The architecture of modern buildings involves a wide variety of aesthetic ...

|

|

The fence in the personal or summer cottage is a visiting card of the owners of the house. AND... |

Crossing special designs that share floors. They can... |

What is the glue for foam. Features and selection criteria

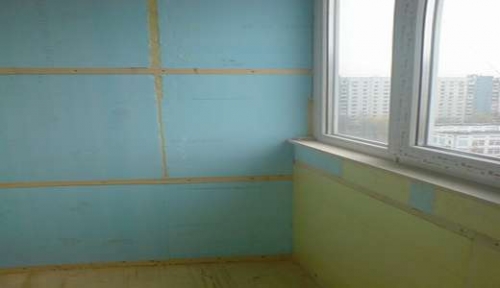

Foam is a sought -after building material, which is massively used in the insulation of balconies, facades, basements and rooms from the inside. Foam installation is carried out using dowels and complemented by planting the material for glue. The tight fit of the foam sheets is the key to effective thermal insulation and the durability of the structure.

In the article, we will describe what types of glue are applicable for working with polystyrene, we give practical recommendations for choosing the adhesive composition and gluing frozen plastic to various surfaces.

- What features of foam should be taken into account when choosing glue

- Types of glue for foam: Pros and cons of use

- Overview of glue of different manufacturers

- Preparation of glue from dry mixture

- Recommendations for gluing foam

What features of foam should be taken into account when choosing glue

Foam is in great demand in mass and individual construction due to high technical and operational characteristics. The material is characterized by low heat and steering, practically does not absorb moisture (0.4-4%), resistant to mold and has a long service life of up to 30 years.

The main volume of foamed plastic occupies air. This determines the low weight of the sheets of foam and allows the material to be held well on the covered surface. On the other hand, such a structure reduces the area of \u200b\u200bcontact and adhesion of glued materials.

When choosing glue for gluing foam, the following points should be taken into account:

- in the composition of the adhesive, there should not be solvents (gasoline, acetone, etc.) they can react and burn polystyrene;

- place of repair work (outside or inside the building);

- type of covering surface (concrete, metal, wood, etc.);

- for gluing foam plates, dry or wet type glue is suitable together.

Types of glue for foam: Pros and cons of use

Dry adhesive mixtures

Dry mixtures are used for both internal and external insulation works. Most often they are sold in bags of 25 kg. Before applying glue to the foam, you need to prepare the working mixture, following the instructions on the package.

All dry glue mixtures for foam can be divided into two groups:

- Glue for foam It is applied to the foam plate immediately before gluing to the roof or wall.

- The reinforcing mixtureIt is applied on top of foam to the installed reinforcing mesh. As a result, a layer is formed that protects against mechanical damage and serves as the basis for the subsequent wall decoration.

Advice! Dry mixtures are best bought in a couple (glue + reinforcement). For example:

- Cerisit CT83 and Cerisit CT85;

- Kreisel 210 and Kreisel 220;

- Master Termol and Master Super

Before buying dry glue, you need to check the date of its manufacture and storage conditions of the goods. The shelf life of adhesive composition is not more than 12 months. Glue must be stored in a dry, closed room. Buying bags on the street is definitely not worth it.

Important! A bag of dry glue must be checked. There should not be stains from moisture on the package, and inside the presence of sticky or hardened lumps of dry mixture is unacceptable

Advantages of glue based on dry mixture:

- available cost (you can buy glue for foam at a price of 200-400 rubles per 25 kg);

- small expense (about 6 kg per m2).

Disadvantages of dry mixtures:

- the need to mess with heavy bags and prepare the solution yourself;

- not suitable for gluing foam on metal surfaces and concrete;

- the fastening of dowels can be carried out only 24 hours after applying the glue.

Polyurethane glue-pen

Many builders note that the best glue for foam polyurethane foam. Such glue aerazol is used to work with different surfaces inside and outside the room.

Among the advantages of polyurethane foam include:

- convenience and speed of application;

- good adhesion of polyurethane glue for foam with a covered surface;

- the moisture resistance of the foam is higher than that of glue based on dry matter;

- low consumption (a cylinder of polyurethane foam is enough for a processing of 10 m2).

The downside of this method of gluing the need to purchase a mounting gun (450-2500 rubles). Thanks to this device, the convenience and efficiency of gluing increases significantly, and the gun itself can be used to carry out other repair and construction work.

The cost of polyurethane glue-pen is about 500 rubles. The price depends on the composition and manufacturer.

Liquid Nails

To cover small surfaces by polystyrene, liquid nails can be used. When choosing them, it is very important to evaluate the composition of adhesive substance. It should not have solvents.

Liquid nails are considered not a rather reliable way of gluing, so they are often combined with another, more durable glue (dry mixture or polyurethane foam).

Reliable fixation is ensured by point application of the adhesive composition in the following proportion: 1/3 of the surface, liquid nails and 2/3 of the surface glue based on a dry mixture

Such a combination is quite justified. Liquid nails are very quickly grasped and it is not necessary to install supports for fixing the foam sheets, and a solution from a dry mixture will provide a strong coupling.

The cost of liquid nails is about 150-200 rubles per 300 ml.

Overview of glue of different manufacturers

Foam glue is represented by a wide range. Among all the abundance of goods, the glue of such manufacturers is in particular demand: Cerisit, Knauf, Master, and Titan.

