Automatic doors have recently gained more and more popularity. They are...

|

|

By finishing the basement of the building with a brick, it is possible to give him grace and ... |

PVC Tiles is a rather popular item in the decoration of the premises. Thanks to the presence of a row ... |

DIY screw foundation for home

A screw foundation in the military and industrial sphere has been used for more than a hundred years, in private construction this technology was actively used not so long ago. The pile-screw foundation has established itself as a strong and universal base that can cope with the soils of dubious stability.

Content

- What is a screw foundation

- Scope of pile-screw foundation

- The advantages and disadvantages of the foundation on stilts

- Types of pile-screw foundations

- How to choose screw piles for the foundation

- DIY screw foundation for home

- Installation tips for pile-screw foundations

What is a screw foundation

A screw foundation is much simpler than traditional buried monolithic types of foundations, which involve excavation and pouring concrete.

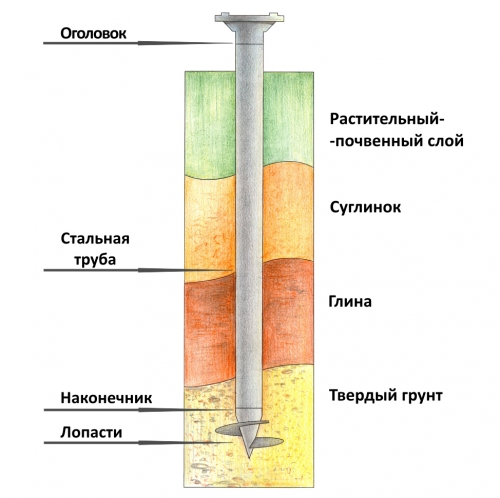

The base using screw supports is one of the varieties of pile foundation. There are some differences in the method of arrangement and the structural material used. The piles are made of reinforced concrete and clogged into the ground of a coprom or mounted in a finished pile. A screw support is made of a galvanized pipe, and a drill is welded to the lower end.

This design allows you to screw pile into the ground without much effort. After installation of the pile, its cavity is filled with reinforcement and poured with concrete. Ultimately, a screw pile turns into a strong reinforced reinforced reinforced pole.

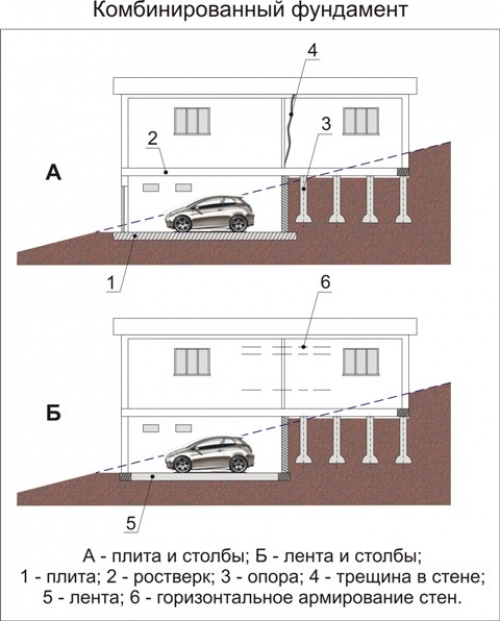

The screw supports are combined with horizontal dressing of a tile or beam type, the base base is formed from a strip block or brickwork.

The choice of grillage (monolithic strip foundation, metal, wooden or reinforced concrete beams) and its location relative to the soil depend on the type of construction multi -story construction or one -story building, and on soil characteristics:

- high grillage (more than 15 cm above the soil) is necessary during construction on the abrasive soils, slopes or in areas with an uneven surface;

- increased grillage (up to 10 cm) is used on weakly bubble soils;

- the buried grillage is equipped below the ground level is suitable for non -borely soils;

- the grillage of wooden beams is usually used in the construction of wooden buildings, a lightweight version of metal corners for a small one -story structure;

- powerful metal and reinforced concrete beams are used in multi -storey building, when the design has significant weight.

To protect piles from corrosion, technologies used in the construction of ships are used. This approach can significantly increase the operation of the screw foundation. Manufacturers of screw piles indicate the terms from 100 to 150 years. However, it is still impossible to confirm or refute the veracity of this information, since this technology in our country is actively used for no more than 30 years.

Scope of pile-screw foundation

In 1838, the English engineer-technologist Alexander Mitchell suggested simplifying a laborious driving back, replacing the process with a simpler and more comfortable screwing of screw piles. The idea was first tested in 1850 during the construction of a lighthouse in the Gulf of Delaware, the USA. This lighthouse is standing today, confirming the success of the innovative idea of \u200b\u200bMitchell.

