A reliable and durable house is not only strong stable walls and non -flowing ...

|

|

What can be more useful than vegetables and fruits grown in their own area? The only way... |

Wallpaper is one of the most popular materials for interior decoration. They distinguish more ... |

Stained glass windows: photo, manufacturing instructions

The vast majority of residents of the metropolis, realizing the advantages of life in private possessions, are increasingly striving to break out of the hugs of the noisy and crowded streets of the city, somehow constraining freedom -loving nature, and settle in their own countryside cottage located on the bosom of nature or in a well -maintained country house, outside Which an endless series of cars will be replaced with joyful birds singing and fragrant greens. But despite the prevailing earnings of living in the bosom of nature, most citizens leave no hope that their house will become not only the subject of pride of the owner, but also a kind of object of admiration for others. One way to achieve this goal is to design a house with stained glass windows, which among many options for decorating the room are particularly bright and original. The room in which stained glass windows are installed acquires a special charm due to special illumination and play of sunlight. Thanks to this, there is a very dynamic use by fashion designers and architects in the process of stained glass windows, which allows you to present the decoamed object the only one among buildings of a similar design. The use of stained glass windows will emphasize not only the internal originality of the house, but also diversifies the outwardly unremarkable facade of ordinary construction. The development of innovative technologies could not but affect the basic technological principles of the production of stained glass compositions, and today, thanks to the ultramoded methods of manufacturing stained -glass windows, you can carry out your most daring ideas and sketches. In addition to the vital compositions themselves, in the process of arranging the interior concept, light that falls through the stained glass and allows for the adjustment of lighting in accordance with the wishes of a particular customer is also used.

Content

- Stained glass windows: Historical aspects

- Why do we recommend choosing stained glass windows?

- The main varieties of stained glass: the principles of classification

- DIY windows in the style of Tiffany

Stained glass windows: Historical aspects

Modern design is at that stage of its development when, in the process of developing any design project, it is necessary to take into account the features of the color filling of the room. The design of the windows, according to experts, is an immense field for imagination, which cannot go unnoticed. Stained windows - a design element that gives a unique expressiveness to the decorated room. It is stained -glass windows that are an element that can bring harmonious notes into the design of the room and place the necessary accents to the color scheme. In most cases, stained glass windows are used to decorate the room, however, a stained -glass window is an element of decor, which carries a functional load, for example, it can become a decorative screen that hides the internal space of the room from extraneous views.

Even in ancient times, people noticed the original effects that occur during the transfusion of multi -colored glass in the sun. The unique, previously unprecedented game of light and shadow pushed the ancient masters to create a decorative mosaic from small multi -colored glasses, which later led to the emergence of the full art of the manufacture of window stained glasses, which were widely used for the decorative design of majestic palaces, temples and cathedrals. However, stained -glass windows were used not only to decorate windows. A multi -colored glass of glass, demonstrating a variety of biblical plots, was inserted into wooden and stone doorways and transformed the interior decoration of the premises due to the constant play of light. Currently, technologies for the manufacture of glass mosaics have stepped far ahead and significantly increased the decorative characteristics of stained glass.

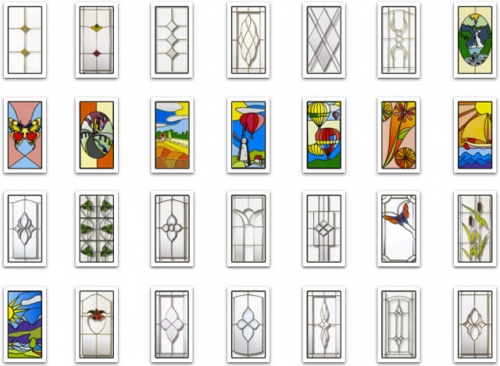

Stained windows photo

Why do we recommend choosing stained glass windows?

