A wide variety of putty mixtures for repair work is presented on sale ....

|

|

The main indicator of the quality of each antenna is its interaction with the etheric signal ... |

To insulate inclined roofs, attic floors or the inner surface of the walls ... |

How to lay reinforced concrete slabs

A reliable and durable house is not only strong stable walls and a non -flowing roof, but also no less strong seismic resistant floors. For the arrangement of inter -story ceilings and between the basement and the first floor, reinforced concrete continuous and multi -empty slabs are used. These products are made of hard or light concrete and amplified by special reinforcement. The floors are durable, fire resistant, resistant to mechanical loads and exclusively durable. In total, there are several types of reinforced concrete plates, each of which is used in a particular situation. Therefore, in order not to make a mistake with the choice, you need to pay attention to the marking and understand what is behind the designations in it. But an even more important and more responsible task is to lay reinforced concrete slabs, which is performed using a crane and a team of workers. We will tell you about how to lay reinforced concrete slabs on ceilings according to TTK in this article so that you can control the performance of work.

- What are reinforced concrete slabs

- The device of the reinforced concrete slab for the foundation

- Working technology with reinforced concrete stove

- How to lay reinforced concrete slabs

What are reinforced concrete slabs

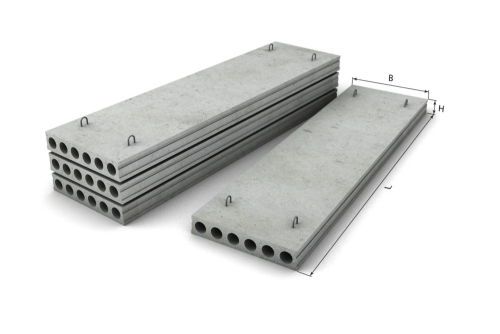

It may seem to the uninitiated person that reinforced concrete floor slabs are all the same, just call the plant and say the required amount. In fact, reinforced concrete plants make slabs and blocks of various structures, purpose, and even from concrete of different brands. Therefore, first of all, pay attention to the marking of the plates.

Marking of reinforced concrete slabs

For example, a brand PC57-15-8Tmeans:

PC Name of the product/type of slab. In this case, a slab of ceilings with round voids.

57-15 - the sizes of reinforced concrete plates indicated in the CCM. In this case, the plate is 5680 mm long and 1500 mm wide.

8 Permissible load on the stove. In this case, the calculated load is 800 kgf/m2.

T Brand of concrete. In this case, heavy concrete is used.

Sometimes in the labeling the thickness of the reinforced concrete slab is indicated. Then it looks like this P-27-15-12-8T. This is indicated by a reinforced concrete continuous plate with a length of 2690 mm 1490 mm wide 120 mm high, with a load of 800 kgf/m2 from heavy concrete.

Types of reinforced concrete slabs

As we have already found out, the first letter values \u200b\u200bin the marking mean the type of plate. Let's find out what they are and what is hiding behind them.

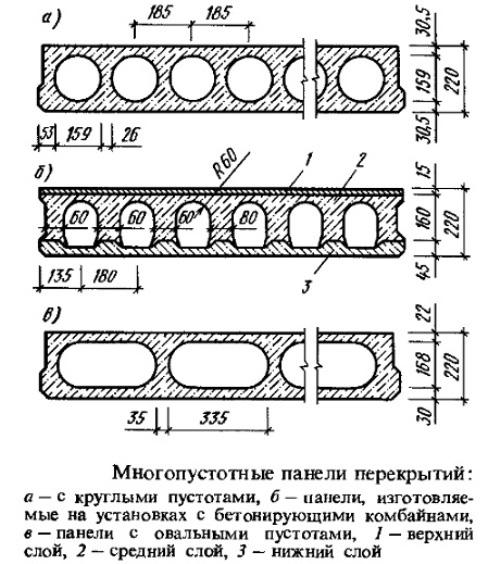

P – reinforced concrete continuous plates, used to install floors in residential and public buildings. Released in different sizes: length from 1790 mm to 6260 mm, width 1190 1490 mm, thickness 120 mm, 160 mm, 220 mm. The weight of the reinforced concrete slab is continuous depends on its size and varies in the range from 0.625 tons to 3.6 tons. For example, the plate P-48-12-22-8AT5 weighs 2.65 tons and the plate P-30-15-16-8A3 Weighs 1.775 tons. Such plates are much heavier than multi -empty ones. Plates with a height of 160 and 220 mm provide sufficient soundproofing of the room due to their mass, but if you use plates with a height of 120 mm, then it is necessary to take additional measures for sound insulation, for example, make layered floors.

