In the modern world of design, a lot of attention is paid to stretch ceilings with a beautiful ...

|

|

The procedure for warming the roof is a rather important process that allows ... |

Warm floor in the kitchen is a modern level of comfort, turning the usual ... |

We warm the front metal door of the apartment with our own hands. Options and instructions for performing work

With the advent of frosty winter, it is not easy to keep the heat in the house not easy to penetrate the door and window slots. Insufficient sealing, distortions of structures and material with low heat capacity of the cause of heat loss. The freezing of the metal door is fraught with the formation of ice growths in the lower part of the canvas, which prevent the normal fit of the door leaf and box. In order to prevent possible problems and increase the efficiency of heating the house, it is necessary to warm the front door in a timely manner.

- Review of materials for insulation: characteristics and features of application

- Entrance door: Ways of insulation depending on the structure

- External thermal insulation of the front door

- Alternative insulation of a non -vegetable door: sawdust or mounting foam

- Thermal insulation of the door frame

- Additional door insulation measures

Review of materials for insulation: characteristics and features of application

Despite the significant advantages of the metal front door, the design has a minus insufficient heat capacity. Through a steel or iron canvas, the room loses about 30% heat. In addition, the sound insulation of the house suffers. Capital thermal insulation of the door allows you to solve two problems at the same time. For work, you can purchase a ready -made insulation kit or choose materials yourself.

Fibrous heat insulators: mineral and glass cotton wool

The most common way to install fibrous insulation. This group includes: varieties of mineral wool and felt. The leaders are considered stone and glass wool.

Distinctive features of stone (basalt) cotton wool:

- low thermal conductivity of not more than 0.048 W/(m*K); The indicator is not inferior to the heat capacity of extruded polystyrene foam, foamed rubber;

- hydrophobic material does not absorb moisture;

- fire resistance The melting temperature of the basalt fiber is +1114C;

- high level of sound insulation of cotton wool absorbs acoustic waves;

- passiveness in chemical and biological terms The stone heat insulator does not react, is not amenable to decay, defeat by microorganisms.

Stone cotton wool is produced by rolons with a length of 10 m, width up to 1.2 m. The dimensions of the slab insulation are 100*120 cm, the thickness is 50-200 mm.

Glass wool is a universal heat insulator used for external and internal work. For insulation of the front door, the material is used relatively rarely due to high cost. Glass wool has the majority of the advantages of basalt insulation. The main differences:

- the vapor permeability of glass wool twice as much as the stone insulator, however, for insulation of the door, this does not play a particular role;

- fiberglass burning temperature is 250.

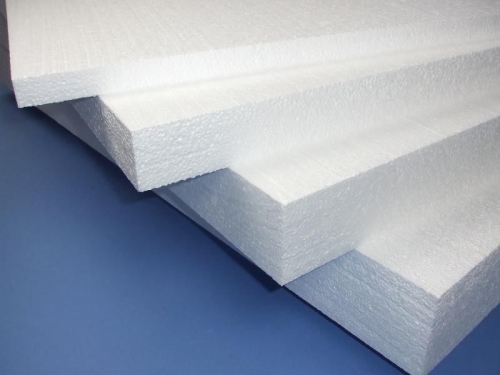

Popular polymers universal heater

The leaders of this category of heat insulators are considered:

- styrofoam;

- polystyrene foam;

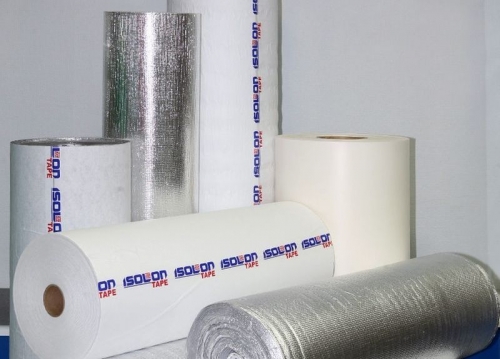

- isolon;

- foamen.