- Houses and cottages decorated with stained glass windows attract attention, even despite the architectural pretentiousness of neighboring buildings and are a real work of art;

- Houses with stained glass windows hover over everyday life. translating it from the category of expensive buildings into the category of exquisite-grinding;

- Stained glass windows emphasize the beauty of the cottage, enhancing its individuality. This is due to the non -standard characteristics of cottage windows, which open the boundless scope for the imagination of creative nature;

- Stained -glass solutions are always individual, since in each case they are based only on personal design preferences of the customer who offers his stained glass sketch or chooses it from the catalog. In the latter case, the stained -glass window, made by the master, always acquires his individuality, becoming unique and the only one in his copy;

- The customer gets the opportunity to independently choose a variety and technique of execution of a stained glass window, as well as choose a stylistic solution of the stained glass window. At this stage, it is decided whether the customer will provide the artist with his sketch, or will use what is in the artist’s arsenal;

- The cottage ensemble can be complemented by a fantastically beautiful veranda or winter garden decorated with stained glass compositions. Thanks to the use of stained -glass windows, the effect of a skillfully made glass box is created, which is an original work of art in any light - both when lighting with sunlight, and in the case of internal illumination with electric lamps;

- By installing stained -glass windows in the entrance group of the cottage, you will demonstrate your high status and emphasize the taste, earned the glory of a real connoisseur of art.

The main varieties of stained glass: the principles of classification

There are many varieties of stained glass, each of which is distinguished in accordance with one or another classification principle. Accordingly, there are also several classifications. First of all, we consider the classification of stained glass, based on the technological features of their production and known only in circles of professional masters.

Classification of stained glass in accordance with the manufacturing technique

- Broken stained glass, the manufacturing technology of which involves the connection of pieces of colored glass using lead soldering, after which they are inserted into a metal frame. A bright representative of the stained glass structure made using this technology is Tiffany stained glass, the characteristics of which will be discussed later;

- An integrated stained glass window, the manufacturing technology of which involves baking small multi -colored fragments into a single glass blade, after which elements of additional decor, for example, pebbles, rhinestones or wire, impose into it. The stained -glass window made using this technology is called Fusing Viture from the English word Fuse - sintering or swimming;

- Sandbrown stained glass involves polishing glass processing, through which a matte pattern is applied to it, not only giving originality to the interior, but also limiting visibility in the room;

- Half stained glass - Another unique technique of manufacturing glass mosaics, which involves the destruction of glass using smelting acid, as a result of which a relief pattern of various depths is formed on the surface of the mosaic canvas. This technique is certain difficulties, since one wrong movement can finally ruin all the work. In addition, work with smelting acid requires wholesale and compliance with safety precautions;

- Painted stained -glass windows - One of the techniques of stained -glass art, which involves the application of special paint on the glass and allows you to make both multi -colored and monochrome pattern. In addition, working in this technique, you can adjust the level of transparency of the glass - to carry out more dimming. It is enough to do an additional layer of paint on its surface. The color intensity is regulated in a similar way;

- Application stained glass- The most affordable method of manufacturing a stained glass, which involves gluing elements of a pattern cut from a multi -colored film on a transparent glass. This technique of manufacturing a stained glass is appropriate in situations when stained glass is subject to shock and should meet the requirements for the strength of the material. The use of application stained glass is especially relevant where there are small children.

Important! The creation of stained glass applications on windows of all types, including plastic and aluminum, is finished. Plastic windows, stained glass windows for which is the main method of decoration, are used when there is a need to hide an unsightly view from the window of a living or office space. If the double -glazed window is two -chamber, the stained glass film is fixed between the outer and medium glass. which ensures its great safety, leveling the effects of steam and condensate from the side of living space.

Important! The aluminum windows of stained -glass windows are used much less often, which is explained by the use of glazing with aluminum profiles mainly in non -residential premises. However, aluminum constructions are often used as screen and partitions in which traditional matte or corrugated glass is often replaced by stained glass compositions.

Technological classification of stained glass for consumer

The classification of stained glasses in accordance with the manufacturing technique is more simple for non -professional and does not imply the need to deepen into technological details, but fully explains the basic production principles of their manufacture. Consider it in more detail:

- Facela stained glass - involves the creation of a stained glass in accordance with the principles of classical stained -glass technology. The only difference between the technique of fatset stained glass is that some (and sometimes all) stained glass elements are subject to cut (removal of fatset). This is carried out in order to increase the aesthetic characteristics of the stained glass by achieving a greater game of light in the created faces;

- Fushing stained glass window It is made by fuse of multi -colored pieces of glass in high -temperature furnaces. Immediately before the fusion, the elements are carefully cut and polished, after which they are laid out on a glass substrate with the formation of the pattern. Temperature processing - the final stage of the manufacture of stained glass composition, after which color elements are combined into a single whole. A distinctive feature of fushing stained glass is a wavy surface.

Important! There is another way to make fushing stained glass windows, which involves the use of a hardened glass substrate characterized by special strength. A substrate of refractory glass, the use of which is advisable in the case of installation of completely glass doors or window openings characterized by a large area of \u200b\u200bglazing, is not recommended to be used for the manufacture of fusin stained glass windows, since during temperature treatment it will lose its original strength. However, there is another technique for the manufacture of fusining stained -glass windows, which eliminates the need for temperature treatment and allows you to maintain the initial strength of the hardened smell. It involves gluing the elements of stained glass on the glass base using transparent adhesive compounds, it will allow you to obtain a reliable stained -glass composition with high artistic characteristics.

- Tiffany - the technology for creating stained -glass windows, which implies fastening of individual parts of the glass using a metal strip or soldering. Thanks to this, the main components of Tiffany stained glass are bright colors, bizarre shapes and intricate stories;

- Mirror stained glass - a technique that involves the manufacture of a stained glass composition in accordance with one of the above methods, followed by applying a thin layer of sodium nitride, adjusting the thickness of which can be increased or reduced by the degree of glass reflection, or get a unilaterally transparent mirror;

- Painted stained -glass windows - a technique that involves the drawing of the drawing with silicate paints using a brush or airbrush on a glass substrate with subsequent high -temperature processing;

- Engraved stained glass window - a technique that involves drawing only manually using specialized engraving equipment or a hand tool. The basis for such stained glass is colored glass, which is created by heating several colored glasses to a liquid state, mixing them followed by pouring onto the table and rolling. The result is glass with a unique color and a pattern that has no analogues;

- Matte stained glass, for the manufacture of which a sandblasting technique is used, which involves the supply of a stream of sand under pressure, which scratches the transparent glass and, knocking out microparticles, turns a transparent surface into a matte one. In order to create a drawing within the framework of this technology, it is necessary to prepare a stencil, which is fixed on the glass, after which the glass is placed in a sandblasting chamber. At the end of the processing, you will see that the surface not closed by the stencil remains transparent, and the closed becomes matte;

- Stained glassit has external similarities with the classic, but is made in a simpler way. The preparation of drawing elements for the stained glass composition is carried out using a machine guided by a computer program. If the elements of the classic stained glass are connected by lead gaskets, then in this case they are replaced with more modern materials that have external resemblance to the previous ones. Having formed a stained glass composition, it is glued on a glass substrate using transparent glue, and therefore, the finished stained glass, unlike the classic one, is characterized by greater strength.

Functional classification of stained glass windows

Stained windows are the most traditional form of using stained glass equipment for interior decoration. The most common types of stained glass windows are the following:

- Stained windows for installing window openings in the wall or the so -called external stained glass windows for the manufacture of which in most cases transparent glass is used, providing the maximum possible level of lighting in the room;

- Interior stained glass windows, for the manufacture of which is used both transparent and matte glass;

- Stained-glass windows, the use of which is relevant where there are no windows, but the need to create an illusion of daylight is maintained.

