The basement in a private house is a multifunctional room and important ...

|

|

High -quality roof guarantee of reliable protection of your home from the vagaries of nature ... |

Pipes are an obligatory element of the bathroom, from the location of which is directly ... |

Warming the walls of the house from the inside

Properly insulated walls of the house will make life in it comfortable, and the heating accounts are minimal. There is a wide variety of thermal insulation materials that differ in their thermal conductivity, installation and price. Consider the most popular ways to warm private houses.

Content:

- Thermal insulation materials

- Features and comparison of thermal insulation materials

- West insulation from the inside of the frame house with mineral wool

- How to insulate the frame house ecowide

- Insulation of the walls of the brick house from the inside

- Insulation of the walls of the barbell from the inside

- A few tips

Thermal insulation materials

There are many species in total. Starting from all the well -known glass wool and ending with a modern heat -insulating solution, which is applied as paint.

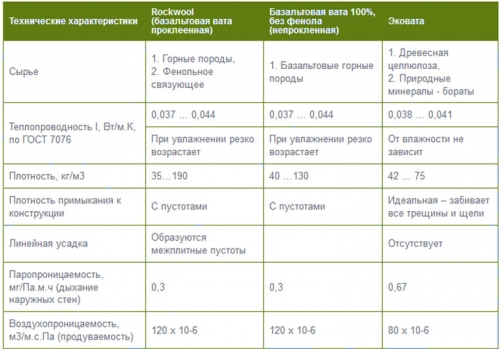

Mineral wool

Minvata is made from fibers of inorganic materials, such as dolomite, basalt, quartz, glass fight, diabase, etc. To create it, the material is first melted, and then placed in a centrifug, where it stretches on thin fibers and settles in a special chamber. The resulting mass is a random interweaving of fibers, in the future, heat -insulating mats and plates form from it.

Properties of mineral wool:

- has low thermal conductivity;

- is a non -combustible material;

- has a high compression strength and no less high strength strength;

- excellent soundproofing qualities;

- resistance to temperature differences;

- environmental friendliness;

- simplicity in installation.

The good heat -insulating properties of the insulation are due to the structure of the material in which the number of air channels is 95%. Mineral wool belongs to the class of non -combustible materials (capable of withstanding the temperature of up to 700 degrees) and its use is allowed not only in private houses, but also in public buildings. It does not lose its operational properties for several decades.

Most opponents of the use of mineral wool as a heater for walls explain their position by the fact that the mats are quite soft and in an upright position, over time, will be shrinking, which will lead to cold bridges. But the fibers in it are randomly located, giving the material the necessary rigidity and resistance to mechanical loads.

When warming mineral wool, it is necessary to use vapor -permeable films to protect against condensate. But this is not its only protection against moisture, even at the manufacturing stage, hydrophobic substances are added, and the basalt fibers themselves are non -hygroscopic raw materials.

Fiberglass

This material has been known for a long time and has been successfully used for many years to warm houses. They are made on the basis of the battle of glass, soda, sand, dolomite, limestone and a number of other components. It is also heated and divided into many thin fibers, which are located in the finished material parallel to each other.

Fiberglass properties:

- in winter, holds heat in the house, and in summer retains coolness;

- has soundproofing properties;

- the fiberglass mats, although they absorb moisture, are easily given it back, which indicates Negigroscopicity;

- due to good elasticity and elasticity for many years, it is not deformed;

- the composition of the material is environmentally friendly, and thanks to the treatment with special drugs, it is not afraid of pests and is not subject to mold;

- unlike mineral wool, fiberglass more vibration resistant;

- great for insulation of uneven surfaces;

- when burning, does not emit harmful substances.

The walls and facades of frame houses are insulated with fiberglass, but nevertheless, this material is more suitable for thermal insulation of floors, inter -story floors and pipelines.

Fiberglass mats are easily cut, but they should work with them in protective clothes and a respirator, because when it enters the skin, irritation begins, which will have to get rid of which will have to be for quite some time.

Extruded polystyrene foam

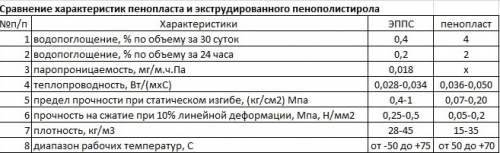

Extruded polystyrene foam is a modern analogue of ordinary foam. It is favorably distinguished by low water absorption and strong resistance to compression from other heater, providing high stability to the material.

He, without losing his properties, withstands very low and high temperatures. When warming, it is not necessary to carry out waterproofing work. There is also no need to purchase vapor barrier films, which serves as an additional advantage.

