The destructive effect of moisture is subject to all structural elements of the building that ...

|

|

Almost no house can do without such an element as a drainage system ... |

Sooner or later everyone has to face the need to install pipes. AT... |

Waterproofing membrane: characteristics, properties, application

To protect the internal space of the room, waterproofing membranes are used from moisture. Thus, with their help it is possible to protect building structures from external stimuli and extend their service life. We will talk about the varieties and characteristics of the waterproofing membranes.

Table of contents:

- Waterproofing membrane: features and advantages of use

- Waterproofing film of the membrane: varieties and characteristics

- Installation of waterproofing membrane of profiled type

- Recommendations for the choice of waterproofing membranes: Review of manufacturers

- Waterproofing membrane for the floor and for the roof: installation features

- Waterproofing membranes for the foundation

Waterproofing membrane: features and advantages of use

As the main components of the polyvinyl chloride membrane, plasticized polyvinyl chloride is between which there is a reinforcing mesh. To reduce the heating of the membrane, it is produced exclusively in light colors. The main elements for the manufacture of the upper layer of the membrane are:

- fillers;

- plasticizers;

- stabilizers;

- antipyrene;

- dyes.

To make the lower layer of the membrane, antipyrene and stabilizers are not used. It is made in dark color.

The waterproofing membrane used in the process of waterproofing work should be characterized by the following criteria:

- high level of reliability;

- ease of installation work;

- Good operational characteristics.

Among the advantages of the use of waterproofing membranes based on polyvinyl chloride, it should be noted:

- frost resistance, installation of such membranes is possible even at a temperature of more than -18 degrees;

- Processing membranes with antipathic compounds increases their fire safety;

- To connect the canvases, it is enough to heat them, therefore, in the process of performing installation work, there are no particular difficulties;

- Also, among the advantages of waterproofing membranes, it should be noted: high indicators of mechanical strength, resistance to ultraviolet radiation, resistance to chemical and temperature effects;

- stability before chemical, mechanical and temperature effects;

- The possibility of further repair allows, when damaged by the membrane, it is quickly repaired;

- the duration of operation, which is more than twenty years;

- ensuring waterproofing in any areas, including hard -to -reach;

- affordable cost;

- Despite temperature changes, PVC film is good elasticity.

Waterproofing film of the membrane: varieties and characteristics

Waterproofing membranes are used in the process of waterproofing of the roof, basement and basement. Each of the types of membranes has its own characteristics, thickness and characteristics. A properly selected waterproofing membrane is able to provide reliable, and most importantly, prolonged protection against moisture.

In relation to the type of source from which moisture comes, they distinguish:

- moisture insulation work - a light type of isolation, a set of works aimed at protecting the entry of surface moisture and capillary sunses into the building;

- Waterproofing work - medium and heavy levels, protect the building from surface moisture, which seeps directly to the building, is used in the danger of moisture accumulation near the foundation.

The waterproofing membrane is called the material that protects the foundation, roof and other structural sections of the building, from moisture penetration. Some types of membranes are able to last more than fifty years. In relation to external indicators, waterproofing membranes are:

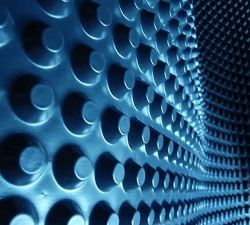

1. Flat - for their manufacture, high -speed or low -tight polyethylene, polyvinyl chloride is used for their manufacture. There are two types of films with a thickness of up to two millimeters in this type of membrane. To perform waterproofing foundations, it is recommended to use a film, the thickness of which is more than 0.5 mm. The film with minimal thickness is used in the process of waterproofing of even floors.

The use of this type of membranes is relevant both when performing waterproofing and moisture insulation work. On some types of flat waterproofing films there is a corrugated surface, due to which its adhesion to the solution increases.

