Work on laying a soft roof is becoming increasingly widespread, thanks to ...

|

|

Wooden houses, baths, saunas and cottages have an important advantage, they are completely ... |

Everyone who decided to build a sauna on his country site is early or ... |

Vapor barrier isopan: Instructions for use

Since 1998, the dynamically developing LLC Haex has launched non-woven materials in production, serving a steam-barrier under TM Isospan. Products are characterized by high operational qualities and acceptable cost, due to which it has become widespread in the field of construction. The article will talk about the vapor barrier of Isospan.

Content:

- The purpose and characteristics of the vapor -iolation isopan

- Three groups of TM products isopan

- Vapor barrier isoppan application

- Vapor barrier Isospan instructions for use

- Advantages and disadvantages of vapor barrier isopan

The purpose and characteristics of the vapor -iolation isopan

The high standard is kept due to modern production lines, an automated process, qualified employees and strict control at each stage. In the creation of new materials, technology is introduced by the experience of domestic and foreign companies.

Non -woven materials in residential, administrative or industrial structures:

- provide the protection of metal surfaces from premature destruction (corrosive processes), and wooden from decay;

- prevent the formation of condensate and subsequent moisture of the thermal insulation layer;

- maintain the temperature regime indoors, buildings;

- effectively translate turbulent air flows into unidirectional (laminar).

Materials are characterized by:

- the ability not to impede free air exchange;

- water resistance;

- protection against UV radiation;

- reflection of the heat flow;

- strength;

- windproof properties;

- high operating temperature.

All products comply with sanitary and epidemiological requirements, has fire safety certificates and technical certificates.

Three groups of TM products isopan

The films and membranes isoospan are successfully used as a comprehensive solution both in individual construction and in the construction of skyscrapers and industrial structures.

Hydro and windproof vapor -permeable membranes isopan

- The material is used in external work (insulation of roofs, walls, in the arrangement of ventilated facades). Due to its characteristics, it protects the structural elements from meteorological phenomena: wind, rain, snow.

- The properties of the diffusion film in this case do not allow condensate and moisture to accumulate in thermal insulating layers on a mineral wool.

- This line presents a membrane treated with fire retardants.

Hydr-paralois-isolation films isopan

- Products are designed for lining the interior of any purpose buildings. The film is designed to protect the thermal insulation layer and structural elements from the penetration of steam and condensate, and therefore from their negative exposure.

- The material will retain the properties of the insulation and extend the service life of surfaces. It prevents the formation and accumulation of moisture. After all, it creates optimal conditions for the development of fungi, and also activates corrosion processes on metal elements.

Heat, hydro-paralois-isolation materials isopan

- The chopped surface of these materials tends to reflect electromagnetic radiation, due to which energy efficiency increases. Thus, they can significantly reduce the cost of heating the room, reduce the time to warm it up.

- In addition to heat saving, the material protects the internal structural elements (roof, walls, overlaps) from moisture, and external from wind and precipitation.

- Depending on the purpose, the price of vapor barrier isospan ranges from 600,000 rubles/roll.

Vapor barrier isoppan application

The first group includes the following materials:Isospan a (density 110 g/m), Isospan am (density 90 g/m) , Isospan aS. (density 115 g/m) , Isospan aQ. proff (density 120 g/m).

- This type is used for arranging walls and roofs. Due to its properties, it prevents the accumulation of moisture in a burden of cake, allows you to freely evaporate the condensate under the skin, which inevitably occurs during the operation of any structure.

- On the one hand, the material has a water -repellent surface, another textured feature (roughness). A microporous film made of 2 or 3 layers, with a high coefficient of water-resistance and vapor permeability, extends the service life of the insulation and structural structural elements.

- Laying a film on a thermal insulation layer allows you to save time and materials for the arrangement of an additional crate. Installation work is possible under any weather conditions.

- The layers of diffusion material are made of polypropylene, and therefore do not have any negative factors affecting a person or the environment. Have resistance to damage by any kind of fungi.

Steamproof isospan is used:

- when warming attic premises and roofs with various types of roofing materials, with a recommended slope angle of at least 35.

- for lining walls with lining or siding low -rise buildings;

- in frame construction;

- to protect the external insulation of ventilated skyscrapers.

