When building a garage after the construction of the walls, the question arises of how to competently build ...

|

|

Soft tiles are modern material for the device of the roof, its main ... |

When the main construction work is completed, the need often arises ... |

Choose a tool for diamond drilling. DIY DIY DIALLING DIY

Diamond drill and drilling is considered to make holes in concrete or other solids using a specialized tool. However, upon a more detailed examination, it turns out that there is a fairly significant difference between them. Including the use of the tool. In this article we will consider how and with what equipment these processes are carried out. We also define the criteria by which it is worth choosing equipment for diamond drilling concrete with your own hands.

Table of contents:

- What tool is used to make holes in concrete?

- How to choose a manual power tool for diamond drilling?

- Advantages of professional attitudes for diamond drilling

- Complete and types of profances

- The principle of operation of the installation

- Examples of equipment for diamond drilling concrete

- Drill and crowns

- Several useful tips

What tool is used to make holes in concrete?

Create technical holes in concrete, reinforced concrete slabs or brick walls may be needed:

- during simple repair work;

- during the installation of water supply, heating and sewage;

- at production.

The size of the holes can also fluctuate depending on the purpose. But not always the usual drilling tool is able to cope with the task properly.

Important! The drilling process differs from drilling in that the latter is produced with vibrations.

To perform small holes, they often use electroleys with a shock mechanism or perforators. The drill is not as powerful as a perforator, and not all models provide a vibration -making system. But it can be used to drill holes in brick, foam concrete and other materials of small density.

Perforator is a more specialized tool. Drilling can be used in combination with a blow or separately. It is intended for work with solid foundations. Concrete and reinforced concrete scope of the perforator. With its help, holes, openings and strobes are made.

In all cases, special drills, drill and crowns with diamond spraying are used to effective work.

How to choose a manual power tool for diamond drilling?

The choice of a drill for diamond drilling should be treated very carefully. A powerful tool will be required (at least 600 watts), with a speed of more than 2500 thousand per minute. Also, the drill for such work must be equipped with a speed regulator, an impact mechanism and return.

The choice of a perforator will be in determining the power, frequency and speed of the impact, the number of revolutions of the torque. Using a drill, you can make holes up to a maximum of 15 mm in diameter. With a perforator, you can use not only drills, but also crowns with a diameter of up to 60 mm.

It is also necessary to clearly determine for what purpose the tool is purchased. For home use and performing small volumes of repair work, 750 watts perforators are suitable. A 2.5 J and rotation frequency of 1,500 revolutions per minute are quite sufficient in order to carry out simple small work. For professional use, you will need a more powerful tool that can withstand long large loads.

But the use of manual power tools is often not justified. The holes are curved, a lot of noise and dust, they have to be performed for a very long time.

When it is necessary to avoid these negative phenomena, resort to the services of a professional tool for dry drilling or with water cooling of cutting elements.

Advantages of professional attitudes for diamond drilling

When it is necessary not just to drill concrete, stone, brick, bring down part of the wall or ceiling, but make in it a perfectly even hole with clear observance of depth and width, resort to specialized drilling plants. The technological features of such a tool allow you to carry out work even in closed rooms, since the dust is practically not formed. Also, holes made by diamond drill do not need additional processing.

Special advantages of using installations, already repeatedly proved in practice:

- it is possible to perform holes of various diameters;

- even in the hardest materials, the drilling installation makes holes in a matter of minutes;

- possible deviation from the specified dimensions of not more than 1 mm in diameter;

- the lack of vibration during the operation of the installation ensures the safety of walls and ceilings (this is especially important when working in old buildings valuable from a historical or architectural point of view);

- during the operation of specialized equipment for diamond drilling, there is practically no dust, but also noise;

- the direction of drilling can be located in vertical, horizontal or inclined planes.

Complete and types of profances

Installations for diamond drilling are used mainly when it is necessary to perform in concrete or reinforced concrete the holes of large diameter (from 30 to 600 mm). They consist of three main parts:

- engine;

- beds;

- drilling crown.

The principle of operation of the installation

The bed is attached in the right place of the surface (these can be ceilings or walls) on spacer questionnaires or studs with nuts, and put in the right position. Drilling, as mentioned earlier, can be in any direction: horizontally, vertically or with a bias.

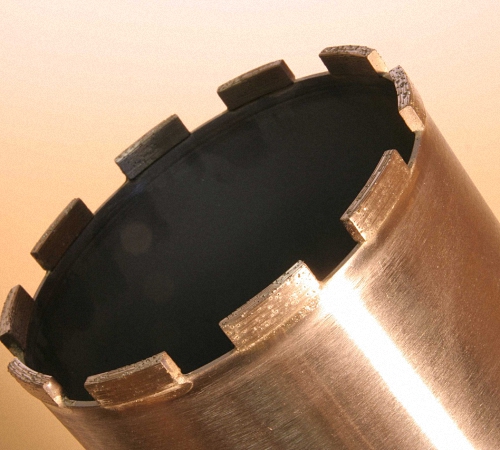

A hollow crown is selected necessary for the diameter hole. It is fixed from the corresponding side and is tightly fixed. To cool the cutting element, a constant supply of running water is required. It, cooling the diamond coating, protects the element from premature destruction, and also cleanses the working surface of the waste.

