The installation procedure of siding requires primarily the arrangement of the frame on which it ...

|

|

A few decades ago, when the building materials market could not ... |

The glazing of the facade is a rather complicated process, but the result is worth ... |

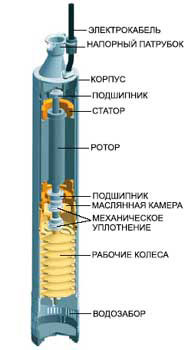

Installation of a submersible pump in a well

To arrange a full -fledged water supply in a country house or in the country, it is not enough just to dig a well with good water, it is also necessary to organize the delivery of this water to the house or to other points of water clearance. If the depth of the well exceeds 8 10 m, and the well itself is at a distance from the house, a submarine pump is used to supply water for the well. Such units can supply water to a height of up to 60 90 m under pressure, spending much less energy on this than surface pumps. Also, an indisputable advantage of submersible pumps for wells is the relative silence of their work, it is only heard how the relay clicks. During the winter operation, the pump loaded into the water is protected from freezing, at any time of the year it works more stably and debugged. The most important thing when operating the submersible pump is to choose the right model for your needs and correctly install the pump in the well, firmly fixed in the limbo, and also observe some nuances.

Choosing a submarine for a well

The main difference between a submersible pump and a superficial one is that a submersible is fully immersed in water, which cools the engine and assembly body. When the water level in the well drops to a critical mark, the pump turns off to avoid the so -called dry move and not overheat. For operation in wells, both pumps for wells and well pumps can be used. They are arranged almost the same and differ only in shape, size and price. For a pump for a submarine, the price is slightly lower than for a well. This is mainly due to the fact that the well pump has an elongated cylindrical shape and a small diameter so that it can be immersed in a narrow well. But for the well, this is rather a drawback. To install the submersible pump, there is a rule that the water level on top of the pump and below should be at least 1 m. If you use a borehole pump 90 cm long, and the well is shallow, then it is almost impossible to observe this requirement. In any case, if you install the pump in an upright position. But, in spite of this, the wells use well pumps even more often than well, simply selecting the dimensions correctly.

In total, there are several types of pumps that can be used in wells, these are centrifugal pumps, vortex, screw and vibrational. They differ in the principle of work.

Vibration pumps for wells

The main difference between the vibration pumps is that they do not have rotating details and elements. Inside the pump body is a core with a winding. As soon as the current is supplied to the core, an electromagnetic field is formed around it. This field attracts a rod fastened to the piston. At this time, water is sucked into the intake chamber, since a vacuum is created in it. After a fraction of a second, the electromagnetic field disappears, the rod returns to its former place. At this moment, the check valve at the entrance to the pump is closed and, under the action of the pressure of the piston, the water from the inlet chamber is pushed into the chamber behind the piston. When the next time the stem with the piston is drawn to the core, the water from the chamber behind the piston pushes into the pipeline leading to the consumer.

All the movements of the rod, in fact, are vibrations, from which the name of the vibrational pumps comes. Vibration data are not able to harm the well, since there are no parts that may collapse. But if the well is built on a float, then the use of vibration pumps is not recommended, since they negatively affect fragile soils. Also, if the pump will not be located too far from the bottom of the well, then it is likely that with its vibrations it will raise small dusty particles of sand from the bottom and suck them. As a result, dirty water will flow from the tap. In other cases, vibrational pumps can be safely installed in wells.

Vibration pumps are cheap category, which is why they are often chosen by summer residents for temporary use. It produces a vibrational submarine for the well Russia, Ukraine, Belarus and China. The most common models are Baby, Stream, Ruchek-1, Harvest, Aquarius, Summer resident and others. The average price of such pumps is 50 cu

Vibration pumps are considered reliable, since there are no parts that can overheat from friction, rotating parts and bearings that must be lubricated. Nevertheless, a centrifugal pump for the well will be a more thorough choice.

Centrifugal pumps for wells

Centrifugal pumps have a fundamentally different structure and work differently. Inside the pump housing is a working wheel on which the blades are fixed, which are curved against the movement of the working wheel. There is also an engine inside that drives a working wheel using a shaft. As a result of the rotation of the working wheel, a centrifugal force occurs, which sucks water into the pump and pushes it to the exit from the pump into the pipeline. In the middle of the working wheel, reduced pressure forms, and closer to the walls of the blades on the periphery, on the contrary, increased pressure forms. Under the influence of this pressure difference, the water is pumped first to the center, and then sent up to the pipeline.

