During a full -fledged repair, you can not do without wall decoration in residential premises, including ...

|

|

The question of how to warm a private house may arise in two cases: the first on ... |

If you have taken up the insulation of the bath, keep in mind, warming the ceiling in the bathhouse ... |

Strengthening floors: features, technology

From the point of view of design features, any building consists of several main elements, such as walls, foundations and floors. And if the first two is considered almost irreplaceable elements of the structure, since in case of failure, it is necessary to disassemble the old building with the subsequent erection of a new building, then a distinctive feature of the latter is the need for a frequent replacement, associated with a frequent failure of the ceilings, most often wooden . They are characterized by the minimum service life, and can be subject to replacement, both on wooden and reinforced concrete floors. And if the service life of the walls, the foundations of reinforced concrete floors are almost the same and is more than a century, then wooden floors can be operated much less (50-60 years), and therefore, the question of economic feasibility of replacing wooden floors with reinforced concrete. It becomes obvious that it depends on the degree of wear of the main irreplaceable structural elements, such as walls and foundations. According to experts, in the case of a small wear of the building as a whole, it is advisable to conduct a radical replacement of wooden floors with reinforced concrete, and in case of significant wear, repair (strengthen) or replace old floors with new ones made of the same tree. Thus, the principle of one -time depreciation of the main structural elements of the building works, according to which the service life of the ceilings does not much exceed the remaining life of the building. Due to the relevance of this problem for modern developers, in this article we decided to talk about how to strengthen various types of ceilings, as well as consider their features and technology.

Content

- Strengthening of floors: the relevance of the problem

- Features of processes associated with strengthening floors

- Strengthening wooden ceilings: main points

- Strengthening reinforced concrete floors: the main methods and technologies

- How to strengthen Clein's overlap?

- How to strengthen ribbed floors? The main technological points

Strengthening of floors: the relevance of the problem

As already noted, the repair of the floor most often involves the replacement of elements or fragments of the ceiling, as well as its strengthening, which is one of the most practiced events. The main reason for the need to strengthen the ceiling is its unsatisfactory technical and operational condition, low bearing capacity, as well as the sudden occurrence of the need to increase the load on the ceiling and on the building as a whole. Also, the reason for strengthening the ceilings may be an irrational selection of building materials and non -compliance with technical requirements, leading to structural errors. There are several main types of floors, each of which is characterized by its own method of amplification. In this regard, for a complete understanding of the problem, we recommend that you familiarize yourself with the next classification of the ceilings.

The main types of ceilings:

- Wooden;

- An overlap, which is based on reinforced concrete monolithic slabs;

- Overlap of Klein, as one of the most rare ceilings;

- Ribbed.

Each of these species has its own methods of amplification, which is performed mainly at the stages of redevelopment and repair of an apartment or office premises and helps to avoid the occurrence of unforeseen emergency situations. But regardless of the constructive features of the overlap, its strengthening begins with the installation of supporting racks, as well as if necessary, the installation of supports for floors of the underlying floors. It is important to remember that the technology of strengthening the floors involves placing supporting racks one above the other. In order for the weight of the floors that have been strengthened to be evenly distributed along the floors of the lower floors, they are installed on the lags, which use steel beams or wooden bars.

Features of processes associated with strengthening floors

- Insufficient level of mechanization of work;

- The implementation of installation measures in the conditions of a deliberately limited front (performing work, the master is in a constrained atmosphere due to limited space of wall structures);

- The need to carry out a set of large -scale preparatory work characterized by high labor intensity (punching nests, a fine and grooves in preserved structures);

- The lack of the possibility of eliminating errors made in the process of implementing the project, which leads to the need to cut individual structural elements.

Strengthening wooden ceilings: main points

The need to strengthen wooden beams is most often due to their destruction or partial damage. In such cases, it is necessary to replace, or strengthening by increasing their cross -section. Most often, such situations arise when the owners plan to radically change the functional purpose of the room located directly at the floor, or plan to increase the load on them, which can be encountered, adapting the attic previously unexploited to the living attic. In this case, you have three options for further actions:

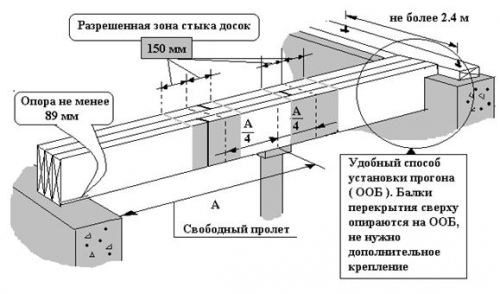

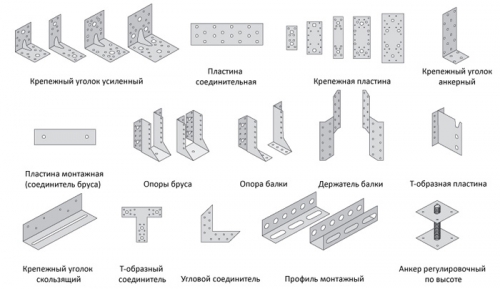

Replacing wooden beams, which is necessary only if they were damaged along their entire length. Within the framework of this event, damaged beams must be removed, after which new nests in the wall are installed in the wall. In most cases, replacing beams involves the replacement of the overlap areas. The laying of prefabricated and steel beams of the new ceiling is carried out directly onto the wall, or attached using reinforced concrete beams and brackets;