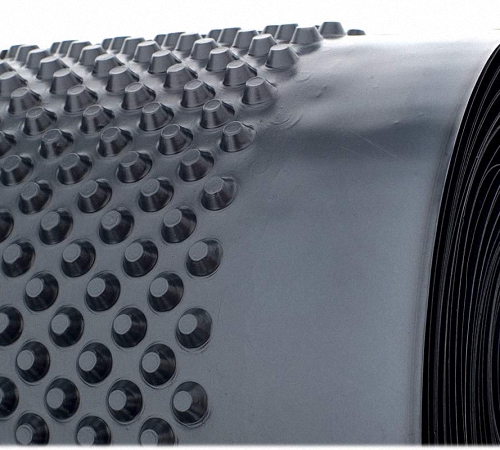

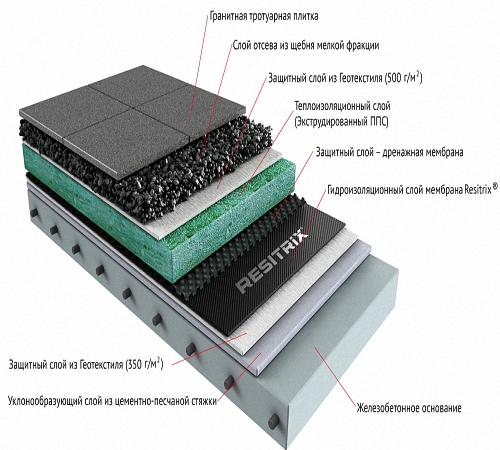

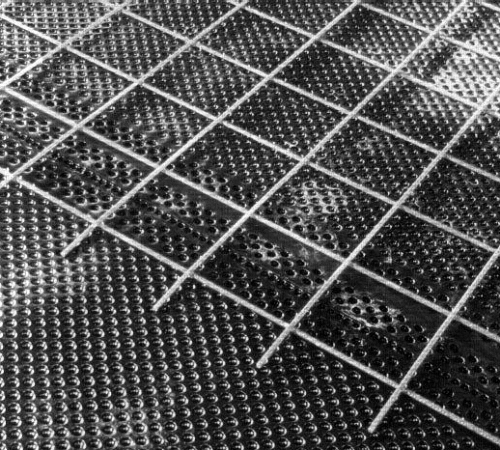

2. The waterproofing material of the profiled type membrane - PEVP is used for its production. The appearance of the material resembles sheets that have a square or round section and protrusions in the form of spikes. Therefore, this material is also called stud or pimpled. There are two options for this waterproofing - single -layer and multi -layer. The option of its use with geotextile elements is possible.

The thickness of the profiled membranes is from half to one millimeter, and the protrusions rise above the surface, a maximum of 2 cm. The thickness of the waterproofing membrane is about one millimeter, such a material is distinguished by a high level of profiling. The dimensions of the paintings themselves are 100x150 cm, 200x250 cm. The canvases are fixed directly on the wall, thus protecting it from both moisture and mechanically damage.

Installation of waterproofing membrane of profiled type

The film is laid so that the protrusions are outside. On top of the film, the surface is covered with geotextiles. Thus, in the surface between the two layers, the water flows along the drainage.

There are options for the manufacture of a combined membrane, which on the one hand consists of a profiled PVC film, and on the other, from geotextiles.

The profiled type of membranes was widely used in the process of arranging a multilayer waterproofing system. It is able to protect the walls of the foundation or basement from mechanical exposure. The membrane is laid on the surface of the walls only when the house is on the soil of a waterproof type, so that the water in no case is between the wall and the membrane.

If there is no complete confidence that the water does not penetrate there, then the lower part of the wall should be covered with a bitumen composition that provides additional waterproofing.

There are several ways to lay a waterproofing membrane, among them:

1. The waterproofing membrane of the flat type should be spread on a flat and dry base. For symmetrical surface isolation, sheets with a small overlap of 50 mm should be interconnected. To do this, use special glue, ribbon or welding.

2. Self -adhesive waterproofing membranes differ in the presence of a protective layer on one side, which is covered with paper, before gluing it to the surface, it is removed. After gluing the film, it should be well pressed to the surface with a roller. The membrane is laid with a small overlap.

3. The profiled version of waterproofing membranes is distinguished by the need for mechanical fixation. For these purposes, it is recommended to use dowels on which there are profiled washers. Thus, the connection gains additional tightness. To connect the sheets with each other, the presence of profiled latches, or special laminated stripes, is required. To fix the upper section, special clamping strips are used to ensure the removal of accumulated moisture. Keep in mind that ventilation ducts on the strips should always be open.

Recommendations for the choice of waterproofing membranes: Review of manufacturers

We offer to familiarize yourself with the main manufacturers of waterproofing membranes in the building materials market:

1. The membrane of the waterproofing technology - is a modern building material, with which it is possible to qualitatively waterproof certain areas of the building. In the lineup of the waterproofing membranes technoinol, there are such types of materials:

- Super premium class - waterproofing used for roofs, in regions with a cold climate, this version of the membrane consists of three layers, for the manufacture of which plasticized PVC is used, and the polyester grid performs the function of internal reinforcement, in addition, the film contains a large amount of antipyreen in the film and additives that increase its resistance before exposure to ultraviolet radiation;

- The premium membrane is used in the process of waterproofing on a flat roof, has the same characteristics as the previous option;

- membranes that allow waterproofing on bridges, tunnels and foundations;

- Polymer waterproofing membranes - are used in the process of waterproofing of pools of any type, an acrylic coating is also present on this type of membrane.