PC – reinforced concrete slabs of ceilings with round voids. They are also used for ceilings, but unlike continuous plates, they provide exceptional sound and thermal insulation of the room due to air enclosed in voids. They are available in such sizes: plates 100 mm wide have a length of 238 mm to 1198 mm; 120 mm wide plates have a length of 168 898 mm; Templates with a width of 150 mm have a length of 238 898 mm. The height of the plates with round voids is the same 220 mm. Information about how much the reinforced concrete slab weighs, it is advisable to immediately find out from the manufacturer on his website. For example, most often used PC45-12-8 coat weighs 1.58 tons, a long PK72-15-8 stove weighs 3.33 tons, and the product PK120-10-8 with dimensions of 1198x100x22 weighs all 5 tons.

Ps – special -purpose reinforced concrete slabs. This category includes slabs for balconies, lodge, biases And for ceilings sanitary units. Their main difference from other plates is the method of support and the presence of additional holes for laying the pipes of the water supply and sewage. The height of such plates is 200 mm.

ETC – reinforced concrete slabs overlapping ribbed. They are used to install floors of brick residential and public buildings, as well as for arranging the supporting base of the roof. They are sometimes called tent, since their dimensions allow you to cover the room completely. The length of such plates can reach 18 m, a width of 3 m, and a height is 300 600 mm.

Rp – reinforced concrete slabs spacers. They are installed between the columns of buildings. Spit out blocks may also be called. Usually their length does not exceed 1.5 m.

PT – heavy concrete slabs. Used for ceilings between columns in public buildings on the ground floor.

In addition to the above, there are also plates of light concrete, as well as lightweight PNO plates, which can withstand the same load as from heavy concrete, although they have less weight and thickness.

On reinforced concrete slabs, the price is completely dependent on their size and type. For example, the plate PK55-12-8 costs 150 cu Each, the most expensive plates of large sizes PK76-15-8 are 500 cu a piece.

The device of the reinforced concrete slab for the foundation

All types of plates listed above are made at the factory and purchased in finished form. But there is another category of reinforced concrete foundation. Such plates are made directly on the construction site.

At the place where it is planned to arrange a monolithic slab foundation, soil excavation, the base is performed, the backfill of crushed stone and sand and even more thorough tamping. Then a formwork of metal shields with supports is formed.

Next, a reinforcing cage is binded or welded, which is lowered into the formwork. For reinforcement, a rod is 8 12 mm in diameter. Next, everything is poured with concrete. After solidification, a monolithic foundation plate is durable, not having cracks, with exact dimensions and the required thickness. Usually such a foundation is required for moving soils.

Working technology with reinforced concrete stove

The most popular plates in private housing construction are multi -empty reinforced concrete slabs with round voids. They can be ordered at the manufacturer, from where a car with goods will arrive at the appointed time. But what to do next? How to store these plates so that they do not crack? And then, when the installation of plates begins directly: how to cut off the excess? How to cut a hole-lover into the attic? A lot of similar ones can arise, so let us dwell in more detail on the technology of working with the LRU plate.

How to store reinforced concrete slabs

Despite the strength of reinforced concrete plates, the possibility of cracks on them is not excluded. There are only two incorrect transportation and improper storage. Given how much the reinforced concrete plate costs, each of them must be treated carefully.

Storage of reinforced concrete plates:

- Only in a horizontal position.

- At sufficient height, so that the plates do not touch the soil.

- Under the plates, it is necessary to put a strong reliable base that can withstand a large weight, while it should not get wet and rot. Otherwise, moisture can fall into the stove, it will get wet, and cracks will appear.