Foam is convenient in installation, does not deform over time, does not gain moisture and has high thermal insulation qualities.

The weaknesses of the insulation:

- in the gaps between the plates, cold bridges are formed;

- fire temperature 350C, melting 270C;

- the working temperature range is from -100C to +80C.

Foam is not the best insulation for a metal door leading to the street. However, for thermal insulation of the entrance to the apartment, its use is justified.

Polystyrene foam due to extruded production technology has low thermal conductivity (0.028 W/MK), for comparison a similar foam parameter is 0.039 W/MK. Additional advantages:

- high bending strength;

- minimal, almost zero, moisture absorption;

- lack of shrinkage during prolonged operation.

The degree of fire safety of polystyrene foam is the same as that of the foam. Refractory class G2-G3.

Izolon foamed polyethylene, produced in two forms of execution: gas -filled (NPE) and physically sewn (PPE). For thermal insulation, the door is more often used with or without foil.

Characteristics of the material:

- the thermal conductivity is limited to 0.040 W/m*C;

- vapor permeability indicator 0.001 mg/ m*h PA;

- water absorption less than 1%;

- excellent elasticity and resistance to bends;

- despite the small thickness, it provides sufficient sound insulation.

The combustible class of foil PPE G1, isolon PPE without foil G4.

Foam is a foamed polymer with a closed porous structure. The material passes the air, but at the same time holds cold and noise. Distinctive features of foam rubber as a heat insulator:

- small density 5-30 kg/cubic meter;

- the degree of heat conductivity is up to 0.03 W/m*K;

- moisture absorption up to 3%.

Foamen is affordable, but short -lived. After 8-11 years of operation, the polymer begins to crumble.

Fanding and pouring materials

Alternative options insulation of the front door, backfill of the inner space with wood sawdust or filling with liquid polyurethane foam. Both methods are possible with a hollow door structure.

Using sawdust has a number of advantages:

- absolute environmental friendliness of the material;

- low cost;

- simplicity of insulation.

When choosing a method, you should remember about its minuses:

- to ensure sufficient thermal insulation, a large layer of wood chips is required;

- the material weights the design of the door;

- frequency of wood insulation.

Often manufacturers of metal doors at the manufacturing stage fill the design with polyurethane foam.

Inside the doors under the pressure of the foam and freezes. As a result, 95-97% of the internal volume are air pores.

Polyanel foam is inherent in high thermal insulation characteristics. The thermal conductivity of the material is 0.017-0.03 W/m*K, 50 mm of liquid insulation is replaced by 80 mm of foam or 100 mm of mineral wool.

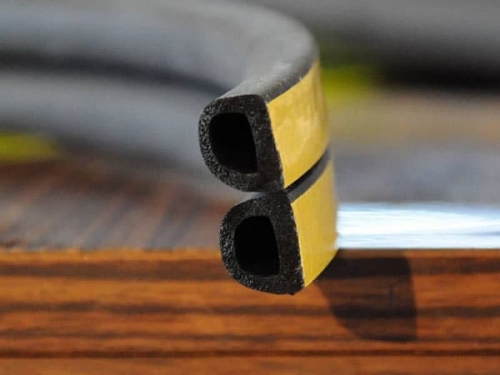

Which seal is better to use

When capital insulation of the door, it is necessary to take care of the high -quality fit of the canvas to the opening. The seals are responsible for completing the task. The main choice parameters: manufacturing material and shape.

Varieties of door seals depending on the material of manufacture:

- Foam is affordable price, short service life.

- The rubber tape is applicable for different structures, provides a tight adjustment of the elements.

- Silicon begins to burst over time and becomes sticky.

- Thermoelastoplast is highly durable and wear resistant. Minus of the complexity of installation.

- Polyurethane is more often produced as a self -adhesive seal. Simple in the installation and durable.

