The tradition of covering the living room with carpets seems to have gone the past, because it appeared ...

|

|

Even in the most provincial village houses, not to mention modern suburban ... |

One of the significant advantages of a private house is the ability to expand residential ... |

Roof insulation with mineral wool

The procedure for warming the roof is a rather important process, which can significantly prevent heat losses not only in the attic, but throughout the house. One of the most popular roof insulation is mineral wool, as it is distinguished by zero moisture absorption, resistance to temperature extremes and good operational characteristics. We will consider how to properly warm the roof of mineral wool.

Table of contents:

- Minvat for the roof: advantages and characteristics

- Mineral wool for roof insulation - Features of choice

- How to insulate the roof of the house with mineral wool: Recommendations

- The technology of roof insulation with mineral wool: Ways of insulation

- Mineral wool for roofs: insulation of the attic

- How to insulate the roof with mineral wool: Name roof

- Roof insulation with mineral wool from the inside with your own hands

- How to warm the roof with mineral wool: stages of insulation

Minvat for the roof: advantages and characteristics

Mineral wool is widely used in the process of warming not only the roof, but also most other structural elements of the building. The scope of mineral wool applies to:

- arrangement of floor systems;

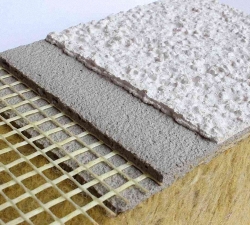

- insulation for plaster;

- arrangement of hinged ventilated facades;

- insulation of walls indoors;

- heat insulator for roofing systems;

- insulation of attics or balcony structures;

- Three -layer concrete panels.

This is due primarily to the advantages of this material:

- The presence of a wide range of products - mineral wool is produced in a roll -shaped form, in the form of plates or mats, thus, it is possible to choose the best option that is best for insulation of a particular section of the building, also mineral wool varies in the ratio with density - roller materials more Light and plates have a high density;

- Mineral wool is resistant before moisture and various kinds of atmospheric influences, therefore it is used both inside and outside the room;

- High indicators of thermal insulation are another important advantage of this material, mineral wool is characterized by a porous structure, which consists of small layers, thus ensures good maintenance of heat and a high level of soundproofing;

- Fire safety - mineral wool is not prone to combustion and is not capable of spreading fire, so it is easily used in the process of insulation of the interactive ceilings, according to statements of certain manufacturers, mineral wool can withstand the temperature of more than 900 degrees of heat;

- The lack of a tendency to deformation is another important parameter, according to which mineral wool does not shrink, which means it does not form the so -called cold bridges that improve heat losses;

- Good frost resistance allows you to use this material on the street or to warm the external structural elements of the building;

- Environmental safety - mineral wool is used as insulation in children's rooms, medical and sanatorium -resort establishments;

- When choosing mineral wool as a heater, it is possible to save significantly, since the material has a high density.

Despite this, some shortcomings of mineral wool should be highlighted:

- low strength level, which is explained by the high porosity of the material;

- This insulation provides reliable thermal insulation only in combination with other materials such as a vapor barrier membrane or waterproofing film;

- Mineral wool in combination with fiberglass is unsafe due to the addition of aldehyde forms to it.

Mineral wool for roof insulation - Features of choice

In the ratio with primary raw materials from which mineral wool is made, it happens:

- slag;

- glassy;

- stone cotton wool.

Stone mineral wool is made in the process of melting various kinds of stone fibers, from which heat -insulating plates are formed. To connect these fibers, phenol -formaldehyde resin is used. During the manufacture of cotton wool, substances harmful to humans are neutralized, so stone wool is environmentally friendly material.

Thanks to the excellent characteristics of heat and sound insulation, mineral wool is one of the most popular heater. The main positive property of this material is low thermal conductivity, thanks to this it is possible to save one ton of conditional fuel per year, per square meter of material.