An increase in the number of beams, which is carried out by inserting additional beams between existing ones, which helps to reduce the distance between them. The load on the room determines both the number of additional beams and their section;

Strengthening the beam beams, which is performed using bars or boards of the corresponding thickness, which must be beaten on both sides of the beam. To do this, you will need the next set of materials and tools:

- Hammer and nails;

- Glue necessary for pasting wood roofing;

- Antiseptic composition;

From the materials you will need:

- Bars or boards with a thickness of at least 38 mm;

- Ruberoid for insulating measures.

As indicated earlier, the reinforcement of wooden floor beams lies in the bilateral mount on the beam of linings, which use the bars or boards of the corresponding (at least 38 mm) thickness. Despite the fact that the lower boundaries of the thickness of the pads and cross -section of the bars, the parameter, clearly established, the most accurate size of the nailed boards is determined by the master during operation. In the event that it is necessary to strengthen the beams due to an increase in the load on the supporting structures, the fastening of the linings must be carried out along the entire length of the intensified beams, while in the case of the repair of damaged beams, the linings must be fixed in the places of damage.

In practice, the most often linings have to be attached at the ends of the beams, which is associated with design errors and, as a result, improper distribution of the load during the support of the beams on the wall or in specially equipped nesting holes. In this regard, there is a constant formation of condensate, contributing to the premature loss of strength and rotting of wood.

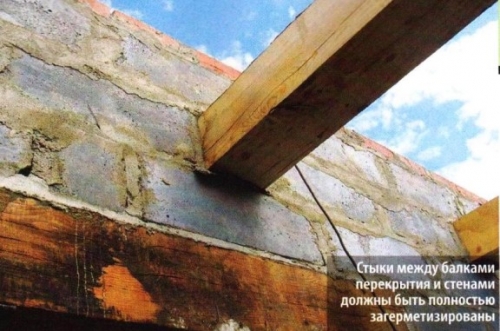

Important! All elements used to strengthen wooden floors should be prone to impregnations, and areas of beams in contact with walls or reinforced concrete should be isolated by roofing material.

Strengthening reinforced concrete floors: the main methods and technologies

According to experts, the strengthening of reinforced concrete ceilings is a rather complex engineering and technical task, in the process of solving which it is often necessary to use not only standard engineering methods, but also non-traditional ones.

The main reasons for the strengthening of the ceilings are the following:

- Engineering errors of designing residential buildings and structures;

- Rude mounting defects;

- Significant wear of the main supporting structures as a result of their irrational operation;

- The reconstruction of buildings, according to the results of which it is planned to increase the load on the ceilings.

In each individual case, it is necessary to develop a design plan for strengthening the ceilings, which should meet the requirements for not only the strength and wear resistance of structures, but also to their aesthetic characteristics. There are several ways to strengthen reinforced concrete floors that are fundamentally different from each other, each of which realizes two main tasks:

- Transmission of the entire load or a separate part of its reinforcement design;

- An increase in the bearing properties of a previously existing design.

An increase in the bearing capacity of reinforced concrete floors can be realized in several ways, the first of which implies an increase in the cross -section of the supporting element with the addition of metal rods, and the second by making adjustments to the static design scheme. At the same time, the strengthening of monolithic ceilings is carried out by increasing the concrete layer in the upper and lower part of the plate, during which it is necessary to expose the reinforcement and, using metal rods, weld a new one to it. After that, it is concrete with a 20-millimeter layer of torque.

The strengthening of the beam beams is carried out from below, also exposing the working reinforcement and welding it to it is a new one, after which the beams are plastered with cement plaster, which leads to an increase in the cross -section of the beams to 80 mm.

Often the need to restore reinforced concrete floors arises in connection with corrosion processes that bring reinforcing rods into disleara. The most common cause of rust on the rods is the insufficient thickness of the concrete layer around them. The consequences of damage to the reinforcing rods cannot remain unnoticed: since in the places of laying metal rods and, accordingly, stripes of rust are clearly visible on the concrete surface. The reinforcement unprotected by the concrete layer is also affected by rust. To prevent further defeat of the reinforcement, the following measures must be taken:

- Clean the lower part of the ceilings;

- A concrete layer localized around open rods must be removed;

- Apply a protective anti -corrosion coating to metal rods;

- The concrete surface is thoroughly primed, and then eliminate the voids in concrete;

- In conclusion, apply cement-lending plaster over the entire surface of the floors, the layer thickness of which should be at least 1.5 cm.

In order to enhance reinforced concrete overlap, prepare the following set of tools:

- Welding machine;

- Electric punch and electric jack of a hammer;

- Concrete mixer;

- CHELLERA, I -TOPARES, Corches, Stoisons;

- The boards necessary for the installation of formwork;

- As well as the components of the part for the preparation of concrete solution (crushed stone, sand, cement).

