Each cottage begins with buildings. Everyone does not want to carry garden equipment with me ...

|

|

The dynamically developing Haex LLC since 1998 has launched into production ... |

The main function of the frame of the house is to ensure its strength and uniform distribution ... |

Bitumen mastic of techno -nicob: properties, consumption, use

Despite the abundance of materials and the so -called paradise of the builder, the market does not stop looking for new favorites. And today this role is rightfully belonged to the company Technonikol. Successfully established itself, a promising corporation, the key competency of which implies the production of materials for waterproofing, occupies dominant positions in its market segment, both in Russia and in the countries of near and far abroad. Despite the stable popularity among the consumer and only positive consumer reviews about the materials produced, the company does not stop there and continues to actively improve the production of products, the main component of which is bitumen. The assortment of the company is constantly expanding and is not organized by the production of bitumen -containing mastics, about the characteristics and application of which we will tell in this article. We will also tell how productive is the cooperation of specialists-developers of the Technonikol Corporation and construction practitioners, thanks to the joint work of which the technical characteristics of the material are achieved, not inferior to European analogues and, sometimes, largely superior.

Content

- Bitumen mastics: overview of the main components of the material

- Classification of bitumen mastics by the method of application: how to make the right choice?

- Classification of bitumen mastics in composition and their use

- Scope of use of bitumen mastics

- Bitumen mastic consumption: basic norms

- Features of the use of various types of bitumen mastics

Bitumen mastics: overview of the main components of the material

Bitumen mastics, from the point of view of the structural composition, represent a material characterized by multifunctionality, which determines its demand in a wide variety of construction sectors, among which the main place is occupied by roofing and other construction manipulations, the purpose of which is to protect the room or surface from moisture. The basis of the mastic of the bitumen waterproofing techno -nicol is bitumen - an artificial or natural asphalt -like product of oil and oil products processing. In order for mastics that are permitted based on bitumen to perform their functional purpose protection of the surface from moisture exposure to the bitumen mixture add polymer components that give mastic waterproofing characteristics. Functional thickeners are considered another obligatory structural component of the material described, among which it is necessary to mention chalk, peat crumbs and ground asbestos. The presence of such components declared by the manufacturer as part of mastic guarantees the convenience of its use, a decrease in consumption and an order of magnitude higher thermal insulation characteristics.

Classification of bitumen mastics by the method of application: how to make the right choice?

The extensive use of Bitumen mastic in the most diverse areas of construction determines a large number of varieties of material, on the correct choice of which the durability and operational characteristics of the coating depends, but also its cost. Consider the main varieties of bitumen mastic in accordance with the method of their use:

Hot bitumen mastic

They are a plastic homogeneous mass, the manufacture of which used asphalt -like oil refining products with the addition of binding fillers. The letters A and G on the labeling of the material indicate the inclusion of antiseptic and herbicidal additives in the mastics. Before use, hot bitumen mastic is a techno -nicn, price per sq. A meter of which is considered a determining factor when choosing it is heated to 160-190 degrees, after which it is applied in a preheated form to the surface undergoing preliminary primer. After application, mastic forms a strong coating with high elasticity, which is not a tendency to shrink, which is a distinctive feature of hot bitumen mastic. In addition, the advantages of hot bitumen mastic include its incorrect structure, the efficiency of use at temperatures below zero, and the disadvantages are additional energy consumption in the preparation of mastic, as well as large labor costs and high risk of fires;

Bitumen Fold Mastics

In view of the simplified technology of use, this type of bitumen mastic is characterized by more popular among consumers. Given this, the use of mastics, the manufacture of which is based on the use of bitumen, cold use gradually becomes the usual way to arrange bitumen waterproofing. This is due to a number of undeniable advantages of this variety of products produced by Technonikol, the main of which are the following:

- The absence of the need for preliminary heating greatly simplifies work on applying mastic;

- The manufacture of bituminous mastics of an extensive color scheme, achieved by inclusion in the mastic of special coloring pigments;

- Achieving the necessary consistency due to the addition of a solvent, which is relevant for cold mastics on solvents;

- The unique composition of the mastic of cold use allows you to obtain a waterproofing layer resistant to not only atmospheric precipitation and temperature differences, but also to the damaging effect of ultraviolet radiation;

- Using the Bitumen mastic, you provide a long -term overhaul operational period of the roof, which, to one degree or another, determines the duration of the service life of structures and other structures involved in construction.

There are two groups of bituminous cold mastics, the fundamental differences in which, the need for a more detailed consideration. Cold use mastics are divided into:

- Cold bitumen mastics made on solvents;

- Cold bitumen mastics made on water -based, or the so -called bitumen emulsions.