A variety of isospan is a film of A-Ozd with antipyren additives, the purpose of which consists not only in protection against wind and moisture, but also from accidental fire (for example, from spark during welded work). The scope is limited to hinged facades.

The second group includes:Isospan in (density 72 g/m), Isospan with (density 90 g/m), IsospanD. (density 105 g/m), IsospanDM (density 105 g/m), IsospanRS (density 84 g/m), IsospanRm (density 100 g/m).

- The materials are 2 layers of them, where everyone performs their own function. One surface is smooth, and the other has a rough structure, which helps to retain steam and condensate with their subsequent removal. Perfectly protects metal and wooden elements from the destructive effect of moisture.

- High -strength canvases are treated with water -repellent compounds, which allows them to be used as a waterproofing layer in the installation of cement screeds, earthen floors in wet rooms.

- The installation of isospan is carried out by the smooth side to the insulation. In some cases, between the diffusion material and the final floor or the heat-insulating layer, the gap of 40-50 mm is equipped with moisture.

- RS and RM films have 3 layers, the additional strength of which gives a polypropylene grid. This material perfectly acts as a vapor barrier when arranging a pitched roof, inter -story floors and wall surfaces.

Used:

- when arranging floors in rooms with high humidity;

- to protect the roof insulation from the inside;

- for lining walls indoors;

- as a waterproofing layer in inter -story, basement and attic floors;

- when installing a laminate or parquet.

The third group is:IsospanFD (density 132 g/m), IsospanFS (density 92 g/m) , IsospanFB (density 132 g/m) , IsospanFX (density 145-175 g/m).

- Dense canvases, where one of the sides has a chopped coating, perfectly combine vapor barrier and reflecting electromagnetic radiation of the properties.

- The FB material is made of craft paper, which strengthens the base and thermoplastic polymer (Lavsana). Such a tandem endows the canvas with excellent moisture and heat-resistant characteristics (retains its properties up to +140C). Reflective abilities will significantly reduce heat loss.

Applied:

- for isolation of insulated and unsold roofs;

- when arranging warm floors;

- for lining the frame walls and wall surfaces in rooms with a special temperature regime;

- in thermal insulation of inter -story, attic and basement floors.

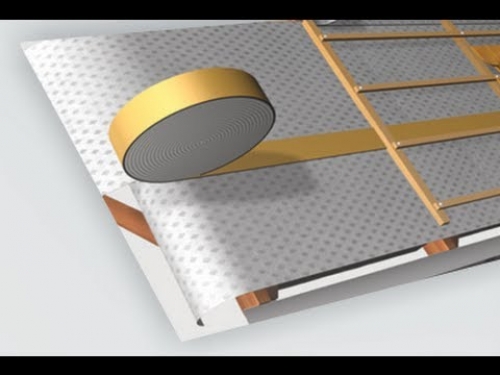

Scotch tape and tape isopan

The variety of materials is striking in the imagination, it is especially pleasing that the manufacturer took care of the concomitant products, namely about adhesive tape and adhesive ribbons.

- The SL connecting tape will record the strips of hydro-vitriol of the material, thereby ensuring the impermeability of the suture line. Installation is carried out at moderate temperatures, and the surfaces should be clean and dry.

- The FL Termo tape is used to connect the canvases, it can also be laid down minor damage. Metalized adhesive tape has a high indicator for wear resistance and exposure.

- Unilateral tape ML Proffs is used in particularly difficult cases, as it is distinguished by excellent adhesion. Fixation can be carried out to uneven bases from different materials: concrete, brick and other porous surfaces.

Vapor barrier Isospan instructions for use

- Work on laying a vapor barrier membrane does not require any qualified knowledge. It is absolutely not important for the installation of the roof, walls or floor, the smooth surface of the film in most cases should be turned to thermal insulation materials.

- If the canvases are laid down by the wrong side, then there is no need to talk about effective insulation and vapor barrier of the structure. The instructions attached to each product will not allow you to make common mistakes during work.

- The material should fit tightly to the surface with a small set in the corner places (3-4 cm or more, if it depends on the structural features). Regarding each other, the canvas is overlapping (at least 15 cm). Fasteners to wooden elements are carried out by means of a furniture or construction stapler. The seams are sealed with tape or ribbon.

- As for the reflective films, they are mounted in such a way that the metallized side looks inside the room. Laying is carried out without overflow. A special adhesive tape is used in the joints.