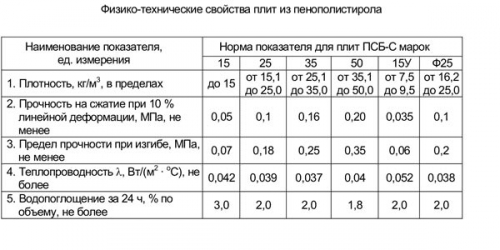

Polistyle foam has special markings, thanks to which it is easy to choose the necessary material according to its characteristics, the strength for compression or stamping of the surface.

Foam polystyrene

Foam has been known for more than half a century. Perhaps this is the cheapest type of thermal insulation material. It is great for insulation of residential and non -residential buildings. Its structure is made up of gas granules filled with gas, which practically do not miss heat.

Despite the artificial origin, according to vapor permeable characteristics, polystyrene foam is similar to wood. And thanks to low hygroscopicity, it is not subject to rotting and formation of mold harmful to health.

Another important advantage is its resistance to acids (exception is nitrogen and acetic acid) and paints.

DIY insulation with your own hands is best suited for PPS plates size 50x100 and 60x120 cm.

Flaws:

- high combustibility of the material;

- enters into a chemical reaction with some solvents (in particular with dichloroethane and benzene);

- fragile material that is easy to break;

- when they insulated with a private house, it suffers from the teeth of mice, who like to arrange their holes in it.

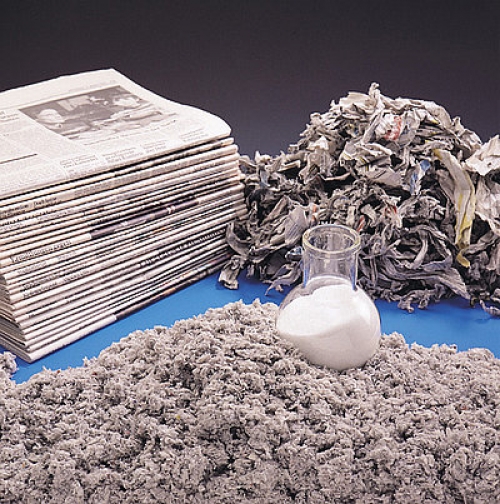

Ecowata

This is a relatively new thermal insulation material that is gaining popularity due to the affordable price, environmental friendliness and excellent technical characteristics.

Advantages:

- made of wood fiber, it has excellent thermal properties;

- during production, special additives are added to Ecowata, making it with difficult to spark material;

- in its manufacture, antiseptics are used, so rodents and other pests do not live in it, and mold and fungus are not formed;

- protects a wooden house from decay, and in frame houses extends the operational period of wooden elements up to 100 years. Due to natural origin (the basis is cellulose), Ecowata has the ability to breathe.

The ecowan layer of 15 cm is: 46 cm of the walls of foam concrete, 18 cm of mineral wool insulation, 50 cm of wooden beam thickness, 90 cm expanded clay, 146 cm walls made of brickwork.

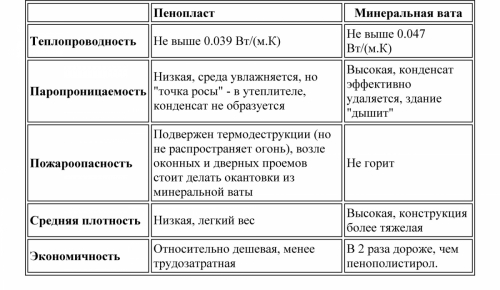

Features and comparison of thermal insulation materials

What should be paid to when choosing thermal insulation material:

- All cotton heaters (mineral wool, fiberglass) suppress air noise well. But polystyrene and polystyrene foam will require the use of additional soundproofing material.

- Cotton heaters, although made of non -gigroscopic materials, absorb water well (the air that is located between the fibers absorbs water). And getting wet by only 2% of the mass, they lose 50% of their properties. Therefore, they are insulated only in Sovokup using vapor -permeable films. PPS and EPS do not absorb moisture, but being in water, for a long time do not lose their characteristics.

- It is not recommended to warm the walls of the house with foam from the inside. It refers to combustible materials, and when burning, it emits toxic substances. But if the choice fell on the PPS, it is worth stopping at the G1 fueling group. Although he will burn in contact with fire, he will not be able to maintain combustion on his own. Of course, groups such as G4 or G3 are much cheaper, but choosing them for insulation of a private house is dangerous.

West insulation from the inside of the frame house with mineral wool

Mineral wool is classified into several types:

- a density of 10-90 kg/m3 is suitable for insulation and soundproof frame houses, in which no load will be provided on it;

- more stringent, with a density of 90 kg/m3, is designed to carry some loads, most often they insulate the contours of structures;

- the third type is technical. It is used to warm equipment and is able to withstand the temperature from 180 to + 700 degrees.

