If the floor of wood began to creak, there are rotten boards or some kind of ...

|

|

Existing types of suspended ceilings, in the first ... |

Own estate requires the owners much more effort than an apartment in the city. AND... |

Installation of a chimney sandwich

If you are the owner of a private house or cottage, you probably know that an integral stage in the construction of any structure heated with a fireplace or furnace is the arrangement of the chimney. The main purpose of this functional element is the removal of combustion products from the furnace, which pose a danger to health, as well as ensuring reliable traction necessary to maintain combustion processes, while the level of traction is determined by the diameter of the chimney and the height of the smoke channel. Among the supporters of the independent performance of all homework without involving specialists, the chimneys of the design of the sandwich are most popular, which is explained by their functionality, practicality, high aesthetic characteristics and other no less significant advantages. However, the prevalence of the chimneys among masters among the masters is more associated with the safety and ease of installation, of course, subject to the acquisition of only certified and high-quality materials. Despite the fact that the installation of a chimney sandwich involves the combination of structural elements and auxiliary details in the correct sequence, a number of certain nuances must be observed in the process of assembly, the neglect of which can significantly reduce the performance of the structure. Given the relevance of this problem, in this article we will consider the technology of installation of the chimney sandwich with your own hands, as well as the main types and features of this constructive element.

Content

- Sandwich Dymage device: Design features

- The main components of the system of sandwich dummage

- Advantages and disadvantages of sandwich dummage

- The main varieties of sandwich dummage: Brief description

- The most relevant methods of connecting a sandwich tube for chimneys: Brief description

- What must be observed during the installation of a chimney from a sandwich tube?

- How to install a sandwich dizzym: step-by-step guide

Sandwich Dymage device: Design features

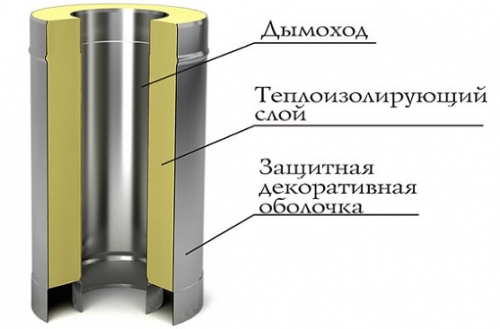

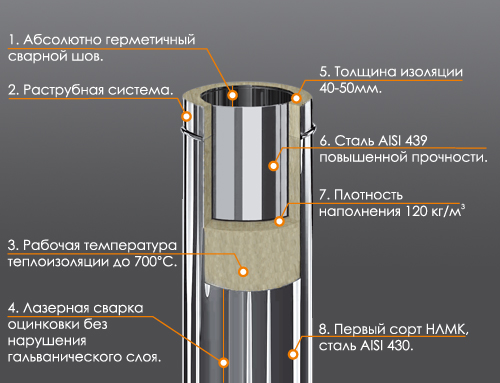

The sandwich dizzymhod is a metal or ceramic structure consisting of several segments, each of which is characterized by a length of one meter and inserted into the other during the installation process. Simplified, the design of the sandwich dizmeam is represented by an internal and outer pipe, between which a layer of a heat insulator is located, most often basalt fiber or mineral wool characterized by high thermal insulation properties, resistance to open flame and immunity to the effects of a number of chemicals. Thanks to a similar three -layer structure, this design was called a sandwich. In most cases, stainless steel is used for the manufacture of the internal contour of the pipe, characterized by increased anti -corrosion properties, and for the external, in order to save money, a less durable galvanized metal.

Important! When choosing a material for the manufacture of the internal circuit of the pipe of the sandwich dummage, it is necessary to be guided by its ability to transfer the fever, and for its external strength characteristics, since it should be rigid enough, which will contribute to the preservation of the original configuration not only of the pipes, but also the entire structure as a whole .