The centrifugal submersible pump must only be operated by plunged completely into water. Substitute must not be allowed. Also, immersion in water is its thermal protection not only from dry stroke, but also from a random jump in voltage or other emergency. Therefore, centrifugal submersible pumps are equipped with special automation or floats that signal the decrease in water level to a critical mark.

The body of submersible centrifugal pumps can be made of plastic or stainless steel. More expensive and durable models are stainless steel pumps. They are not afraid of abrasive particles, sand and have excellent performance. Also, the plus of such pumps is the ability to pump water with sand content to 185 g/m3.

The price range for centrifugal submersible pumps is quite large: from 80 cu Up to 700 cu Depending on the quality and manufacturer. It produces submersible pumps for wells Italy, Germany, Denmark, China, Russia and Ukraine. The most expensive and reliable pumps are Italian Pedrollo and ZDS, Germanic Wilo And Danish Grundfos. Budget, but high -quality units are produced by domestic Vodutet. But to buy a Chinese -made pump or not, you already decide. It may make sense to buy a domestic pump, it will be no less reliable.

What performance of the submersible pump to choose

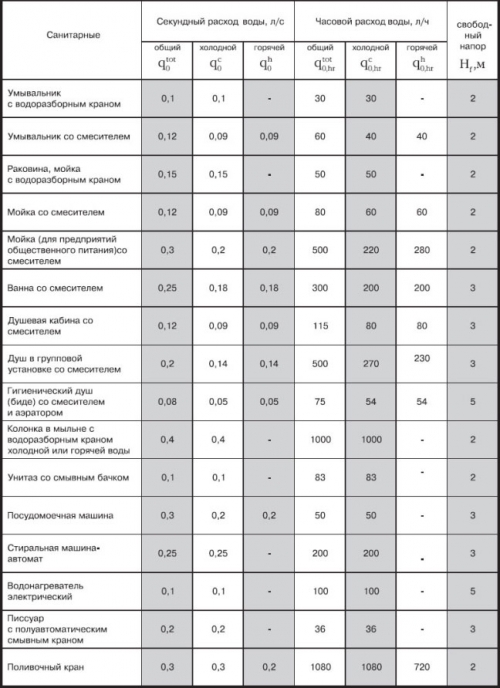

The required performance of the pump completely depends on the flow of water in the water supply. It should equal or be a little more than the needs of the residents in the water. You can determine the required water consumption by pricing consumption from different consumers, for example, washbasin, shells in the kitchen, shower and washing machine. First you need to make a list of all plumbing devices that will be used, then see in table 1 the value of the water flow through them and dry it.

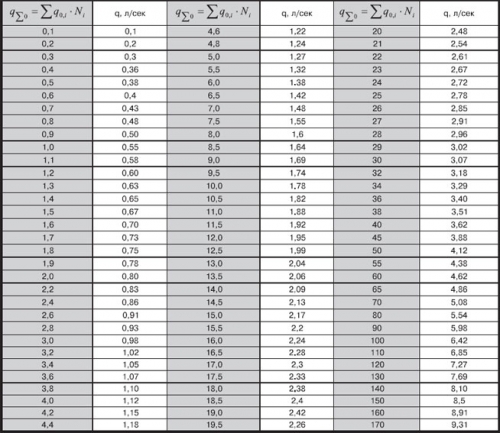

Table 1. Water consumption through plumbing.

The next step will be the definition of real consumption per unit time. After all, the inclusion of all plumbers is at the same time unlikely. Therefore, the real consumption will be less, it can be viewed in table 2. Sometimes, instead of tables, real consumption is determined by multiplying the consumption of all consumers by 0.6 0.8. This means that at the same time 60 80 % plumbing will work. But this method is not entirely correct, especially when it comes to the water supply of a large mansion, where there can be many plumbing devices, but few residents.

Table 2. The calculated water consumption.

The tables data are indicated in l/ h, and in the characteristics of the pump most often in M3/ hour, therefore the resulting value must be multiplied by 3.6.

An example of calculating the performance of the pump:

If there are such plumbers in the house:

- Electric water heater 0.1 l/s;

- Shower with a mixer of 0.09 l/s;

- Watering tap 0.3 l/s;

- Shell in the kitchen 0.15 l/s;

- Washbasin 0.09 l/s;

- Toilet 0.1 l/s.

We summarize consumer expenses: 0.1+0.09+0.3+0.15+0.09+0.1 \u003d 0.83 l/s.

