A car for many people is more than just a means of transportation. It...

|

|

The vast majority of residents of the metropolis, realizing the advantages of life in private ... |

The first task that arises from the owner after buying a site for construction ... |

Connection of sewer pipes

Sooner or later everyone has to face the need to install pipes. Depending on what material you chose from, the installation technology itself will depend. We will talk about which connection is better to choose welded, threaded or bell -shaped when working with pipes from various materials in this article.

Content:

- Types of sewer pipes and connections

- Sewer connection angle video

- Preparatory work

- Connection of metal sewer pipes video

- Connection of plastic sewer pipes

Types of sewer pipes and connections

If earlier sewer pipes were made mainly of metal, today on the market you can find not only steel cast iron pipes, but also ceramic or plastic ones.

Ceramic sewer pipes are produced by a dimeter of 150-600 mm and are more often used in the installation of external sewage. The main advantage of such pipes is the resistance of ceramics to the effects of aggressive groundwater. In household construction, the use of ceramic pipes is extremely rare. As for the connection of sewer pipes from ceramics, it is similar to the combination of cast -iron pipes.

The most used plastic pipes are made of polypropylene, high and low density polyethylene, as well as polyvinyl chloride. Such pipes differ in simplicity of installation, lightness, as well as mechanical strength and resistance to corrosion. There are plastic pipes for external and internal installation and they differ not only in diameter, but also with color. The former are painted in orange, the latter in gray.

And finally, the traditional material for the manufacture of sewer pipes of cast iron. Such pipes have excellent indicators of mechanical strength and resistance to corrosion.

Steel sewer pipes are also represented on the market, however, they are quite rarely used when laying sewers, as they are subject to pernicious exposure to corrosion and are unstable to aggressive groundwater.

As for the method of connecting the pipes, it can be carried out by welding or gluing. If you plan to create a collapsible sewage system, then the connection of the pipes can be carried out on the thread using fittings or on flanks. In this case, flange compounds are used on large diameter pipes, since it will simply be inconvenient to connect by thread. Which of these types of compounds is most suitable for PVC pipes or pipe from cast iron, as well as how to connect these pipes, we will tell you below.

Sewer connection angle

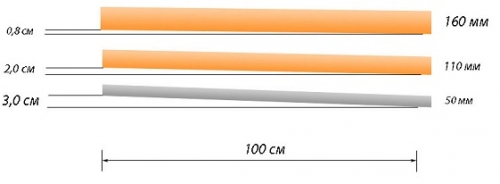

When arranging a sewer system in the house with your own hands, it must be remembered that for normal operation, pipes should be laid under a slight inclination. In general, the slope should not be less than 0.02, which means that with the total length of the water supply of one meter, the height difference at the ends of the pipe should be equal to two centimeters.

Moreover, if the volume of the drains is small, then the inclination indicator should be larger and be 0.03.

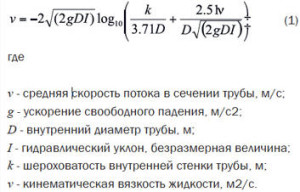

In general, the angle of connection of sewer pipes can be calculated independently using the formula:

Or just use ready -made solutions.

Preparatory work

Before proceeding directly to the connection of sewer pipes, it is necessary to carry out some preparatory work:

- Make sure that the entire range of accompanying goods has been purchased and when the pipes are installed suddenly it does not discover that there is not enough special glue or, for example, heat -resistant mittens.

- Sovele the location of communications, prepare a site for work and create a plan for placing pipes.

- Carefully checking with a plan for placing pipes, mark the blanks and proceed to cutting the material. To avoid overrun of the material, it is recommended to cut from large sizes to smaller ones.

- To join the pipes, it was convenient, the scraps must be cleaned from the burr, wiped from pollution and degreased with a special composition.

- If the installation of metal pipes is supposed, then an external or internal thread is applied to them.

Connection of metal sewer pipes

The connection of metal sewer pipes can be carried out in one of two methods: installation for welding and installation in the bell. In this case, installation in the bell, as a rule, is carried out when combining cast -iron pipes, while welding is mainly used when connecting steel pipes.

Pipe connection from cast iron

As mentioned above, the combination of cast -iron sewer pipes is carried out using bunks. Such installation is made according to the following scheme:

- The cast -iron pipe (with the side that without a bell) is inserted into the bell already installed.

- We take the linen dad and seal the gap between the installed tail of the pipe and the internal edges of the bell. To do this, we take a special wooden shoulder blade and, striking on it with a hammer, we score the first wound layer of pack into the bell. At the same time, be sure to make sure that when clogging Packl does not get into the pipe, as this can lead to the formation of blockages. By the end, 2/3 of the bell should be filled by the seal.

- The remaining third of the bell will need to be filled with the seal without impregnations.

- After the bell is filled with a cement mortar prepared in the proportion of 9 cement volumes for 1 water. The solution must also be thoroughly compacted in the cereal, and then cover with a damp cloth. This is done so that when drying on cement does not form cracks. In addition to cement mortar, you can also use an asbestos -cement mixture, bitumen mastic or silicone sealant.