Important! The crowns used to carry out diamond drilling of concrete are not intended for sharpening and are not repaired.

Among the equipment for diamond drilling, a single -phase installation with a capacity of 3 kW is most popular. They have a relatively not large weight, sufficient power for cutting concrete slabs, drilling holes in them of large diameter. They are connected to a conventional 220V electric network.

For professional use, it is better to choose a three -phase drilling rig. Among its advantages:

- the ability to drill to a depth of more than 2 meters;

- the ability to perform holes with a diameter up to one meter;

- the speed of the cut on average about 2 cm per minute;

- the minimum amount of dust and noise;

- simplified maintenance.

But there are negative points, such as:

- quite impressive installation weight;

- connection only to the network 380V;

- very high cost.

Only solid construction organizations can afford to buy a good three -phase drilling installation, for which such work is priority.

Diamond drilling of concrete using specialized productivity installations is greatly ahead of manual labor. It is simply impossible to perform a manual power tool of holes of this quality. So, in the production, construction or when performing repair work in residential premises, the speed and cleanliness of the performance of such work is of great importance.

Examples of equipment for diamond drilling concrete

The choice of drilling plants is quite wide. Here are some examples of equipment quite popular among the builders, because they are striving to do their work with the most qualitatively and quickly, and at the same time pay for the purchase of the tool as little as possible.

1. Installation for diamond drilling Hilti

According to the manufacturer and confirm the masters using it, the noise level during the installation is so minimal that you can talk calmly nearby, only the sound of the motor is heard. Vibration when cutting reinforced concrete is minimal, which is important for residential premises. The speed of drilling the hole in the reinforced concrete to a depth of 400 mm and 10 cm with a diameter of 10 cm lasts no more than 8 10 minutes. The even hole in the wall allows the rapid installation of the pipes of the water supply, sewage, ventilation, as well as cut off the undeveloped holes for the installation of equipment, railing and other fences.

2. Tyrolit installations

DRS 160 is a system for diamond drilling (drilling) concrete equipped with sensors and an electronic control panel, which displays all process parameters to the monitor. With its help, you can make holes in concrete with a diameter of up to 160 mm. The engine power is 2.2 kW.

A more powerful DRU 250 model. It is designed to drill holes with a maximum diameter of 250 mm.

The installation of this trademark DRA 500 with the maximum engine power and the diameter of the hole (up to 500 mm) provides clean and safe operation. This is a professional installation and it costs a lot.

Some beds are equipped with vacuum slabs for reliable fixation of the installation. With the help of a vacuum pump, which is included with the installation, this equipment is tightly fixed on the work surface. At the end of the working process, air is supplied through a special valve and the vacuum is dumped.

Any installation for diamond drilling requires the most attentive approach and uncompromising compliance with safety precautions. Before starting work, you should check:

- the reliability of an anchor, dowel, bunching mount;

- adjust the position of the carriage and guide;

- check the presence of a backlash and eliminate possible deviations.

Drill and crowns

For manual power tools and professional installations, appropriate types of diamond drills and crowns are available. Standard small drills are available 25 cm long and with a diameter of 8 to 16 mm. They can be divided into types:

1. SKA 1 are designed for work with concrete bases of the M250 300 brand;

2. SKA 2 works with M300 500;

3. SKA 3 is necessary in the case of working with a concrete base made of a brand above M 500.

Drills with a thickness of 20 to 160 mm have a length of 35 cm for deeper holes, you can use special extension cords.

A drill crown is part of a seamless thin -walled pipe with diamond segments attacked on its edge. Such a crown in diameter can reach 1 meter, and in some cases according to individual orders, even more.

Several useful tips

- To perform diamond cutting concrete and other materials that have a greater density, it is necessary to periodically clean the suction from the drill.

The moment when this procedure must be carried out by a reduced level of performance. To clean up the crown, you should remove it from the hole and multiple softer brick or other coarse -grained abrasive several times. In this case, water should not be supplied. After such a simple procedure, newly opened diamond grain will appear on the surface and performance will grow again. Standard for good -quality crowns is about 30 40 mm per minute of work.

- Sometimes it is worthwhile to outline the center of the future hole.

When drilling a hole with a crown of more than 25 mm, it is very difficult to accurately determine the right location by eye, so it is recommended to first outline it with a bash (drill with a winning attack).

- High -quality crowns are able to self -load.

With proper operation, an acute edge with diamond segments soldered to it can be self -maintained and maintain a high cutting ability for a long time.

- Different materials are different crowns.

For softer materials, ring nozzles should be used to drill with larger diamond grain. And, conversely, for solid materials such as granite or ceramics, it is recommended to use smaller ones.

- For cooling it is better to use running water.

Before starting drilling, you should start the supply of water to the working surface. For an approximate calculation of the amount of water used, you should take the average values: 0.4 liters for one minute of work at the rate per 1 cm diameter of the crown.

Diamond drilling concrete greatly simplifies construction and repair work. The correct, neat operation of the equipment will provide quick, high -quality and safe performance of work.

Repair

Repair of power tools.

Repair of a benzo tool.

http://korolev-master.ru

The workshop performs the repair of benzo tools and power tools.