In modern private construction, the rafter system of the attic roof gives ...

|

|

In the process of laying paving slabs, a very important aspect is sand tamping ... |

Correctly insulated walls of the house will make life in it comfortable, and heating accounts ... |

The device of reinforced concrete foundations

The construction of the reinforced concrete foundation in the construction of the building is evidence of its durability. Since it is this type of foundation that differs in strength and reliability in operation. We will talk about the technology for building a reinforced concrete foundation further.

Table of contents:

- Features and varieties of reinforced concrete foundation

- The foundation reinforced concrete strip - technology of the structure

- Collective reinforced concrete foundations - installation rules

- The device of reinforced concrete foundations of continuous type

Features and varieties of reinforced concrete foundation

The use of reinforced concrete foundation is widespread in the process of building both industrial and public buildings, and housing structures. There are three main types of such foundations:

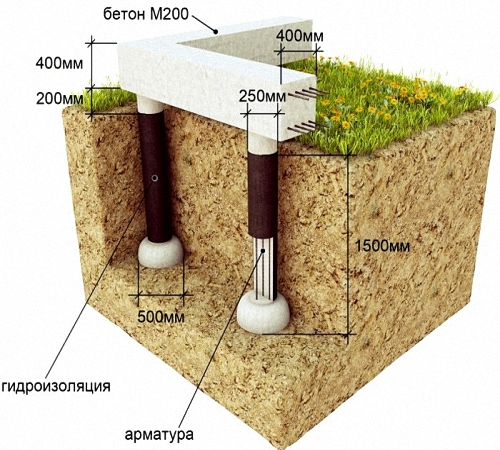

- column or separate;

- tape;

- Solid.

The column foundation is a design of reinforced concrete piles or columns, which separately are installed on the supporting parts of the building structure. The flight type of reinforced concrete foundation is the most popular. Its arrangement is based on the construction of the structure around the perimeter of the building. A continuous reinforced concrete foundation is installed under the whole building.

The installation of individual foundations is acceptable in the presence of a small load and a rare location of the columns. The installation of a strip foundation under the column is used when the foundation soles are not far from each other. This fact is observed when building a building on weak ground or with a large load.

In addition, it is recommended to use a strip reinforced concrete foundation in the presence of a heterogeneous in the texture of the soil cover, when exposed to external load or with uneven precipitation of the base.

If the load on the strip foundation, which leads to deformation of the structure, is recommended to install a reinforced concrete foundation of a continuous type. It is he who is able to completely align the sediment of the main part of the building. The use of this foundation is permissible in the presence of heterogeneous soil and too much load.

The average cost of the construction of a reinforced concrete foundation is from 5 to 7 % of the cost of all costs for its construction. With a thorough study and proper choice of the type of foundation, a significant economical effect on building the building itself is achieved.

During the construction of large structures, the design of the foundation is selected in the relationship with the cost of the consumption of material and labor resources when performing various kinds of foundations.

In relation to the method of performing the reinforced concrete foundation, they are divided into design:

- prefabricated;

- monolithic purpose.

In relation to the size, prefabricated foundations are whole or composite type. The teams of whole foundations are small in size. For their manufacture, concrete of class from 15 to 25 is used. The installation of such a foundation is made on a pillow made of sand and gravel, its thickness is about 12 cm. In addition, the reinforcement is laid on the surface of the sole of the foundation, in the form of a welded mesh. The minimum layer of reinforcement is 4 cm. In the absence of preparation for the foundation, the thickness of the reinforcing layer increases to 6.5 cm.

Installation of prefabricated columns is carried out in specially prepared nests, called a glass of foundation. The column is installed in the nest using the lining, then it is made and filling out the dawn with concrete.

The design of the prefabricated foundation consists of several parts, the manufacture of which requires a larger amount of concrete than for whole. The connection of the blocks of composite foundations is carried out using issues, anchors or welding of parts.

The foundation reinforced concrete strip - technology of the structure

The initial stage of the construction of the strip foundation involves the work on marking the territory and the preparation of the necessary materials. The marking of the site begins with the installation of reinforcing bars to the places of the foundation. They are installed to a small depth of up to 100-150 mm. Follow the compliance of the markings of the previously provided technical documentation. We offer to get acquainted with the main recommendations that will help mark the territory for a strip reinforced concrete foundation correctly:

- For marking, use pegs and a strong thread, pull them around the entire perimeter of the foundation, use the tape measure to measure the correctness of the distance, in the absence of roulette, the option of using a thread of a certain size is possible, choose threads that do not stretch, since otherwise, there will be errors in calculations;

- When the work on the marking is completed, measure the length of the parallel sides of the foundation again, they must be identical, the size of the diagonal lines should also be equal, if this is not done, then the risk of arranging the foundation with curves of the corners is possible, which will lead to damage to the appearance of the building itself ;

- Consider, when building a trench, its width should exceed the design width of the foundation by 35-60 cm, this distance will help to set the formwork, equip the protective drainage system and backfill, and the foundation depth indicated in the project increases by 15-20 cm, to compensate the pillow drainage, equipped with crushed stone and sand;

- If there are no errors when checking the marking, then proceed to the direct digging trench.