This method is used to combine cast -iron pipes among themselves, but there are also situations when it is required to combine a cast -iron pipe with a plastic one. In this case, it is recommended to use special adapters and couplings. They are suitable for connecting sewer pipes of different diameters, as well as from different materials.

In order to qualitatively perform the transition from a cast -iron pipe to plastic, it is necessary to evenly apply a silicone sealant on a clean and dry inner surface of the chubby pipe. We also apply it to the adapter itself, after which we insert the adapter into the bell. The compound will become completely tight immediately after silicone sealant is polymerized.

Connection of metal sewage pipes video:

Drinking steel pipes

Welding is used to connect steel pipes. And here is the main thing to do everything professionally and taking into account all the nuances of the process. However, even having spent on a welding machine and properly weld steel pipes, we get a rather unreliable design. Since steel pipes themselves are not quite perfect for sewage, and the welding seam, compared with the rest of the metal, will be more exposed to corrosion. That is, only by putting into operation the sewer system, we already know that it has weaknesses, which over time can cause water leakage.

Of course, in addition to welding, steel pipes can be connected using detachable threaded joints. So, the-American fitting is the most popular of these connectors and is two endings, which are interconnected by a pitch nut.

Connection of sewer plastic pipes

When connecting sewer plastic pipes can be carried out in one of three ways: on a threaded coupling, for welding and in the bell. Each of the technologies requires the use of certain skills and equipment, therefore we will consider each of them more details.

Installation on the coupling

First you need to decide on the type of clutch on a plastic pipe. However, before proceeding directly to the description of the installation process on the coupling, it should be noted that this method of connecting sewer pipes is allowed only if their diameter does not exceed 63 mm. In the same case, if the diameter of the pipes allows installation on the coupling, you can get a fully collapsible water drainage system.

The process of connecting the pipes through a compression or threaded coupling itself is quite simple. It is enough to simply disassemble the fastener element, put a countrogike and a sealing ring on the pipe. Next, you need to insert the pipe into the fittings of the coupling and wind up a counter -gamer on the thread of the end of the coupling, which will fix the junction.

The threaded installation is considered the fastest way to connect the sewer pipes, since the system can be operated immediately after twisting the locknut. However, it must be understood that this quickly does not mean reliably. Also, in the case of threaded couplings, a threaded steam can spin over time and water will begin to seep at the junction.

Installation for welding

Depending on the material from which sewer pipes are made, cold welding technology, or what it is also called gluing, as well as diffusion welding technology. Cold welding is used when installing pipe from polypropylene, and diffusion when connecting pvc pipes. At the same time, both welding methods are used when fixing the pipe in the bell or when installing in the coupling.

Installation of polypropylene pipes by welding is as follows:

1. Cut the end of the pipe and measure the depth of placement of the pipe in the coupling. Pruning and labeling of depth must necessarily precede welding, since otherwise you significantly risk the installation with the quality of the installation, and, therefore, the reliability of the entire system.

2. Using a special soldering iron, heat the coupling and pipe. To do this, both products must be put on a nozzle and warm up to 260 degrees.

3. Heated parts are removed from the guides, after which the pipe is impressed at the fabric depth of the coupling.

With this version of the installation of polypropylene pipes, the system is considered ready for operation immediately after cooling seams to room temperature.

The connection of PVC sewer pipes is carried out as follows:

1. We carry out the trim of the end and marking the depth of immersion.

2. On the inner parts of the coupling and the outer part of the pipe we apply a special glue, after which we insert the pipe into the clutch to the blown up depth. We turn a little around the axis. Note that when choosing glue, it is better to give preference to the product that the manufacturers of fittings and pipes themselves recommend.

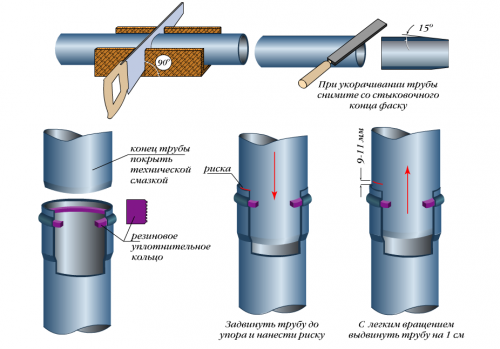

Installation in the bell

Installation in the bell can be carried out only if it comes to connecting pipes, which will subsequently become part of non -pressure networks. Also, the pipes themselves for installation in the bell should have a special thickening at the end.

The trim is carried out as follows:

1. A pipe is installed on the supporting surface. The bell is installed in the direction of the opposite movement of the flow.

2. Insert the sealing ring into the bell of the receiving pipes.

3. When the sealing ring is installed, we introduce the smooth end of the second pipe.

4. After assembling the connection, it is necessary to fix the second pipe on the supporting surface.