The main components of the system of sandwich dummage

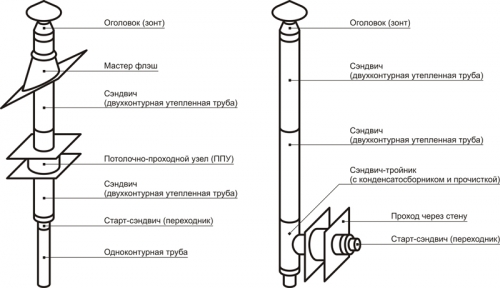

It is logical that only straight pipes cannot be used to install a system used to remove smoke. This is explained by the structural features of the building: a sandwich dizard must go through its elements, pass through the ceilings and the roof. In this regard, in the process of assembly, sectional fragments are used, the connection of which is carried out using additional elements. To understand this in more detail, we will consider what elements a sandwich ditect consists of.

The structure of the sandwich dummage system includes the following main elements:

- Sandwich pipe;

- Tees structural elements of the system that are used to connect the chimney with fireboxes of fireplaces and furnaces, as well as in areas of branching channel branching;

- The knees are elements designed for the installation of the curves of the chimney. For these purposes, models with bends are used for 15, 30, 45 and 90 degrees;

- The condensate collection is another part of the chimney designed to remove and remove moisture accumulating on the internal walls of the chimney as a result of temperature changes;

- Elements of the roof of the system parts designed for the installation of a sandwich dummage in places of overcoming the roof structures while ensuring effective heat and waterproofing;

- A revision tee, a device equipped with a door designed to control the purity of the smoke channel and cleaning of soot;

- The mouth of the structural element necessary for the arrangement of the upper edge of the chimney;

- The support console element of the structure necessary for the installation of a wall or floor base for the chimney;

- A wall clamp designed for reliable fixation of the chimney relative to the wall.

Advantages and disadvantages of sandwich dummage

- High aesthetic characteristics and spectacular appearance;

- Thanks to constructive features, sandwich dummies are effectively combined with various models of furnaces and boilers;

- Due to the lightness and versatility of the structure, a sandwich dummage can be used both outside and indoors;

- Unlike brick chimneys, a significantly smaller volume of sandwich structures allows them not to clutter up the internal space of the room;

- Due to the fact that the sandwich dummies are made of stainless steel, resistant to factors formed during the combustion of fuel, namely chemical and thermal aggression;

- During the operation of the sandwich dummage, there is no damage to the inner layer of the structure under the influence of aggressive factors, and therefore, it retains its operational characteristics for a long time;

- The next advantage of the sandwich dummage is especially relevant for structures, during the operation of which equipment with direct hood is used. Thanks to effective thermal insulation, sandwich structures are reliably protected from condensate formation;

- Due to the fact that the inner surface of the chimney is smooth, in the process of its operation, soot does not settle on it, which allows cleaning the chimney channel quite rarely;

- Thanks to effective thermal insulation, the external contour of the chimney to critical temperatures does not occur, which can cause the fire of the combustible elements of the construction. With this in mind, we can talk about the high fire safety of the system;

- Due to the convenience of the design, in the process of installation of which it becomes possible to carry out turns and bends of the chimney, laying a sandwich diteous, you can go around any obstacles on its path without resorting to disassembly of the ceilings or removing the roof elements;

- Due to the possibility of building a structure without an additional foundation, its installation becomes easier and cheap.

Despite a significant number of advantages of sandwich dummage, these designs are also characterized by certain disadvantages that also deserve attention.

Disadvantages of sandwich dummies:

- The ability to lose the tightness of the structure in case of its long -term operation;

- Violation of the integrity of the sandwich dummage in the case of constant sharp temperature differences;

- A fairly high cost of design;

Important!Despite the service life declared by the manufacturer, not more than 10-15 years, in practice, sandwich dizardies operate effectively for a longer time.

The main varieties of sandwich dummage: Brief description

Earlier it was noted that the sandwich dummage is multilayer structures made of ceramics or stainless steel. Currently, in the construction market, they are presented in the form of ready -made elements, which are further collected in a single design. Despite the fact that both varieties of the structure are characterized by a similar installation method, each of them is characterized by their own characteristics, which will be discussed later.