The value of 0.83 l/s corresponds to the value of 0.48 l/s according to table 2. We translate the value into M3/hour: 0.48*3.6 \u003d 1.73 m3/hour. If the performance of the pump is indicated in l/hour, then 0.48*3600 \u003d 1728 l/hour1700 l/hour.

Among the entire assortment of submersible pumps for wells, suitable models can be distinguished Pedrollo 4sr 2m/7 with a productivity of 2 m3/h, 63 Aquarius NVP-0.32-63U performance of 1.8 m3/h and Chinese unit 80 Aquatica 96 (80 m) 2 m3/h. You can more accurately determine the model of a suitable pump only after the pressure of the pressure.

Determining the pressure of the submersible pump

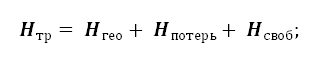

The required pressure of the submersible pump depends on the depth of the well, the mirror of water and the remoteness of the well from the house. To calculate the pressure, use the formula:

HTR the required pressure of the submarine for the well;

Hgeo the difference in heights between the depth of the well and the highest point in the water supply system;

FoldThe sum of all pressure losses in the pipeline from friction of water on the material of the water supply, in rotary nodes and tees. This indicator is calculated individually for each project, which takes into account the number of tees, corner elements in the pipeline, pipe material. We will not bother too much and just add 25 % to the calculations for losses.

Hight Free pressure required for comfortable use of plumbing. So that when opening the crane there is a normal pressure, not a thin stream. This indicator is usually taken 12 20 m, the minimum acceptable value is 5 m.

An example of calculating the pressure of a submersible pump:

If the water supply in the house is arranged in this way:

- The depth of the well 10 m;

- Water height in a well 3 m from the top;

- The depth of the pump is 8.5 m;

- The well is at a distance from the house 10 m;

- The house is two -story, the supply of water to the second floor is 5 m.

Total, hgeo \u003d 8.5+5 \u003d 13.5 m.

We calculate the ferris in the horizontal pipeline as follows: for every 10 m of the horizontal pipeline, 1 m of pressure is lost and add 20%, i.e. The pressure loss will be equal:

Fold \u003d 1+2 \u003d 3 m.

We take 20 m.

Total HTR \u003d 13.5+3+20 \u003d 36.5 m.

Conclusion: we need a submersible pump with performance equal to or more than 1728 l/hour and a pressure of 36 40 m. These characteristics correspond to such pumps: 63 Aquarius NVP-0.32-63U, 25 sprut 90qjd 109-0.37, 80 Aquatica 96, 45 Pedrollo 4sr 2m/7and many others. Almost all submersible pumps have more than 40 m. As reviews are shown to submersible pumps for wells, it is best to use Pedrollo Italian pumps, they have the smallest percentage of breakdowns.

Pump dimensions and other amenities

When choosing a submersible pump for a well, pay attention to its size. As a rule, the diameter of the pump does not matter, but the length significantly affects the safety of operation. For example, if our well has such characteristics, as described in the example above, the depth of 10 m, and the water begins already 3 m from the top, then any pumps can be used in it, including long wells of submersible pumps with a length of 90 cm or more . After all, on top and below the pump will be a sufficient layer of water. If there is little water in the well, for example, from the bottom to the top of the water only 1.5 m, then you cannot use long pumps. In such cases, it is necessary to pay attention to submersible well pumps.

Compared to well pumps, submersible pumps for wells have the best cooling and are less sensitive to sand impurities and other solid particles. In addition, they are equipped with float switches that protect the unit from dry move.

In submersible pumps for the well, the water hole is located from below, there is also a filter that protects from the ingress of large solid particles inside. But there are also models with a nozzle that sucks water from the surface layer of water, a floating filter is installed on it, which is supported by a float. This is the most convenient option for a well for a well with a small amount of water. Also, a similar method of fence prevents the situation when sand is absorbed from the bottom of the well.

Installation of a submersible pump in a well

After buying a submersible pump for the well, the question arises of how to install it in a well and how to conduct a water supply. In fact, these tasks are not so complex, although there are some nuances that must be observed. It is better to install the pump together together or even three, the well is the case, you never know what, and so there will always be an insurance.

