Modern landscape design often includes such a component as forged ...

|

|

If, recently, wet spots began to appear on the ceiling, which after a while ... |

Compliance with the installation technology of the folding roof allows you to prevent corrosion ... |

Waterproofing materials

The destructive effect of moisture is subject to all structural elements of the building, which directly affects their reliability and durability. In order to minimize the effects of moisture and extend the life of the building, at all stages of its construction, starting from the filling of the foundation, the construction of walls, roofing and ending with the interior decoration, it is necessary to pay special attention to waterproofing. Depending on the structural elements and conditions of further operation, certain waterproofing materials are selected. Creating a reliable waterproofing coating is quite simple, requiring knowledge and understanding what waterproofing is, and the ability to handle the tool.

Content:

Requirements for waterproofing materials

When choosing certain waterproofing materials, attention should be paid to their operational characteristics. Her reliability and durability will depend on how waterproofing will correspond to the aggressive conditions of the environment. The following requirements are applied to waterproofing:

- Atmospheric resistance The ability to maintain the original characteristics for a certain time under the influence of various atmospheric phenomena. This parameter is measured in points on a special scale or displayed by the temporary frames (days, months, years).

- Biological stability resistance to aggressive effects of various bacteria, fungi and microorganisms.

- Water resistance The ability not to absorb or miss water. This is the main parameter for waterproofing materials.

- Water resistance resistance to prolonged exposure to water without loss of initial properties.

- Durability The ability to maintain the original qualities and integrity of the structure for a certain time under the influence of all aggressive environmental factors.

- Vapor permeability The ability to pass water vapors through a layer of waterproofing. This parameter is very important when creating waterproofing roofs and internal walls.

- Resistance to large temperature extremes Indicates the ability of waterproofing to maintain its original properties and integrity of the structure at certain temperatures. This parameter for external waterproofing is especially important.

- Resistance to mechanical damage The ability to maintain the integrity of the structure with increased loads on the surface.

- Chemical resistance The ability to maintain the original characteristics and integrity of the structure under the influence of various chemical solvents.

Due to the fact that various elements of the building (foundation, walls, roof) are affected by different natural factors, the selection and arrangement of waterproofing materials should be based on their characteristics. The technology of waterproofing materials of any type is based on their properties.

Types and classification of waterproofing materials

Today in the market of waterproofing materials you can find a large range of products, in the variety of which it is easy enough to get confused. In order to be quite easy to navigate among all waterproofing materials, it is necessary to know their classification and types.

First of all, waterproofing is divided according to the area of \u200b\u200bits application. It can be for internal or external works. Also, waterproofing is divided according to the main component, it can be bitumen, mineral components, polymer or bitumen-polymer.

The main gradation of waterproofing materials is performed by type. They can be rolled, film, caps, membranes, powder, penetrating, plaster, bruthing and painting waterproofing materials. As well as many others, depending on the method of styling and physical condition. Below are the most common waterproofing materials that are used in private construction and repair.

Rolled waterproofing materials

This type of materials was one of the most common in the last century. The most affordable materials of this type ruberoid, only, glass -rubled. They were used as waterproofing materials For the foundation, roofs and sexes. The basis for the materials of the roll type was cardboard or fiberglass, soaked in bitumen with the addition of basalt crumbs. More modern waterproofing materials of a roll type are created as multi-layer membranes and combine the quality of water and thermal insulation. Laying roller materials is carried out in several ways.

The first is a simple flooring to the surface under any other building material with subsequent joint mount.

The second way to lay roll waterproofing is to pay to the surface using a gas burner. This method is fire hazard, therefore, using it, it is so important to comply with all fire -fighting norms.

The third way of laying is the gluing of roll waterproofing to the surface using various mastics or special adhesives.