The idea of \u200b\u200bbuilding a base on screw stilts was picked up by the military. The foundation device made it possible to build a reliable base for a strategic object in a short time.

Subsequently, such a development began to be actively introduced into the construction of peaceful facilities:

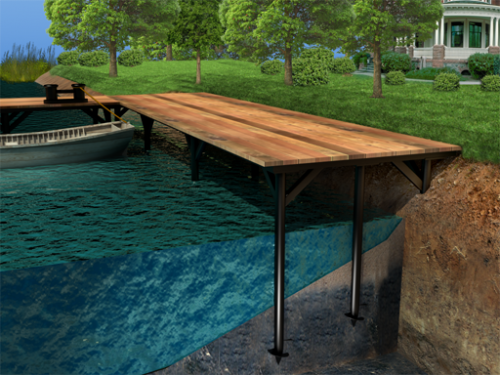

- embankments, piers;

- power lines of power lines;

- scientific and geological research centers in hard-to-reach places;

- private households and apartment buildings;

- outbuildings;

- a screw foundation for the old house replacing and repairing a damaged base;

- industrial facilities;

- a screw foundation for a frame house can be built such a structure in 2-3 weeks.

The design of the screw piles was improved. And today, they are made of high -strength special steel, and some models are equipped with a special naked man with blades, which, when deepened, compacts adjacent layers of the soil.

A screw foundation is the best option when building:

- sites with ditches and slopes;

- sites on which pile clogging is prohibited near the underground tunnels, metro, etc.;

- sites with an increased level of soil moisture;

- peat sections;

- areas with deep freezing of the soil;

- zones with a equipped landscape.

The advantages and disadvantages of the foundation on stilts

Thanks to the design features, the installation and operation of the screw foundation has a number of advantages:

- speed of construction (about 2 days);

- the high bearing capacity of the pile can be immersed in the soil by 8-12 meters, and at this depth the soil layers are quite stable and are able to withstand the weight of a multi-storey building;

- a screw foundation for lightweight structures can be made independently;

- work can be carried out at any time of the year;

- there is no need to equip access roads for special equipment;

- houses on a pile-screw foundation can be easily expanded by attaching a new structure;

- lack of preparatory labor -intensive work: alignment of the site and tamping of soil;

- buildings on screw foundations do not violate the natural environment;

- wide possibilities of using pile-screw foundations (loam, swimming or dense soil; exception to rocky soil);

- repeated use of piles for the construction of a new building (garage, terraces, verandas, outbuildings).

The construction of a screw foundation for the home will reduce the construction budget by 25-40% - a screw foundation is almost three times cheaper than a strip

Some disadvantages are also inherent in the screw foundation:

- If the level of freezing of the soil is not taken into account or the load on the piles is incorrectly calculated, then the foundation is possible.

- The deformation of the foundation may be the result of impaired installation technology:

- the position of the piles during screwing was not fixed;

- installation of piles in dug pits;

- incorrect strapping piles;

- the piles did not screw, but clogged.

- In the house on a screw foundation, you cannot equip the cellar.

- The need to insulate the lower part of the structure.

- A really large, large -scale building is impossible to build on screw stilts.

- High -quality screw piles are not so easy to buy.

It is better to buy screw piles not from intermediaries, but from manufacturers who have their own design and research departments where products are tested. Company representatives can control the compliance with technology when performing installation work

Types of pile-screw foundations

Designing the foundation on screw stilts can be performed differently, it depends on the construction project and the type of soil.

- Pile ribbon under the walls of the building. With this design, piles are screwed into one or more rows.

- Single piles are combined by another type of foundation and serve to support a particular construction element. For example, the terrace is installed on screw stilts, and the base of the house is a concrete strip foundation.

- Standard placement of piles. The screw piles are mounted under the leading elements of the frame of the building and columns.

- The pile field of the piles are placed over the entire area of \u200b\u200bthe structure with the same interval. This is an enhanced version of the screw foundation that is suitable for heavy structures.

How to choose screw piles for the foundation

The bearing capacity of piles depends on the following parameters.

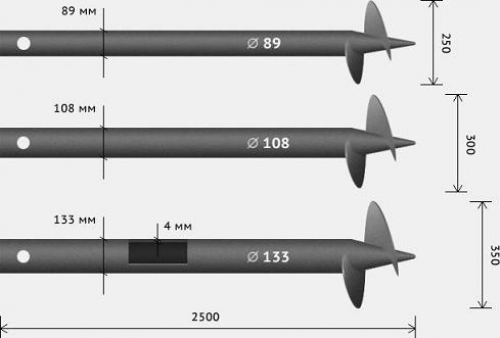

Diameter of piles.