This stage involves the use of special construction equipment in the form of an excavator or manual work. The main advantage of using special equipment is the acceleration of the process of work.

But, the use of manual type of work is characterized by the following features:

- the amount of soil that is extracted from the trench is much less;

- The walls of the structure are absolutely evenness;

- The manual type of work allows you to adjust the width of the trench, therefore, when pouring, the amount of concrete decreases, and as a result, the costs of its purchase are reduced.

Please note that 300 mm above the bottom of the pit, you should equip an extension called a heel. This process will lead to an increase in the support area and to a more uniform load distribution.

After completing work on the construction of the trench, install a pillow of crushed stone and sand on its bottom, pour it with water and compact well. The recommended thickness of this layer is about 20 cm. Its main function is depreciation of the load, that is, a decrease in soil fluke and an increase in the resistance of the structure of a variety of loads.

After these work, the process of installing formwork for the strip foundation follows. With its help, the design acquires the correct shape. To collect formwork, use wooden boards interconnected by a transverse screed and resting into the ground using wooden spacers and pegs.

After laying the pillow of sand and gravel, the waterproofing procedure follows the foundation. For this purpose, permamine or a thick plastic film is used. This process helps to preserve moisture, just flooded with a concrete mixture solution. If this is not done, then the risk of microcracks increases, which through years will lead to the destruction of the foundation.

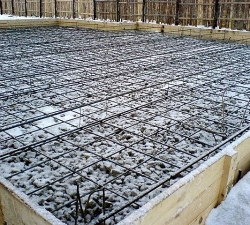

The next stage involves the performance of the reinforcement of the structure. This is done to enhance the supporting characteristics of the foundation. Namely, due to the presence of a steel frame, the design takes the type of reinforced concrete. For the construction of the reinforcement layer, metal rods are used, with a cross section of 1 to 2 cm, longitudinal, vertical and transverse type. For their connection, wire and a metal hook or a device that can be visited with a reinforcing layer is used.

Please note that the assembly of reinforcement for the foundation is carried out only with the help of knitting. The use of the welding machine is unacceptable. Since in the process of arranging a frame from reinforced concrete, it must move, thereby ensuring hardening of the concrete mixture. With the help of this approach, the supporting characteristics of the building are strengthened several times.

After installing the reinforcement, the process of arranging the ventilation holes of the foundation follows. They appear in the form of an outlet or a lot. With the help of an outlet, the strip foundation does not accumulate excessive moisture in the underground purpose. For their arrangement, it is recommended to use pipes from asbest cement, with a diameter of 10 or 15 cm. The place of their installation is a shield of formwork and inter -reservoir space, a height of about 20 cm from the base of the reinforcement. After installing the ventilation ducts, the communication system is mounted.

To fill the reinforced concrete foundation, the cement of the brand 200 and higher is used. The preparation of the solution should be carried out using a concrete mixer. After pouring each of the layers, the process of their rammed with a vibrator for concrete follows. It will help get rid of excess air in the concrete mixture, thereby preventing the appearance of pores and improving concrete strength.

Tip: When using a vibrator, you need to ensure that it does not affect the integrity of the reinforcement. When small destruction of the reinforcing frame appears, immediately stop the filling process and proceed to its repair.

If the foundation is poured in the cold season, take care of using special additives for concrete. With their help, he will not lose his strength.

The weather during the filling should not be too hot or rainy, as this will affect the quality of the foundation.

The formwork is removed after twenty, and better than thirty days after pouring.

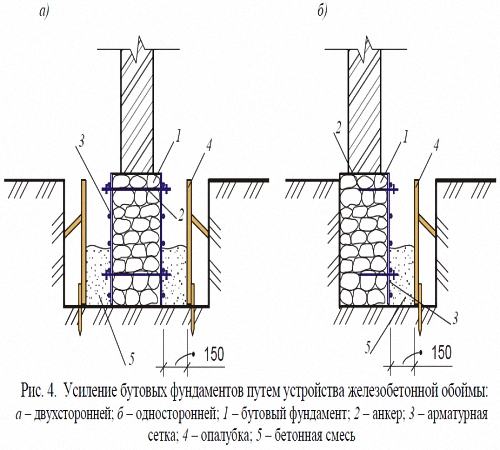

Collective reinforced concrete foundations - installation rules

For the manufacture of a prefabricated reinforced concrete foundation, standard reinforced concrete parts are used, made at special industrial enterprises. They are used in the construction of private houses due to the impossibility of building a strip or other type of foundation or by justification in technical and economic calculations.

