Existing types of suspended ceilings, in the first ...

|

|

Every year exponentially, the number of owners of apartments increases, ... |

Available cost, excellent performance, variety of models and ... |

We make the foundation on the sand with our own hands

The construction of a house with a high sand content is a rather complicated process. The foundation, which is the basis of the building, should be selected and technologically correctly made. We will consider the features of the selection of the foundation for sandy soil and the technology of its manufacture further.

Table of contents:

- Sand foundation: soil research before construction

- Choosing a foundation for building a house on sandy ground: foundation, sand, gravel

- Sand -back foundation - preparatory work

- Sand and cement for the foundation: technology for making the foundation on fine -grained soil

Sand foundation: soil research before construction

To determine the type of foundation that is most suitable for building a house, you should explore the soil for the content of sand in it. Several varieties of sand are distinguished, which differ in size of fractions.

Coarse -grained sand is an excellent basis for laying almost any foundations. Among its advantages, we note an excellent characteristic of moisture, the lack of frosty heaving, resistance before seasonal movements. If the sand particles in the soil are quite small, then in the process of impact on them moisture, they hold it without passing it through themselves. In this case, the formation of dirt occurs, which, when solidified, increases the size. Therefore, the soil is the Dentent, consider the moment.

In addition, the sandy soil of fine -grained composition is characterized by a sloping type is characterized by a high tendency to fusion. In the process of working on the project, foundation waters are quite high. In any case, before starting to erect to the formation of a swimming unit. This is especially true for the areas in which the ground and the preparation of its project should be carried out by the soil examination for the location of groundwater.

In the ratio with the percentage composition of sandy soil, several of its types should be distinguished:

1. The soil that contains dusty sand. This base is the most unsuccessful building on it. Since it is the humidity indicator that determines the bearing abilities of this soil. If such sand is saturated with moisture, then it has properties, similar to clay.

2. The construction of a house on small sandy soil is also characterized by a decrease in its supporting abilities, with moisture. In this case, it is recommended to waterproof the pit using a polyethylene film. About seventy -five percent of the composition of such soil contains sand, from 0.1 mm.

3. Soil with medium and high size. The diameter of its particles by more than half consists of fractions half a millimeter. Such soil has excellent bearing capacity. This soil is an ideal solution for the construction of any buildings.

4. Sand soil of gravel type - it contains more than twenty -four percent of parts, in size of more than two millimeters. This type of soil also remove moisture well, is not prone to fusion and has excellent performance.

If we consider the features of sand mail, then first of all, the level of its supporting abilities, which depend on the density of the soil, should be noted first of all. The denser the soil, the greater the load from the building it withstands.

In the presence of too wet soil, bearing abilities are reduced. If the size of the rock with a depth increases, then the sand is more opposed to compression. Therefore, the deeper the foundation is laid, the less shrinkage the building is subject to. In the process of performing the construction of the foundation, it is necessary to first of all perform high -quality waterproofing of the base. Regardless of the type of sand, waterproofing is mandatory.

The sand base is rarely characterized by heaving, since moisture passes through it. Therefore, almost any type of foundation is suitable for sandy soil. If the site is characterized by high humidity, then to eliminate this problem, you should equip a drainage system and warm the house around the perimeter.

The option of changing the structure of sandy soil in depth is possible. Therefore, by studying it, you should pay attention to the deep soil samples. Due to the presence of a low moisture level on sandy soil, it rarely freezes.

Choosing a foundation for building a house on sandy ground: foundation, sand, gravel

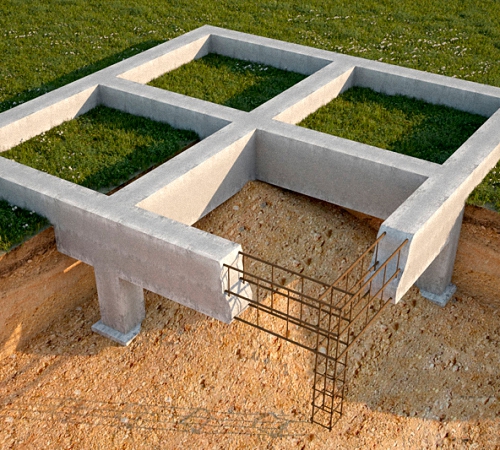

Coarse -grained sand involves the construction on its basis of almost any foundation. However, the most economical option will be the construction of a strip foundation with a fine -chained base. It is most often equipped for buildings in which there is no basement or under wooden houses.

There are two variants of a small -sized striped foundation:

- made;

- monolithic.

If there is a need to quickly carry out work, then it is better to dwell on the first version of the foundation. For its construction, special blocks of reinforced concrete are used. They are interconnected by concrete solution. The cost of work in this case is slightly reduced, however, compared with a monolithic foundation, the quality remains at the lower level.

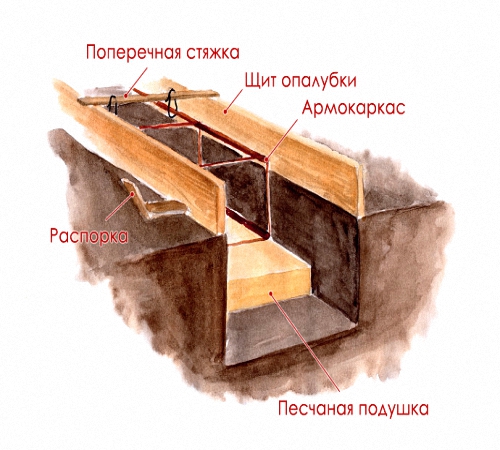

The monolithic foundation is equipped directly on the site. For its manufacture, the formwork is mounted, the reinforcing cage is installed and the entire area of \u200b\u200bthe foundation is poured with concrete solution.