2. The Tyvek Soft waterproofing membrane is used to maintain an optimal temperature and humidity mode in the room. There are several options for waterproofing membranes Taik software:

- wind waterproofing membrane - is used to protect the walls from moisture and wind in the system of the ventilated facade;

- Steaming membranes - have limited vapor permeability, relevant in the process of arranging wooden houses.

3. The Tyvek Supro waterproofing membrane is a strong waterproofing material on a polypropylene basis. Installation of this material on the roof does not need additional arrangement of roof ventilation. Among the advantages of this membrane, it should be noted:

- resistance in front of low temperature and ultraviolet light;

- high waterproofing characteristics;

- air and vapor-permeable characteristics;

- providing a healthy microclimate in the room;

- Duration of operation.

Waterproofing membrane for the floor and for the roof: installation features

In the process of laying waterproofing on the floor, you should adhere to the following recommendations:

- carry out work exclusively at low humidity;

- prepare the surface, having previously dried it and cleanse it from dirt and dust;

- prevent contact between the film and the insulation, between them should be present in the form of a ventilation clearance;

- The absorbing surface of the film should be in contact with the insulation.

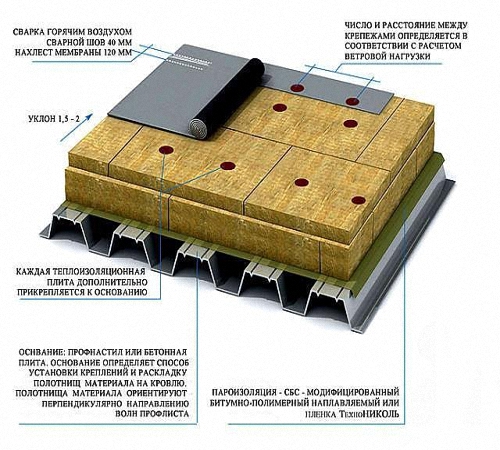

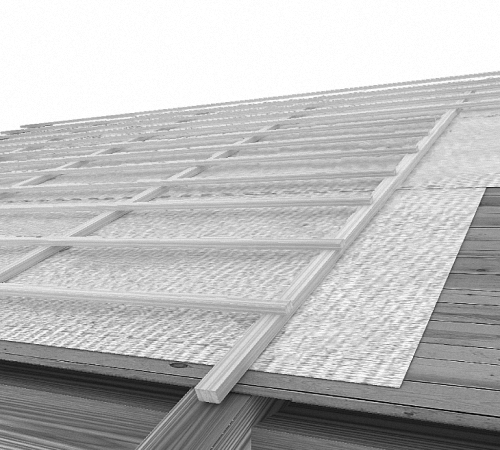

Installation of the waterproofing membrane on the roof is carried out in this way:

1. First, the material is rolled around the perimeter of cornice overhangs. Keep in mind that the film should sag over the surface of the rafters by 2 cm.

2. Between the waterproofing membrane and a layer of insulation, it is recommended to leave a gap of 4-5 cm.

3. The waterproofing is installed in a horizontal position, from the cornice to the ridge part. All extreme sections of the film must be hermetically interconnected, use a special tape to add joints to the joints.

4. To fix the film, it is recommended to use a mechanical stapler, or nails made of galvanized steel.

5. The next row of the membrane is laid in the same way, only with an overlap about 20 cm.

6. The tape is installed on the control crate, the gap between it and waterproofing is about 10 cm.

Waterproofing membranes for the foundation

There are several ways to lay a waterproofing membrane on the foundation. The first of them is horizontal. First, on a horizontal surface, a geotextile -based lining should be laid. They protect the foundation from mechanical exposure and pressure. This material is recommended to lay 15 cm overword.

Next, the waterproofing membrane is installed, with an overlap for 10 cm. To connect the material, hot welding is used. Each of the seams should be about 1.5 cm, and the air channel - 2 cm.

The second method is vertical. To fix the membrane on such a site, its point welding is used using hot air and steel elements. After fixing the membrane, vertical and horizontal sections of the foundation are covered with another layer of geotextile. To fix it, special glue is used on the surface of the membrane.

Next, a polyethylene film is laid for gluing its paintings among themselves, it is recommended to use double -sided tape.

The welding procedure of PVC membranes is as follows:

- Remove dirt from the seams with a special cleaner if you have;

- minimum work temperature -15 degrees;

- First, a suture is trim welding;

- After half an hour after the welding, the seam and its quality are checked.

If the work is carried out at air temperature, less than the +4 degrees of heat, it is recommended to maintain the membrane in a warm room, for twelve hours, and only then use for its intended purpose. The base on which the membrane is installed should be absolutely dry and clean.