Warming of the walls of the frame house with mineral wool is the best option. It does not burn, perfectly retains heat, isolates the rooms from noise and safe for health and the environment.

The main task when working with it is to create sealed vapor barrier from all sides, reliably protecting the material from condensate and moisture. It will also be necessary to equip a ventilated gap between the vapor barrier that closes the insulation and the finish line of the walls.

Stages of work

- The distance between the vertical racks in the frame house is 60 cm, which in width corresponds to the size of the basalt plate. For wall insulation, material in the form of plates with a density of at least 30 kg/m3 is suitable. The standard thickness of the sheet is 5 cm, so the number of layers is selected individually, depending on the weather conditions of the region. So, for the south of Russia, it is enough to make a layer of insulation 10 cm. And during construction in the northern regions, the optimal thickness of 15 cm of thermal insulation material from the inside, and 5 cm outside. Moreover, external insulation is attached in such a way as to block all the wooden beams of the frame, thereby excluding the possibility of the occurrence of cold bridges.

- On the outside, the frame house, as a rule, already has a layer of vapor barrier to protect external insulation, so it makes no sense to duplicate it, from the inside before laying the insulation. If small cracks have formed between the OSB plates, they are necessarily disconnected with mounting foam.

- The insulation between the vertical racks should be laid tightly so that there are no gaps. Thanks to the good elasticity of the material, it is easy to do this. From above it is closed by a vapor barrier film, which is overlapped, and all its seams are additionally glued with construction reinforced tape.

- On top of the membrane film, a crate is attached to the frame for drying plasterboard.

How to insulate the frame house ecowide

The second optimal way to insulate the frame house is to use ecovata. In most cases, the companies that produce it offer its installation services. But it is easy to spray it independently, it is enough to rent a special vacuum cleaner. True, it should be noted that the manufacturer will be certified in the absence of the need for vapor barrier of the material. This is partly true, but to extend the service life and to prevent unpleasant situations, additional protection against condensate is necessary.

Ecowata is applied in three ways:

- Dry way. This is the most common option, it is suitable for insulation of the walls of a private house from the inside, floor, inter -story floors and inclined attic roofs. Spraying is carried out using a hose from which the insulation is supplied. It is simply falling asleep into the prepared cavities of the walls or fill the floor space between the beams.

- Wet method. Optimal for insulation of inclined surfaces. Water is added to it, due to which adhesion increases and the material sticks to the wall. And after drying, a more dense coating is created.

- Adhesive method. As the name is clear, glue is added to the insulation. This method is used for insulation of concrete or metal walls, such as hangars. In this case, the finished lining is not required.

Insulation of the walls of the brick house from the inside

When choosing a thermal insulation material for insulation of a brick house from the inside, it is important that it has high thermal insulation properties, but has a small thickness. Unlike the frame house in which the insulation is inside the walls, in the brick it occupies useful area. Therefore, it is so important to find the best option without prejudice to residential meters.

Consider three methods of insulation - plaster, polystyrene and mineral wool.

Insulation of the walls of a brick house from the inside with plaster

The first layer of primary brush with a hard brush is applied to the aligned walls. It must have a liquid consistency, and when applying, fill out all the gaps and small cracks. On average, the thickness of the first layer is 5-8 mm.

Then the coating is coated. It is it that is the main thermal insulation material, so it should be distributed evenly. First, a fabric reinforcing mesh is mounted on the wall, and a composition is applied on top of it with a spatula with a flat surface. Gradually, in two stages, a layer of 5 cm is created (the thickness of the layer is 1.5-2 cm, but not more).

At the final stage, the plaster is covered with the last leveling layer. To do this, a liquid consistency of the solution is diluted and fine -grained sand is added to it. The thickness of this layer is approximately 5 mm.

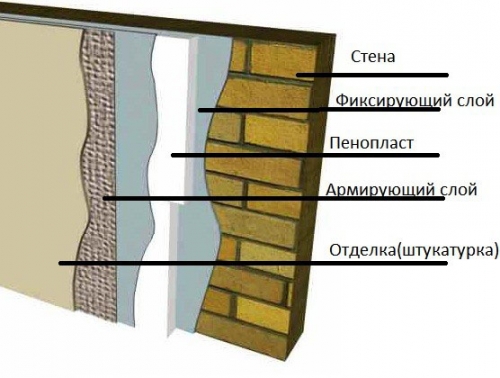

Insulation of the walls of a brick house from the inside with polystyrene

All the advantages and disadvantages of insulation with foam have already been described above, so we will consider directly the stages of work.

For more effective insulation, the brick wall is first plastered. Then, a layer of putty is aligned with a tight fit of foam sheets.