Classification in the form of section:

- C- and K-shaped sealing slots with a thickness of no more than 3 mm;

- V- and P-profile Elimination of clearances in the amount of 3-5 mm;

- O- and D-sowing adjustment of holes of more than 5 mm, restriction of 7 mm.

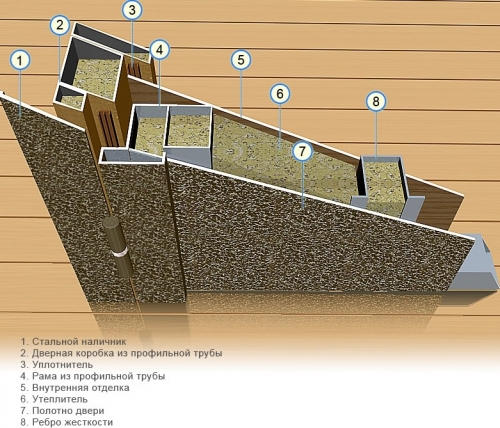

Entrance door: Ways of insulation depending on the structure

The technology of work is determined based on the design features of the door. Possible options: internal and external method.

The first option is suitable for collapsible doors when two canvases are attached to the frame with fasteners. The internal method provides for filling the cavity with insulating material.

The second method (external sheathing) is applicable if the outer and internally metal canvas are interconnected by a welding seam. The insulation technology consists in stuffing the frame, filling cells with heat -adherent material and decorative sheathing.

A variety of the external method of pasting the door leaf with insulation.

External thermal insulation of the front door

Below is the instructions for insulation of the front door using foam. The external sheathing tactics used. Thermal insulation material can be replaced with mineral wool or polystyrene foam.

List of necessary tools and materials

In addition to the cutting of the insulation in accordance with the dimensions of the door, for thermal insulation of the non -vegetable structure you will need:

- laminated fiberboard;

- liquid Nails;

- alcohol or acetone;

- wooden dry strips 20*30 mm;

- sealant;

- mounting foam;

- thin screws;

- artificial leather;

- seal.

From the tools you need to prepare: a screwdriver, an electrician or a hacksaw, a spatula and a sharp knife.

Assembly of the frame and insulation insert

Carcass assembly sequence:

- Remove overhead accessories from the door: pen, lock, eye.

- Remove the canvas from the loops and lay on an even horizontal surface.

- Prepare the sides of the frame and crossbars from wooden planks.

- Put the frame on the door leaf and fix with screws through the pre -made holes. To improve tightness on the rails before installation, you can treat with silicone sealant.

- Fill the educated cells with insulation:

- cut the foam by the size of the frame;

- apply glue to the inside of the door leaf;

- lay out polystyrene;

- all the cracks are blamed, excluding foam entering the castle and the mechanism of adjustment by crossbars;

- after drying, remove the excess of the mounting foam with a sharp knife.

Check the canvas for the lack of visible cracks. The existing gaps can be filled with foam strips.

The upholstery of the door leaf

The sheathing performs three functions at the same time:

- provides additional isolation from cold and noise;

- protects the insulation;

- improves the appearance of the door.

For decoration, laminated fiberboard, MDF or moisture -resistant plywood, sheathed with leatherette are used.

Upholstery technology:

- Drink a canvas from the fiberboard that is clearly suitable for the parameters of the door structure. It should not stand beyond the borders, otherwise the door will cling to the box.

- Pull the workpiece from the fiberboard with artificial skin:

- cut a piece of leatherette on the dimensions of the door, leaving allowances on four sides of 10 cm;

- lay dermantine on a laminated canvas, wrap the allowances and fix with furniture brackets;

- so that the skin does not pair from the outside, it is advisable to fix it with decorative brackets.

- Mark the bars of the frame with glue and attach to the frame a decorated canvas from fiberboard.

- Every 30 cm, screw the screws.

At the end, install the keyhole, handle and door pens in place.