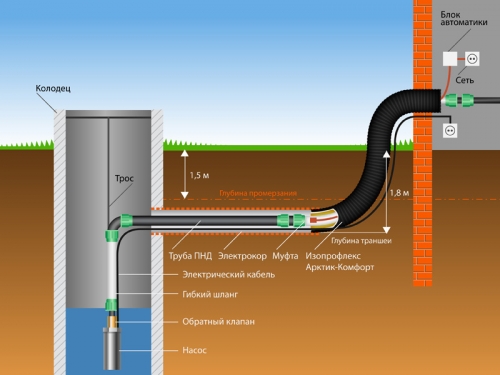

Excavation

First of all, even before the direct installation of the pump in the well, it is necessary to stretch the water supply leading from the well to the house. To do this, we dig a trench from home to the well. It is desirable that the trench does not have turns and bends, but be flat, this will provide minimal pressure loss. The depth of the trench should be lower than the level of freezing of the soil, i.e. About 1 1.5 m.

So, we dig a trench with a depth of 1.5 m and a width of 40 50 cm. At the bottom of the trench, there should be no acute stones, glass and construction waste. We perform the sand pillow at the bottom of the trench, pour the sand with a layer of 15,100 cm. Next, it is necessary to spread the geotextile into which the water pipe will be wrapped. Now you can start laying the pipes.

Laying of water pipes

For a street water supply, you can use several types of pipes steel pipes, metal -plastic, stainless, polypropylene and ordinary garden hoses. The latter are suitable only for a temporary water supply, which will be used for watering a garden or garden in the spring-summer season. Steel pipes are subject to corrosion and there is a lot of trouble with them, so polypropylene pipes, stainless or metal -plastic are used for a stationary water supply.

- We connect the segments of the pipes between each other from the house to the well.

- Then we wrap them with thermal insulation material and put them into a larger diameter pipe. Usually use either asbestos pipe or a plastic sewer pipe. In fact, the sandwich pipe system in the pipe serves as protection against mechanical influences and protects thermal insulation material from destruction.

- We lay the resulting sandwich pipe in the trench and outline the places of insertion of the water pipe into the well and into the wall of the house. Next, you can temporarily remove the pipe to make holes in the wall of the well and the wall of the house or the foundation.

- In the wall of the well, a hole with a diameter of 15 cm is cut out. Inside, insert a sleeve with a length of at least 0.5 m, around the sleeve we cover the hole with a cement-sand solution, and after drying it with waterproofing with bitumen mastic.

- We put the pipe into the trench again and draw its end through the sleeve. The water pipe should go inside the well by at least 25 cm.

- At the end of the water pipe, we install a drain crane with a tee. The drain valve is useful to us in case of emergency drain of water from the water supply system. Turning the pipe down leads it to the installation site of the pump.

- Next, you need to calculate the distance from the drain crane to the installation site of the submersible pump and cut off this length of the piece of water pipe.

We proceed to the installation of a submersible pump.

Installation of a submersible pump in a well

A submersible pump is suspended in a well using a cable. Since the end of the cable must be fixed for something, first we perform the fastener. The easiest way to cook a 50x50 mm steel square square frame, which will be installed on the head of the well. In one of the corners, a hole is made through which the end of the cable will stretch and then fixed.

- We lay the pump at the end of the pipe segment, which will connect the pump with the tee leading to the pipeline.

- We unwind an electric connection cable to the pump to the network and lay it next to the pipe.

- Then we install the check valve on the outlet of the pump, if it is not installed at the factory. At the same time, we use packing plumbing material.

- We attach a plastic or brass coupon to the opposite valve.

- We attach the pipe to the coupling.

- Next, the electric cable must be attached to the water pipe so that it does not dangle in the well. To do this, it can be wrapped in an electrical tape in a pipe with a step of 0.5 m or use plastic clamps. It is necessary to get an electric cable with a small sag.

- To suspend the pump in the well, you can use a steel cable, galvanized cable or kapron. It is pointless to use steel to use it quickly. Therefore, there are only two options galvanized and kapron. You can take anyone. We stretch the safety cable into the eyes on the head of the pump and fix it.

- Having spread all this into a straight line: a pipe, an electric cable and a safety cable, we begin to slowly lower the pump into the well. For this, two people will need at least. Gently lower the pump into the well, holding it for the safety cable. It is forbidden to raise the pump for an electric cable.

- When the pump drops to the required depth, it is necessary to fix the second end of the safety cable on our frame. To do this, the end is threaded through the hole and is fixed.

- Now it is necessary to attach a vertical pipeline with a tee. To do this, someone must go into the well and connect them with an American with Pacley and plumbing.