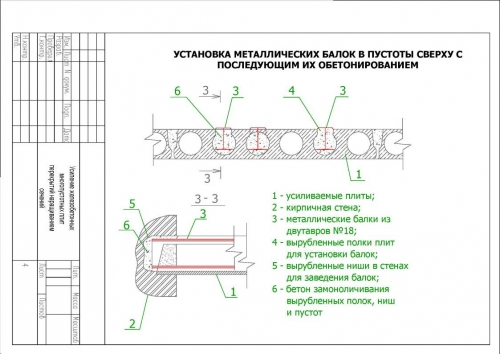

After installing the supporting pillars, which is a universal effect for all types of ceilings, in monolithic reinforced concrete floors they cut out the opening of small sizes and break off the end so that the reinforcement protrudes no less than 15-20 cm. An electric jack of launching is used to break the end. A channel is welded to the protruding reinforcement around the entire perimeter of the opening, the formwork is set, after which the free distance between the concrete and the channel is poured with a concrete solution, which must be prepared in advance. After a partial drying of concrete, the formwork and time poles are recommended to be removed.

If you plan to carry out large sizes in reinforced concrete ceilings, and at the same time, the supporting structures of the lower level are located close to each other (at a distance of 7-15 m), experts recommend using suspended underground structures fixed on the walls. According to experts, these measures to strengthen the ceilings must be made before you begin cutting the opening. The corners and channels of the necessary sizes should be installed as close as possible to the planned opening in the lower part of the monolithic floor, after which they are started in two ends in the niches, which should be prepared in advance. After the end of the niche, as well as the distance between the floor slabs, must be sealed.

How to strengthen Clein's overlap?

Despite the fact that this type of ceiling some time ago was quite popular, today it gradually loses its relevance. But today you can find developers who seek to return the popularity of this variety of ceilings. For its installation, I -sail beams of steel are used, the height of which ranges from 80 to 240 mm. They are laid at a distance of 100-160 mm from each other. A plate rests on the lower shelves of the beams, for the manufacture of which ceramic brick was used. In this case, it seems possible to increase the bearing characteristics of the beams in this case by strengthening the I -beams of steel, or by strengthening the filling of brick. For work, as before, you will need:

- Jackhammer;

- Concrete mixer;

- Welding machine.

- As for the materials, in this case it is necessary to stock up:

- Strip steel;

- Wire mesh;

- Components for the preparation of concrete solution (sand, cement, gravel).

To strengthen the beams, strip steel is welded to the shelves of the I -beam profile or a slave is performed on steel beams, that is, they are strengthened by arranging an additional monolithic floor. The thickness of the concrete, as well as the reinforcement option, is determined in the process of designing the structure. In order to carry out this event, it is necessary to use steel clamps that resemble the rods in shape, which must be welded to the beams, and then lay the concrete layer. The strengthening of the plate must be carried out by manufacturing and laying an additional concrete slab with a thickness of at least 3 cm, which is laid on top of brick. Another way to strengthen the plate is to use the components of ribbed reinforced concrete floors in those places where preliminary dismantling of brick filling was carried out.

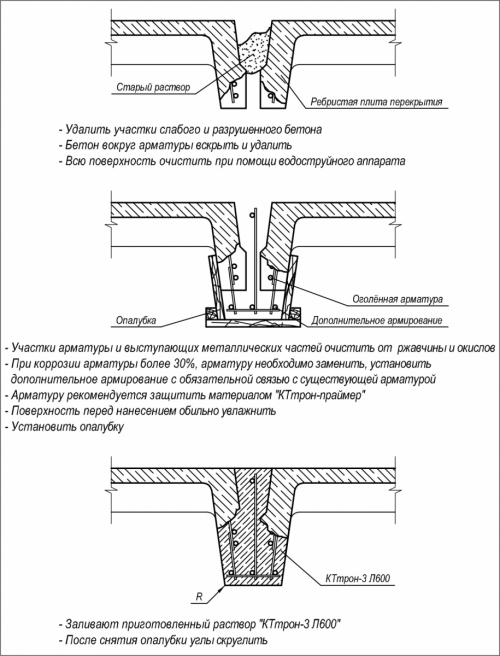

How to strengthen ribbed floors? The main technological points

The technology for strengthening the ceilings of a ribbed nature is largely similar to such for reinforced concrete slabs. From this we can conclude that in this case, it is necessary to make a slave. Since the strengthening technology is similar to such in the case of reinforced concrete slabs, materials and tools remain the same. Another way to strengthen ribbed floors, which has recently been used, is the implementation of additional ribs, the location of which is parallel to existing.

In order to carry out this event, concrete is dismantled in the places of attachment of new beams, after which in the blocks located in the field of view, part of the upper surface is removed, which allows you to open their middle. According to the results of this event, a free space is formed, which is subjected to cleaning and removing crushed stone. Then reinforcement and concrete are laid in it. It is easy to calculate that, thanks to the organization of additional ribs, the load on each individual rib and on the ceiling as a whole is reduced, which was the initial purpose of this event.