Ceresit

Cerisit has developed a whole line of client compounds for gluing foam. The most popular are the following types of glue:

- Cerisit CT84Foam foam glue is used to warm the facades in a wet method. Glue characteristics:

- Cerisit CT83 Dry mixture for mounting plates. Glue has the following characteristics:

- drying time about 3 days (air temperature +20C, air humidity is not more than 60%);

- work cannot be performed if the air temperature is less than 0C;

- a method of applying a gear spatula;

- the consumption of the solution of the mortar mixture is 6 kg/m2;

- the cost is 1 bag (25 kg) 350 rubles.

- Cerisit CT85 Reinforcing glue for foam. It can be used both for gluing foam plates, and for their subsequent reinforcement. Main characteristics:

- Universal glue moment For foam. The mixture is suitable for gluing slabs of foam plastic and creating a protective reinforcing layer. The characteristics of the mortar mixture is the moment:

- using temperature +5C/ +30C;

- operating temperature -50C/+70C;

- crowding the finished composition of 10 minutes, consumption 1 hour;

- glue consumption 5.5-6.5 kg/m2;

- the cost of 1 bag is about 250 rubles (25 kg).

Video: Application of Cerezite glue for foam

KNAUF CLABERSHER

KNAUF is glued to foam Klebashpatel - it is used as an adhesive or reinforcing solution for laying polystyrene sheets/extruded polystyrene foam. The composition of the glue includes a special supplement (a combination of aggregates and binding substances), which gives the additional strength of the clutch of the foam with the base.

Characteristics KNAUF CLABSHPER:

- drying time of one layer of glue 24 hours;

- consumption of the prepared solution 2 hours;

- the time of exposure of the reinforcing layer is 3 days;

- the temperature of the base and air should be +5C and higher;

- material consumption 8kg/m2;

- the cost of 1 bag (25 kg) is about 250 rubles.

Master

For insulation of facades, experts recommend combining glue for foam MASET Termol and a reinforcing mixture of Master Super.

Master Termolit has the following properties:

- a wide range of operating temperatures, gluing can be performed at temperatures from -5C to +30C;

- excellent adhesion with brick, concrete and cement-lime surfaces;

- the ability to adjust the laying of plates (50 minutes);

- puppies can be dowel 12 hours after gluing;

- operation temperature -50C/+70C (28 days after application);

- the consumption of the mixture is up to 5 kg/m2.

Additional advantage of Master Termol Available cost of glue for foam (price for 25 kg 230-250 rubles).

Master Super A universal construction mixture for gluing polystyrene or creating a reinforcing layer. The solution has high adhesion strength (1MPA), plasticity and modified with polymer additives.

Master-Super vapor permeable, so it is recommended to use it indoors. The mixture allows the walls to breathe and retains a favorable microclimate in the house

Technical characteristics of Master Super:

- the time of use of the finished composition is 30 minutes;

- the permissible base temperature for gluing and reinforcing +5C/ +50C;

- material consumption 6 kg/m2 of foam gluing, 5 kg/m2 The device of the reinforcing layer.

Tytan Professional

The Polish company Tytan Professional has launched a universal glue-Peny Tytan Styro 753. Aerosol glue is compatible with all types of external insulation systems, where sheets of foamed polystyrene are used.

The use of titan glue for foam significantly reduces the time of installation work of the hitch with the base occurs 5 times faster compared to dry mixtures. Grinding foam and mounting with mechanical anchors can be carried out 2 hours after gluing

Technical and operational characteristics of the glue Tytan Styro 753:

- use temperature from 0C to +30C;

- adjustment time for 15 minutes;

- the temperature of the cylinder during operation is +10C/ +30C;

- full solidification time for about 30 minutes;

- consumption 1 cylinder (750 ml) 10 m2;

- the cost of the cylinder is 350-400 rubles.

Preparation of glue from dry mixture

The following tools and materials will be needed to prepare an adhesive solution:

- clean container (a large plastic bucket is suitable);

- water without third -party impurities;

- construction mixer/drill with a nozzle for kneading solutions;

- dry mixture.

Pour into the dry mixture into the water (the proportions are indicated on the package). For breeding 1 kg of dry glue Cerisit ST 83, 0.24 liters of water are needed. Stir with a low -speed drill or mixer until a homogeneous mass is formed. Let the solution brew for 5 minutes, mix again and start work.

Advice! Drill or mixer blades when mixing must be completely immersed in the mixture. This is done so that air bubbles do not fall into the solution, otherwise the quality of the glue will decrease sharply

Recommendations for gluing foam

Here are some tips that will help to correctly glue thermal insulation slabs:

- Before gluing, the base must be thoroughly cleaned from stains of fuel and lubricants, paint coatings and the remains of bitumen mastic. Remove the fungus and mold with a brush, and treat the surface with fungicides.

- If the foam is glued to highly absorbing surfaces (silicate unit, foam and aerated concrete), then the base must be pre-treated with special moisture resistant soil.

- It is better to carry out work in warm, calm and dry weather, this will reduce the period of grasping the glue.

- The surfaces with cracks and chips must first be leveled to plastered and putty.

- For pasting small, even metal surfaces indoors, bilateral tape can be used. The consumption of the material and the cost are quite large, so it is advisable to use adhesive tape for small repair.

- You can first glue the burlap to the metal surface. After this, the PVA building glue will not arise with fixing the foam plates for work.

A wide range of

A wide range of construction and stationery glue in the MHT RU online store. https://moshoztorg.ru/catalog/stroitelnaya_khimiya/klei/

Building store and

The store of construction and finishing materials http: // Remertvest.rf/ offers building materials wholesale and retail. Our store has a wide range of products at minimal prices, because We work directly with factories and manufacturers. We cooperate with Russian and European firms of finishing materials and have a well -established sales network, so we are always in stock building materials in bulk, and the supply of construction projects in Moscow passes as quickly as possible