- The electric cable is excreted out through the top or also started into a trench if it is planned to lead it into the house in this way.

After installing the pump in the well, you can start laying the pipeline through the foundation and conducting it to the place of installation of water equipment of the accumulator, filters and boiler. When all the pipes are mounted, the pipeline in the trench is wrapped in geotextiles, covered with sand with a layer of 10 cm, and then covered with soil.

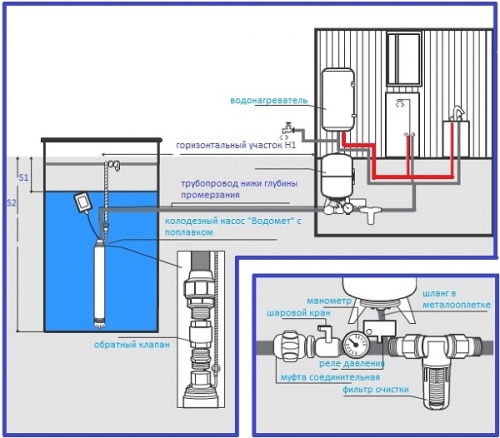

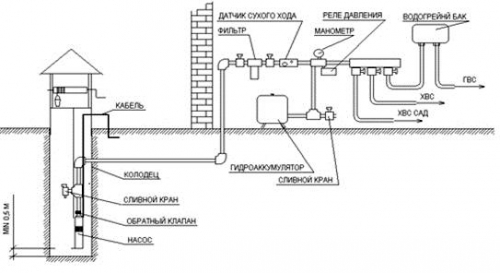

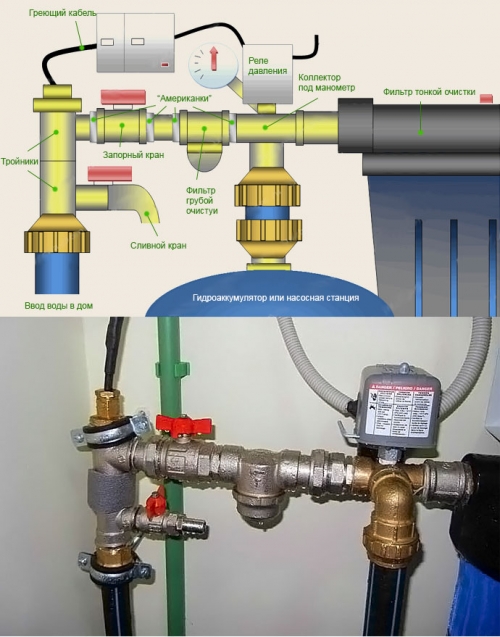

Connection of the accumulator and automation

To automate the work of the submersible pump and make it more comfortable, the automation relay (pressure relay) and the accumulator are used.

The accumulator is a membrane tank, which is partially filled with water and partially with air. When the container with water is filled, the air pressure increases, when the water becomes less, the air pressure drops. In fact, the accumulator is a transshipment point for the water between the well and consumers. So that the pump does not turn on every time the plumbing tap opens, a hydraulic accumulator is used. Its capacity is enough for several hours of use.

When the air pressure in the accumulator drops to a critical mark, the pressure relay is triggered and turns on the pump, which immediately fills the accumulator with water. As soon as the container is filled, the pressure relay will give a signal to turn off the pump.

The pressure relay and the accumulator are installed in the room. The relay is installed on top horizontally so that the condensate does not flow inside. The electric cable leading to the relay is protected by corrugation. The pressure relay is connected through an RCD with a leakage current of 10 mA and a shutdown automatic to 6 A.

The installation of a submersible pump in a well is associated with only one difficulty with the fact that it is necessary to descend into the well to the level of the sleeve in order to connect the pipes. But this can be avoided if you use a flexible hose or pipe for the pipeline. Then all the work can be done on top without going down. Also note that if you do not have the opportunity to conduct a water supply below the level of freezing of the soil, then you can not deepen the pipes, but wrap them with a warming electric cable so that they do not freeze.

Which pump to pick up pump

Which pump to take pump from 50 meters

We have a submarine Gardena pump

We have a submissive pump Gardena 6000/5 Automatic, lowered by 10 m in 110 mm, the squash. To the mirror of water 1 meter. The distance to the house is also 1 m. Being next to the well, the working pump is practically not heard. But in the house, the rumble spreads to all rooms. How to reduce the pump of the pump in the house. Thank you.

is it possible to install

is it possible to install a screw pump horizontally?