The installation of skirting boards is considered a joyful moment of repair, because this procedure is...

|

|

To protect your house from the penetration of groundwater, damp, capillary water, ... |

A reliable roof is one of the main elements of a private house that protects ... |

Roof device from asbestos -cement sheets

For the most part, this is over 51% individual houses, cottages and garages are covered with slate sheets. In the agricultural structure, the use of this material reaches 80%. Such popularity was achieved thanks to the acceptable cost of asbestos -cement roof, operational characteristics and easy installation. Of course, many consumers will say about the harmfulness of the slate, what damage he causes human health. However, not everyone can specifically substantiate the negativeness of the material. The article will consider in detail everything that concerns the asbestos -cement roof.

Content:

- Are asbestos -cement sheets so destructive?

- Types of roofs from asbestos -cement sheets

- Advantages and disadvantages

- Than and how to cut slate sheets

- The main provisions

- Schifer protection

- Roof device from asbestos -cement sheets

Are asbestos -cement sheets so destructive?

The classic recipe includes the following components: Portland cement, water and asbestos. So, speaking of danger, the last element is implied.

Asbestos -cement roof photo

Mostly asbestos are found in two species that differ in mineral groups:

- chrysotilov, the microscopic form of which is the finest tubes. The mineral is resistant to caustic chemical compounds (alkalis), but unstable to acids. Half -down fibers occurs in a couple of weeks, then excreted from the human body. The dose is dangerous to health does not even accumulate at enterprises involved in the production of asbestos -cement sheets, should we talk about the harmfulness of the roofing in the open air?

- Amphibols With fragile needle -shaped fibers. This group of minerals made of heavy metals is endowed with high resistance to a neutral and acidic environment, but dissolves into alkali. Inhalation of particles produces a carcinogenic effect. The half -life period is 1.5 years.

So where did the prejudice on the harmfulness of the asbestos-cement roof come from, and the fact is that chrysothyl-Assobest in Europe practically does not occur, and production was built on amphibole. Accordingly, when scientists revealed the harm caused by amphibol asbestos, then all asbestos -containing building materials fell under the ban. In addition, there is another significant factor banal competition, because Russia occupies more than 50% of the world market for the production and supply of this product.

Despite the fact that asbestos -cement sheets are harmless to health, when working with them, safety precautions should not be neglected. So, when drilling or sawing the material, protective glasses and a respirator are used.

Types of roofs from asbestos -cement sheets

This artificial material is carried out mainly by casting a mixture with further hardening. Asbestos fibers perform a reinforcing role, increasing the strength of the finished product. In this way, flat and wave -like sheets are formed.

Roofs from asbestos -cement wavy sheets They are used in the arrangement of production, residential and agricultural buildings. They have the following modification:

- IN (ordinary wave) is produced by the correct rectangular shape with 7 or 8 waves. The standard dimensions according to GOST are 1,750x1 130x5.8 mm, step 150 mm, wave height 40 mm, medium weight 26 kg. A sheet of 1,200x680x5.5 mm weighing 8.5 kg is especially popular among consumers.

- Wu (wave reinforced) is used for the installation of roofs of industrial buildings. Distinctive features are the size of the sheet length can be 2 300-2 800 mm, a width of 994 mm, thickness 8 mm, step 167 mm, wave height of 50 mm and weight 36-44 kg.

- Uv (unified wave) has, as a rule, a 6 wave profile. Product width is 1 125 mm, length 1 750-2 500 mm, thickness 6-7.5 mm. The characteristics determine the purpose of the sheets, for example, for residential and public structures, UV-6-1 750, production buildings UV-7.5-2,000 are used.

Application area flat sheets Satisfied is wide. They are used for the installation of internal partitions, as facing buildings (internal and external), as well as to cover roofs.

- The release of sheets is carried out in a pressed and unrequited form. A pressed molding involves the larger weight of the product, higher strength properties. So, for example, the limit of strength on the bend is 23 MPa, against 18 MPa of unprotected products. The last sheets are used mainly for internal work.

In addition to sheets, manufacturers are offered elements designed to cover yends, skates and for the intersection of vertical parts with a roof, such as pipes, parapets, exhaust systems.

Advantages and disadvantages

The wide distribution of asbestos -cement sheets is due to many positive qualities:

- the price of an asbestos -cement roof for many consumers is a fundamental factor when choosing a roof material;

- a long service life of 50 years or more;

- the strength of the slate, since the dry sheet is able to withstand human weight;

- does not heat up and does not fade under the influence of direct sunlight;

- fire resistance is the main advantage of the material, in addition, it has good electrical insulation properties;

- not afraid of corrosion;

- it is characterized by high soundproofing properties, so the sound from rain or hail is minimal;

- amenable to repair or replacement of individual damaged sheets;

- it is not worth mentioning a low decorative form, today the slate of a wide range is produced.