- 57 mm piles for light fences;

- 76 mm piles for fences made of wood, profiled sheet, for arranging the foundation for light household buildings (summer kitchens, arbors, toilets, household blocks); the bearing capacity of the pile is not more than 3 tons;

- 89 mm installation of heavy and high fences, foundation for one -story frame houses and extensions to the house of terrace, verandas; the bearing capacity of the pile is 3-5 tons;

- 108 mm, the construction of the base for two -story frame houses is suitable for building houses made of light stone, wood and buildings of extensions; The bearing capacity of 5-7 tons.

The length of the pile Depends on the type of soil on the site, the depth of screwing and freezing of the soil.

The occurrence of the dense layers of the soil can be determined independently. The garden drill must slowly screw into the ground, periodically pulling it out and checking the presence of dense lumps of sand or clay. By the length of the drill, you can calculate the depth of favorable soil for the installation of piles.

For the accuracy of the result, you can use the services of a specialized company that will produce trial drilling and determine the necessary length of the screw piles. The cost of such a service is about 1,500 rubles

The pile length is also affected by the relief of the site. For example, with the total length of the house 6 meters and a drop of heights of 1 meter, three types of piles will be required: 2.5 meters for the installation of the upper row, 3 meters installation of the middle row and 3.5 meters of the lower row of piles.

Advice. If the differences of heights are more than 0.5 meters, then it is better to take piles 0.5 meters longer in the calculation than it should be usually, when installing a screw foundation on embossed areas on the lower rows of the piles, about 30 cm is not enough

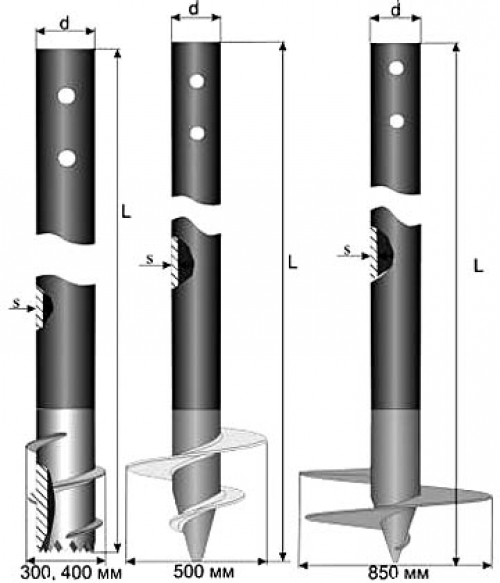

By type of tip. Typical species of piles are presented in the figure below.

The first option is intended for installation on sandstones, eternal -free soils, as well as dense loams with increased bearing capacity. The soil inside the pile does not compress, holding it both outside and from the inside. Pile parameters:

- wall thickness 8-20 mm;

- pile length 4-16 m;

- the step between the piles is 4 m;

- diameter 219 and 325 mm;

- pile diameter with a heel - 300 and 400 mm;

- incomparable load 0.7-2.5 tons;

- estimated price from 4500 rubles/unit.

Pile for ordinary soils has a diameter with a heel of about 500 mm. Such piles are suitable for the construction of light non -residential buildings and fences. Pile parameters:

- wall thickness 4-16 mm;

- pile length 2.5-15 m;

- step between the hills 2.5 m;

- piles are available in various diameters from 47 to 325 mm;

- incomparable load 0.7-2.5 tons;

- estimated cost from 2000 rubles/unit.

A pile with a wide heel is used on floating, clue and loose soils. The screw blades reach almost the tip of the tip, the number of revolutions is no 2.

Pile parameters:

- wall thickness 4-16 mm;

- pile length 3-15 m;

- step between piles 3 m;

- diameter of piles 159, 219 and 325 mm;

- incomplete load 1-3.5 t;

- estimated cost from 3500 rubles/unit.

I exist and more complex structures of piles with multi -storage turns, built -in drainage system and additional blades. Such models are quite expensive, and their installation technology is more complicated. Therefore, such types of piles are practically not used in private construction.

DIY screw foundation for home

Design and calculation

First of all, it is necessary to conduct a qualitative analysis of the soil. The study of the geology of the area is best entrusted to professionals of a company engaged in the construction of houses on screw stilts. Experts will calculate the bearing capacity of the piles and the life of the foundation in a particular area, determine the indicators of soil aggressiveness and give out the appropriate conclusion.