In addition, mineral wool is resistant to mold and fungus on it, it is not eaten by insects and rodents, unlike foam. Fire safety of mineral wool allows you to use the material as insulation for objects whose temperature does not exceed 900 degrees of heat.

The vapor permeability of mineral wool avoids the accumulation of moisture in it, thus, excess moisture from the room with its help are excreted. The service life of this material exceeds 45 years. Stone wool is very stable before bending and deformation, so it is used in insulation of systems with large loads.

Due to the fact that mineral fibers are located in a chaotic manner, this material has excellent soundproofing characteristics.

How to insulate the roof of the house with mineral wool: Recommendations

Thermal energy most often comes out of the separation through non-insulated areas of the roof. Therefore, even a non -residential premises need roof insulation. Thus, it is possible not only to reduce the level of heat losses, but also to extend the life of the materials used in the process of decorating the attic.

The use of mineral wool has unlimited use. The simplest and most optimal option is the installation of mineral wool on the roof of a non -residential room. To do this, you need material in the form of plates, which is laid on an overlap made of concrete or wood. This procedure is simplicity and does not require bending of the rafters. For these purposes, it is best to use hard slabs with maximum density.

Keep in mind that this procedure also requires adjusting the seams. To ensure full -fledged thermal insulation, a plate of 250 mm thick is enough.

The flat type of roof happens:

- ventilated;

- non -premised.

On it, there is practically no room for the attic space, therefore, on such a roof there is exclusively insulation. For insulation of ventilated roofs, it is necessary to observe such a technology as during insulation of non -residential roof. A 250 mm thick layer is installed on the floor, if the roof is non -premised, then a vapor barrier film is laid before thermal insulation. Next, mineral wool is installed, dowels are used to fix the insulation. In addition, it is possible to use bitumen mastic, which improve adhesion between mineral wool and surface. Ruberoid is covered upstairs.

The most difficult thing is to lay mineral wool on a roof of a pitched type with a design of rafters. In this case, the material consumption and time for its installation increases significantly. Thermal insulation material is laid on the crate between the elements of the rafter system.

Keep in mind that cotton wool should have a high density, but should not be too heavy, since it will load the design of the roof. To cover the joints, wool should be laid in two or three layers. Mineral wool installation should be carried out at a temperature of up to 22 degrees, humidity of about 35% and in the absence of any kind of drafts.

The technology of roof insulation with mineral wool: Ways of insulation

To obtain a qualitatively insulated roof using mineral wool, you should carefully calculate the thickness, type and amount of material. In addition, it is necessary to observe all the technological features of this process.

In order to reduce thermal losses in the room, a number of actions should be performed:

- insulate the attic - it is this room that performs the function of the barrier, which does not allow warm air to leave the rooms, if the insulation is not carried out in the attic, then all heat will fall on it, even with a well -insulated roof, will be cool in the rooms;

- Warm the roof - insulated roof - the second stage that protects the building from thermal losses, keep in mind that high -quality insulation requires a clear observance of all the rules and instructions that are indicated in the instructions for insulation materials.

Mineral wool for roofs: insulation of the attic

For the manufacture of inter -story, including attic, reinforced concrete slabs or bearing beams are used. In the first case, the insulation is located directly on the surface of the plates, and in the second - in the space between the beams.

Keep in mind that for high -quality insulation, you first need to lay a vapor barrier material that will help protect the insulation from steam and moisture. In the process of laying vapor barrier, carefully study the instructions for its use. Since the vapor barrier film is characterized by unilateral functionality, and its improper styling will lead to non -fulfillment of its functions.

In addition, it is possible to use sawdust for roof insulation. This material is used in combination with clay, sand, cement and even lime. The solution perfectly thermal insulates the roof, provides the room with a healthy microclimate, and also has an antiseptic effect.

In addition, the use of expanded clay, artificial material in which there is a large number of pores, just and performing the function of insulation is common as insulation for the attic.

To perform these methods, less money will be required, although the quality will not yield to mineral wool. The feasibility of a particular method of insulation should be selected based on the materials from which the building, its area, height and other individual parameters are built.