DIY windows in the style of Tiffany

Sketch development and selection of material

The manufacture of a stained glass starts with the development of a sketch, during which a number of requirements must be observed:

- In order to ensure stability of stained glass to mechanical influences, the stained glass project must have a large number of cross -shaped connecting lines;

- If wide connecting seams are used in the process of compiling a design project of the stained glass window, abandon narrow and long elements, as well as retracted and sharp corners, which will eliminate the appearance of cracks in the process of heating;

- After a thorough selection of the drawing for the window, make a list of the parts used and numbered them by color. Print a finished sketch, not forgetting to leave the allowance for seams at least 0.126-0.127 cm, which is necessary to create tin satching;

- Prepare the mounting table and lay the cut pattern on it, fixing the edges of the glazing at the edges, which will allow the stained glass composition of clear boundaries;

Important!Next, select the glass for the manufacture of a stained glass window. The modern market offers various types of glass and materials for the manufacture of stained -glass windows, which differ in color, intensity and thickness. To choose the right glass, the sketch must be made in color. If the differences in glass elements are not provided for a design project, it is necessary to choose glasses of the same texture and thickness.

- Next, proceed to cutting glass, for which it is necessary to attach a stencil sketch to it and draw a thin line along the contour of each element. Remember that all elements are numbered and circle only those that belong to the specified shade. If you work with textured glass, it must be cut only on the smooth side. Glass cutting is carried out on a flat surface, smooth movements without pressure, which can lead to cracking of glass. To prevent the appearance of chips, at the end of each movement it is necessary to weaken the pressure.

Important! If you need to make a recess for the lens (glass balls -elements of the decor, use a grinding machine equipped with a stone of the corresponding diameter.

Processing of decorative details of the stained glass composition

- After you have completed the cutting of decorative elements using a grinding machine that removes all chips and irregularities, process all the ends of the parts. Having implemented this, wrap each element along the edge with a folic, which is an adhesive tape with a sticky layer, which is glued to the end of the type of adhesive tape. In order not to cut your hands, use protective gloves during operation.

Important! The selection of the adhesive layer for the tape is important in the process of work. There are transparent and black glue, the choice of which is determined by the characteristics of the glass with which you work. If you use transparent glass using a black patina, choose a folic with a glue layer of black color, so that the tape will remain invisible, and the pattern will look like a single canvas.

Remember!Sticking sticking the tape must be carried out on dry, polished glass.

- Having completed the winding, reward the tape with a plastic stack and put all the elements on the tracing paper in the order corresponding to the previously developed sketch. To work faster, the layout of the elements start from the corner, observing between them a distance of at least 1 mm, which will allow tin to carefully connect the parts among themselves.

- Using a brush, cover the seams with soldering acid-flus, which will remove the oxide from the tape, and the tin is firmly connected.

Soldering: recommendations of specialists

- Next, it is necessary to solder. If the stained-glass window is designed to decorate the window opening, experts recommend using the Tin solder PO-61. Tin wire melting is carried out with a stained glass soldering iron, which is held as a regular handle for writing. Along the stained seam, they are carefully carried out with solder, without lingering for a long time at one point to prevent glass overheating. Having thus processed all the details, make a final soldering using a thin tin layer.

- Next, using a flat soldering, treat the perimeter of the stained -glass window with a brass profile frame, which should be durable to reliably hold the stained -glass window. Rinse the stained -glass window with water and detergent and polish its surface with a clean piece of fabric, then proceed to the application of a patina that is carried out using a brush. This will create the desired decorative effect - from gold and bronze to black. In the process, use rubber gloves. After applying the patina, leave the stained glass for 15 minutes, then rinse its surface again and treat with antioxidants, which will prevent oxidation of the seams. Then let the staining steam finally dry and treat with polish and soft cloth. Having prepared a stained glass window, insert it into the frame.