The first is originally ready for use and is suitable for organizing waterproofing of a coating type, the arrangement of which is relevant even at negative temperatures. The presence of a solvent in the mastic leads to its instant evaporation and the formation of a monolithic layer of waterproofing. The main use of cold mastic is the organization of the waterproofing layer of the roof. Despite the fact that the mastic dries 12-24 hours after its application, it acquires the final properties no earlier than a week later.

Cold bitumen mastic made on water -based (bitumen emulsion) is produced using high -tech plants and modern materials, among which the main role is assigned to polymers and emulsifier. Unlike hot mastic and cold mastics made using a solvent, the use of bitumen emulsion helps to organize an environmentally friendly and safe waterproofing roof system. After applying the bitumen emulsion, which is the know-how of the technonic corporation, the water evaporates, after which a monolithic waterproofing layer of high strength forms.

Bitumen emulsions are characterized by the following advantages:

- A more convenient application process;

- Absolute non -toxicity in view of the absence of solvent in the composition of the mastic;

- Fire and explosion safety, which determines the possibility of using a bitumen emulsion inside residential premises;

- Shorter drying of complete drying;

Despite the wide range of advantages, the bitumen emulsion is characterized by the only restriction, at the same time its deficiency, the seasonality of the specified product produced by the corporation.

Indeed, bitumen emulsions are forbidden to store and carry out the necessary manipulations with them at temperatures below 5 degrees above zero, due to the loss of operational characteristics and the decay of the bitumen emulsion when the water is moving into a solid aggregate state.

Classification of bitumen mastics in composition and their use

In composition, all varieties of bitumen mastics can be classified as follows:

- One -component bitumen mastics, using which a complete set of properties of the finished waterproofing coating occurs after the complete evaporation of water or other secondary components;

- Two -component bitumen mastics demonstrate their properties only after adding the second component, most often it is hardener.

In accordance with the initial component of mastic, they distinguish:

- Bitumen mastic, the production technology of which does not imply their modification by polymers. This variety is undesirable to use for the arrangement of the roof, while they are perfect for waterproofing foundations, since in this case frequent temperature changes will not affect it;

- Bitumen-polymer mastics The most common type of bitumen mastic, designed mainly for the device of roofing waterproofing, as well as for gluing roll materials for the roof. In addition to its main purpose, bitumen-polymer mastic can be used to arrange waterproofing foundations;

- Bitumen-response mastics, the structure of which is included in rubber crumb, are rarely used to arrange a roofing system, in view of the parameters of rubber crumbs that are inappropriate for working with roofing systems;

- Polymer mastics of know-how of modern construction chemistry, which determines their high cost and less distribution in the field of construction. However, their high mechanical, waterproofing, operational (the declared service life of more than 20 years) characteristics and resistance to ultraviolet light without additional protection prophesies a great future with polymer mastics.

Scope of use of bitumen mastics

Systematizing the above, we denote the main spheres of the use of bitumen products of the Technonikol corporation.

- Arranging a mastic roof, as well as repair work with bitumen-polymer and bitumen roof;

- As for the protection of the roof, the use of bitumen mastic is relevant to strengthen bitumen tiles and roller roof materials, protect the roof from overheating and exposure to ultraviolet radiation, as well as for applying conservation coloring;

- The arrangement of the roof is not the only scope of the bitumen mastic, which can also be successfully used to install the waterproofing layer of various building structures, such as piles, foundations and basements;

- Anti -corrosion protection of the foundation and gluing thermal insulation plates all this is carried out using bitumen mastic;

- The arrangement and repair of the interior is also not complete without the use of bitumen mastic. In this area, bitumen mastic is used to arrange waterproofing of rooms characterized by limited ventilation, for example, bathrooms, bathrooms, garages and loggias;

- Installation of waterproofing of terraces and pools another area of \u200b\u200buse of the Bitumen mastic of Technonikol.

Bitumen mastic consumption: basic norms

The consumption of bitumen mastic depends on the method of its use and the type of material on which its application will be carried out. Cold type mastic is made on the basis of water or solvent, and its application is carried out without preliminary heating. The application of hot -type mastic provides a layer that is not characterized by shrinkage, and therefore, after application, it practically does not change its thickness. In addition, the consumption of bitumen mastic depends on the type of work carried out during its use. For example, in the process of gluing surfaces, the consumption of bitumen mastic is at least 0.8-1 kg per 1 square. A meter of surface, while when arranging a waterproofing layer 1 mm thick, this figure increases to 2-3 kg per square meter. meter. And if the thickness of the waterproofing layer is 2 mm and more than 3.5-3.8 kg per square meter. meter in the dry balance.