A buried strip foundation is used in the process of building a house with a basement or basement. In this case, there is a need to manufacture an additional drainage system that removes moisture from the house. In addition, reliable waterproofing of walls and floor in the basement should be ensured.

A more economical option will be the construction of a pile foundation. In this case, the total cost of work is significantly reduced. This version of the foundation is simpler and easier to execute.

The choice of one or another type of foundation is based on the type of soil and the level of groundwater. The depth of the foundation is determined by the depth of freezing of sandy soil and the level of groundwater.

Technologically correctly constructed foundation is the key to long -term operation of the house. Keep in mind that you should not save on the foundation. A poorly equipped base will lead to a decrease in the operational characteristics of the house, the appearance of cracks in the foundation, the appearance of humidity and dampness in the house.

Sand -back foundation - preparatory work

Previously, the site is cleaned of weeds, trees, garbage and dirt. The following should be removed the upper fertile layer of the soil. In order to prevent the flooding of the trench under the foundation with water, the moisture system should be provided.

According to the project of the house, marking the base on the sand under the foundation is made. First, marking the outer walls of the house, and then internal. The type and method of marking depends on the type of foundation selected for the construction of the building.

If it is planned to build a strip foundation, then the marking is performed in a ratio with the perimeter of the building and the location of the load -bearing walls. When building a column foundation, you should mark the installation sites of the pillars or supports on which it is based. If the foundation of the slab type is made, for example, for houses with a basement, then in this case, only the perimeter of the building is marked, and the trench is dug up.

Please note that before starting work, a geodetic study should be carried out, aimed at determining the type of soil and the level of groundwater. If the work is carried out on a soil, which is characterized by fine granularity, then the soil should be prevented and frost resistant to increase it. In this case, the sole of the foundation should be larger than its upper part. It is preferable if the foundation has the form of a trapezoid. In order to prevent deformation of the base, it should be waterproof. For these purposes, it is optimal to use roller materials. With their help, gliding of frozen soil is provided. In addition, in order to reduce soil, you should take care of its insulation.

The next stage of work on the foundation involves the digging of the foundation pit. For these purposes, specialized equipment is most often used. The type and size of the pit is determined by the type of foundation that is selected for the construction of the house. To calculate the depth of the sand trench under the foundation, use the following recommendations:

1. In the construction of the foundation on solid ground, a depth of 100 cm is enough.

2. If the work is carried out on the sandy loam, then the foundation will become optimal a depth of 120 cm.

3. For clay soil or for sandy soil with a large content of small particles, you should be equipped with a trench with a depth of about 150 cm.

If it is planned to arrange a columnar foundation, then we will make deepening a round or square configuration. More racks in front of the soil, trenches with round corners.

The trench should be isolated from the flow of running water. For these purposes, you should build a system of ditches or dumps. The base of the foundation is laid immediately after digging the pit, thus, it will be possible to increase its strength.

Tip: Never fill up the earth back into the trench. This will lead to an uneven shrinkage of the building and its cracking.

If you too overdo it and dug a trench a little more than required, then you should fall asleep into it, carefully compacted sand, gravel or gravel. The most optimal option, pouring the base using a concrete solution.

Sand and cement for the foundation: technology for making the foundation on fine -grained soil

We offer to familiarize yourself with the option of manufacturing a tape-piece type of foundation on the soil of fine-grained type. In this case, piles installed on the supporting parts of the house are used to strengthen the strip foundation.

The foundation - sand proportions and the execution of the foundation with sand:

1. First, the foundation is prepared before marking. To do this, remove garbage, plants from the site and remove the upper soil layer. Most often, the pit under the foundation is equipped under a slope of forty -five degrees. At the same time, the formwork is built in height. For its manufacture, wooden boards are used, and for strengthening - screed and struts. At the corners and places of intersection of the foundation tapes, you should drill wells under the foundation.

2. If a flock was found on the site, then pipes on an asbestos -cement basis should be used to make a pile foundation. First, the pipes are installed into the well, then they should be fixed using spacers. Keep in mind that the pipes should have such a height to completely occupy the trench. In the presence of not very wet soil, the piles are made of concrete, with their preliminary reinforcement.

3. Pouring piles is carried out using a concrete solution, while the first stage of filling involves filling only the third part of the pipe. The concrete solution should fill the bottom of the well. Thus, it is possible to thicken the pile.

4. For the manufacture of reinforcement using wire, rods are connected with each other. The reinforcement should have such a height to connect it with the upper part of the strip foundation.

5. Next, pour the foundation with sand or gravel. If the question is about what sand for the foundation is the most optimal, then the sand on the foundation pillow should be used coarse -grained.

6. The reinforcement for the foundation should have a corrugated surface. Thus, its more dense adhesion with concrete is ensured. Use wire to knit the reinforcement horizontally. Welding is an unreliable means of combining reinforcing bars, since under the influence of concrete, it is corroded.

7. Bill with concrete is performed simultaneously on the entire part of the foundation. Vertical joints on the tape are unacceptable, as they contribute to a decrease in the bearing capacity of the foundation. The pouring of concrete ends with aligning the base and covering the foundation with a film made of polyethylene.

8. After the foundation dries, its vertical waterproofing is produced. For these purposes, roll materials are used that protect the foundation from the load. If the soil differs in humidity, then the drainage system is without fail. If necessary, the foundation is insulated with polyurethane foam or other alternative material.

Steel piles will help equip the foundation directly on the surface of the swim, if any. At the same time, the main key to the construction of a high -quality foundation is the correct determination of its type, depth of laying, width and styling method. Remember that on the basis of the building it is impossible to save in any case, since the durability of the building directly depends on the quality of its performance.