How to insulate the roof with mineral wool: Name roof

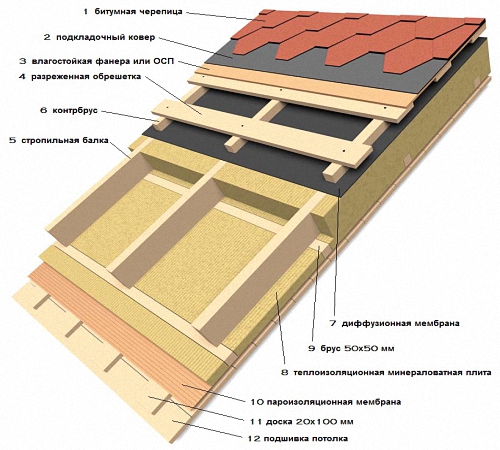

To warm the roof, it will need to be erected by the so -called warm multi -layer structure. It consists of materials of hydro-steam and thermal insulation purposes. The pitched part of this roof consists of a multilayer pie, which is installed both outside and inside the roof.

To increase the efficiency of roof insulation, a number of actions should be performed:

- Install a vapor barrier that can prevent the air of too saturated with moisture of the air;

- Mineral wool acts as the main material, it is best if it is stone;

- In order to protect the entire system from moisture and atmospheric influences, it is recommended to establish waterproofing;

- To form a ventilation gap, a counter -oret is filled, it also removes condensate;

- Next, the direct installation of roofing finishing material is performed.

Roof insulation with mineral wool from the inside with your own hands

In order to prevent errors in the process of insulation, read the recommendations for the implementation of this process:

1. In the process of warming the roof from the inside with mineral wool, you should make sure that the insulation does not overlap the ventilation hole.

2. If the superdiffusion membrane is used during the work, then the insulation should lie down very tightly on it, in order to avoid blocking the ventilation clearance.

3. When using a standard roofing film, you need to equip two clearance, upper and lower.

4. Warming slabs laid in rows should be distinguished by unequal joints that do not coincide with each other.

5. For a more even fitting insulation on the surface of the rafters, the material should be selected, a little more wide than this distance.

6. Keep in mind that thermal insulation in the form of mineral wool should fit very tightly to each other.

7. When choosing mineral wool as a heater, waterproofing is mandatory. In addition, monitor the quality of the film connection and the lack of joints.

8. For a more reliable fixation of mineral wool slabs, self -tapping screws or wire stretched above the rafters are used.

How to warm the roof with mineral wool: stages of insulation

Before starting insulation work, the following actions should be performed:

- Check the roofing system and all its elements - in the presence of damp, defects, decay, damaged elements should be replaced;

- To process the roof, use antiseptic compounds;

- In addition, we should check communication systems, such as electricity and water supply.

To warm the roof of the pitched type, it is recommended to use the material in rolls or in a slab form. They lie well on the crate. Keep in mind that to protect the insulation in front of it should be installed vapor barrier.

Between the roof and a layer of insulation, it is necessary to leave the space that provides its ventilation. When laying the insulation on the surface of the rafters, it is possible to equip not only the thermal insulation system, but also a good sound insulation.

Roof insulation is a rather complicated process, when performing which inexperienced specialists make mistakes that we offer to consider:

- Do not use materials whose width is less than the width of the space between the rafters, since the cracks will significantly increase the thermal losses of the building;

- It is forbidden to use thermal insulation material with high humidity, as this will lead to decay of the tree from which the roofing system is made;

- The neglect of the installation of the steam and waterproofing system will lead to the fact that all material costs spent on insulation will not justify themselves, since without these components the system will not work properly.

If it is planned to insulate the attic premises of housing, then to improve the microclimate, it is recommended to use a reinforced -coated film.

Pay special attention to the sections of the ceiling and walls. If cornices are present in the room, they should also be insulated. In the presence of complex areas, the film is fixed using a stapler.

Roof insulation with mineral video: