Foam is a sought -after building material, which is massively used ...

|

|

The construction of the reinforced concrete foundation in the construction of the building is evidence of its ... |

The conditions of comfortable residence in the rooms of the attic directly depend on correctly ... |

Block tape foundation device

The foundation of blocks has all the advantages of reinforced concrete, but is built much in a faster time than a monolithic strip foundation. After its construction, you can immediately proceed to the next stages of construction, without waiting for its hardening. Plates are produced of different sizes, including specifically for private construction, when laying which does not need to attract equipment.

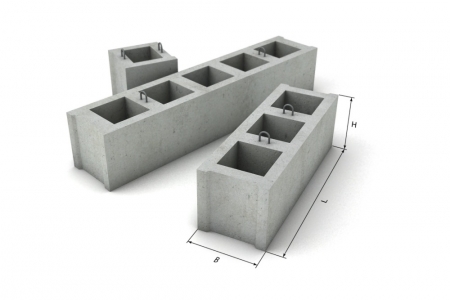

What are foundation blocks

These are building elements from which they form a prefabricated foundation of the building. The most popular concrete blocks of the FBS produced at the FBI plant, which ensures compliance with the requirements for high quality products: the exact ratio of the proportions of the mixture ingredients, reinforcement, pouring high -quality concrete and further vibration pressing, prophet in special chambers and final concrete hardening.

It is theoretically possible to make them with your own hands, but in practice it turns into a large cost of time and money, as a result of which the price of the blocks will turn out above the factory. But the cost of the prefabricated foundation is already higher than the cost of monolithic. To date, they are produced by a large number of factories, due to high competition, the price of foundation blocks is not overpriced, and when buying a large volume, it can be reduced even more.

But choosing blocks should not be focused on the price, but primarily on the load that they are able to withstand. For each type of FBS, the norms in GOST are spelled out, and the blocks made in factories are necessarily undergoing quality check. In addition, additional additives are introduced into the concrete mixture that improve their quality.

- Frost resistance It is achieved by special additives. Such blocks withstand significant temperature changes. They should be chosen for regions with harsh winters.

- Stability to acidic environments rises with the addition of granite crushed stone to concrete. As can be seen from the characteristics, they are adapted for operation on acidic soils.

- A variety of products produced at the factory. For the construction of large developers with special equipment, large -sized blocks are produced, and small builders are provided for small builders.

But, despite all the improvements, the foundation blocks have disadvantages:

- high price. The foundation of them is at least 30% more expensive than monolithic;

- the need for a double layer of waterproofing;

- the seams that have masonry are very susceptible to the effects of external factors, so they need insulation.

Types of foundation blocks

All types of foundation blocks are divided into three main types:

- monolithic (FBS) is continuous concrete blocks with steel reinforcement, they are the most durable of all types;

- monolithic with a groove (FBV), they are also made of reinforced concrete, but have special cuts designed to lay various types of communications;

- hollow (FBP) have cavities inside. They are the least durable and are almost not used for the construction of the foundation. Only the construction of a light frame or wooden house can be used.

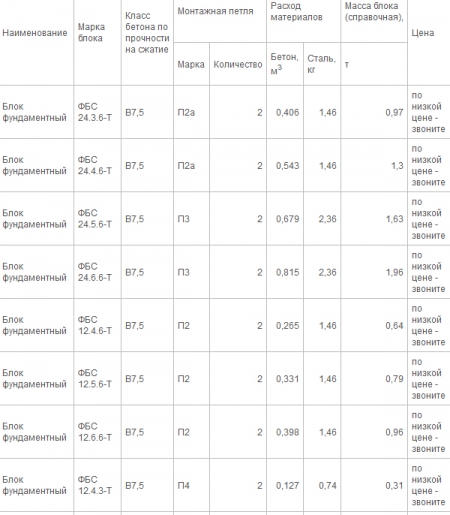

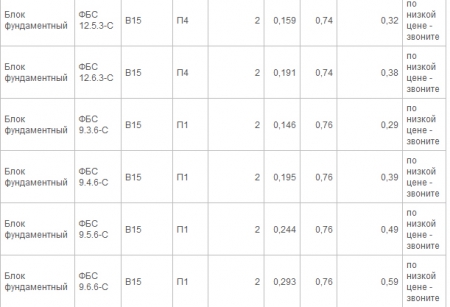

When choosing a material for a strip foundation from the FBS blocks, you need to know their characteristics and be able to decipher the abbreviation. For example, FBS 2-2-4 means that its length is 20 cm, width 20 cm, and the height is 40 cm. Thus, the first digit indicates the length of the blocks, the second width, and their third height.

For tape foundations from concrete blocks, FBS 4, 6, 8, 9, 12, 24 with steel reinforcement are used. Their choice depends on the load that will be on them by the building.

For low -rise construction, blocks with a size of 20x20x40 are most convenient. In their composition, instead of lime crushed stone, granite is added, so they are suitable for the construction of cellars, basements, interior partitions, etc. The strip foundation from blocks of 20x20x40 can be made independently, because its weight is only 31.7 kg.

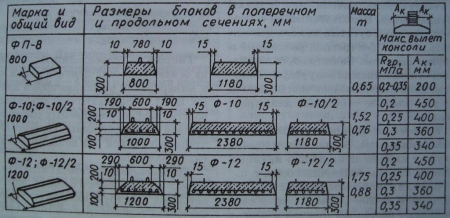

More details about the technical characteristics of the FBS blocks are shown in the table

DIY tape foundation device

As in the construction of any foundation, first of all, you need to build on the characteristics of the soil. Subject to technology, a tape assembly foundation can be installed even on heaving soils.

Ideal for construction is the non-poudy sandy or rocky soils with the content of crushed stone and gravel, and with the occurrence of soil at a depth of at least 3 meters. If these conditions are available, the basement from the FBS blocks will turn out to be a full -fledged dry room. But if on the construction site clay and loamy soils, as well as close groundwater, will have to take a number of measures to protect the block foundation. Due to groundwater, in the basement it will always be wet even in the presence of high-quality waterproofing.

In addition, you need to do:

- to strengthen masonry from the FBS at the top and on the sole of the foundation, monolithic belts are made;

- the sinuses fall asleep around the entire perimeter with medium -grained sand;

- bitumen is applied to the outer side surface of the foundation;

- warming the foundation with moisture -resistant thermal insulation material.

All this will require additional financial costs, which will greatly affect the total cost of the foundation.

Stages of construction

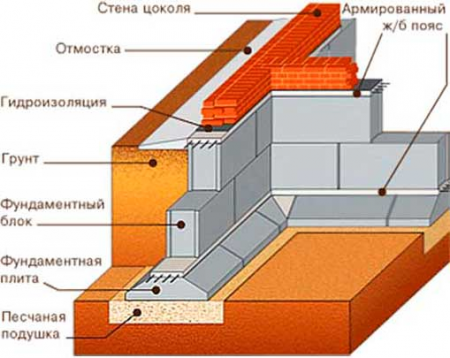

A prefabricated strip foundation is a reinforced concrete structure that is mounted around the entire perimeter of the house and under its supporting walls.

Initially, the marking of the site is made for the future foundation with the help of pegs and the ropes stretched between them. This is one of the most critical stages, in which it is necessary to achieve the perfect evenness of all angles. After that, clearly by marking, the trench is dug to the required depth. Its bottom should be leveled as much as possible.

A sand pillow is laid on the bottom of the trench with a layer of 15-20 cm and wider than the block by 20-30 cm, tamped and spilled with water. A layer of waterproofing is placed on top of it, for which a plastic film is suitable.

For the lower layer of the strip foundation from the blocks, reinforced concrete stoves (FL) are used, which are installed on top of waterproofing.

Now the laying of the blocks themselves begins. Initially, the musical blocks are installed in the corners and at the places of intersection of the walls. On their faces, the orientation thread is pulled and the rest of the blocks in a checkerboard pattern are mounted along it.

Before the final installation, their evenness is checked using level and plumb line. Minor distortions are eliminated with scrap that can be moved. With significant unevenness, the block should be dismantled, the base under it is aligned and, having applied a new layer of solution, install it again.

To lay them, a layer of cement mortar is applied 2 cm thick, distributing it by a rail along the frame. All vertical seams are densely filled with solution as masonry is installed. If the length of the wall is not the length of the block length, then you will need an elemental element called a seal. It should be remembered that between the blocks it is necessary to leave the distance for laying communications.

When the foundation is lined, the gap between its outer walls and soil is covered with sand, stampedly rammed and watered with water. The outer part of the foundation on all sides is covered with waterproofing.

It remains only to wait for the connecting solution to dry and the construction of the walls can begin.

The video shows how the assembly foundation is mounted by professionals

Summing up, it becomes clear that the assembly strip foundation from blocks, although it requires less time to build, is more expensive and labor -cost. Even with a relatively small weight of the material, it is difficult and difficult to build it yourself. Therefore, private developers, as a rule, use foundation blocks to build a column foundation.

Good article.

Good article.