Details of the prefabricated foundation are too heavy, so the installation requires special lifting equipment. The units are installed on a specially prepared pillow of sand or concrete mixture. Their fixation and fastening is carried out using a cement mortar. In the presence of incomplete areas in which standard blocks are not placed, the installation of additional blocks is carried out, the length of which is less from the main one third.

In the absence of such elements, it is possible to fill the sites with monolithic concrete.

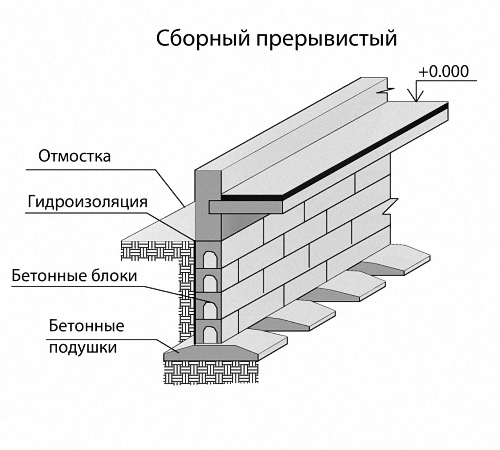

The device of reinforced concrete foundations of the prefabricated type consists of:

- sand pillow;

- foundation slab;

- foundation block;

- soil;

- waterproofing;

- reinforced belt;

- blind spots;

- basement wall.

The foundation of a monolithic reinforced concrete prefabricated type is produced in structures with the presence of a basement or basement. To arrange them, the presence of a pit located under the building is necessary. The foundation of the pit should be even. Next, the sand pillow is laid around the perimeter of the building, and the foundation is already installed on it.

To fill in the interlock seams, a cement solution is used, and the outer part of the foundation is covered with waterproofing. Standard prefabricated blocks have special recesses designed to fill with cement mortar, they are responsible for connecting the blocks among themselves. The installation of concrete blocks should be carried out with the presence of dressing between the seams, this technology helps to improve the strength of their connection.

When arranging a reinforced concrete foundation of this type, pay attention to the presence of technological areas in which engineering communications will be located in the form of a power supply, water supply or sewer system. To do this, in the supporting parts, cases are installed for the manufacture of which steel, ceramic or plastic pipes of a certain size are used, if there are no such materials, the option of using steel of roofing is possible.

Places in which communications will be carried out are carefully verified with the sketch of the working project, since during subsequent alterations a risk of violation of the integrity of the structure is possible. A temporary overlap of technological holes occurs using a rag, covered with resin or other similar materials.

The device of reinforced concrete foundations of continuous type

The decision on arranging the foundation of this type is based on engineering-geological work at the construction site. Using the design of a continuous foundation, the strength and duration of the operation of the building being built are ensured. The type of foundation used is affected by the purpose of the building.

The foundation of the slab type has the form of a monolithic reinforced concrete slab, which is located over the entire area of \u200b\u200bthe structure. In this case, there is a rigid reinforcement of the entire slab. This process makes it stable before various loads and soil movements.

The use of the foundation of the slab type is common in areas with the presence of frequent seismic phenomena, as well as in areas with a high groundwater level.

In the ratio with the purpose of the building, the construction of a slab foundation is carried out in the form of flat or ribbed plates. There is an option to build a cross -monolithic tape. To lay out some types of slab foundations, ready -made reinforced concrete slabs are used. During the construction of a large building in which underground premises will be built, a box -type foundation is used.

The construction of the slab foundation occurs directly on the construction site. For laying the foundation, it is necessary to build a base based on concrete of brand 50, its minimum thickness is 10 cm. When carrying out construction on a high level of groundwater, a sand pillow is required, with a thickness of 20 cm. Consider that sand requires thorough tamping and watering from using water. After the construction of the base, the process of its coating is followed by a waterproofing layer that protects the plate from humidity. Under the foundation plate, it requires a frame of reinforcement, welding is used to connect the rods. It will ensure the rigidity and stability of the structure.

Laying a reinforcing frame is carried out on a waterproofing layer, and after that the foundation occurs. If it is necessary to build a slab with the presence of basement ribs, their construction is carried out by installing prefabricated parts from reinforced concrete.

If work is carried out in areas with seismic instability, then monolithic concrete is used to build the ribs, and the reinforcement is welded with the foundation. In such buildings, ribs are concreted along with the stove. The thickness of the plates, in this case, is about 20 cm.

The use of slab foundations is also relevant in climatic regions with a high level of soil freezing. In this case, the frost -resistant foundation has a thickness of about 20 cm, and the plate is characterized by the presence of contour ribs. For insulation of this kind of foundation, foamopylene thermal insulation is used.

Requirements for concrete for the manufacture of a monolithic reinforced concrete foundation:

- The minimum value of the brand is 200;

- The percentage of waterwork - 5;

- The level of water resistance is the second;

- frost resistance depends on the region of installation of the foundation.