However, like any building materials, the slate has disadvantages:

- the presence of asbestos in the composition, although not fatal, but still affects human health;

- primer processing or similar solutions is necessary, in the absence of protection on the sheets, moss appears;

- small impact resistance requires careful handling during transportation, storage, installation;

- it does not allow to equip roofs of complex shapes, for example, dome -shaped.

Than and how to cut slate sheets

At the stages of construction, there is a need for a certain size of the material. Work can be carried out in various tools and methods.

- An even cut will turn out when using a grinder and a cutting disk on a stone with diamond spraying. With this method, a large accumulation of dust and small particles is formed, so the use of personal protection products is mandatory.

- A hacksaw on wood, but you need to keep in mind that you will have to change the files often. In addition, with large volumes, this tool is not advisable to use. To facilitate the work, the cut line must be moistened abundantly with water and left for a while.

- You can perform perforation along the intended line with a nail or sharp chisel, and then break. The only drawback is the rough edge of the material.

- On both sides of the wave is carried out with a grinder or hacksaw, after the sheet is broken.

The main provisions

- The slope of the roof should be in the range of 25-45. It should be remembered that the cooler the slope, the higher its water resistance, since snow and meltwater do not accumulate on the surface of the roof. However, the device will need more material.

- In addition to the sheets, additional elements will be required: external and internal corners (trays), the skate part. They will close all the corner joints, thereby providing protection against moisture.

- As fasteners, nails with a large hat or dowel-gvo, equipped with a puck and rubber gasket, which prevent the penetration of moisture at the fixation points, are used. Special wire nails for asbestos -cement roof are also popular.

- To prevent the cracking of slate, it is necessary to drill holes in advance, the diameter of which should slightly exceed the diameter of the nail.

- The length of the metizes is calculated as follows: the height of the wave + the thickness of the board or the bar of the crate.

- It is not recommended to hammer fasteners to the roofing material, but leaving a large gap is not recommended. It is necessary to pick up the middle ground, where the nail hat will only come into contact with asbestos -cement sheets.

- All cut edges are treated with acrylic paint.

Schifer protection

I would like to note right away that painting sheets is necessary not so much to improve aesthetic perception, but to increase the service life of this roofing material.

- Like any staining, work begins with a primer primer. When choosing a mixture, attention is paid to its alkalinability. The packaging also indicates for which materials the product is intended, in this case there should be a point for the slate.

- If the choice is limited, then you can take an acrylate primer of deep penetration. The paint and paint acquired for painting the roof will serve perfectly as the basis. Only it must be diluted about 1:10.

- After drying the primer, you can proceed to the painting itself. Painting material can be both foreign and domestic production. In principle, there are no special differences in terms of properties, but there is a significant difference in cost.

- Acrylic paint is well suited for these purposes, the seller should clarify whether it is intended for slate. You can use special rubber paint. Its main differences are heat resistance, high resistance to any weather conditions. When applied, it forms an elastic film that provides protection for roofing material.

- The coating is carried out in two stages: the first layer made on the final surface is easily absorbed, in connection with this the roof seems heterogeneous. The second application is called finishing. It should be carried out more carefully and more thoroughly.

- For work, a brush, roller or spray gun is used. The last tool will undoubtedly increase effectiveness, but at the same time increase the flow rate.

- Coloring is performed in clear warm weather. You can not work on a wet or hot (heated by sunlight) surface. In these cases, the paint will soon begin to peel off.

- Improving the appearance of the old slate is carried out in the same way, only before this the material is cleaned of moss, dust and other extraneous particles. A metal brush is used for cleaning, but this process is quite laborious and will take a fairly large amount of time. Here you can use an electric drill with an appropriate nozzle. Another effective tool is a washing machine that almost any car owner has.

- If necessary, local repair work or a complete replacement of some sheets are carried out.

- If the roofing material does not have significant defects, but there are the smallest cracks, then they can be recorded with the following mixture:

- the cement is diluted with water to the state of liquid sour cream, with the addition of 1 cup of PVA glue per bucket of the mixture.

- Asbestos -cement sheets are covered with the resulting solution. Then you can do a color to give a decorative look.

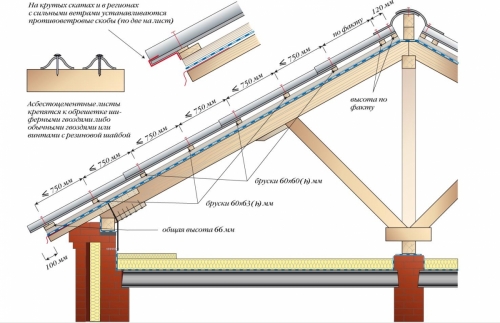

Roof device from asbestos -cement sheets

- The weight of asbestos -cement sheets determines the presence of a thorough roofing device using increased lumber thickness. So, for example, diagonal rafter legs (100x150 mm bars) of a large length, it is necessary to strengthen supports with struts.