Sandwich dummage made of stainless steel

In the design of stainless steel chimneys, an internal pipe can be distinguished, characterized by resistance to high temperatures, which is wrapped in non -combustible thermal insulation material. It is protected from the external influence of another pipe called an external contour and made of stainless steel or galvanized metal, the use of which is a budget option. It is important to note that the internal circuit can be made of metal or ceramics, which is typical for combined chimneys.

Ceramics sandwich

The design of ceramic chimneys is represented by a pipe made of heat -resistant ceramics. Outside, it is wrapped in heat -insulating mats, and from the inside it is covered with high -strength icing. This design must be placed in the outer shell, for the manufacture of which expanded clay concrete and foam concrete blocks are used. Features of the design of ceramic chimneys, namely, the presence of a thermal insulation layer, allow them not to heat up from the outside, which determines their absolute fire safety.

Important! Despite the fact that the design of ceramic and metal chimneys is generally similar, it is also characterized by differences, the main of which is weight. The weight of a full ceramic chimney can reach a ton, while the mass of the chimney made of stainless steel does not exceed two hundred kilograms. In addition, an integral stage in the installation of a ceramic chimney is the arrangement of the foundation, while the installation of a stainless steel chimney is limited to the arrangement of unloading sites at each level of ceilings.

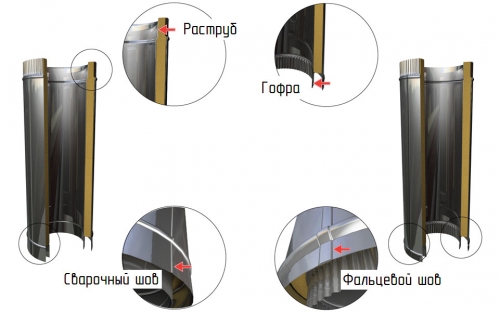

The most relevant methods of connecting a sandwich tube for chimneys: Brief description

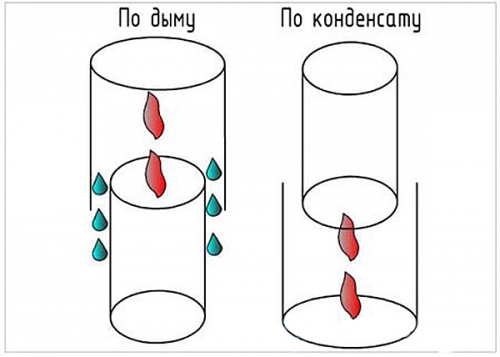

There are several ways to connect a sandwich tube for chimneys. The most popular of them are a flange method, byonet, according to the cold bridge, condensate and smoke.

The last method of assembling the chimney fully guarantees that carbon monoxide will not penetrate the house or bath. And using the condensate method, you can be sure that condensate formed inside the chimney will flow freely on the walls of the pipe.

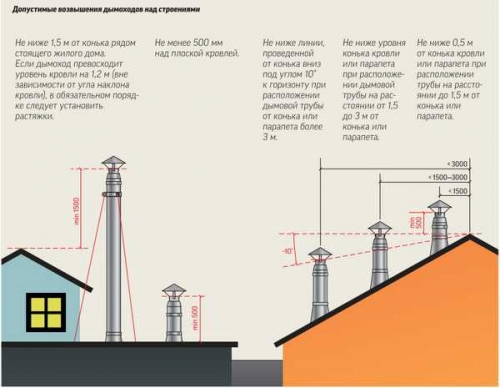

What must be observed during the installation of a chimney from a sandwich tube?

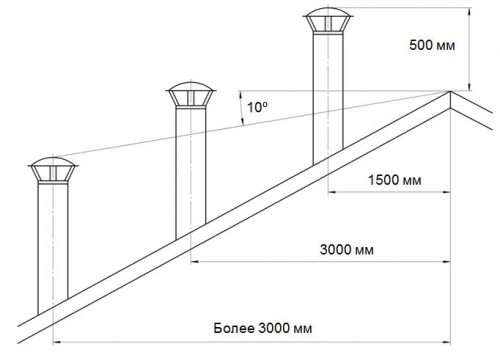

- The height of the chimney from the heating device to the heading is quite constant and should be at least 5 m;