If the house does not have waterproofing outside, it must be made from the inside. It can be a liquid primer or a vapor barrier film. Despite the moisture resistance of the PPS, moisture formed on brickwork penetrates and destroys it.

Now the installation of sheets begins. On a flat surface, it is attached to a special glue, which is applied to the walls or directly to the material. Foam sheets should fit tightly to each other, without the formation of cracks in the joints.

On top of the thermal insulation material is closed with vapor barrier. The insulation is completed, you can proceed to the finish.

Insulation of the walls of a brick house from the inside with mineral wool

With this type of insulation, the brick wall must also be closed by hydro- or vapor barrier.

Then a crate of metal profiles or wooden racks located vertically is mounted. The distance between them should be equal to the width of thermal insulation material. You can’t do it a little wider, you add allowances, because mineral wool is a soft material that is easy to lay, but it should be located in the frame very tightly.

Next, mineral wool is laid. If its thickness is slightly wider than the crate, and it strives to fall out, it must be immediately fixed with a vapor barrier film, and all the work is gradually performed in stages.

After the entire insulation is laid and closed with a vapor barrier, a crate is nailed for finishing.

The walls of the panel house from the inside are also insulated in the same ways. But depending on the initial thickness of the walls, a thicker layer of insulation may be required.

Insulation of the walls of the barbell from the inside

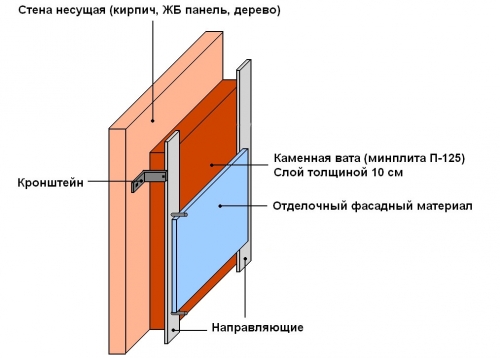

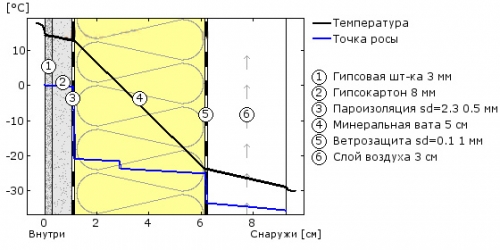

The above is the scheme of the insulation cake of a timber house. When warming a wooden house with mineral wool, it is necessary to provide a ventilated gap between the bar wall and a layer of insulation to prevent accumulation of condensate.

Wood is an organic material that is subject to decay. Therefore, it will be necessary to build, from the inside a whole frame system with a filler from the insulation. If you neglect this, the beam will rot in 4-5 years.

For the frame, boards are selected with a length of equal height of the room from the ceiling to the floor. They are installed with a step of 60 cm, it is such a standard width of all mineral water heater. They are attached with an indent from the wall by 2-3 cm, thus creating a venturezor.

But in order for moisture to go into the atmosphere, it will be necessary to make perfume in the wall. To do this, in the first from the floor, a hole with a diameter of 2 cm is drilled from the floor at an angle of 45 degrees to the ground. They must be made along the entire length of 1 m. On top of the venture, it is left open, with access to the attic or under the cornice.

To protect the blowing from the overlap with mineral wool and to delay warm air indoors, a vapor barrier film is attached to the frame.

After installing vapor barrier, the insulation is tightly laid, without the formation of cold bridges. On top, as shown in the diagram, the design is also closed with a vapor barrier film.

The insulation is finished, it remains to make a crate for the internal skin of the walls.

A few tips

All information about the required thickness of the layer is approached approximately. For accurate calculation in each case, many factors should take into account the material of the walls, the presence of external insulation, climatic features, the characteristics of the thermal insulation of a particular manufacturer, etc.

One and the same thermal insulation material cannot be insulated with everything. But if the seller or builder assures you in the opposite, this only indicates their personal benefit.

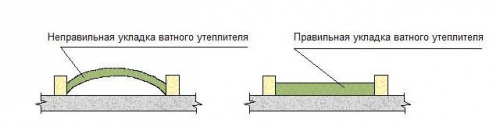

It is necessary to lay cotton materials tightly, but, in no case do not compress it. It must be located exactly in the crate and not have bending.

According to the above technologies, the walls of country houses are insulated from the inside, cottages for year -round residence or city apartments. The only difference is that in the first and last case, a layer of insulation is made minimal.

For a residential building only

For a residential building, only natural heaters. Steico? Beltermo, Ecotiplin.

I don't know how you are like that for me

I don’t know how it is better for me to entrust all to specialists all the more the best way to warm this is the insulation of polyuritan foam foam. These guys made me not expensive and efficiently http://ppu-prof.ru/