- The rafters are laid on the upper strapping of walls or a Mauerlat (a beam with a cross section of 100-150 mm) with an overhang of at least 300 mm. The beams are fixed in pre-made nests-pins. At this stage, the drainage system is mounted.

Asbestos -cement roof nodes

- If roller materials are used as waterproofing, then a continuous wooden flooring is needed. Ruberoid, film, only or membrane are attached in accordance with the instructions. The material should be placed vertically, cutting off the length with a margin of at least 50-60 cm, half of which will go to another roof slope, the other to fasten the cornice with a certain inversion.

- The following stripes are overlapped 50-60 mm. The horse is protected by a tape of waterproofing material.

- The crate is made of non -cut boards of 50x100 mm, the distance between them should be such that the asbestos -cement leaf rests on them in three places. So, for the sheet (GOST) the step will be 540 mm, respectively for a sheet with a length of 1,200 mm 600 mm.

- A solid crate must be performed along the cornice, skate, at auditory windows or pipes.

Laying

The sheets are laid from right to left and bottom up, thus, preventing moisture from entering the docking seams. The wave material of this kind is fixed only in the crest of the wave.

There are two main types of installation.

Classical

- This method involves laying sheets overlapping and is suitable for long spans with a small distance between the skate and the cornice. The work begins with the lower part of the front -line overhang. The sheet is fixed at 5-6 points, the next is mounted with a displacement by one wave of the previous slate of slate. Similarly, the laying of the 1st row is completed.

- The upper sheets are also mounted with a lower row by about 10-15 cm.

- During work, horizontal and verticality of sheets are observed. Otherwise, there will be a skew of all subsequent material. Pruning and adjusting the slate is carried out in advance on the ground. This will greatly simplify the raising of the sheets to the roof and their installation.

- This method has one drawback forms of 4 sheets, through which melt and rainwater penetrate. Such consequences can be avoided if on all extreme sheets to cut the angle along the diagonal, looking inside. In the subsequent rows, two opposite corners are cut off in the sheets.

Razzing

- This method is advisable to use on wide slopes of small length. To do this, it is better to use slate with 8-mi waves, since its use will reduce waste and, accordingly, expenses.

- A certain number of sheets must be cut in half (in length). Halves are laid alternately with whole stripes. So, for example, if the first row began with a fragmentary element, then a whole sheet is mounted above it. The third is again from the half of the slate.

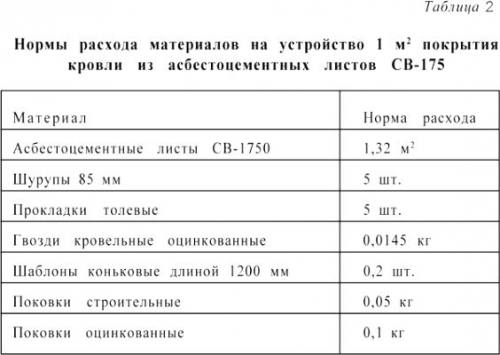

Calculation of the material

A properly calculated amount of asbestos -cement sheets will save time and, undoubtedly, nerves, since you do not have to throw roofing and headlong to go to the construction market behind a single sheet.

The calculation is performed as follows:

- the number of sheets per 1 row \u003d the length of the roof is divided into the width of the sheet, the spare 10 %are plused to the resulting result;

- number of rows \u003d distance from the roof crest to the cornice, including an overhang, divided into sheet length, plus 13%;

- the total number of slate \u003d the number of rows is multiplied by the number of lanes for the 1st row.

If the roof is gable and from the side of the pediment forms an isosceles triangle, then the result is increased by 2 times. If the roof has an asymmetric shape, then each element is calculated separately. During calculations, all fractional results are rounded in a large way.

For example, it looks like this:

- suppose that the slope has the following dimensions of 6 000x3 100 mm (the calculation is performed for asbestos -cement sheets performed according to GOST 1 750x1 130x5.8 mm);

- this means that whole sheets for 1 row will need 6,000/1 130 \u003d 5 pieces, a margin for overlap is added 10% - 0.5. Total is 6 sheets;

- next is the number of rows: 3 100/1 750 + 0.2 (13%) \u003d 2 sheets, respectively 2 rows;

- the total amount of material (6+2) ˣ2 \u003d 16 sheets.

As for flat sheets, the principle of installation does not differ from the traditional slate. The only difference is the step of the crate, here it should not exceed 40-50 cm. You can create a continuous crate, in this case the strength characteristics are increased, and the price of work increases.

As you can see, new technologies allow you to arrange roofs of various purposes affordable in cost and with a good decorative type of material. After all, an unpresentable, gray and dull color remained in the distant past. Asbestos -cement sheets for a whole century were able to prove their excellent operational properties, unlike new thoroughly not studied and not tested by modern roofing coatings.