- It is necessary to pay attention to the roof of neighboring buildings: the elevation of the chimney relative to neighboring buildings should not be more than 1.5 m;

- In the case of an elevation of the chimney above the roof by 1.5 m or more, it needs additional fixing using stretch marks;

- In accordance with the recommendations of experts, the design of the chimney should include plugs equipped with a condensate -air conveyor, which is designed to remove condensate and revision of the chimney;

- In case of installation of a roof of combustible materials, the design of the chimney should include the presence of a sparkle made by their mesh with a cell of at least 5x5 mm;

- In the process of installing a sandwich dizme, a narrowing of the diameter of the chimney is unacceptable, but its expansion is possible. For example, by installing a chimney sandwich with an outgoing chimney diameter of 115 mm, you can use pipes with a diameter of 120 mm, however, the use of a chimney with a section of 110 mm is strictly prohibited;

- Horizontal sections of the chimney should be characterized by a length of not more than 1 m;

- Elements of the chimney should be mounted in such a way that their joints do not coincide with the sections of ceiling and roofing passes;

- The installation of bouncers and tees should be carried out so that they do not carry the load from the weight of the chimney elements that are installed above it.

How to install a sandwich dizzym: step-by-step guide

How to choose the dimensions of chimneys: we make the necessary calculations

Before starting the installation of a sandwich dummage with your own hands, you need to know the following parameters:

- The size of the cross -section of the chimney pipe;

- The length of the chimney pipe.

The size of the cross -section of the pipe is determined in accordance with the construction rules and norms (SNiP). They are calculated as follows:

- If thermal power does not exceed 3.5 kW, the calculations look as follows: 0.14 m x 0.14 m;

- If thermal power is in the range from 3.5 kW to 5.2 kW, the cross section should be characterized by the following parameters: 0.14 m x 0.2 m;

- With the value of thermal power from 5.2 kW to 7 kW, the size of the cross section is 0.14 m x 0.27 m.

Important! As can be seen from previous calculations, the size of the cross section directly depends on the thermal power. Having familiarized yourself with the parameters above, you can choose the most optimal dimensions of the cross -section of the pipes for the chimney. Having preferred a round cross section, you should know that its dimensions should be equivalent to rectangular sizes.

The length of the chimney pipe is also calculated in accordance with the construction rules and norms (SNiP):

- SNiP 41-03-2001 states that the minimum height of the pipes that capture smoke should be at least 500 cm;

- The chimney should be bred above the skate of the house by at least 50 cm;

- Provided that the roof is made of combustible materials, the pipe must be removed from the ridge or parapet to a distance of 1 to 1.5 m;

Nuances that should be taken into account in the installation process

The arrangement of the chimney should begin from the heating device, after which it gradually moves up. To make it according to all the rules, it is necessary to take into account the following nuances:

- Smoke pipes should be characterized by the absence of ledges;

- The temperature of the gases carried out on the outlet pipe should not be higher than 500 degrees;

- The maximum angle of pipes should not exceed 30 degrees;

- Pipe sections located under the slope should be deprived of roughness, and their cross -sectional area should be no less than that vertical;

- The installation of a deflector, umbrella or other nozzles that protect the chimney from atmospheric precipitation will not be superfluous, but they should not interfere with the free exit of smoke from the pipe;

Important!Installation of the chimney should be carried out so that the gas pipeline, electric wiring and other communications do not come into contact with it.

How to assemble a sandwich diving? Recommendations of specialists

The chimney originates from a fireplace or furnace. First of all, it is necessary to combine the pipe of the heating device with the first link in the chimney and close it with a plug so that the insulation sticking out of it is not visible and steam does not come out of it;

The pipes are inserted one into the other. To make this manipulation, you must carefully examine the pipe, after which you will notice that one of its ends is characterized by a smaller diameter. This end must be inserted into the next pipe;

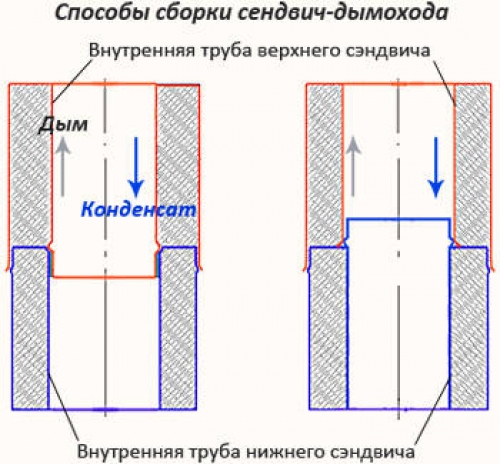

Important! In the process of installing the chimney, monitor the fact that the pipe links were collected in such a way that the condensation formed during their operation flows down without hindrance.