Alternative insulation of a non -vegetable door: sawdust or mounting foam

Simplified option for thermal insulation of the front door, filling the voids with loose material (granulated polystyrene or sawdust).

The course of work:

- In the upper part of the door leaf, make several large holes.

- The voids for drilling holes can be determined by tapping areas of the door leaf.

- Pour chips into the holes.

The described method is not effective enough for harsh winters, since it is difficult to achieve dense stuffing. The use of shavings is suitable for those who think how to insulate the door in the apartment here is the requirements for heat capacity less.

To fill with polyurethane foam, you will have to respond the door frame throughout the height. The mounting gun is placed in the direction from the bottom up. The disadvantage of the method is inability to control the uniformity of filling.

Thermal insulation of the door frame

The technology of insulation of the box is reduced to removing possible cracks between the doorway and the box. The whole process can be divided into several stages:

- Drop the gaps, excess foam to cut off after drying.

- The joint between the wall and the door of the door is plastered in two or three layers, between which the reinforcing tape made of metal is laid.

- Eliminate the likelihood of gaps between the box and the door leaf using a sealing tape. To do this, degrease the surface with alcohol and glue the seal along the perimeter of the door. Sometimes it is enough to glue only the bottom and top or side sides.

The quality of the door installation can be checked experimentally. From the opposite side of the entrance, open the door, attach a wet hand to the place of dock and box. The presence of a draft indicates the deficiency of the seal. Solving the problem of the armor of the rubber profile.

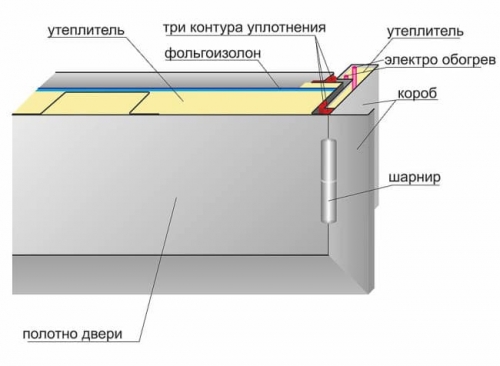

Additional door insulation measures

Some experts for heating a steel door use a cable -type warm floor system. The technology prevents condensate formation in situations where the room is high in humidity.

A heating cable assembled in the bay is suitable for work. The length of the wire of 10 m is enough to finish the box around the perimeter, the rest will go to insulate the threshold from the tile.

Cable laying technology:

- Put it from the slopes plaster and remove the tile coating from the floor.

- Free the space under the cable cut out the foam.

- Fill the resulting hole around the perimeter with tile glue designed for the installation of a warm floor.

- Drowning inside adhesive mass The electrical wire cable should not protrude above the surface.

- Continue laying the wire on the floor, making several turns at the threshold.

- Place a temperature sensor in the corrugated tube.

- Through a mechanical regulator, connect a warm system to the network.

The heating mode is regulated using the control relay.

A competent selection of insulation for the door and its high -quality installation provide additional thermal insulation of the room. In addition, the life of the metal structure at the expense of the heat -conductive material provides condensate protection.

Warming of a metal door: video

www.stal-master.tt34.ru 8 (90

www.stal-master.tt34.ru

8 (903) 715-91-15 Odintsovo doors is vestibule.

8 (903) 715-91-15 Odintsovo doors Hollow.

8 (903) 715-91-15 Odintsovo doors metal.

8 (903) 715-91-15 Odintsovo doors technical.

8 (903) 715-91-15 Odintsovo doors steel.

8 (903) 715-91-15 Odintsovo doors with MDF finishes, laminate.

8 (903) 715-91-15 Odintsovo doors with powder spraying.

8 (903) 715-91-15 Odintsovo doors with a photo seal.

8 (903) 715-91-15 Odintsovo doors.

8 (903) 715-91-15 Odintsovo doors with castles of Gardian.

www.stal-master.tt34.ru installation of the entrance doors in Odintsovo.