When determining the type and number of piles, the following indicators are taken into account:

- properties and type of soil;

- groundwater level and their seasonal fluctuation;

- the weight of the future structure with all the filling;

- load from snow in winter;

- soil freezing depth;

- the margin for cutting piles during installation (about 20 cm).

The calculation of the screw foundation can also be made by companies engaged in the sale of piles. Very often they offer to pick up the sole for the future building for free.

The resulting value of the total load is recommended to increase by 20% - margin of strength. Based on this result, the required number of piles is determined

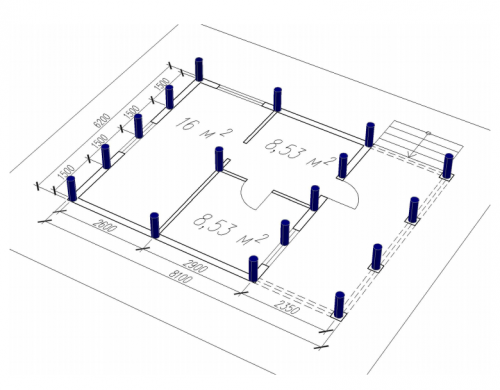

When designing a screw foundation, it is necessary to take into account:

- The distance between the hills is not more than 2.5-3 meters.

- Each corner of the house should rely on the pile.

Stages of the construction of the foundation

Screwing the pile is quite laborious process, so it is better to enlist the support of two or three people.

For work, you can independently make a lever that will facilitate and accelerate screwing piles into the ground. To do this, in the holes at the upper end of the screw pile it is necessary to insert the reinforcement (scrap) with a diameter of 3 cm. On scrap on both sides, put on the cuts of the square pipe. The optimal length of the sleeves of a homemade lever is 2.5-3 meters.

Phased installation of a screw foundation:

- Clean the site of garbage.

- Marking. On the surface of the soil, draw the contours of the foundation and the location of the piles to the plane of the construction site transfer the contour mesh. The boundaries of the grid determine the perimeter of the basement, the intersection of the rods are the location of the piles.

- In the place of each pile, digging pits with a depth of 15-20 cm.

- Twisting piles. During the screwing of the pile, one person must control the vertical position of the pile and the horizontality of the upper cut of the pile relative to the surface of the soil using the construction level.

- First of all, corner piles are screwed.

- The spiral lobe of the pile should completely plunge into a layer of non -dashing soil.

- After twisting the piles, intermediate piles are screwed in the corners of the foundation.

- Leveling piles. Using a laser level or optical rangefinder, determine the height of the pile field, mark the marking and cut the piles with a grinder. The heads should rise 40-50 cm above the ground.

- The cavity of the pile can be filled with a solution of concrete (the ratio of cement and sand - 1: 4).

- A steel plate (head) is welded to the trunk of each pile, evenly distributing the load over the entire area of \u200b\u200bthe cross -section. Welded seams must be treated with an anti -corrosion composition and painted.

- The strapping of the pile field with a wooden beam, railway grinder or channel.

Home screw foundation: photo

A screw foundation is ready for further construction work.

Home screw foundation: video

Installation tips for pile-screw foundations

We list the recommendations of specialists who will help to build a strong and durable house on screw stilts.

- The vertical deviation of the pile should not be more than 2.

- If the pile during screwing has deviated significantly or stumbled upon an obstacle, it must be dismantled and reinstalled in another place.

- I pile, screwed at an angle cannot be increased.

- The depth of the pile screws into the root soil of at least 600 mm.

- When adjusting the height, pile cannot be unscrewed. In the future, this will lead to the drawdown of the foundation and, as a result, deformation of the building.

- The pile should go into the plane of dense soil by 600-800 mm.

- If a temporary design is built, then the piles are better not to be concrete, since the material can be used in the construction of another object.

Recently, a screw foundation has begun to be actively used in Russia to reconstruct old buildings and erect new houses on problem soils.

I want to build a garage for

I want to build a garage on screw piles. I am interested in how long the piles will last and will not collapse my garage in about 5 years. Because as far as I know, the metal rot and amenable to corrosion over time.

Yes, feel free to build, I have a summer house

Yes, boldly build, I have a summer cottage on screw stilts for many years, moreover, so that the soil is not so hot. The main thing when choosing, pay special attention to the brand, thickness of steel, and whether there is an anti -corrosion coating.

I would not dare to put

I would not dare to put any buildings on the piles. Since the neighbors built a bathhouse not so long ago and a couple of months later the bath simply skewed. Now they understand what's the matter, the piles with poor -quality steel or the installers are pairing.