- The height of the base should be such that even if it is subsided, the slabs do not touch the soil. If the lower plate comes into contact with the wet land, cracks can appear not only on it, but also on the above.

- Between the plates in one stack, wooden rails are laid with a thickness of 40 50 mm. They should be located strictly one above the other and at a distance of 20 40 cm from the edge.

- The maximum number of plates in one stack, provided that a sufficiently strong base should be 8 10 pieces.

- Do not store them in a vertically tied position, resting on the wall.

These tips will help protect the slabs from the appearance of cracks.

How to shorten the hollow reinforced concrete slab

Among all the typical products that the plant can make, you can always find plates of the desired size. But there are situations when, for various reasons, the plate must be shortened either along the length or in width. This will require a grinder, scrap and a hammer.

Cutting the stove across/width:

- We lay the plate horizontally on the lining.

- We apply the marking line to the surface of the plate on which we will cut.

- The lining should be strictly under this line.

- Cut the plate along the line with a grinder with a concrete disk, cutting the upper part of the stove.

- With a hammer, we tap the plate in the place of voids throughout its width. Usually 3 5 beats are enough to cut the stove in the place of voids.

- To redesign the ribs, we strike at them with the same fist, not only on top, but from the side.

- A piece of the plate destroyed to half will sag under its own weight, so that between the parts you can easily stick scrap. With the help of scrap, punch the lower wall in the thinnest place of the round hole of the plate.

- The reinforcement should be below, clean it of concrete residues and cut it with a grinder.

The edge of the stove will not be as flat as that of the factory product, so it must be buried on the wall of the rest at a sufficient distance.

Cutting the stove along/in length:

- We also lay the plate on the supports in a horizontal position, draw the cut line.

- We make an incision along the line with a grinder.

- Then we drift the hammer throughout the line. To destroy the upper wall of the plate will be simple, since the incision will pass along the line of the hollow hole.

- We destroy the lower wall in the same way.

- If reinforcing rods are found with a diameter of 3 8 mm, cut them with a grinder.

Important! Please note that the reinforcement in the reinforced concrete plate can be tense, so it cannot be cut to the very end. Otherwise, the reinforcement can clamp the disk of the grinder. The rod is not cut to the end, and the remaining piece is beaten off with a hammer or scrap.

How to put reinforced concrete slabs if they are not enough in the width of the room

What to do if the total width of all the plates is not enough to block the entire room. For example, 500 mm remains, which can be cut off from the new stove, or you can try to close in another way.

Method 1. Leave the gaps on the sides:

- The total gap is divided into two parts of 250 mm. We lay the first floor slab at a distance of 250 mm from the edge of the wall.

- We lay all other plates at the end, without cracks.

- A gap of 250 mm should also remain between the last stove and the wall.

- We take a slag block with a length of at least 500 mm, lay it with the pumpkin side to the plate on the cement mortar.

- We perform a laying from a cinder block according to the model, resting it with a poke into the stove. On both sides of the room.

When the wall continues to be built, its masonry will press the slag block even stronger and fix it completely. For greater reliability, when performing the floor screed on the top floor, you can use a reinforcing mesh of a rod of 6 mm with a diameter of 6 mm.

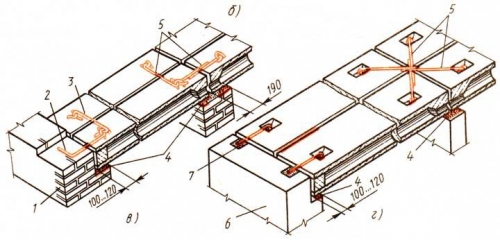

Method 2. Leave the gaps between the plates:

- Distribute the total size of the clearance between all plates. For example, the width of the room is 7800 mm, a plate of 1200 mm wide. We make calculations: 7800/1200 \u003d 6.5. We multiply the whole number of plates by the width of each 6x1200 \u003d 7200 mm, remove from the total width of the room 7800 7200 \u003d 600 mm. We have 6 whole plates, so there will be 5 gaps between them, we divide 600/5 \u003d 120 mm. In total, we should have five gaps of 120 mm.

- We put the first plate back to the wall.

- The next with an indent of 120 mm.

