on the website https://formbeton.dp.ua/formyi_dlya_stolbov.html.html