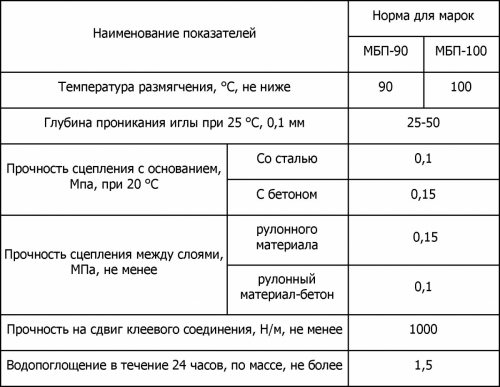

Bitumen mastic of Technonikol is one of the most popular materials in the modern construction market in its field. According to manufacturers, it is completely ready for use without preliminary preparation, implying modification of rubber, the presence of mineral fillers, solvents of organic origin and other technological additives. Thanks to the unique composition of the Bitumen mastic, the techno-nickel, the coating formed during its use is characterized not only by high clutch with the base, but also with increased elasticity, moisture and heat resistance. The consumption of the Bitumen mastic of Technonikol is 2.5-3.5 kg per square meter. A meter when arranging a waterproofing layer and 1 kg when gluing roller materials.

Features of the use of various types of bitumen mastics

Hot bitumen mastics: features of application

The mastic related to the MBK-G series, which is deciphered as a mastumic roofing hot coat is considered a product of economy class. Its composition includes oxidized bitumen and several mineral fillers and gives the finished product not only the highest penetrating capacity, but also excellent water -alcoholing properties. Hot mastics are made and implemented in briquettes that are packaged in specialized craft bags characterized by the presence of a siliconized inner layer. Despite the fact that a distinctive feature of such mastics is a low price, in the process of their use it is necessary to clearly follow all the rules.

The sequence of actions is as follows:

- The working surface is cleaned of contaminants;

- Mastic must be heated to a temperature of 150-190 degrees;

- Then it is applied to the surface using a roller or brush;

- The material applied is leveled with a rowing.

- Thus, the use of hot bitumen mastic contributes to reliability, integrity and long -term operational period of the roofing system.

Cold bitumen mastics: features of application

A feature of cold bitumber-containing mastics is their readiness for use without the implementation of any preparatory measures. Regardless of a variety of cold mastic, whether it be a bituminous emulsion or bitumen mastic on a solvent, applying a cold mastic to an isolated surface without any features.

To date, the Technonikol Corporation offers the consumer an extensive series of bitumen mastic, designed to successfully solve the problems of waterproofing underground and aboveground structures. For example, the universal bitumen-polymer mastic of Technonikol No. 21, designed to arrange the repair of all types of mastic roofs, as well as to solve various problems associated with waterproofing, is very popular.

The sequence of actions when applying cold bitumen mastic:

- The surface that needs waterproofing measures is cleaned of various pollution, such as dust, dirt, fat and ice. To clean the surface of fine garbage, use varippiles of various brushes designed for cleaning;

- Further, the dry and clean surface is treated with a primer (the technonic corporation offers a consumer interested in high -quality waterproofing, a specialized technonic primer). The purpose of this event is to achieve the greatest adhesion of the isolated base and mastic. In this regard, the use of a bitumen primer is common in the process of preparing insulated surfaces, such as concrete slabs, cement-sand screed, before direct laying of self-adhesive and melted waterproofing roofing materials;

- Mastic is thoroughly mixed to a state of homogeneous mass;

- Then it is applied in layers, using a brush, roller or spatula, as well as using a bulk method, after which it is thoroughly leveled by means of a special ridge to achieve a uniform waterproofing layer. In this case, the layer of material should not exceed 1.5 mm, and each subsequent layer is applied after the final drying of the previous one. To ensure effective waterproofing of building structures, two layers of bitumen mastic are applied;

- Having carried out the above measures, they proceed to gluing roll materials.

- The consumption of bitumen mastic during the arrangement of a mastic roof can vary from 3.5 to 5.7 kg per square meter. Meter of the surface.

When working with mastics, it is necessary to follow all the safety rules indicated by the manufacturer. Work involving the use of mastic is forbidden to carry out in rooms characterized by the lack of effective ventilation. It is also supposed to comply with fire safety rules prohibiting work with mastic near fire sources.

In more detail, the application of bitumen mastic can be found by reading the instructions that the manufacturer places on the labels or in the accompanying instructions.