It must be remembered that the installation technology of a sandwich dizmiza provides for the incapation of both the outer and internal pipe, which is often associated with some difficulties. In this regard, a more simple method of assembling a sandwich tube was developed, in accordance with which it is necessary to release internal pipes by 15 cm and connect them, and then join the external pipes;

Strengthening the educated joint. In order to produce this manipulation, it is necessary to prepare a steel clamp and, having wrapping it with the junction of the joint, pull the clamps with bolts, nuts or wires;

The next stage involves applying a sealant to the pipe, which retains its operational characteristics at a temperature of up to 1000 degrees;

The assembly of the sandwich dummage is completed. Working on the above principle, it is necessary to fix the tee, angle, umbrella and tip. Every 2 m pipes, it is necessary to fasten the chimney to the wall using brackets. To reduce the load laid on the design, the location of the tee is also fixed using brackets.

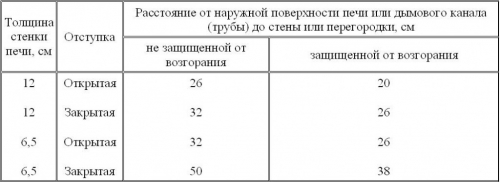

Important! The chimney, the installation of which was carried out with your own hands, involves the arrangement of the indentation. The indent is a space between the wall and the smoke channel, the value of which is calculated according to the table presented below.

If the compact is located in the walls that cover it, then above the furnace it is necessary to equip two holes with different levels equipped with gratings. The minimum cross -sectional area of \u200b\u200beach hole should be at least 150 square meters. See during the installation of a closed indentation, it is necessary to take into account the fact that the floor in it is mounted from non -combustible materials and should be 7 cm higher relative to the floor of the room.

Installation of the chimney in places of contact with the house

How to go through ceilings

Crossing (ceiling) must be passed by the so -called cutting. In those places where the chimney is in contact with the constructive elements of the house, it is necessary to install a special link in the chimney, which is a passing pipe or box with a hole inside. It must be remembered that the size of the cutting should be 7 cm exceeding the thickness of the overlap. The cutting is designed to protect the flammable structure from the fire.

Important! Refuse the tight connection of the cutting with the design. The pipe in the pipe should be characterized by the absence of joints.

In the overlap, prepare a hole for the chimney and mark the marker, several times overwhelming the fidelity of your calculations. After making sure that the pipe is located in the overlap and checked the dimensions of the pipe with the applied marks, proceed to the cut.

Experts recommend with the internal and on the outside to cover the pipe with a foil basalt mat with refractory mastic. The hole itself should also be isolated using mineral wool insulation in places of contact with a pipe.

In the prepared hole, set the passage pipe and check the verticality of the installed pipe. If it is located not strictly vertically, it must be leveled.

The roof, like the ceiling, passes a special link, which at this stage is called roof cutting. To choose it correctly, you need to know the angle of inclination of the roof.

In the roof, it is necessary to prepare a hole for the chimney, which is also carried out using a marker and is carefully checked. Cut the hole from the inside of the roof.

A galvanized metal sheet with a hole under the pipe is applied from the inside of the roof, after which the pipe is removed, and the sheet is fixed from the inside. Roofing is mounted on top of the roof. If the need arises, the metal sheet of roof cutting is developed to the edge of the roof or horse. Next, it is necessary to install the required number of links to the required height of the chimney and fix the umbrella.

To get a more complete, from a practical point of view, the answer to the question: how to make a sandwich ditect?, View the video presented below.

Sandwich Dymage Video