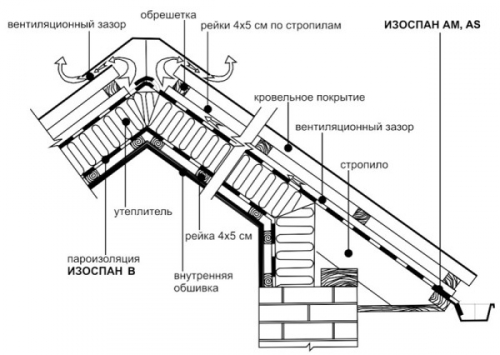

Stages of work on the installation of vapor barrier of the insulated roof

- Work is carried out from the bottom up. The canvas is rolled horizontally, it should fit tightly to the rafters, the sailing should not be allowed.

- For fixation to the rafters, 4x5 cm rails treated with antiseptic agents are used. In this case, the crate provides a venture to freely evaporate condensate. Later, the lining or galvanized ears are performed to the rails for the installation of the profile for drywall sheets.

General form:

- interior decoration;

- isospan B, C or DM;

- rafter system;

- insulation;

- hydraulic protection membrane;

- roofing.

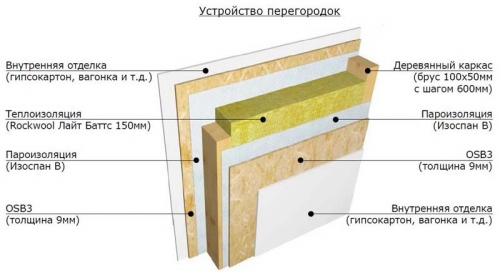

Stages of work on the installation of vapor barrier of internal partitions

- Frame interior walls also need vapor barrier. The isospan with an index in is mounted on any side of the wall surface to the supporting elements of the frame by means of a stapler or nails with an anti -corrosion coating. The canvas is spread horizontally (from the bottom up).

- On top of the membrane, slats are fixed, which form a venturezor and serve as the basis for fastening the finishing wall decoration with drywall, lining, plastic panels, etc. On the other side of the wall is the isospan A or AM.

General form:

- finishing;

- rail;

- vapor barrier;

- frame;

- insulation;

- moisture protection;

- rail;

- finishing.

Stages of work on the installation of vapor barrier of inter -story floors

- To increase the efficient operation of the thermal insulation layer, a vapor barrier is used, which is laid on the black ceiling with a rough side down. On the sex lags above the layer of insulation of the membrane, it is spread up the smooth surface up.

Ventilation gaps of 3-5 cm are necessary:

- between the insulation and the upper layer of vapor barrier;

- between the flooring and vapor barrier;

- between the ceiling coating and a layer of isospan.

General form:

- ceiling finishes;

- reiki;

- vapor barrier;

- black floor;

- beams;

- insulation;

- vapor barrier;

- reiki;

- flooring.

How to lay vapor barrier isopan when placing floors

- Black floors are laid on the waterproofing film. Next, beams and counter -attacks between which are placed are installed. The membrane is spread out according to the insulation, where the side with the rough structure turns to thermal insulation.

- Rolled material is laid in a small set on the walls. The joints of the paintings are sealed with tape.

General form:

- flooring;

- vapor barrier;

- thermal insulation layer;

- beams (lags);

- waterproofing membrane.

On a concrete base for a laminate or parquet board, an isospan FX is laid. Metallized coating should be facing up. The canvases of this material are laid in the end, the seams are glued with a special adhesive tape. A foamed substrate is spread under the laminate into isoospan.

Advantages and disadvantages of vapor barrier isopan

TM Isospan offers a comprehensive solution in the field of construction. The nomenclature group allows you to choose a membrane or film corresponding to certain requests. In any case, the material will fully correspond to its purpose.

The advantages include:

- strength;

- water -repellent ability;

- resistance to mold and infusion of fungi;

- a large range of the temperature range;

- simple installation;

- environmental friendliness of the material;

- the service life is at least 50 years.

Of the shortcomings, only low fire resistance can be noted.

Isospan is of good quality at an affordable price. He is able to solve many problems related to the construction of an object, of any purpose.

The high characteristics of each name from the presented series allow you to protect the insulation from the negative effects of moisture both outside and from the inside of the room. Thus giving him the opportunity to fulfill his thermal insulation functions in full force.