- All the rest are also with an indentation of 120 mm. The latter should adjoin the wall.

- We tie the formwork under the gaps.

- Inside, insert the frame from the reinforcement and tie it to the slabs.

- Pour concrete.

All further work can be continued only after concrete in the gaps between the plates gains maximum strength.

How to cut the hatch into the attic in a hollow reinforced concrete slab

When laying reinforced concrete slabs on the attic overlap, there is almost always a need to cut the hatch leading to the attic in the ceiling.

The main rule: the hatch is always cut at the junction of two plates, and not in one plate.

The permissible dimensions of the hatch depend on the width of the reinforced concrete slab and its load. The wider the plate and less loaded, the larger the hatch can be cut. The dimensions of the hatch are selected based on the sizes of stairs: 600x1200 mm, 600x1300 mm, 700x1200 mm, 700x1300 mm and 700x1400 mm.

The large side of the hatch is located along the plates. For example, the hole is 600x1200 mm as follows: at the junction of the plates, an incision is made, then one plate is cut by 300 mm, the opposite by 300 mm, and then a cut is made along 1200 mm.

How to lay reinforced concrete slabs

We figured out the main questions about working with the slabs, now the most important laying of the ceilings. Despite the apparent simplicity of the algorithm of work, there are still such nuances that must be known and taken into account. Even before ordering the plates at the factory, it is necessary to perform all preparatory measures, since when the car with the plates arrives, everything should be prepared for styling.

Preparatory work

The first task is – the ideal surface of support. This refers to the perfect horizon without a monstrous drop of heights of 4 5 cm. This is unacceptable. We check the surface of the walls, if there are significant flaws, align the plane with a concrete solution. Accordingly, you will have to wait until he gains maximum strength, and only then start laying.

The second task is – the strength of the zone of support. If the house is made of stone materials of brick, concrete, blocks, then no additional actions are required.

Important! If the walls are made of gas blocks or foam blocks, then before laying reinforced concrete floor slabs it is necessary to fill in armo -piles. A formwork is performed along the entire perimeter of the building, a reinforcing cage from a rod of 8 12 mm is inserted inside. Then everything is poured with concrete. Further work is possible only after the concrete solidification.

The third task is – installation of mounting towers. They are needed in order to take on the weight of the stove, if for some reason it slides from the surface of the support. The tower is used only during installation, then it is removed.

Laying reinforced concrete slabs using a crane

When all the preparatory work is completed, everything that should dry and gain strength has dried up and gained strength, you can order plates. For their unloading and laying, you will need a crane, depending on the size and weight of the reinforced concrete plate, it can have a carrying capacity of 3 to 7 tons.

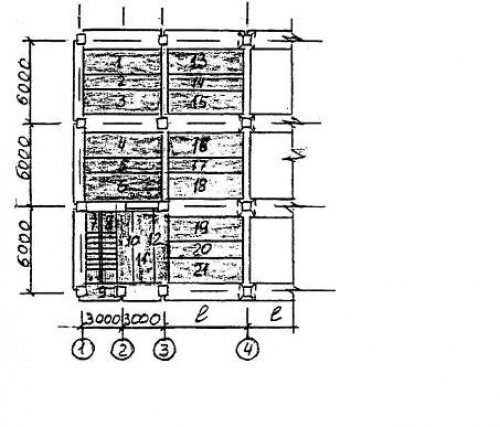

You can lay the plates directly from the machine without unloading. To do this, the foreman at the construction site must have design documentation for the house, which indicates the location of the plates.

Laying reinforced concrete slabs scheme

Stages of work:

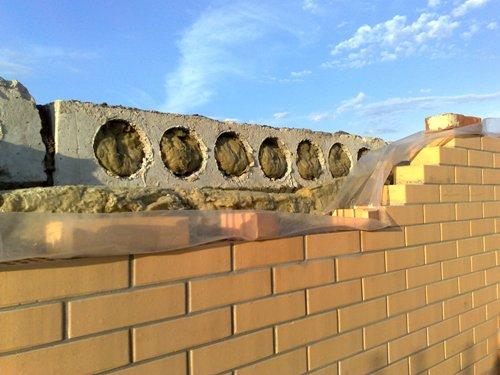

- First you need to prepare the surface of the support. At a depth of 150 mm, a concrete solution is applied with a layer of 2 3 cm. It is necessary to light the entire surface on which the plates will now be laid. If the method of support on two sides, then only from opposite walls. If the method of support on three sides, then it is necessary to apply the solution to three walls. You can lay the plate on top when the solution takes 50% of its strength.

- At this time, the crane operator can hook and raise one of the plates.

- A signal is given to the craneler, you can lower the plate to the prepared place. A person goes to a safe distance. Holding the stove with the Bagmam, unfold it to extinguish the swing.

- When the plate is already very close, two people on one wall, the other on the opposite, carefully direct the plate to the right place. The plate should be based on the walls at least 120 mm, it is better by 150 mm. An excess solution of the plate will squeeze out and take a convenient place, distributing evenly the load on the base.

- After completely aligning the stove, which can be made with scrap, slings are removed from the mounting ears. The alignment of the plate can only be done along the styling zone, in no case across, otherwise the walls can fall over. A signal is given to the craneler to pick up the slings.

- Further, the procedure is repeated for all other plates. In this case, it is necessary to level the plates along the lower edge, which will be a ceiling in the room. For this, the plates are laid down down, and a cone -shaped excavation up.

Important! In some sources, you can find a recommendation in addition to the solution to put the reinforcement under the slabs in the based on the basis. This is due to the fact that it is more convenient to move and smooth it than without nothing. In fact, it is impossible to lay the reinforcement, it is forbidden TTK. Firstly, the load will be unevenly distributed, and secondly, the plate will easily slide through the fittings, so it can move out of place.

If there is a non -standard option for supporting the plate, then there are special steel elements for this. But it is better not to perform such work without a specialist.

Binding of plates between a survey

The so -called survey can be performed in various ways to connect the plates with each other with reinforcement or arranging an annular anchor, in which the plates will be clamped from all sides.

To special fasteners on the reinforced concrete plate, rods with a diameter of 12 mm are welded, connecting the slabs together. For different manufacturers, the location of such elements is provided in different ways. The most optimal is considered when these rods are diagonally to the plate, i.e. The points are not binded at the same level, but with a displacement.

The a survey of plates is carried out not only among themselves, but also with the wall. To do this, the reinforcement must be equipped in it in advance.

Ring Anchor is somewhat reminiscent of Armopome. Along the entire perimeter of the plates, formwork 10 15 cm wide is performed, a frame is inserted into it, in the corners of which the reinforcement is bent. Then concrete is poured into the formwork. The resulting design is very durable.

Sealing joints between reinforced concrete slabs

The joints between the floor slabs, they are also called Rustami, are filled with fine -grained concrete of the M150 brand. If the cracks are large, then a board/formwork is installed under them. All work on the sealing of ores begin only after all the plates are interconnected. The plate can withstand the full load the next day. Naturally, if the cracks between the plates are not too large.

Sealing voids on the ends in the stoves

The voids on the ends of the plates must be filled with something for at least 20 30 cm deep. This is necessary so that the plates do not freeze and do not let the cold from the street. Mineral wool can be flooded into the voids, you can fill them with concrete solution, plug it with ready -made concrete traffic jams or fill with bottle bricks and be filled with a solution.

It is necessary to close the voids in the floor slabs not only from those sides that are based on the outer walls, but also from those that are inside the house and rest on internal partitions.

All slabs laying work take several hours, from 2 to 4. Since the payment of the crane is hourly, it can be released immediately after laying the plates for the ceiling. And the survey, filling ores and voids in the ends can be performed independently, slowly and without looking back for a while.

Thanks for the useful

Thanks for the useful information, everything is explained very simply and intelligibly ...

Thanks!!!! Everything is clear and clear

Thanks!!!! Everything is clearly and clearly stated!

not all plates can be sawed

not all plates can be sawed

seryozha? The plate in length

seryozha? Cut the stove along the length? And if pre -stretched reinforcement? "Do you have accidents? They will!" Traffic jams are needed so that the mass of the wall does not sell the stove!