Film waterproofing

Another collection of roller waterproofing materials is film waterproofing. Unlike roofing material, it is made of polymers, such as polyethylene, polypropylene, PVC. Polyethylene films are very common waterproofing for the roof Thanks to their operational qualities. In addition, polyethylene waterproofing is used when creating a concrete screed in room. Among the film waterproofing, PVC membranes, which are a multi -layer pie from various polymers with certain qualities and properties, should be especially noted. The laying of film waterproofing is carried out by a simple flooring or using special adhesives, and film membranes can already be with an adhesive layer.

Waterproofing materials based on mastic

The second most popular waterproofing materials are mastics. They are plastic adhesive compounds of cold or hot type. Their area of \u200b\u200bapplication is quite wide and includes roofs, foundations, pools, the walls of the basements. You can also use these waterproofing materials for the bathroom, kitchens and toilet, processing all the joints of the ceilings or the surface of the floor.

Mastics are made on the basis of bitumen, various polymers or combinations of polymers and bitumen. With the development of technologies in construction, it became possible to produce bitumen mastics with the addition of rubber, which made it possible to increase the insulating and mechanical qualities of waterproofing of this type.

Another achievement was the creation cold mastic. If the classic bitumen waterproofing required heating to a certain temperature, then modern cold mastics allow you to perform all work without their heating. It is quite simple to apply mastic. To do this, it is enough to apply waterproofing to the surface with a spatula and smooth it with the same spatula or a roller or brush.

Liquid waterproofing materials

This variety is a rather colorful set of waterproofing of various types. It can be paints, primers, mastic, adhesives, impregnations, injection materials and many other fluid materials.

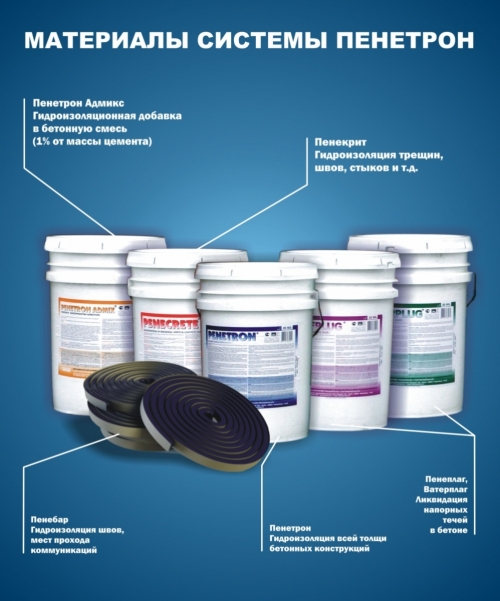

Particularly noted waterproofing material Penetron. It belongs to liquid waterproofing of a penetrating type. Its principle of action is based on penetration into the structure of the base. It is applied to the surface, penetrates inside the air capillary system and after drying it forms crystals that repel water. A feature of the penetron crystals is the ability to pass air through itself and at the same time repulsing water. If you choose waterproofing materials for flooring in residential premises, you should pay attention to penetron, as it allows the surface to breathe, which means that it does not complicate the natural circulation of air in the room. Liquid waterproofing materials are applied using conventional brushes or sprayers.

Powder waterproofing materials

Such materials are various dry mixes based cement With adding plasticizers, adhesive and bindingcomponents. Their feature is that they are prepared immediately before applying to the surface. The cooking process itself is the same as all dry building mixtures - add water and stir thoroughly. These waterproofing materials are most often used for pools, when creating concrete screeds or plastering walls in the basements. Powder materials have quite high waterproofing qualities, penetrating all possible cracks, cracks and filling any voids. Unfortunately, powder waterproofing has one significant drawback of the mixture dries very quickly. And therefore, you have to make in small portions and apply at a time in small areas.

To perform high-quality waterproofing, no special skills or skills are required. All modern materials are made using technology that allows you to facilitate the arrangement and at the same time achieve the maximum possible protective effect. The main thing is to choose the right materials. This is the key to successful protection against moisture and durable operation of the entire structure as a whole.